Bearing Isolators Market Report

Published Date: 22 January 2026 | Report Code: bearing-isolators

Bearing Isolators Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Bearing Isolators market, offering insights into current trends, segmentation, and forecasts up to 2033. It includes details about market size, growth rate, regional insights, and competitive landscape.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

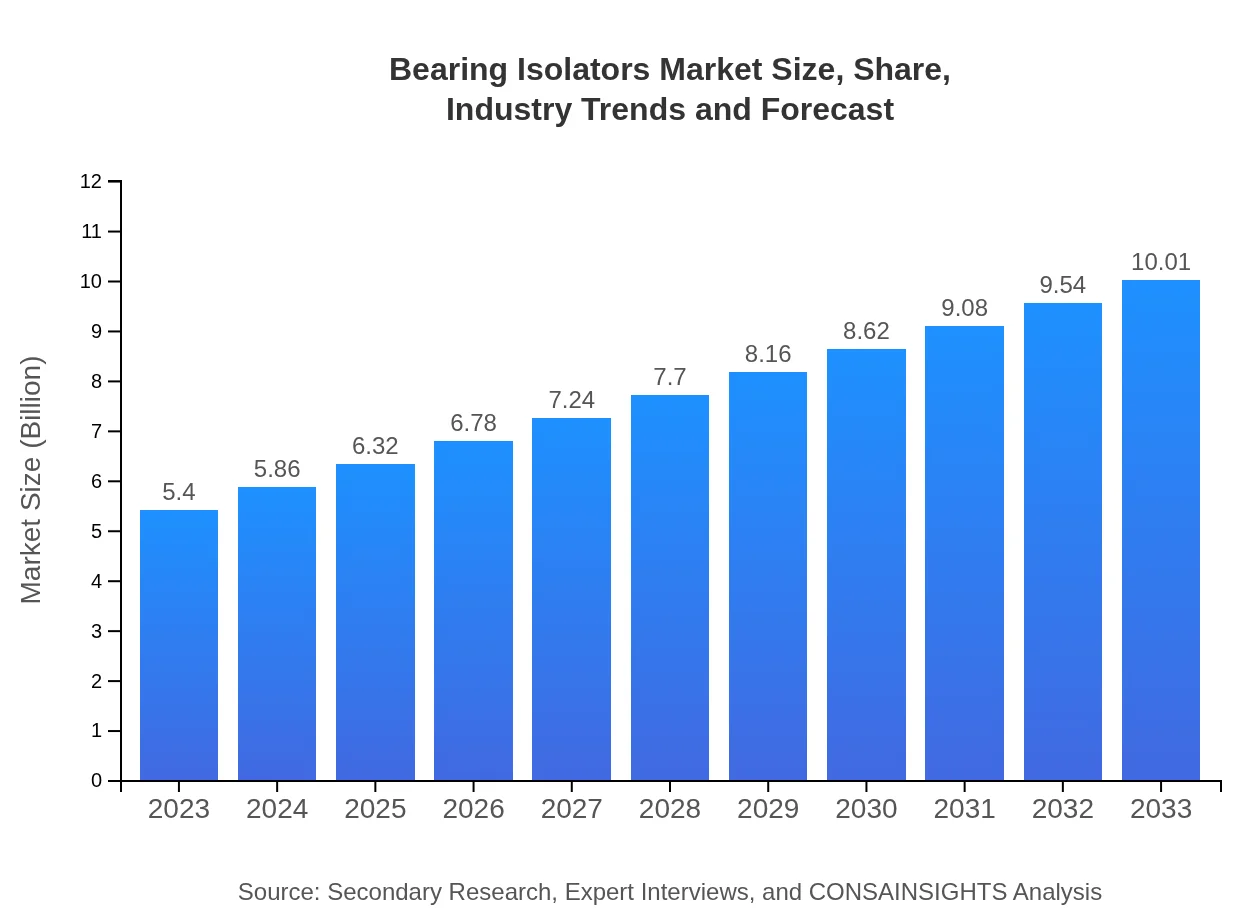

| 2023 Market Size | $5.40 Billion |

| CAGR (2023-2033) | 6.2% |

| 2033 Market Size | $10.01 Billion |

| Top Companies | SKF Group, Timken Company, Trelleborg AB, Gates Corporation |

| Last Modified Date | 22 January 2026 |

Bearing Isolators Market Overview

Customize Bearing Isolators Market Report market research report

- ✔ Get in-depth analysis of Bearing Isolators market size, growth, and forecasts.

- ✔ Understand Bearing Isolators's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Bearing Isolators

What is the Market Size & CAGR of Bearing Isolators market in 2023?

Bearing Isolators Industry Analysis

Bearing Isolators Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Bearing Isolators Market Analysis Report by Region

Europe Bearing Isolators Market Report:

Europe's market is expected to grow from $1.37 billion in 2023 to $2.54 billion by 2033. Enhanced demand for advanced engineering solutions in both manufacturing and automotive sectors, along with stringent regulations regarding emissions, are pivotal contributors to this growth.Asia Pacific Bearing Isolators Market Report:

The Asia Pacific region, with a market size of $1.08 billion in 2023, is expected to grow to $2.00 billion by 2033. This growth is attributed to rapid industrialization, infrastructural developments, and immense demand from the automotive and manufacturing sectors coupled with supportive government initiatives.North America Bearing Isolators Market Report:

North America will observe significant growth, with the market size increasing from $1.97 billion in 2023 to $3.66 billion by 2033. Influential driving factors include the development of renewable energy projects, manufacturing sectors modernizing their processes, and an increased focus on sustainability.South America Bearing Isolators Market Report:

In South America, the Bearing Isolators market is projected to expand from $0.24 billion in 2023 to $0.44 billion by 2033. The growth in this region is driven by increasing investments in mining and energy production, aiming to modernize equipment with effective sealing technologies.Middle East & Africa Bearing Isolators Market Report:

The Middle East and Africa (MEA) region's market is forecasted to grow from $0.74 billion in 2023 to $1.37 billion by 2033, spearheaded by the oil and gas sector as it seeks more reliable bearing solutions, alongside infrastructural developments.Tell us your focus area and get a customized research report.

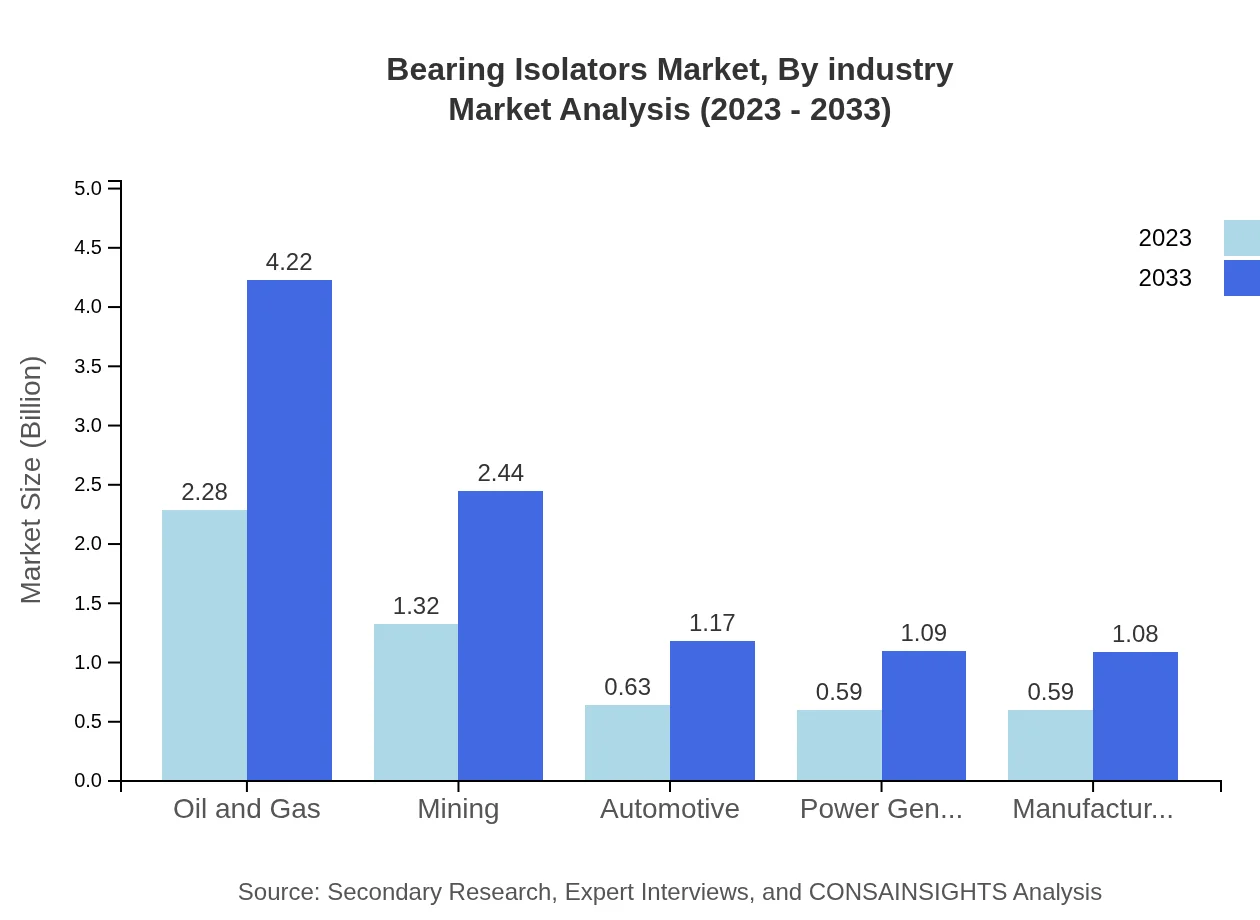

Bearing Isolators Market Analysis By Industry

The Bearing Isolators market shows strong performance across various industries. The Oil and Gas sector currently dominates the market with a size of $2.28 billion in 2023 and projected growth to $4.22 billion by 2033, maintaining a market share of 42.13%. The Mining sector follows, with a market size of $1.32 billion expected to reach $2.44 billion, holding 24.42% market share. Industries such as Automotive, Power Generation, and Manufacturing also present significant shares, reinforcing the crucial role of bearing isolators across industrial applications.

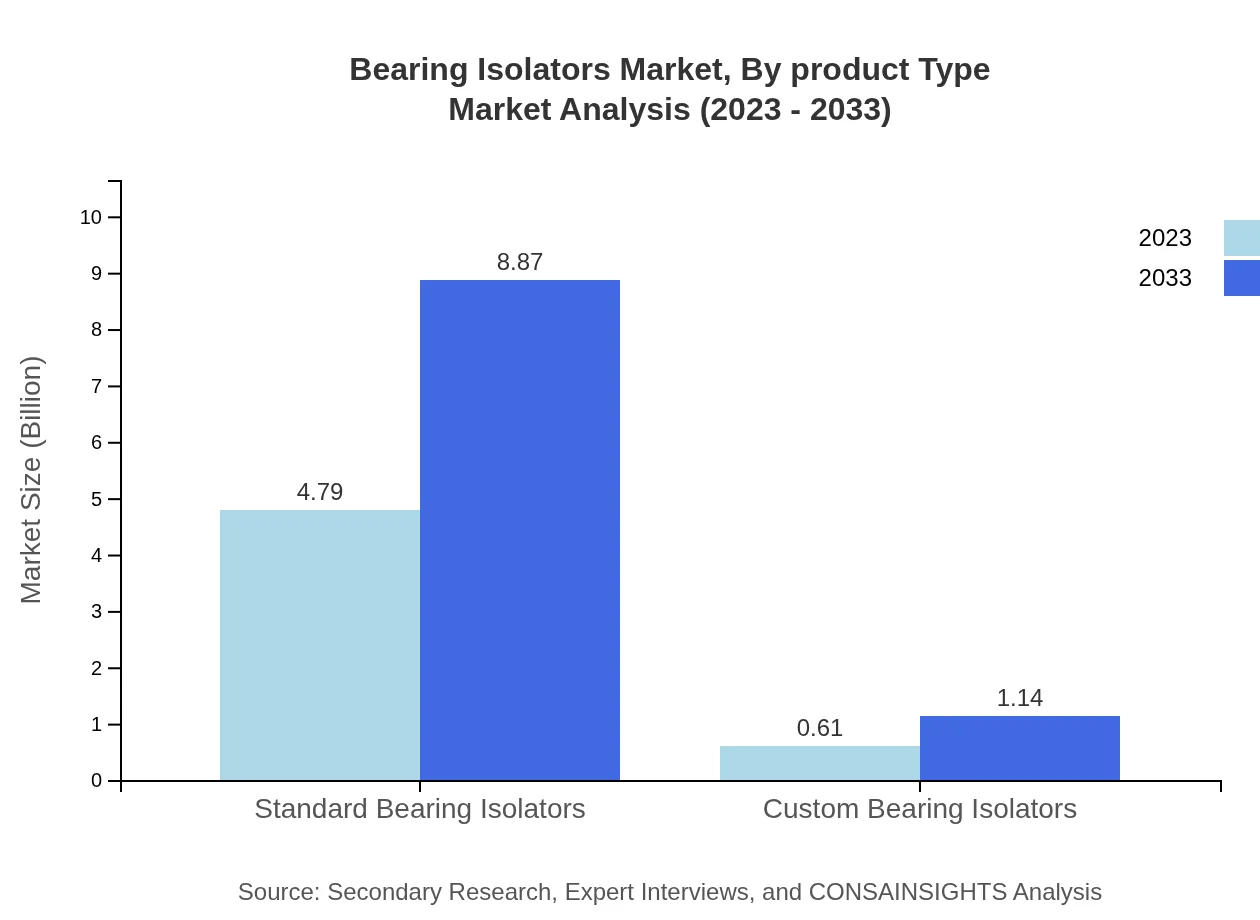

Bearing Isolators Market Analysis By Product Type

The product type analysis indicates a dominant market performance in Sealed Bearing Isolators, accounting for $4.79 billion in 2023 and projected to increase to $8.87 billion by 2033, representing an 88.62% market share. Custom Bearing Isolators, while smaller with $0.61 billion in 2023, showcase potential for growth with a projected rise to $1.14 billion, maintaining an 11.38% share.

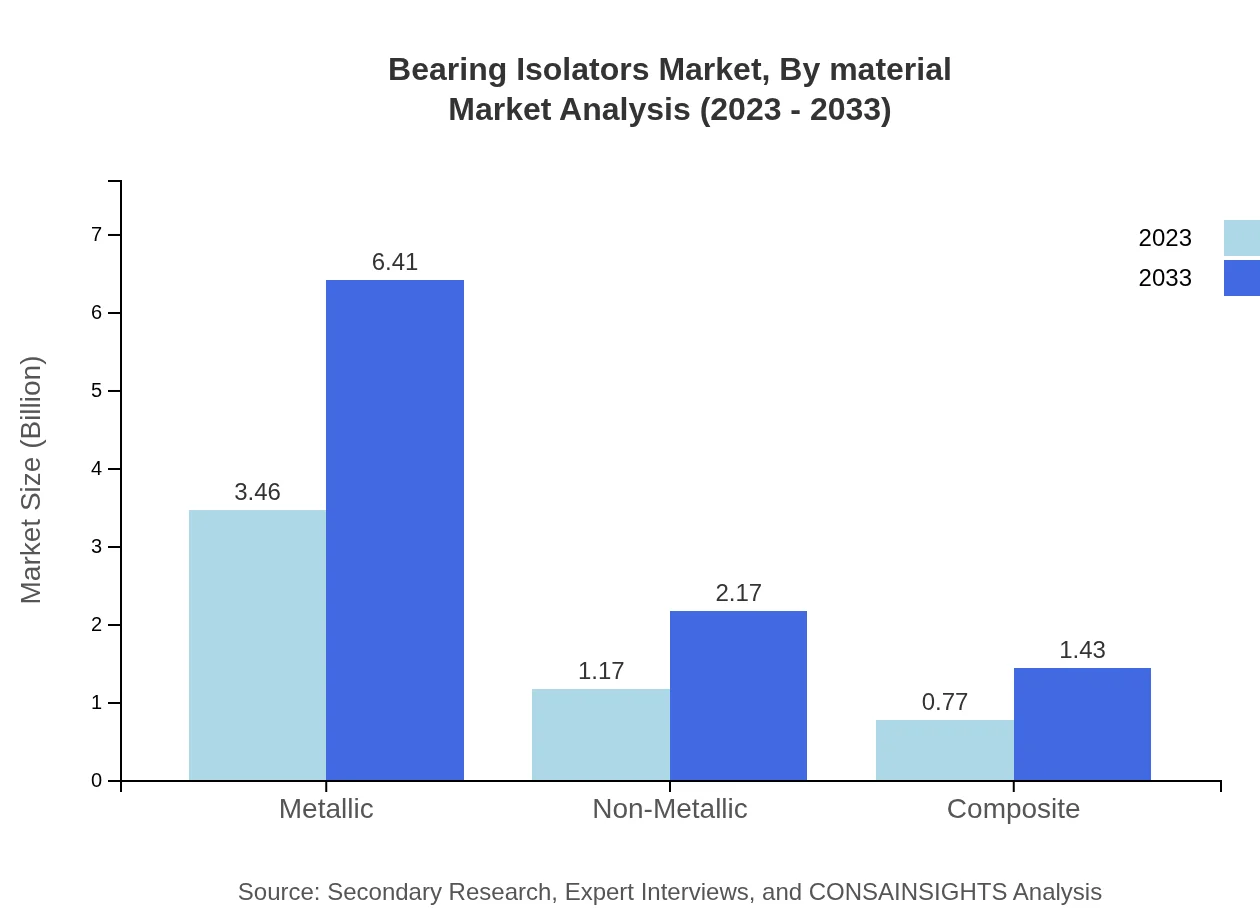

Bearing Isolators Market Analysis By Material

Metallic isolators are leading the market segment with $3.46 billion in 2023 and are expected to reach $6.41 billion by 2033, capturing 64.06% of the market share. Non-metallic and composite materials also play important roles but command smaller portions of the market, suggesting a trend toward specialized solutions depending on industry demands.

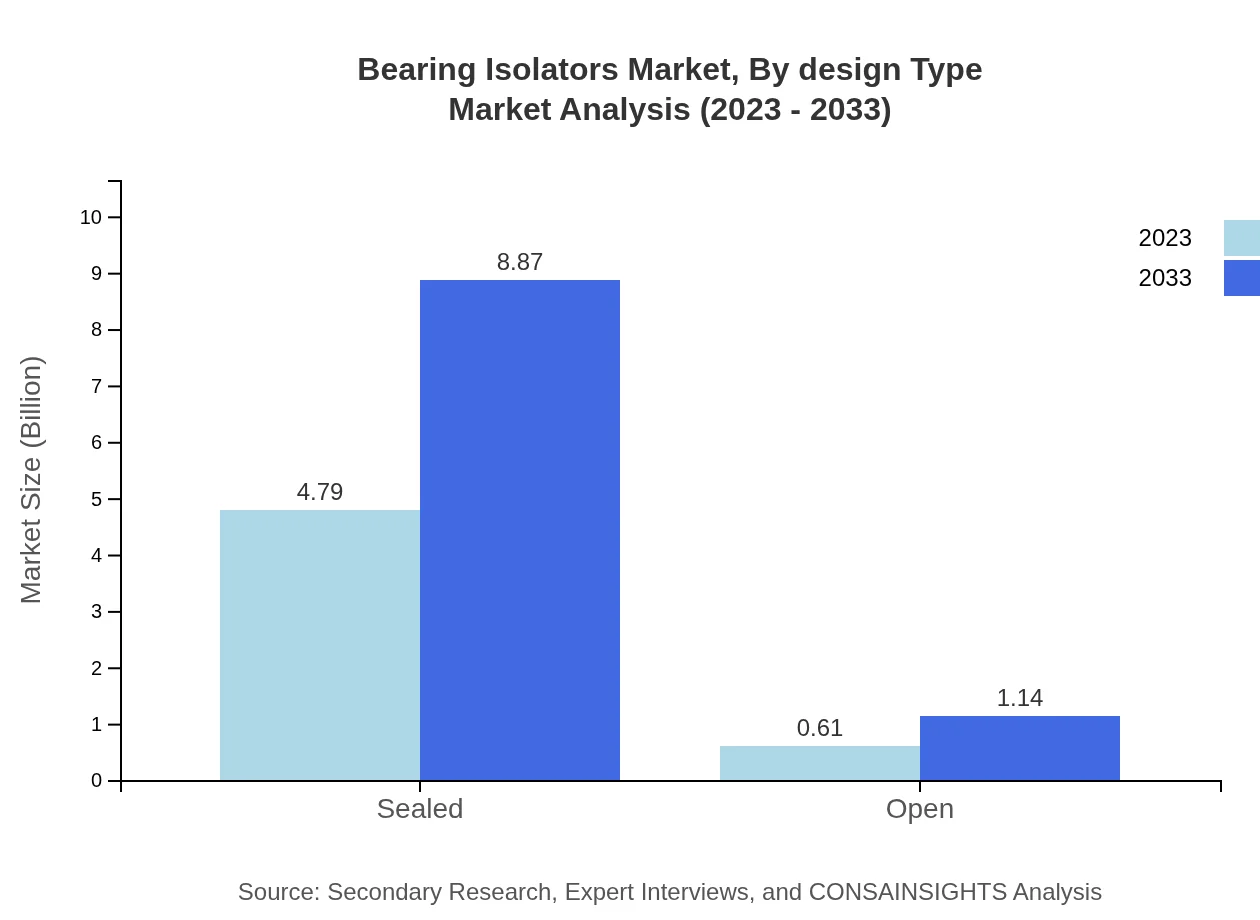

Bearing Isolators Market Analysis By Design Type

Sealed design types for bearing isolators dominate the market due to their effectiveness in preventing contamination, claimed at $4.79 billion in 2023, with growth to $8.87 billion expected. In contrast, Open design types remain less prominent but reveal potential growth opportunities.

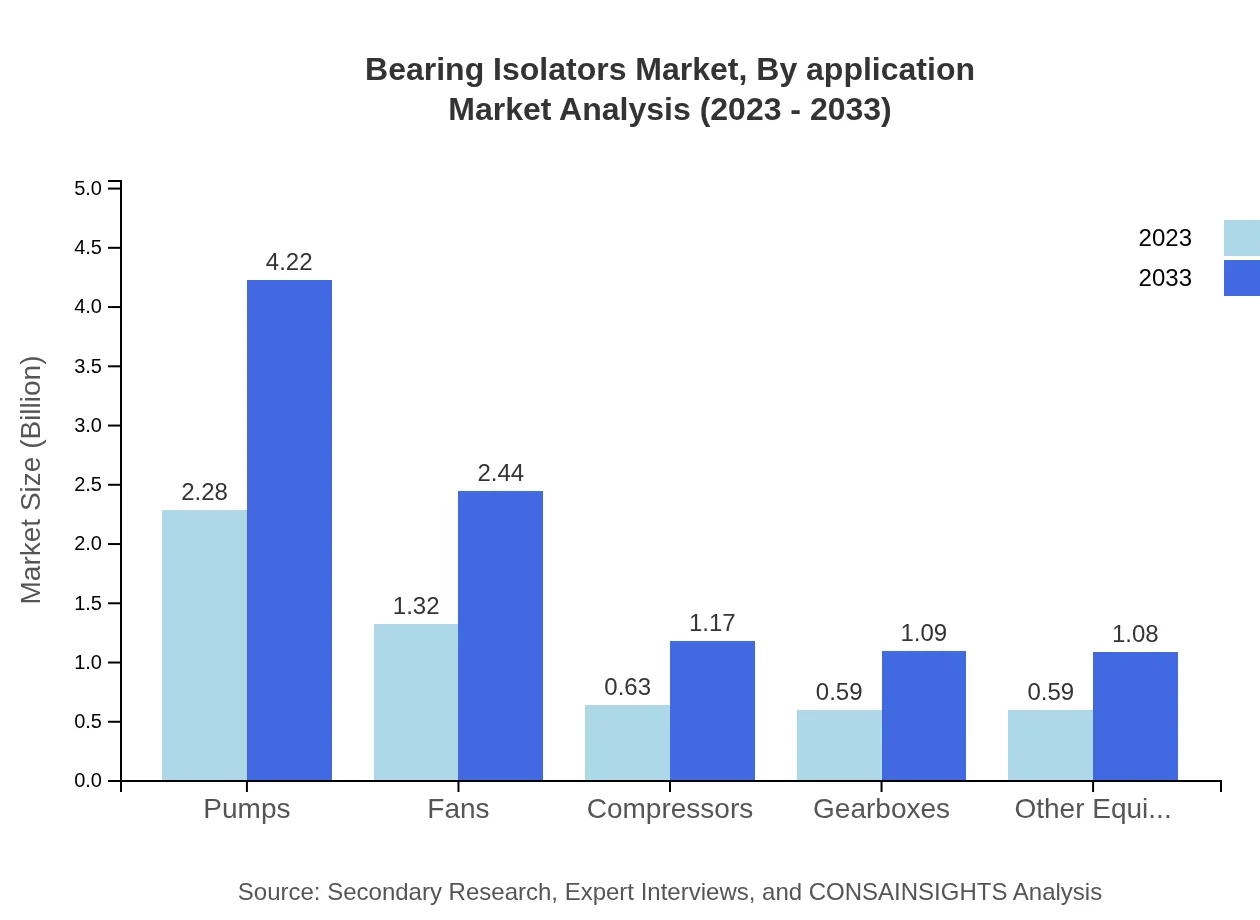

Bearing Isolators Market Analysis By Application

The analysis by application illustrates that Pumps and Fans are the largest applications for bearing isolators, contributing significantly to market revenue, with expected growth patterns aligning with general market trends. Other applications, including Compressors, Gearboxes, and Other Equipment, also showcase steady demand.

Bearing Isolators Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Bearing Isolators Industry

SKF Group:

A leading global supplier of bearings and related products, SKF focuses on innovative solutions for bearing isolation, enhancing reliability and performance in various applications.Timken Company:

Known for their high-quality bearings, Timken also advances isolation technologies to prevent contamination, ensuring long-lasting performance in key industries, including automotive and aerospace.Trelleborg AB:

Trelleborg specializes in engineered polymer solutions, providing innovative bearing isolators that cater to a diverse range of industries, offering superior sealing performance.Gates Corporation:

Gates is well-recognized for their power transmission belts and fluid power solutions. They also produce high-quality isolators that enhance machinery longevity and efficiency.We're grateful to work with incredible clients.

FAQs

What is the market size of bearing isolators?

The global bearing isolators market is valued at approximately $5.4 billion in 2023 and is projected to grow at a CAGR of 6.2%, reaching significant growth by 2033.

What are the key market players or companies in this bearing isolators industry?

Key players in the bearing isolators market include leading corporations specializing in sealing technologies and industrial products, among which strong contenders are recognized for innovative solutions.

What are the primary factors driving the growth in the bearing isolators industry?

The growth of the bearing isolators market is primarily driven by increased demand in oil & gas, mining, and power generation sectors, coupled with technological advancements and escalating industrial applications.

Which region is the fastest Growing in the bearing isolators?

North America is the fastest-growing region in the bearing isolators market, expected to expand from $1.97 billion in 2023 to $3.66 billion by 2033.

Does ConsaInsights provide customized market report data for the bearing isolators industry?

Yes, ConsaInsights offers customized market report data for the bearing isolators industry, allowing clients to receive tailored insights based on specific needs and market segments.

What deliverables can I expect from this bearing isolators market research project?

Deliverables typically include comprehensive market analysis, trends, forecasts, regional insights, and competitive landscape assessments customized for your requirements.

What are the market trends of bearing isolators?

Current trends in the bearing isolators market include a surge in the adoption of sealed designs and technological innovations to enhance operational efficiency and environmental sustainability.