Beverage Carton Packaging Machinery Market Report

Published Date: 22 January 2026 | Report Code: beverage-carton-packaging-machinery

Beverage Carton Packaging Machinery Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Beverage Carton Packaging Machinery market, covering trends, market sizing, regional insights, segmentation, and forecasts from 2023 to 2033.

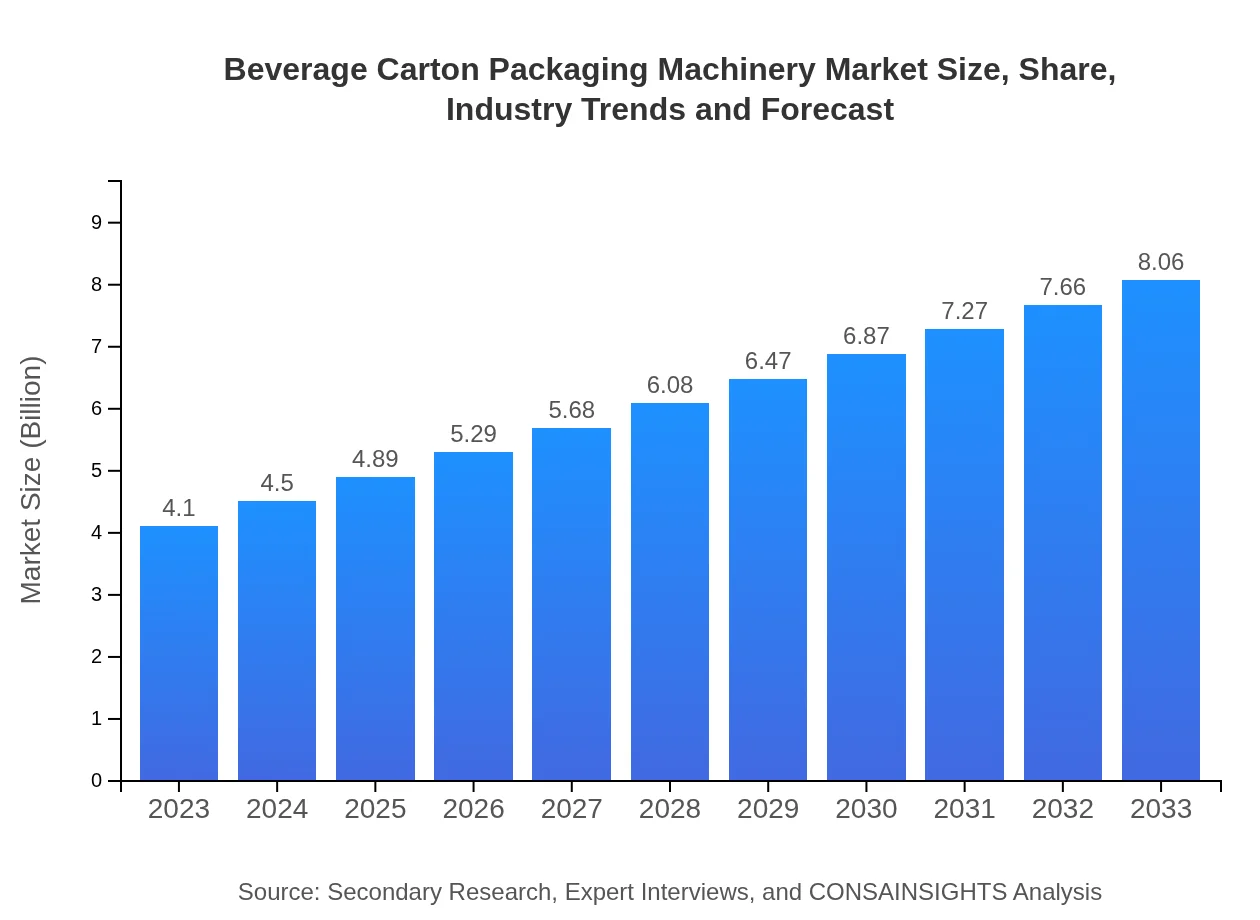

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $4.10 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $8.06 Billion |

| Top Companies | Tetra Pak, SIG Combibloc, Krones AG, Bosch Packaging Technology |

| Last Modified Date | 22 January 2026 |

Beverage Carton Packaging Machinery Market Overview

Customize Beverage Carton Packaging Machinery Market Report market research report

- ✔ Get in-depth analysis of Beverage Carton Packaging Machinery market size, growth, and forecasts.

- ✔ Understand Beverage Carton Packaging Machinery's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Beverage Carton Packaging Machinery

What is the Market Size & CAGR of Beverage Carton Packaging Machinery market in 2023?

Beverage Carton Packaging Machinery Industry Analysis

Beverage Carton Packaging Machinery Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Beverage Carton Packaging Machinery Market Analysis Report by Region

Europe Beverage Carton Packaging Machinery Market Report:

Europe's market size will journey from $1.03 billion in 2023 to $2.03 billion by 2033. The region demands state-of-the-art packaging machinery driven by stricter regulations related to food safety and environmental sustainability. Germany and the UK are key markets within Europe.Asia Pacific Beverage Carton Packaging Machinery Market Report:

The Asia Pacific region is anticipated to witness substantial growth, escalating from $0.78 billion in 2023 to $1.54 billion by 2033. Driven by expanding economies and increasing consumer purchasing power, manufacturers in countries like China and India are increasingly investing in advanced packaging technologies to cater to the burgeoning beverage market.North America Beverage Carton Packaging Machinery Market Report:

The North American market is projected to grow from $1.59 billion in 2023 to an estimated $3.13 billion by 2033. The region leads in adopting innovative packaging technologies characterized by high consumer acceptance of novel packaging solutions. The United States is expected to dominate, with a strong emphasis on sustainable packaging practices.South America Beverage Carton Packaging Machinery Market Report:

In South America, the market size is expected to grow from $0.32 billion in 2023 to $0.63 billion in 2033. Growing awareness of sustainable practices and rising demand for packaged beverages are significantly propelling the market. Brazil and Argentina are likely to be key contributors to this growth.Middle East & Africa Beverage Carton Packaging Machinery Market Report:

The Middle East and Africa market is expected to experience growth from $0.37 billion in 2023 to $0.73 billion by 2033. Rapid urbanization and increasing disposable incomes in the region are likely to foster growth in the beverage sector, thereby driving the demand for carton packaging machinery.Tell us your focus area and get a customized research report.

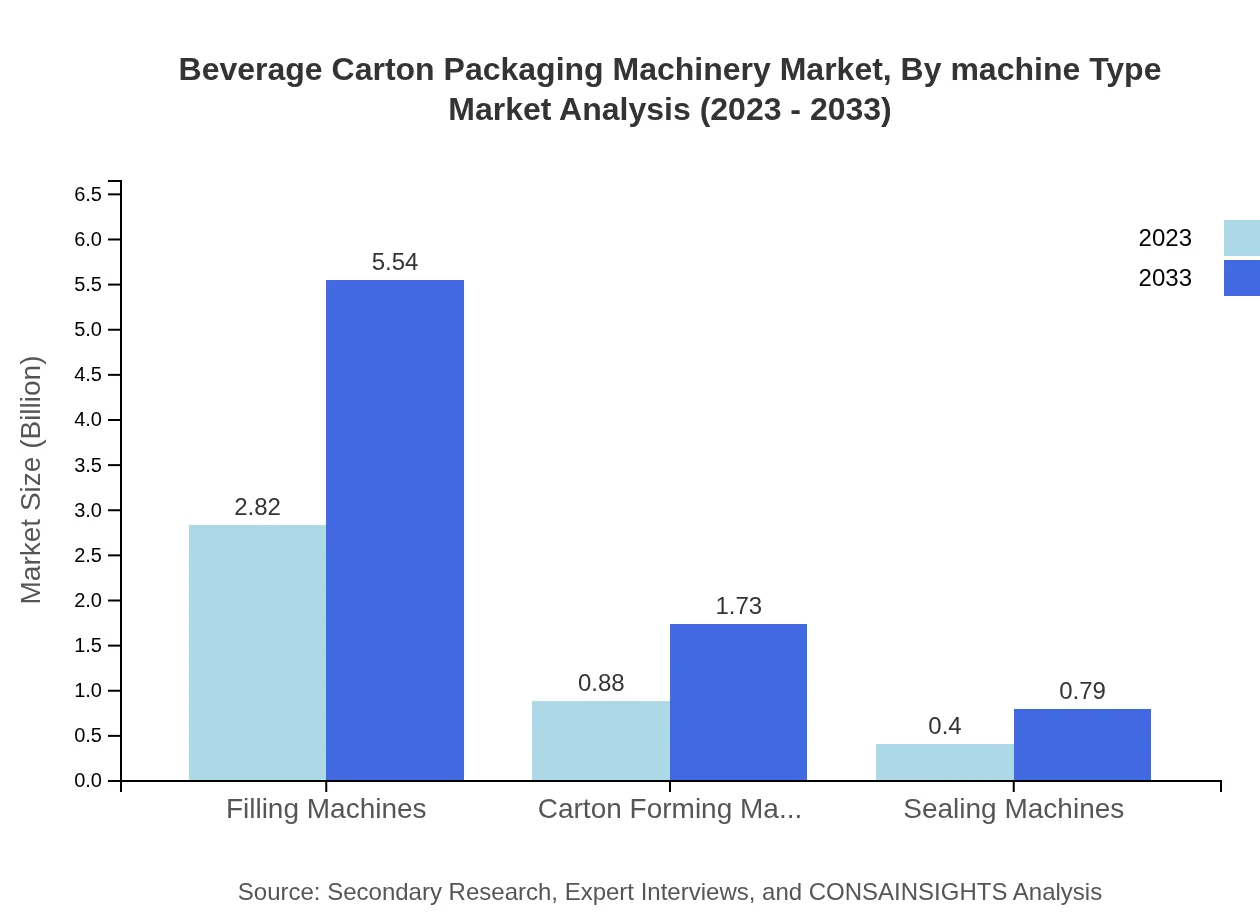

Beverage Carton Packaging Machinery Market Analysis By Machine Type

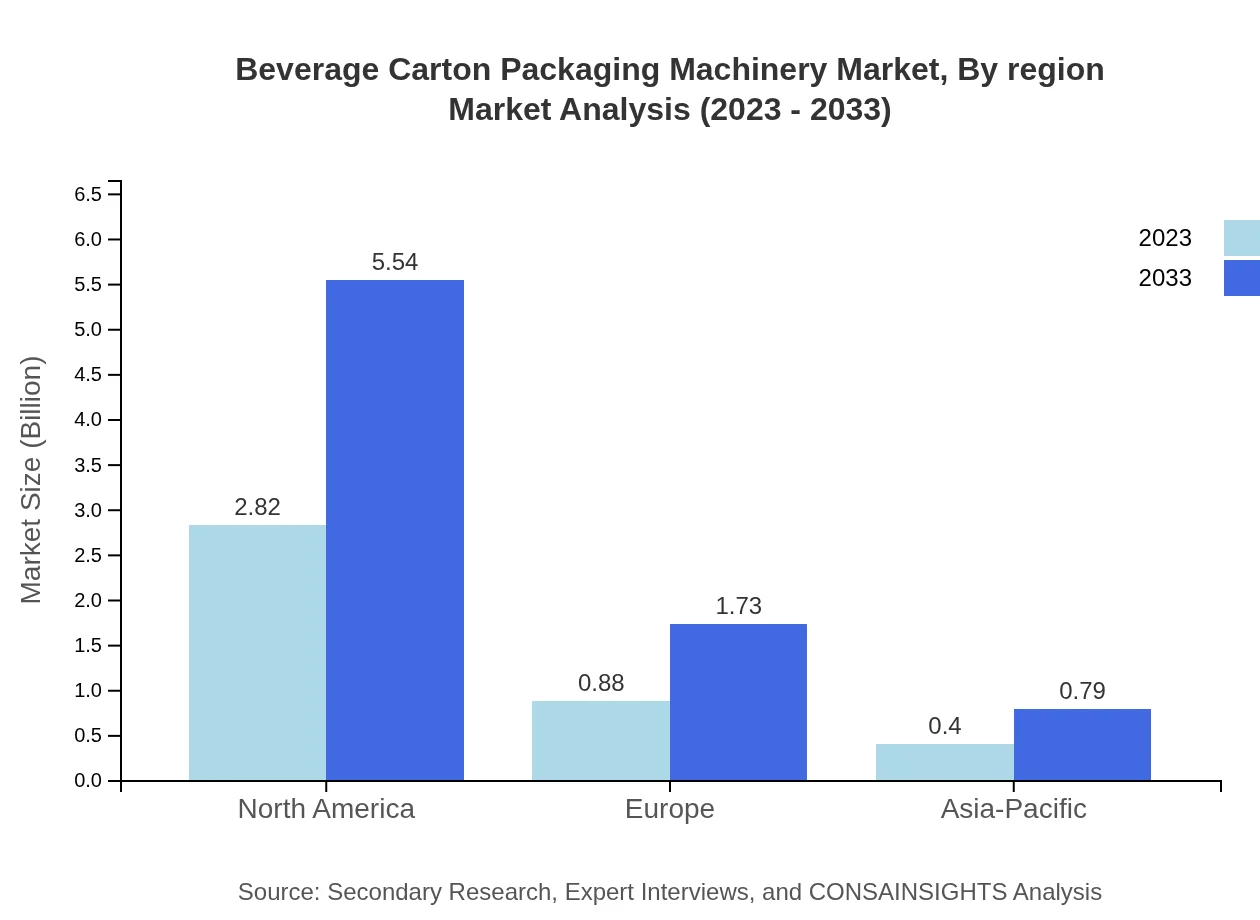

Filling machines dominate the market with a size projected at $2.82 billion in 2023, growing to $5.54 billion by 2033, holding a 68.72% market share. Carton forming machines rank second, with $0.88 billion to $1.73 billion forecasted in the same period, representing 21.52% of market share. Sealing machines contribute smaller portions but are crucial for maintaining product integrity, while automatic machinery leads with an 80.3% share, reflecting a substantial shift towards automation.

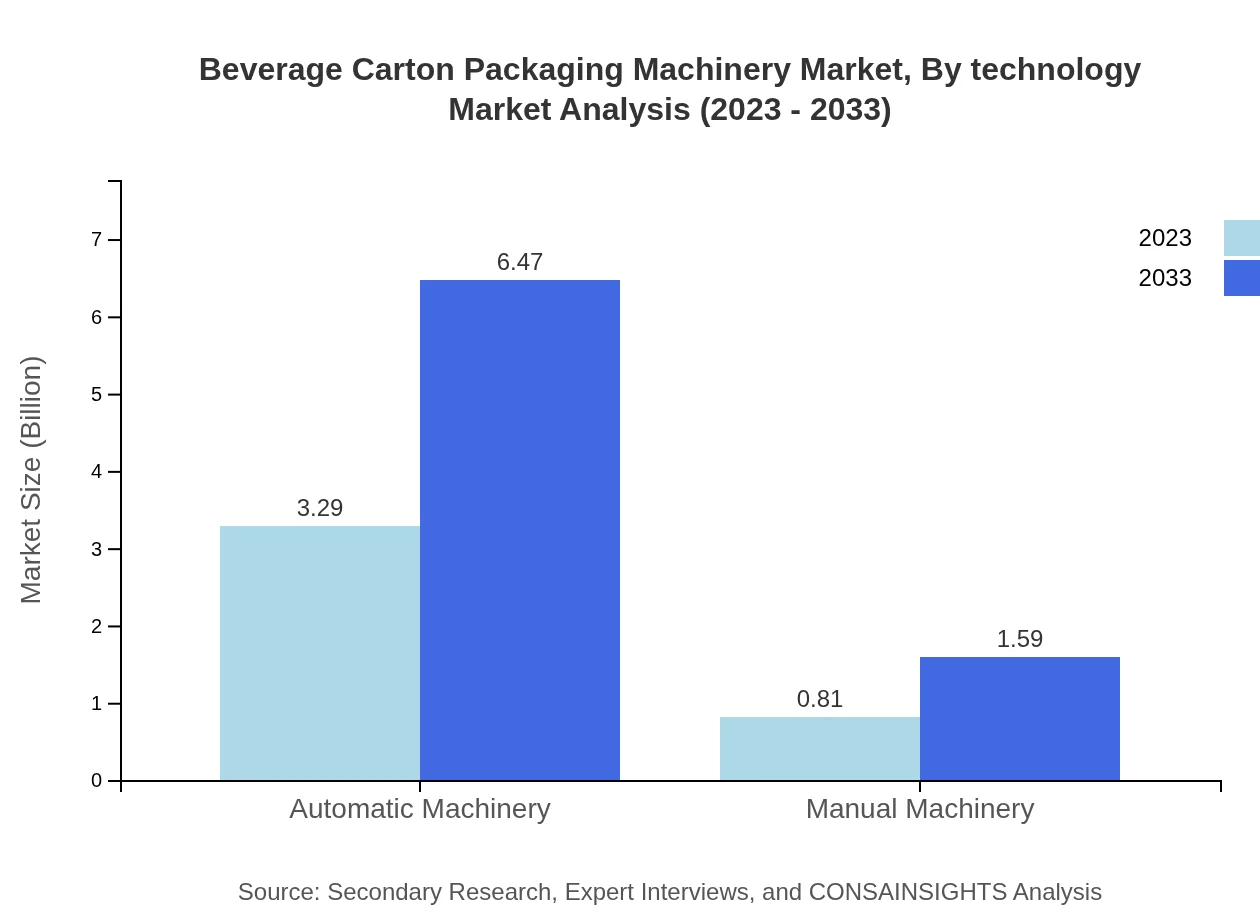

Beverage Carton Packaging Machinery Market Analysis By Technology

Technological advancements in automatic machinery continue to reshape the industry. In 2023, automatic machines accounted for $3.29 billion with a projected growth to $6.47 billion by 2033. This technology emphasizes efficiency, precision, and reduced operational costs. Conversely, manual machinery, though on a decline, holds a 19.7% market share. Innovations focusing on automation, IoT integration, and real-time monitoring represent significant future growth opportunities.

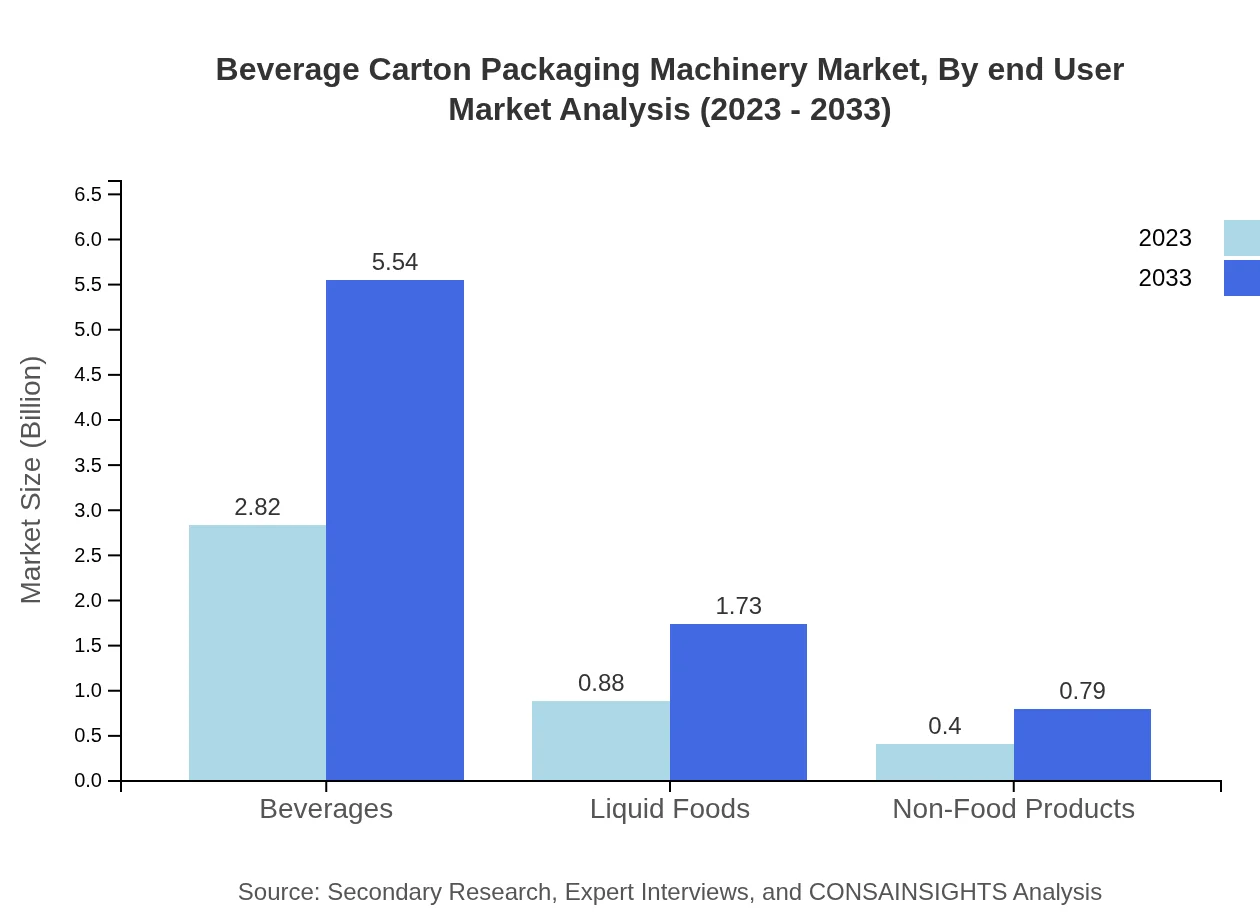

Beverage Carton Packaging Machinery Market Analysis By End User

The beverage segment is the largest end-user, projected to maintain a significant market size from $2.82 billion to $5.54 billion between 2023 and 2033, representing 68.72% market share. The liquid foods sector shows robust growth potential from $0.88 billion to $1.73 billion, while non-food products, although smaller, are expected to expand from $0.40 billion to $0.79 billion, demonstrating diversification in packaging usage.

Beverage Carton Packaging Machinery Market Analysis By Region

Regional analysis shows North America as a frontrunner, expected to hold significant market share. Europe follows closely, while Asia-Pacific is emerging rapidly due to rising economic activities and demand for packaged beverages. Each region's unique dynamics present tailored opportunities for growth, ranging from sustainability in Europe to increasing investments in Asia-Pacific.

Beverage Carton Packaging Machinery Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Beverage Carton Packaging Machinery Industry

Tetra Pak:

A global leader in food processing and packaging solutions, Tetra Pak is known for its innovative carton packaging technologies aimed at enhancing food safety and environmental sustainability.SIG Combibloc:

SIG Combibloc specializes in providing beverage carton packaging systems, focusing on sustainability and efficiency in its product offerings, addressing market needs with advanced solutions.Krones AG:

Krones AG provides bottling and packaging technology and has established itself as a key player in market innovation, offering a wide range of machines tailored for beverage carton packaging.Bosch Packaging Technology:

Known for its high-quality packaging machinery, Bosch offers solutions catering to various packaging needs, including those specific to beverage cartons, focusing on automation and efficiency.We're grateful to work with incredible clients.

FAQs

What is the market size of beverage Carton Packaging Machinery?

The beverage carton packaging machinery market is valued at $4.1 billion in 2023 and is projected to grow at a CAGR of 6.8% through 2033.

What are the key market players or companies in the beverage Carton Packaging Machinery industry?

Key players in the beverage carton packaging machinery industry include Tetra Pak, SIG Combibloc, and Busch Machinery. These companies are known for their innovative technologies and sustainable packaging solutions.

What are the primary factors driving the growth in the beverage Carton Packaging Machinery industry?

Growth in the beverage carton packaging machinery industry is driven by increasing demand for sustainable packaging, innovations in automated machinery, and rising consumption of packaged beverages across global markets.

Which region is the fastest Growing in the beverage Carton Packaging Machinery market?

North America is the fastest-growing region for beverage carton packaging machinery, with a market size expected to reach $3.13 billion by 2033, growing from $1.59 billion in 2023.

Does ConsaInsights provide customized market report data for the beverage Carton Packaging Machinery industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs in the beverage carton packaging machinery industry, allowing businesses to gain relevant insights.

What deliverables can I expect from this beverage Carton Packaging Machinery market research project?

Deliverables from the market research project include detailed reports on market size, growth forecasts, competitive analysis, and insights into market trends and customer preferences.

What are the market trends of beverage Carton Packaging Machinery?

Current trends in the beverage carton packaging machinery market include increased automation, a shift towards sustainability in packaging materials, and innovation targeting consumer convenience and product safety.