Bakery Processing Equipment Market Report

Published Date: 22 January 2026 | Report Code: bakery-processing-equipment

Bakery Processing Equipment Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Bakery Processing Equipment market from 2023 to 2033, highlighting key trends, regional insights, and market dynamics shaping the industry landscape. It also offers data-driven forecasts and identifies leading players in the market.

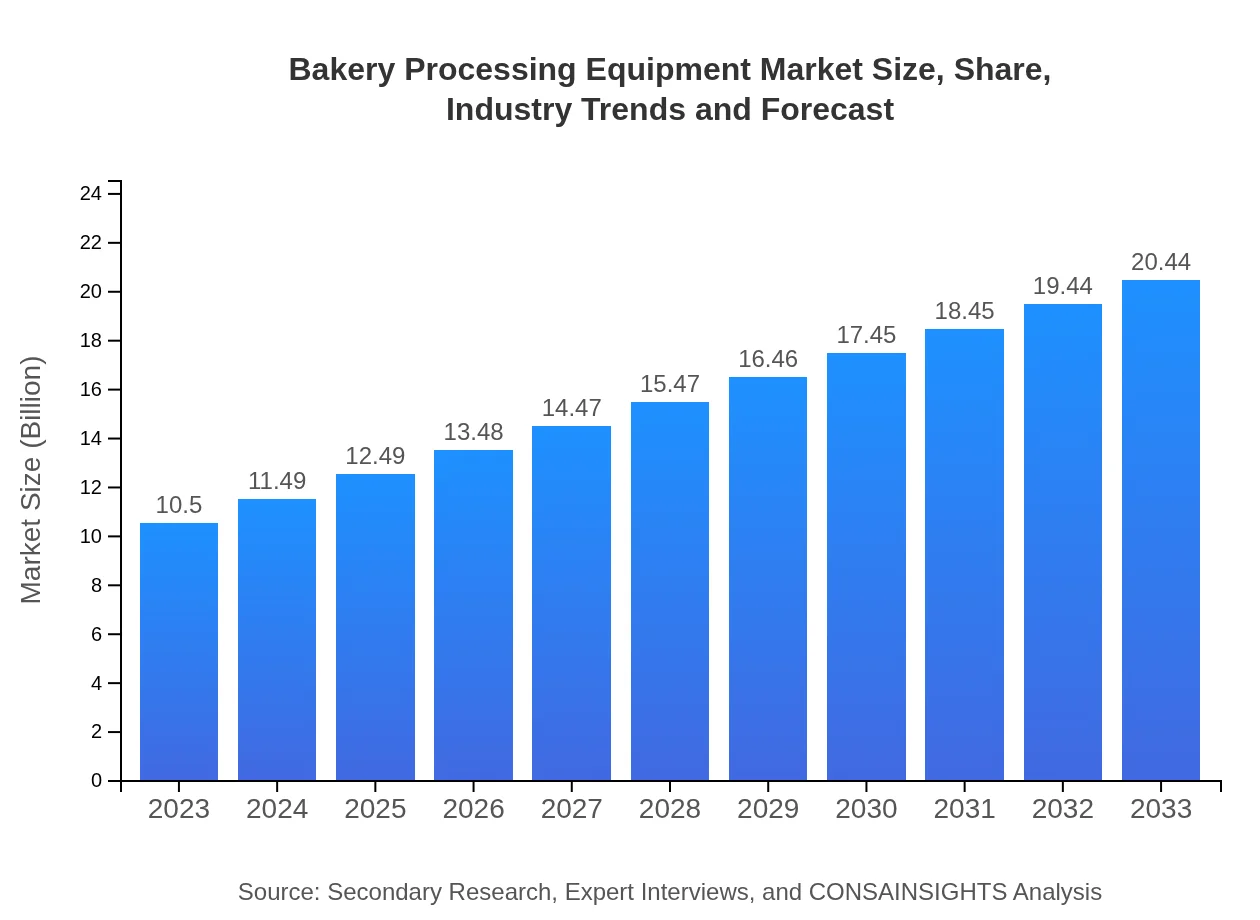

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $10.50 Billion |

| CAGR (2023-2033) | 6.7% |

| 2033 Market Size | $20.44 Billion |

| Top Companies | Bühler AG, MARRIOTT, Baker Perkins, Varimixer |

| Last Modified Date | 22 January 2026 |

Bakery Processing Equipment Market Overview

Customize Bakery Processing Equipment Market Report market research report

- ✔ Get in-depth analysis of Bakery Processing Equipment market size, growth, and forecasts.

- ✔ Understand Bakery Processing Equipment's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Bakery Processing Equipment

What is the Market Size & CAGR of Bakery Processing Equipment market in 2023?

Bakery Processing Equipment Industry Analysis

Bakery Processing Equipment Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Bakery Processing Equipment Market Analysis Report by Region

Europe Bakery Processing Equipment Market Report:

Europe holds a substantial share of the Bakery Processing Equipment market, with projections increasing from $3.83 billion in 2023 to $7.46 billion in 2033. The region is a focal point for innovations in the baking industry, with a growing preference for premium products and artisan offerings. Additionally, sustainability trends are influencing the adoption of eco-friendly baking equipment.Asia Pacific Bakery Processing Equipment Market Report:

The Asia Pacific region shows a rapidly growing Bakery Processing Equipment market, with a projected market size of $3.74 billion by 2033, up from $1.92 billion in 2023. This growth is driven by an expanding population, increasing urbanization, and rising disposable incomes, leading to higher consumption of baked goods. Additionally, the region is seeing significant advancements in technology, improving production efficiency across various types of bakeries.North America Bakery Processing Equipment Market Report:

In North America, the Bakery Processing Equipment market is anticipated to grow from $3.50 billion in 2023 to $6.81 billion by 2033. Factors such as a strong foodservice industry, high consumer spending on baked products, and a focus on healthier alternatives are driving this growth. Technological adoption is also significant, with many producers investing in smart baking technologies and automation.South America Bakery Processing Equipment Market Report:

South America is expected to see steady growth in the Bakery Processing Equipment market, projected to rise from $0.78 billion in 2023 to $1.52 billion by 2033. This growth is attributed to the increasing demand for innovative bakeries that offer a variety of products and the gradual shift towards mechanization and automation in food processing industries.Middle East & Africa Bakery Processing Equipment Market Report:

The Middle East and Africa region exhibits niche market growth from $0.47 billion in 2023 to an estimated $0.91 billion by 2033, influenced by changing dietary habits and the ongoing development of modern retailing and distribution channels. The region's diverse cultural influences result in unique demands for various baked goods, supporting the market for specialized bakery equipment.Tell us your focus area and get a customized research report.

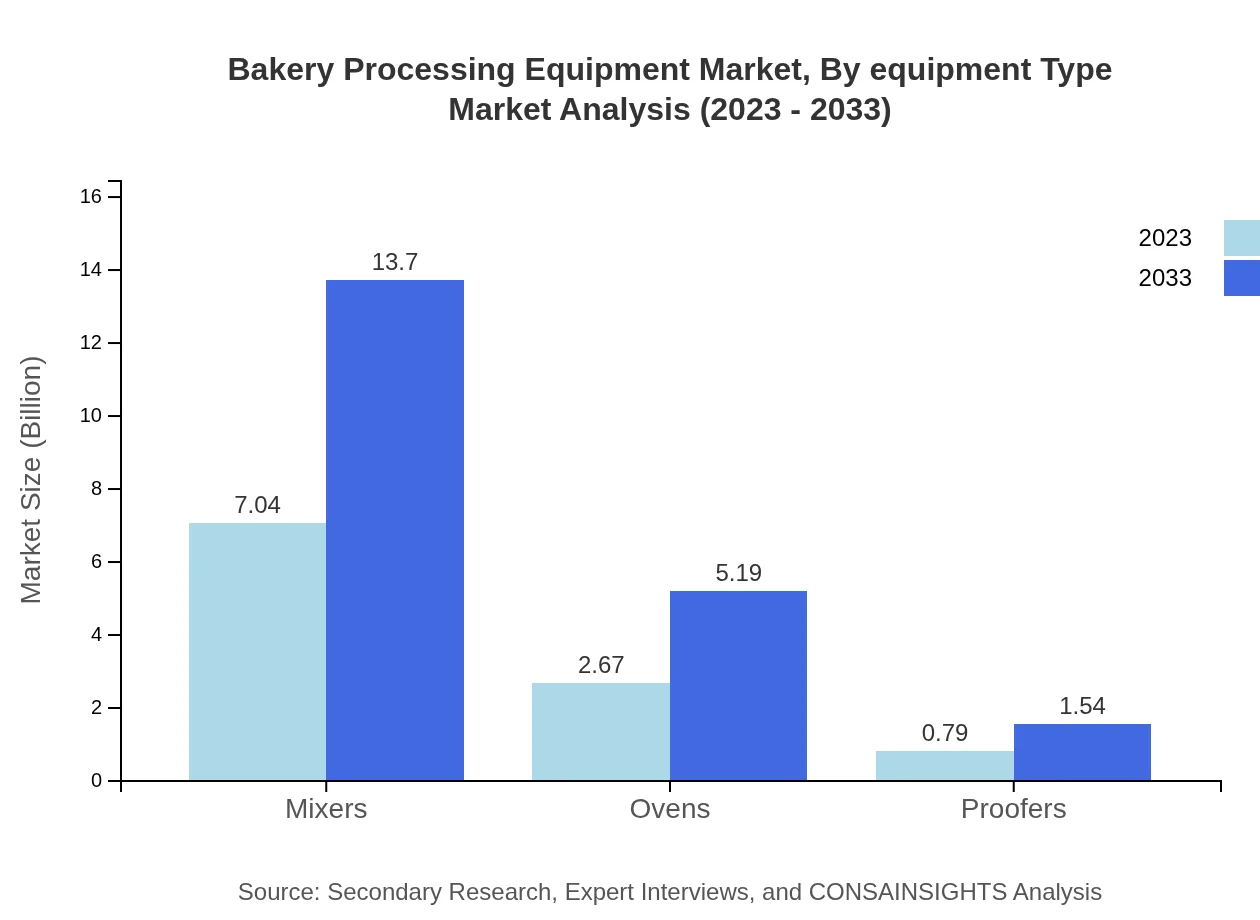

Bakery Processing Equipment Market Analysis By Equipment Type

In the Bakery Processing Equipment market, mixers represent the largest revenue share, projected to reach $13.70 billion by 2033 from $7.04 billion in 2023. Ovens follow, with a growth trajectory from $2.67 billion to $5.19 billion in the same period. Proofers and other essential equipment types also show steady demand as bakeries seek to enhance productivity and product quality.

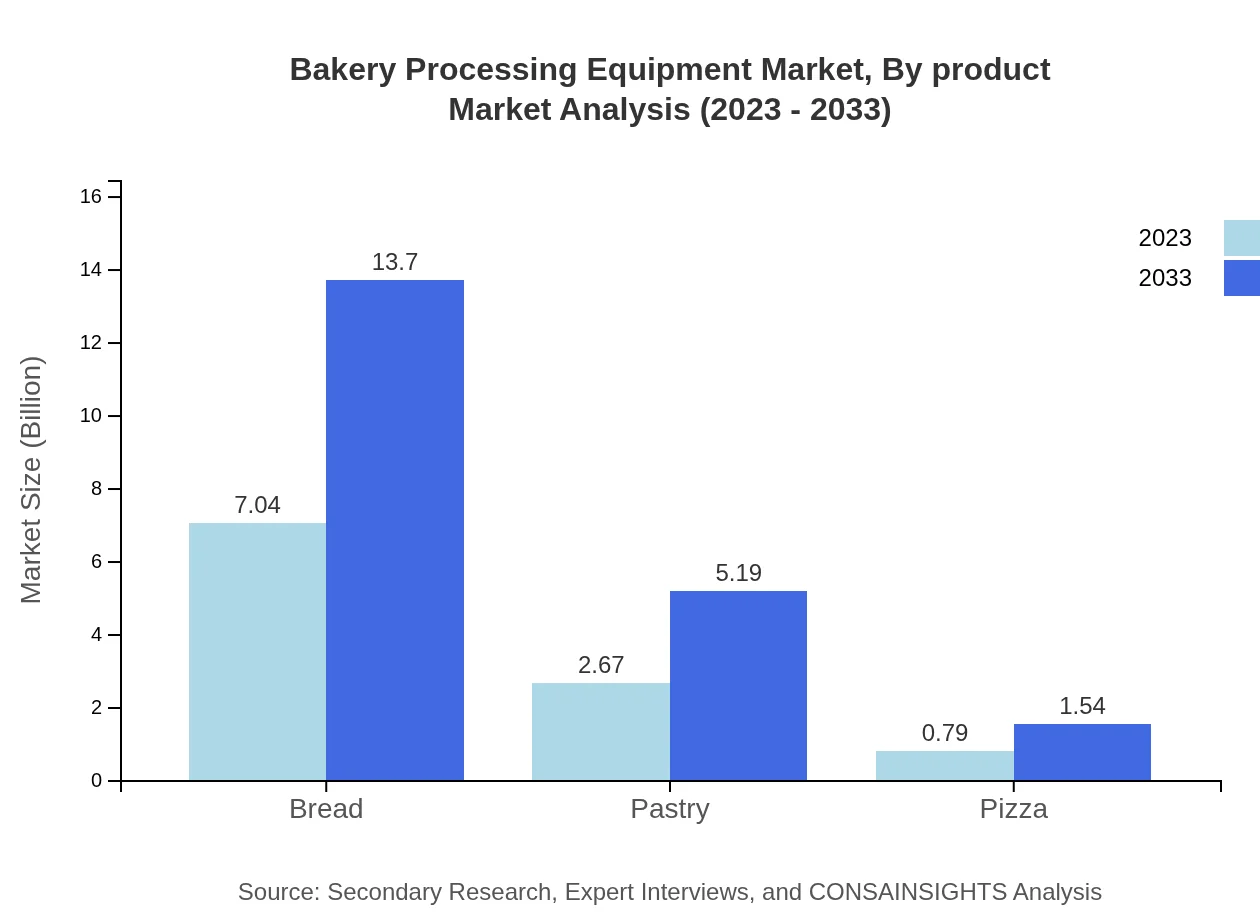

Bakery Processing Equipment Market Analysis By Product

The product segment data reveals that bread dominates the market with a share projected to be 67.06% throughout the forecast period. The market size for bread production is expected to grow from $7.04 billion in 2023 to $13.70 billion by 2033. Pastries are next in line, expected to increase from $2.67 billion to $5.19 billion, constituting a 25.42% market share. Special attention is given to pizza processing equipment, anticipated to rise from $0.79 billion to $1.54 billion.

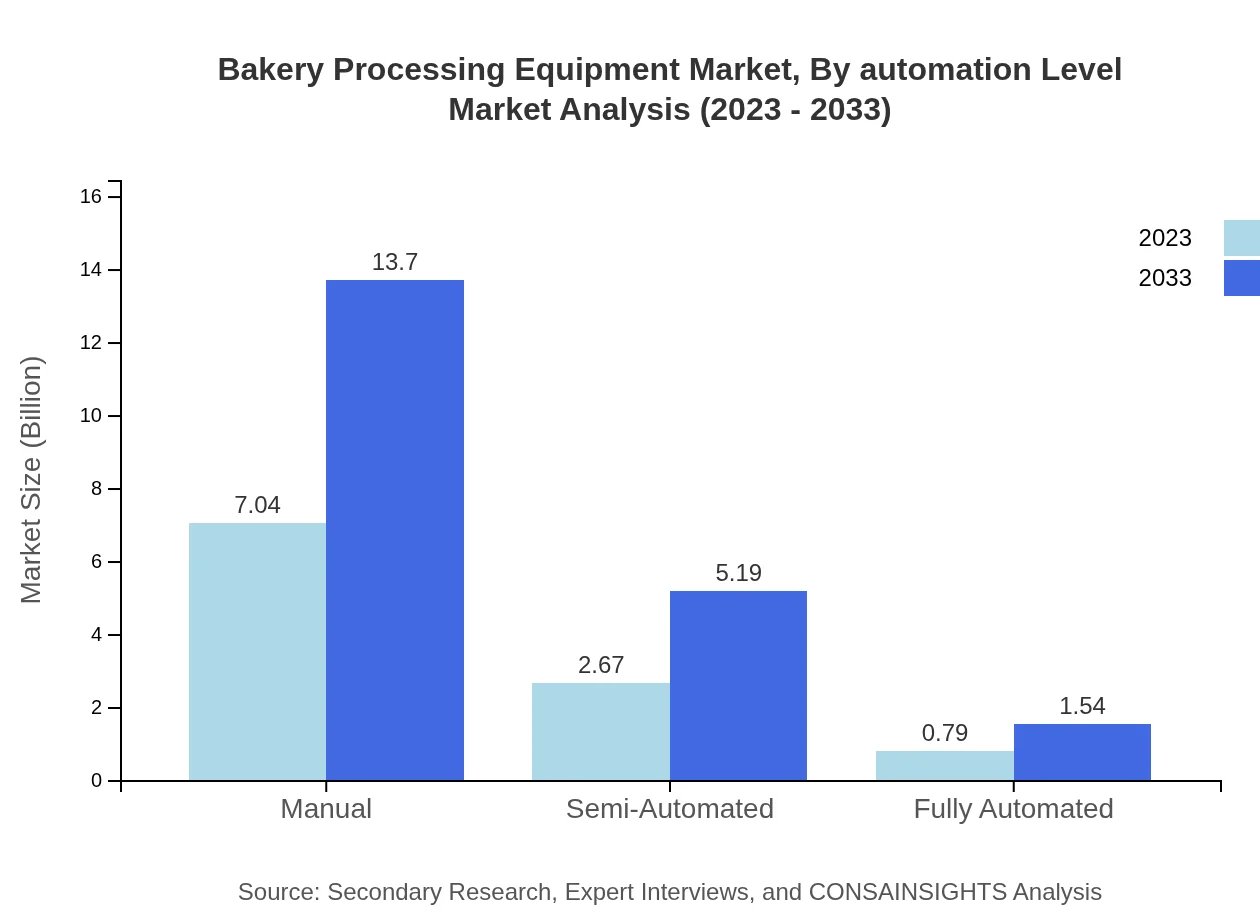

Bakery Processing Equipment Market Analysis By Automation Level

In examining the automation levels, manually operated machinery still holds a significant segment at 67.06% in 2023, while semi-automated and fully automated systems are gaining ground, expected to rise to 25.42% and 7.52% market share respectively, emphasizing the industry's gradual shift towards automation for efficiency and consistency.

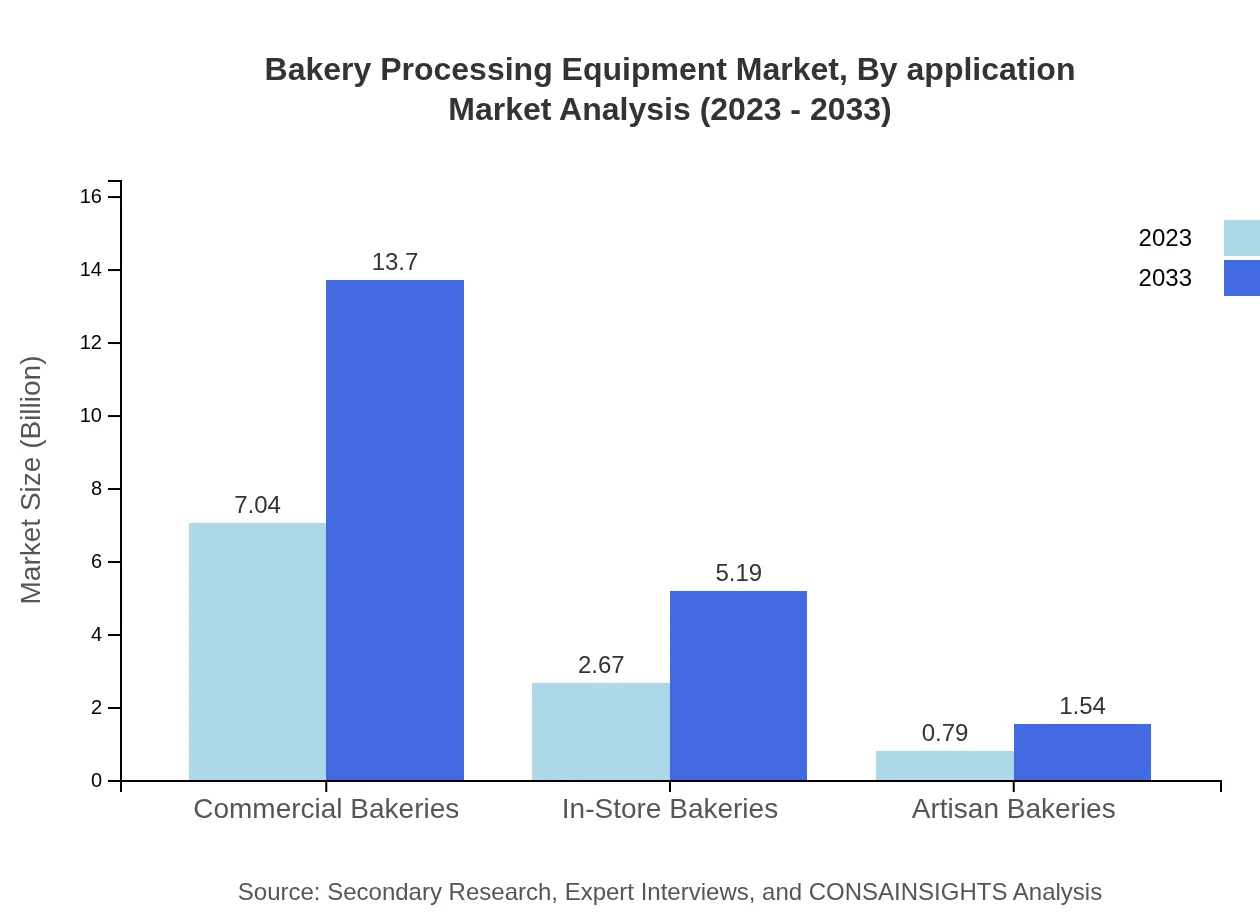

Bakery Processing Equipment Market Analysis By Application

Commercial bakeries are predicted to hold a dominant position with a 67.06% market share in 2023, worth $7.04 billion, and expanding to $13.70 billion by 2033. In-store bakeries account for 25.42% and are projected to grow from $2.67 billion to $5.19 billion, while artisan bakeries capture a smaller segment maintaining around 7.52%.

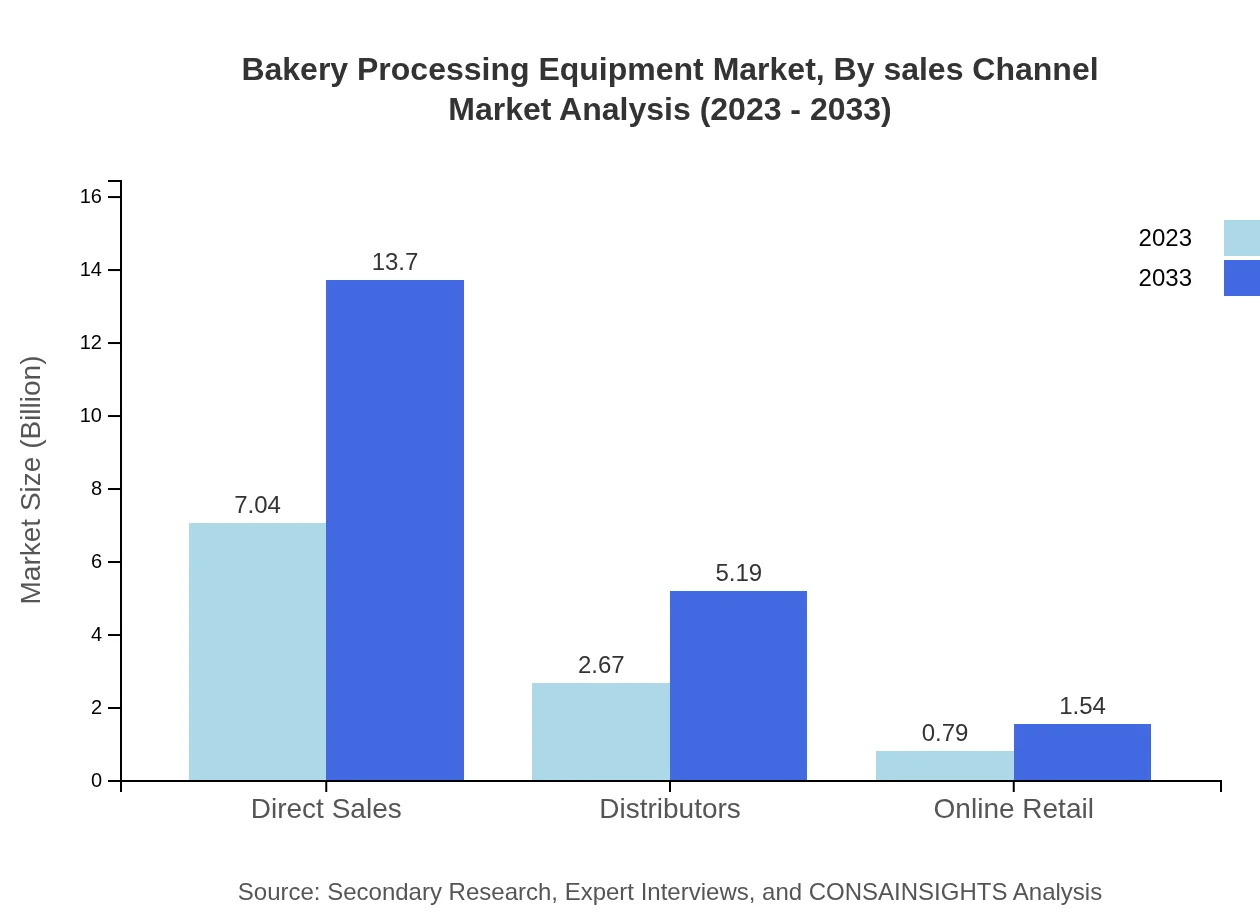

Bakery Processing Equipment Market Analysis By Sales Channel

Direct sales channels dominate the Bakery Processing Equipment market, projected to maintain a 67.06% share from $7.04 billion in 2023 to $13.70 billion by 2033. Distributors are expected to hold 25.42% share, while online sales are emerging with 7.52% estimated growth, reflecting changing consumer purchasing behavior.

Bakery Processing Equipment Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Bakery Processing Equipment Industry

Bühler AG:

Bühler AG is a Swiss company recognized for its high-precision machinery in the baking and food processing sector. Their emphasis is on innovative technology and sustainability, with products designed to enhance production efficiency.MARRIOTT:

MARRIOTT specializes in bakery equipment design and manufacturing, offering a wide range of mixers, ovens, and ovens that cater to both commercial and industrial baking applications with a commitment to quality and innovation.Baker Perkins:

Baker Perkins is a leading British manufacturer of baking equipment, providing a comprehensive range of solutions to create a variety of baked goods, with a strong focus on customer relationship management and service.Varimixer:

As a recognized supplier of high-performing mixers, Varimixer focuses on creating durable and versatile equipment aimed at commercial bakeries, helping them achieve consistent product quality.We're grateful to work with incredible clients.

FAQs

What is the market size of bakery Processing Equipment?

The global bakery processing equipment market was valued at approximately $10.5 billion in 2023 and is projected to grow at a CAGR of 6.7%, indicating strong future growth potential in the industry.

What are the key market players or companies in this bakery Processing equipment industry?

Key players in the bakery processing equipment market include renowned manufacturers such as Baker Perkins, Markel Food Group, and Bühler AG, who drive innovation and product development in this competitive landscape.

What are the primary factors driving the growth in the bakery processing equipment industry?

Several factors drive the growth of the bakery processing equipment industry, including increasing consumer demand for baked goods, technological advancements in baking equipment, and the growth of commercial bakeries expanding to meet consumer preferences.

Which region is the fastest Growing in the bakery processing equipment market?

The fastest-growing region in the bakery processing equipment market is Europe, expected to grow from $3.83 billion in 2023 to $7.46 billion by 2033, showcasing a significant market expansion.

Does ConsaInsights provide customized market report data for the bakery processing equipment industry?

Yes, ConsaInsights offers customized market reports tailored to specific needs, providing valuable insights and detailed data analysis for stakeholders in the bakery processing equipment industry.

What deliverables can I expect from this bakery processing equipment market research project?

Deliverables from the bakery processing equipment market research project typically include comprehensive reports, trend analyses, statistical data, and actionable insights to help inform strategic decisions.

What are the market trends of bakery processing equipment?

Market trends in bakery processing equipment include a shift towards automation, rising demand for artisanal products, and innovative equipment designs that cater to health-conscious consumer preferences.