Biaxially Oriented Polyethylene Terephthalate Market Report

Published Date: 02 February 2026 | Report Code: biaxially-oriented-polyethylene-terephthalate

Biaxially Oriented Polyethylene Terephthalate Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Biaxially Oriented Polyethylene Terephthalate (BOPET) market from 2023 to 2033, covering market trends, size, growth factors, and regional insights. It aims to guide stakeholders in making informed decisions.

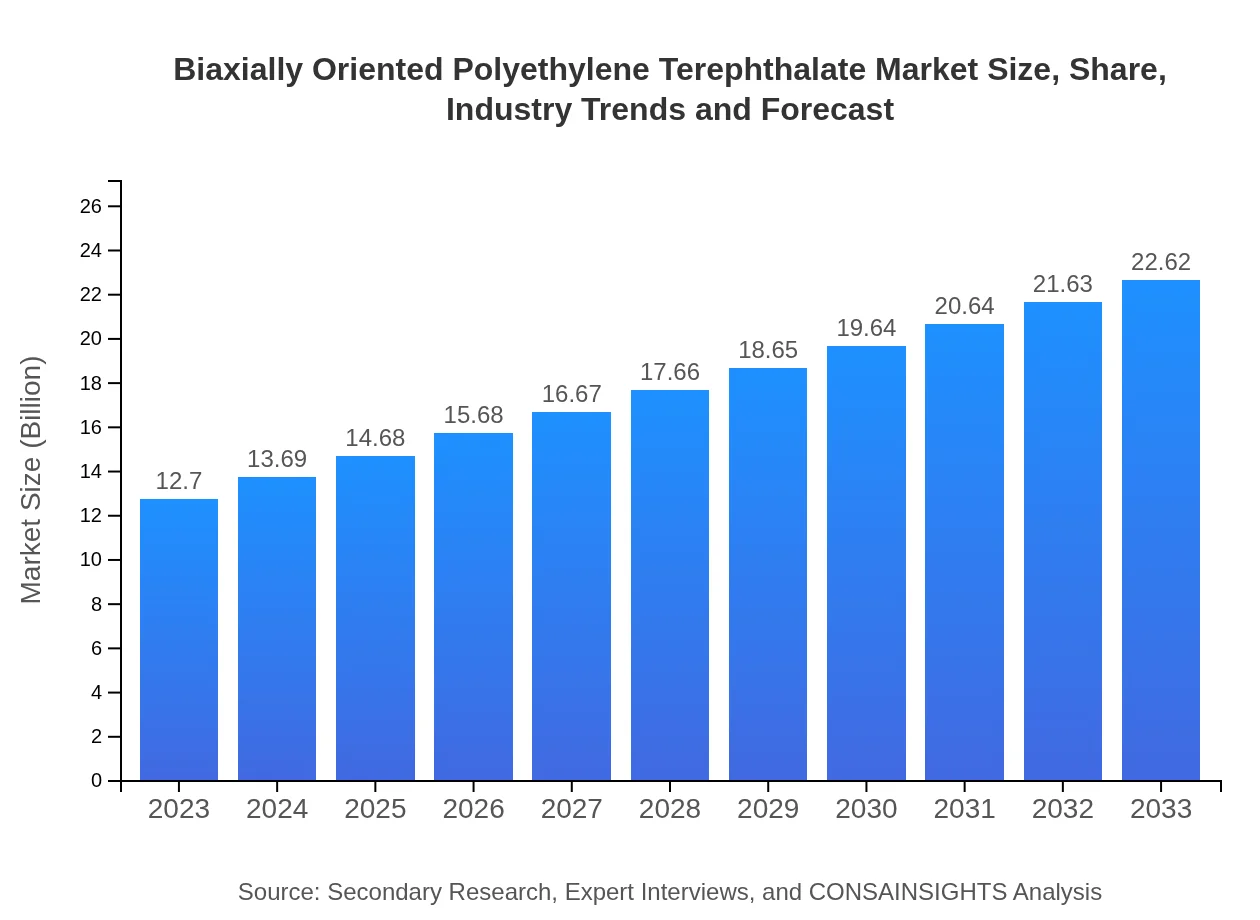

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $12.70 Billion |

| CAGR (2023-2033) | 5.8% |

| 2033 Market Size | $22.62 Billion |

| Top Companies | DuPont, Mitsubishi Polyester Film, Toray Industries, BOPET Corporation |

| Last Modified Date | 02 February 2026 |

Biaxially Oriented Polyethylene Terephthalate Market Overview

Customize Biaxially Oriented Polyethylene Terephthalate Market Report market research report

- ✔ Get in-depth analysis of Biaxially Oriented Polyethylene Terephthalate market size, growth, and forecasts.

- ✔ Understand Biaxially Oriented Polyethylene Terephthalate's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Biaxially Oriented Polyethylene Terephthalate

What is the Market Size & CAGR of Biaxially Oriented Polyethylene Terephthalate market in 2023?

Biaxially Oriented Polyethylene Terephthalate Industry Analysis

Biaxially Oriented Polyethylene Terephthalate Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Biaxially Oriented Polyethylene Terephthalate Market Analysis Report by Region

Europe Biaxially Oriented Polyethylene Terephthalate Market Report:

Europe’s BOPET market, estimated at $3.28 billion in 2023, is projected to grow to $5.83 billion by 2033. A significant driver is the stringent regulations on plastic waste, prompting a shift towards recyclable materials.Asia Pacific Biaxially Oriented Polyethylene Terephthalate Market Report:

The Asia Pacific region is a significant market for BOPET, projected to grow from $2.56 billion in 2023 to $4.55 billion in 2033, fueled by rising industrialization and demand for flexible packaging solutions, particularly in China and India.North America Biaxially Oriented Polyethylene Terephthalate Market Report:

The North American BOPET market stands at $4.59 billion in 2023 and is expected to reach $8.17 billion by 2033. This increase is supported by the growing electronic and medical industries, emphasizing high-quality, durable materials.South America Biaxially Oriented Polyethylene Terephthalate Market Report:

South America's BOPET market, valued at $1.22 billion in 2023, is expected to increase to $2.17 billion by 2033. This growth is mainly driven by the food and beverage and consumer goods sectors.Middle East & Africa Biaxially Oriented Polyethylene Terephthalate Market Report:

The Middle East and Africa market for BOPET is currently valued at $1.06 billion and is forecasted to grow to $1.89 billion by 2033. The increasing demand for consumer goods and packaging solutions in these regions is a contributing factor.Tell us your focus area and get a customized research report.

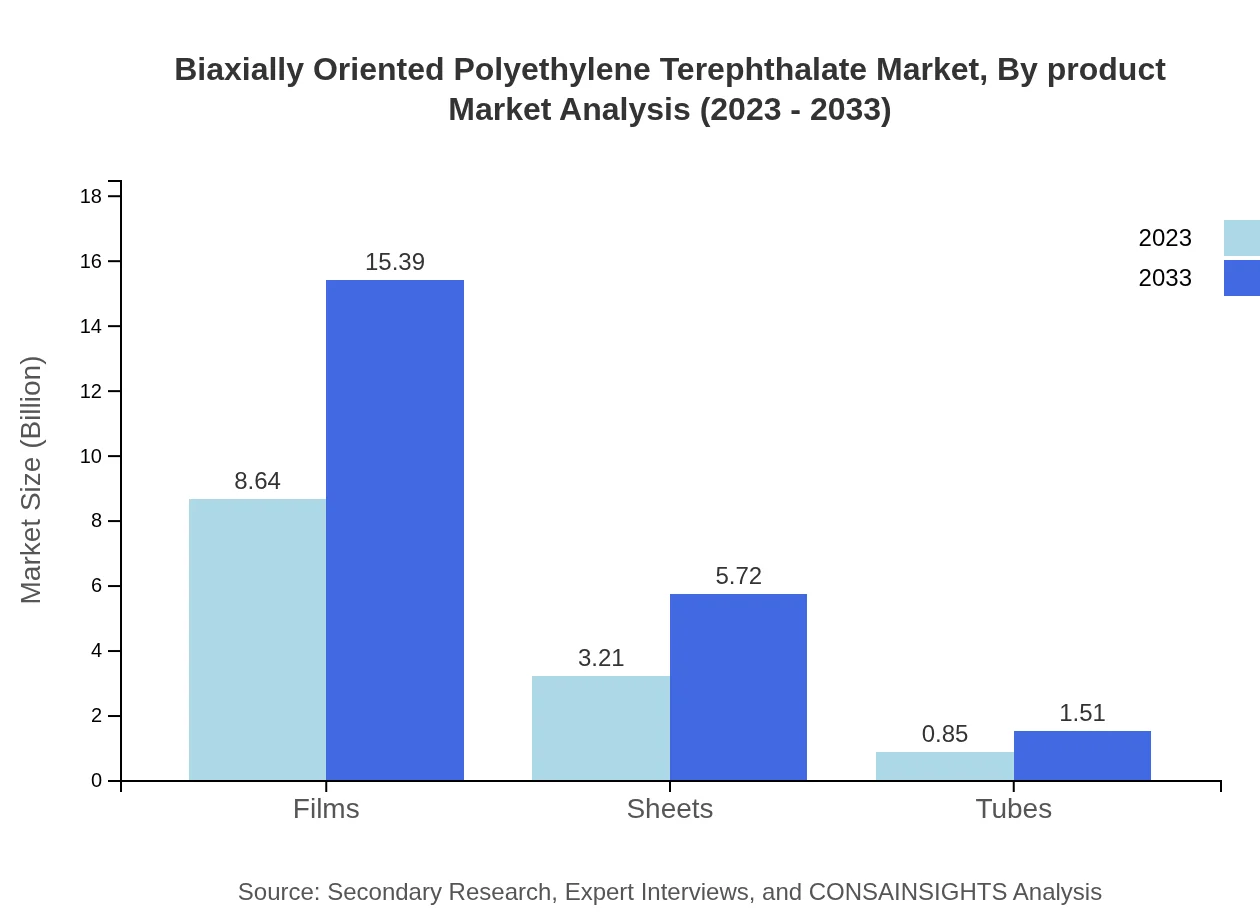

Biaxially Oriented Polyethylene Terephthalate Market Analysis By Product

The BOPET market by product segment includes soft films, rigid sheets, tubes, and composite materials. Soft films dominate the market with a size of $8.64 billion in 2023, expected to grow to $15.39 billion by 2033, capturing a share of 68.05%. Rigid sheets are valued at $3.21 billion in 2023 and are projected to reach $5.72 billion by 2033, holding a market share of 25.28%.

Biaxially Oriented Polyethylene Terephthalate Market Analysis By Application

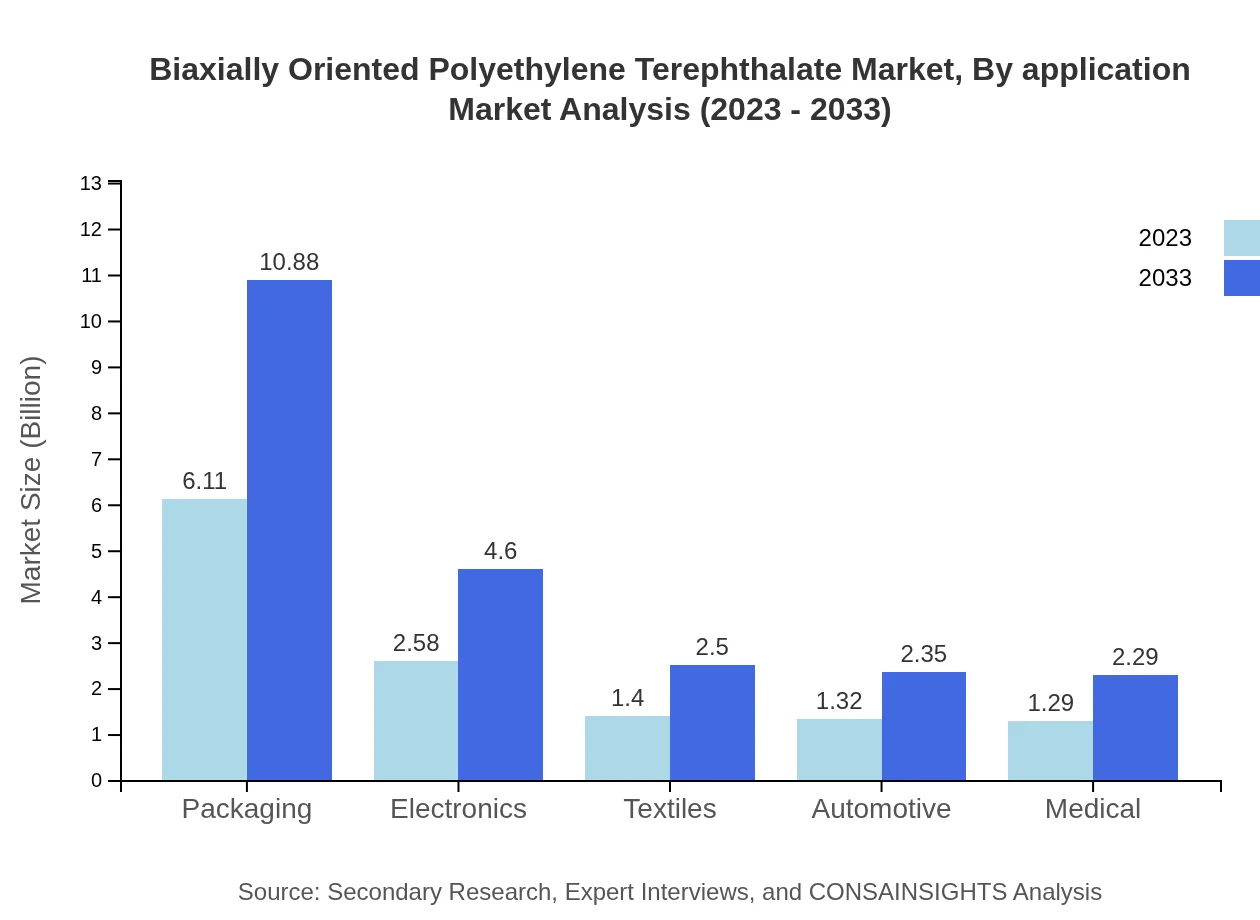

In terms of application, the packaging segment is pivotal, with a market size of $6.11 billion in 2023, increasing to $10.88 billion by 2033. Electronics follow, with an estimated market size of $2.58 billion in 2023 and growth to $4.60 billion expected. The food and beverages segment also holds significant share, reflecting the utility of BOPET in maintaining product integrity and extending shelf life.

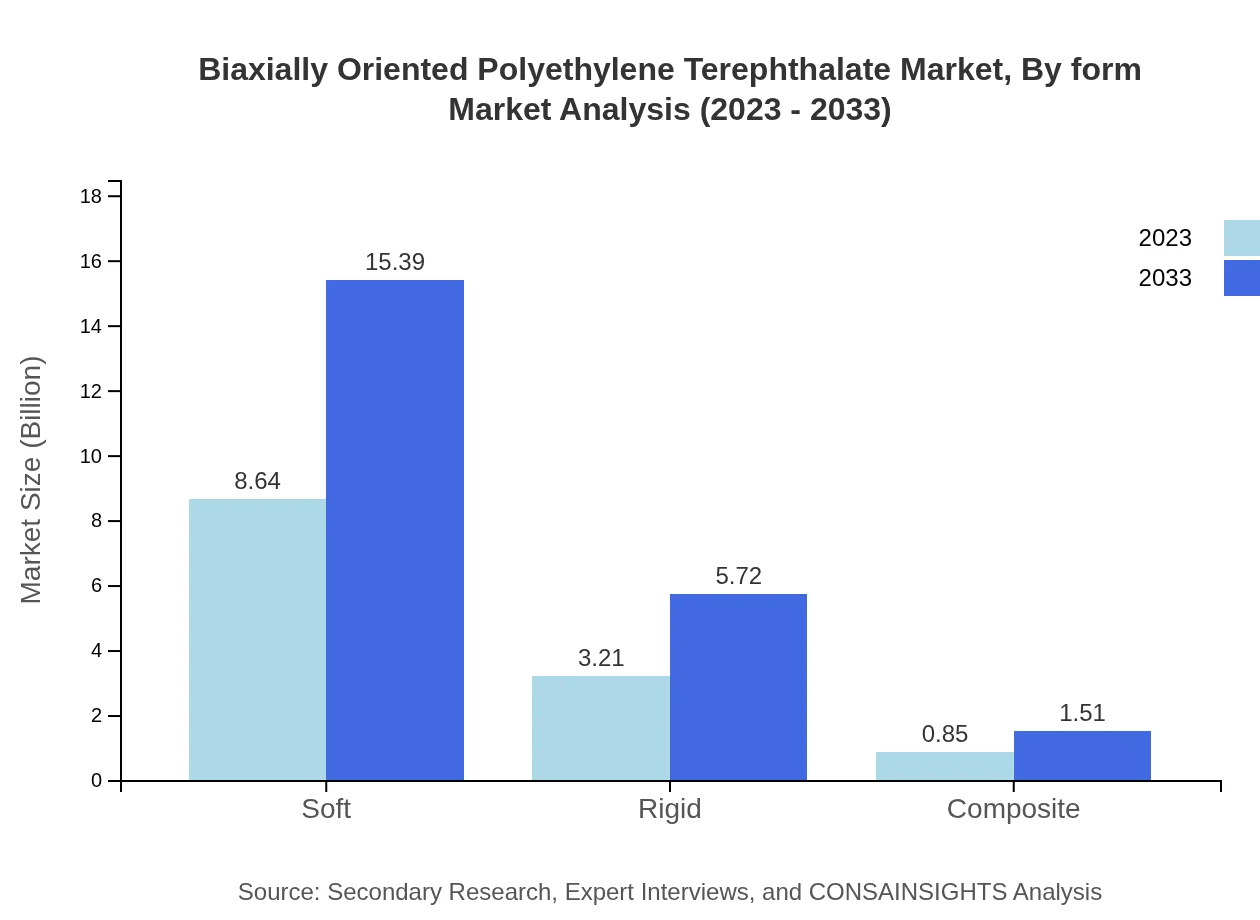

Biaxially Oriented Polyethylene Terephthalate Market Analysis By Form

BOPET is available in various forms including films, sheets, and tubes, with films being the largest segment. The market for films stands at $8.64 billion in 2023 with substantial growth anticipated. Sheets and tubes capture lesser market shares but serve critical functions in specific applications.

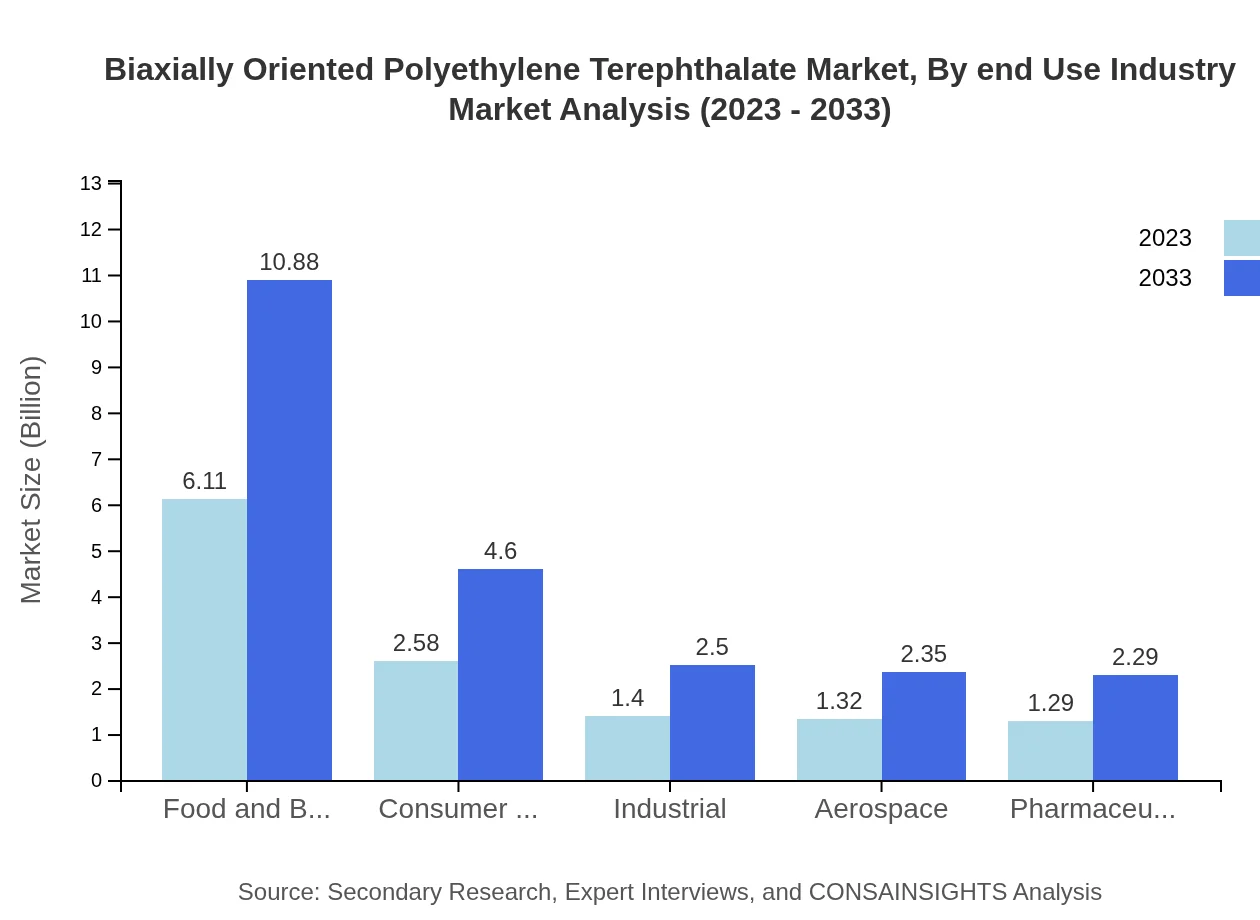

Biaxially Oriented Polyethylene Terephthalate Market Analysis By End Use Industry

The end-use industries utilizing BOPET include food and beverages, consumer goods, textiles, medical, and automotive. The food and beverage sector leads with a size of $6.11 billion in 2023 and expected growth to $10.88 billion by 2033. The automotive and medical industries show strong growth potential as demand for advanced materials and solutions increases.

Biaxially Oriented Polyethylene Terephthalate Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Biaxially Oriented Polyethylene Terephthalate Industry

DuPont:

DuPont is a leading player in the BOPET market, known for its innovative materials and sustainable packaging solutions.Mitsubishi Polyester Film:

Mitsubishi specializes in providing high-quality BOPET films, known for their strength and durability in harsh applications.Toray Industries:

Toray is recognized for integrating advanced technology into BOPET production, enhancing film properties for various applications.BOPET Corporation:

BOPET Corporation focuses on producing BOPET films and has a robust product portfolio catering to diverse industries.We're grateful to work with incredible clients.

FAQs

What is the market size of biaxially Oriented Polyethylene Terephthalate?

The global market size for biaxially-oriented polyethylene terephthalate was valued at approximately $12.7 billion in 2023, with an anticipated compound annual growth rate (CAGR) of 5.8% from 2023 to 2033.

What are the key market players or companies in the biaxially Oriented Polyethylene Terephthalate industry?

Key market players include major manufacturers and suppliers focused on innovative products and sustainability in the BPA market. Their investments in technology and capacity expansion are pivotal to shaping the industry landscape.

What are the primary factors driving the growth in the biaxially Oriented Polyethylene Terephthalate industry?

Growth is driven by rising demand in various sectors such as packaging, electronics, and automotive industries, where BPA's properties enhance product performance. Increased consumer awareness regarding eco-friendly materials also fuels market expansion.

Which region is the fastest Growing in the biaxially Oriented Polyethylene Terephthalate market?

The fastest-growing region is Europe, with the market projected to grow from $3.28 billion in 2023 to $5.83 billion by 2033. Asia Pacific also shows significant growth, expanding from $2.56 billion to $4.55 billion in the same period.

Does ConsaInsights provide customized market report data for the biaxially Oriented Polyethylene Terephthalate industry?

Yes, ConsaInsights offers customized market reports that cater to specific research needs in the biaxially-oriented polyethylene terephthalate industry, ensuring tailored insights and data.

What deliverables can I expect from this biaxially Oriented Polyethylene Terephthalate market research project?

Deliverables include detailed market analyses, growth forecasts, competitive landscape assessments, and segmentation data, providing a comprehensive overview of the market structure and growth opportunities.

What are the market trends of biaxially Oriented Polyethylene Terephthalate?

Current trends include increasing adoption in sustainable packaging solutions, advancements in production technologies, and a shift towards lightweight materials in various industries, reflecting a broader commitment to environmental sustainability.