Biocompatible-3d Printing Materials Market Report

Published Date: 31 January 2026 | Report Code: biocompatible-3d-printing-materials

Biocompatible-3d Printing Materials Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Biocompatible-3D Printing Materials market, including current trends, market size, forecasts for 2023-2033, and regional insights that cater to stakeholders in this innovative sector.

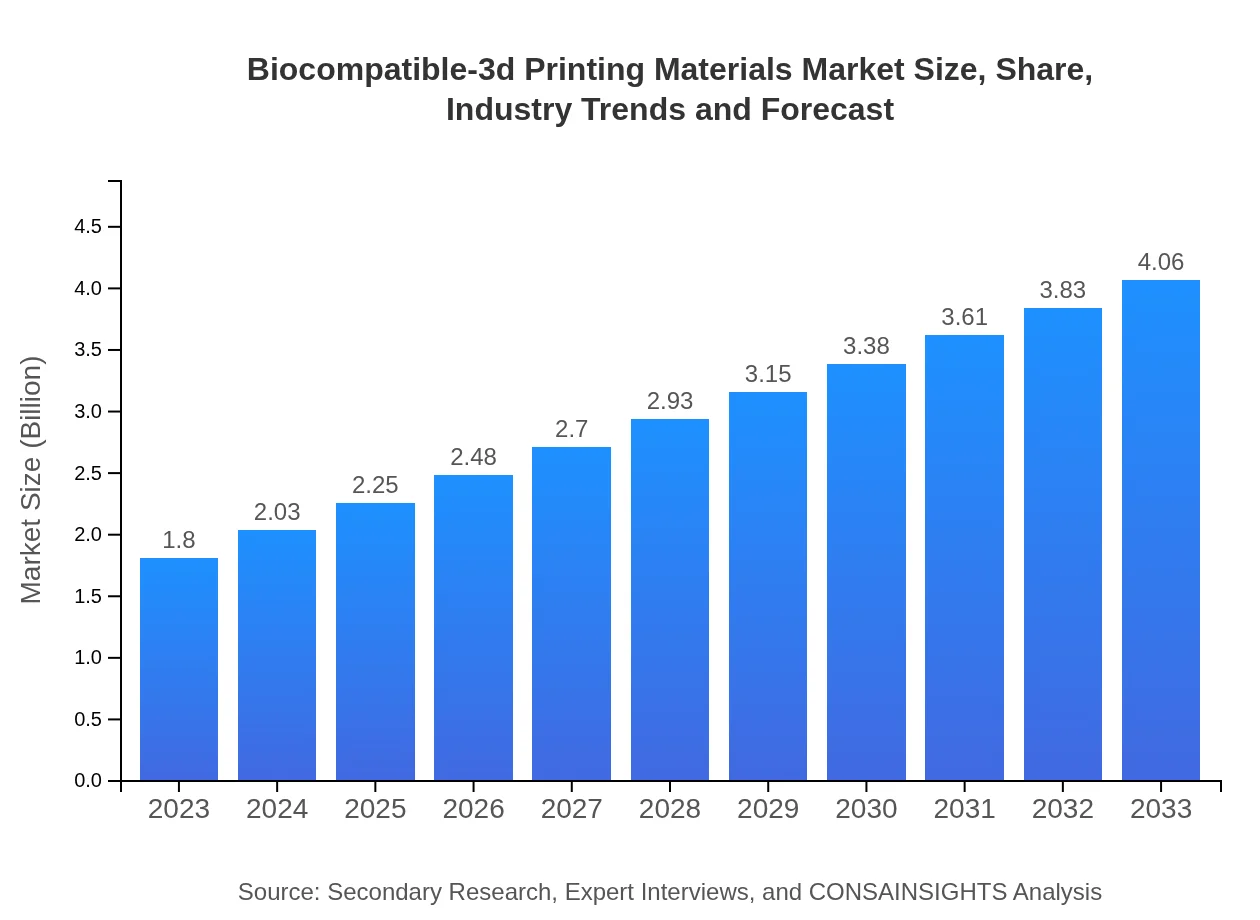

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $1.80 Billion |

| CAGR (2023-2033) | 8.2% |

| 2033 Market Size | $4.06 Billion |

| Top Companies | Stratasys Ltd., 3D Systems Corporation, Materialise NV |

| Last Modified Date | 31 January 2026 |

Biocompatible-3d Printing Materials Market Overview

Customize Biocompatible-3d Printing Materials Market Report market research report

- ✔ Get in-depth analysis of Biocompatible-3d Printing Materials market size, growth, and forecasts.

- ✔ Understand Biocompatible-3d Printing Materials's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Biocompatible-3d Printing Materials

What is the Market Size & CAGR of Biocompatible-3d Printing Materials market in 2023?

Biocompatible-3d Printing Materials Industry Analysis

Biocompatible-3d Printing Materials Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Biocompatible-3d Printing Materials Market Analysis Report by Region

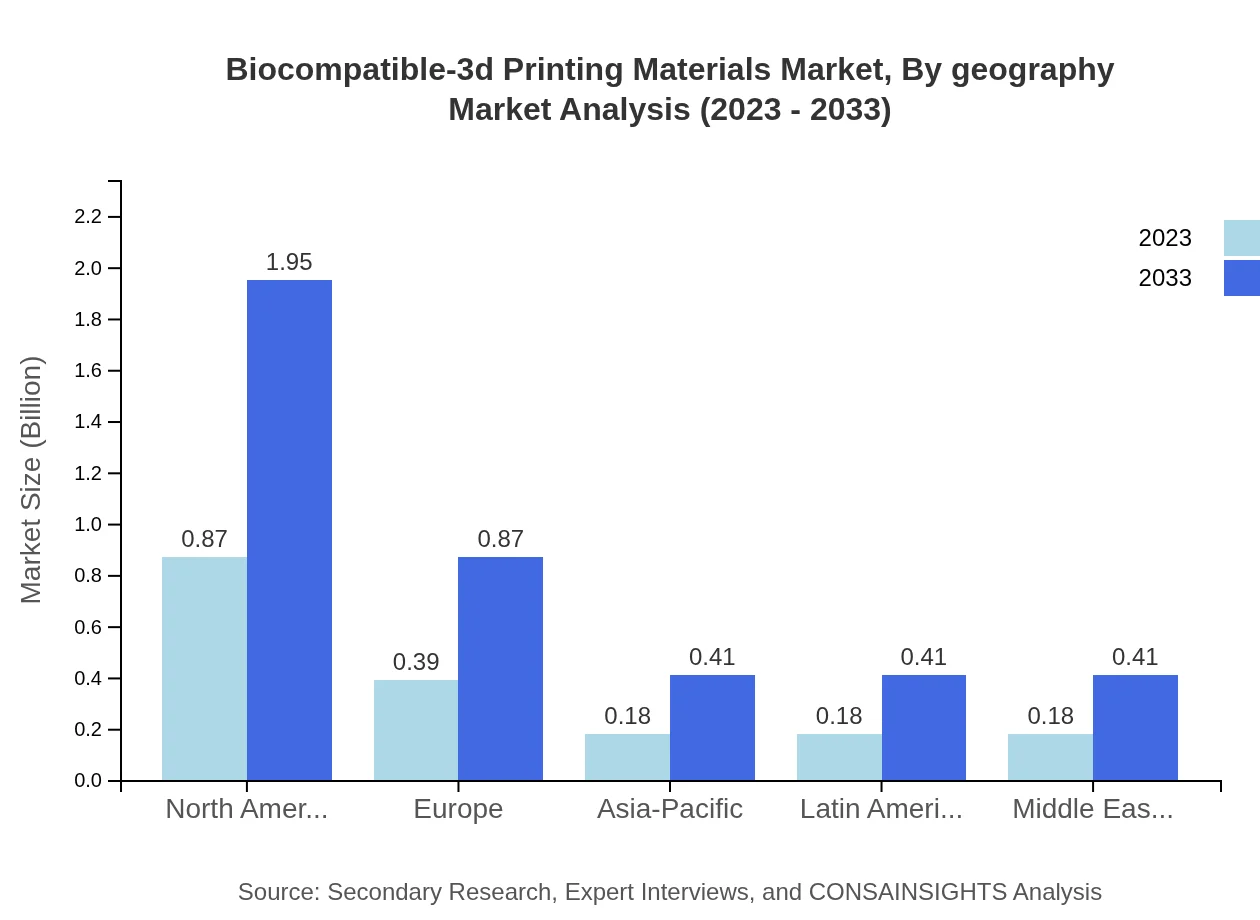

Europe Biocompatible-3d Printing Materials Market Report:

Europe is foreseen to grow from $0.52 billion in 2023 to $1.16 billion by 2033, benefiting from stringent regulatory frameworks promoting the use of advanced 3D printing technologies in medical applications.Asia Pacific Biocompatible-3d Printing Materials Market Report:

The Asia Pacific region is witnessing robust growth in the biocompatible 3D printing materials market, primarily driven by advancements in healthcare infrastructure and increasing investment in medical technology. Market size is projected to grow from $0.36 billion in 2023 to $0.81 billion by 2033.North America Biocompatible-3d Printing Materials Market Report:

North America is currently the largest market, valued at $0.61 billion in 2023, with growth expected to reach $1.37 billion by 2033. This growth is propelled by significant investments in R&D and the presence of key players in the bioprinting landscape.South America Biocompatible-3d Printing Materials Market Report:

South America’s market for biocompatible 3D printing materials is expected to increase from $0.13 billion in 2023 to $0.30 billion by 2033, fueled by rising healthcare awareness and improvements in medical devices.Middle East & Africa Biocompatible-3d Printing Materials Market Report:

The Middle East and Africa region is projected to expand from $0.19 billion in 2023 to $0.43 billion by 2033, driven by increasing healthcare investments and a growing interest in advanced manufacturing technologies.Tell us your focus area and get a customized research report.

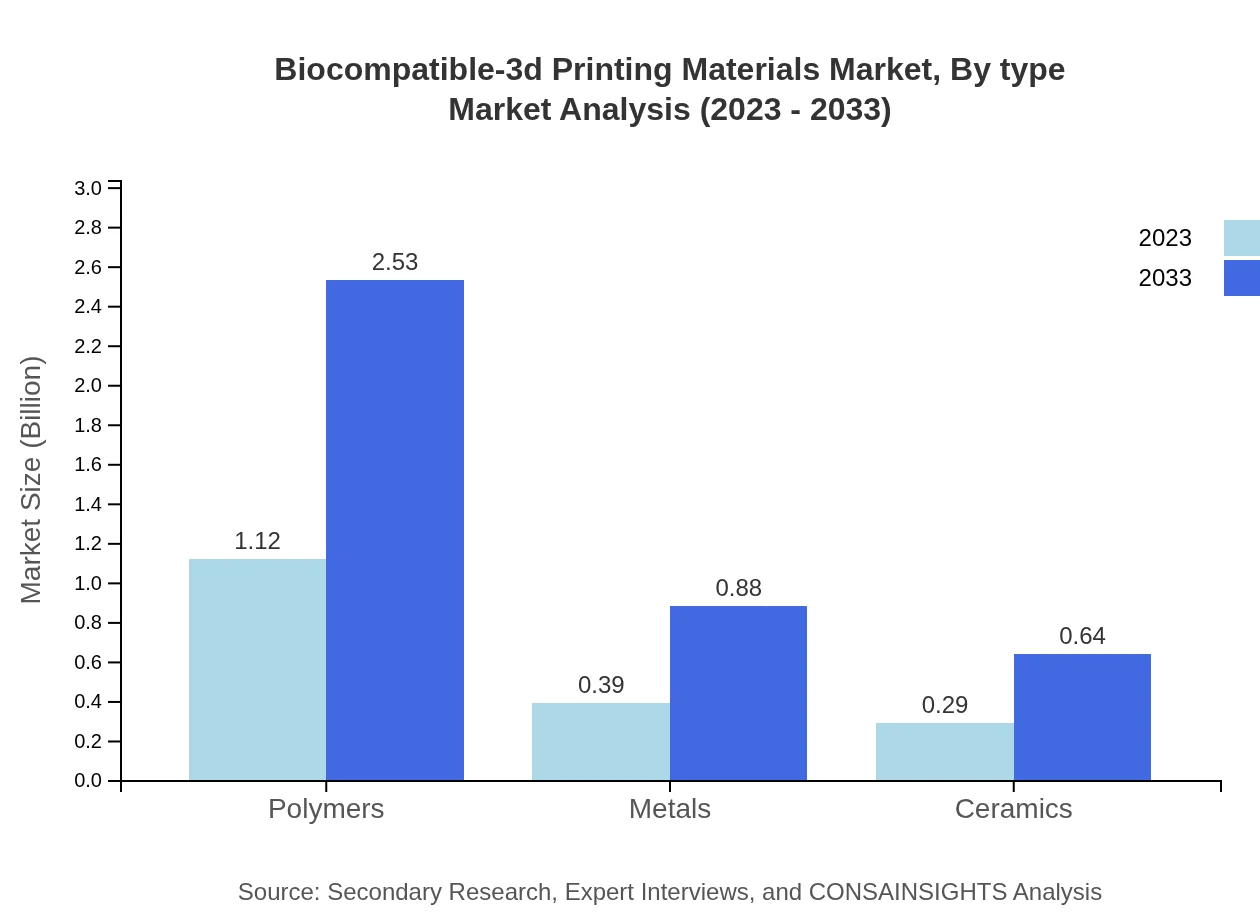

Biocompatible-3d Printing Materials Market Analysis By Type

The Biocompatible 3D Printing Materials market is greatly influenced by polymer types, which represent over 62% market share in 2023, with revenues expected to grow from $1.12 billion to $2.53 billion by 2033. Metals and ceramics, although trailing behind in revenue, have shown significant niche applications in dental and surgical instruments, with respective market sizes of $0.39 billion to $0.88 billion and $0.29 billion to $0.64 billion over the same period.

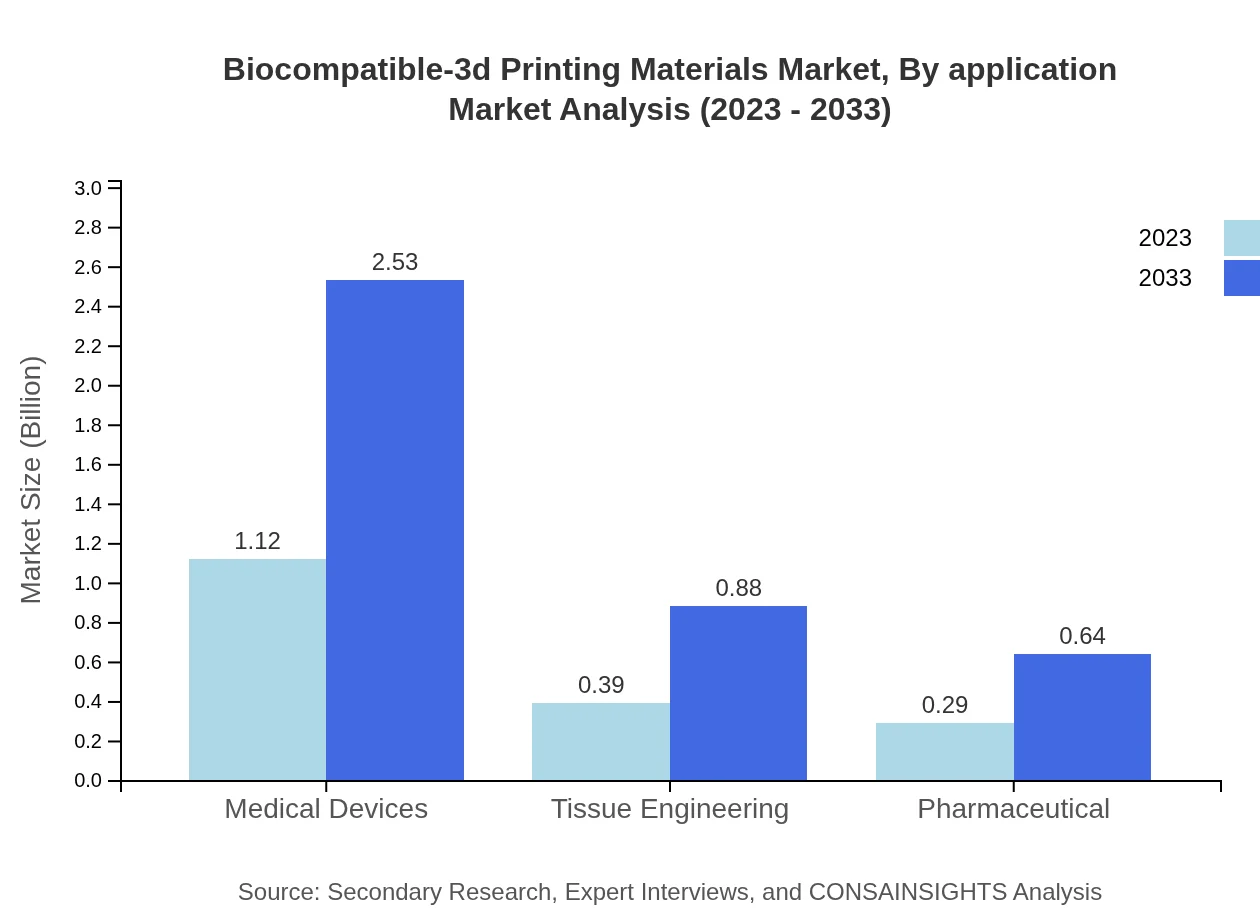

Biocompatible-3d Printing Materials Market Analysis By Application

The applications of biocompatible 3D printing materials are predominantly focused on medical devices, which dominate the industry with a market size of $1.12 billion in 2023. Other applications include tissue engineering and pharmaceuticals, both of which are expected to grow significantly as new treatment avenues are explored, particularly in regenerative medicine.

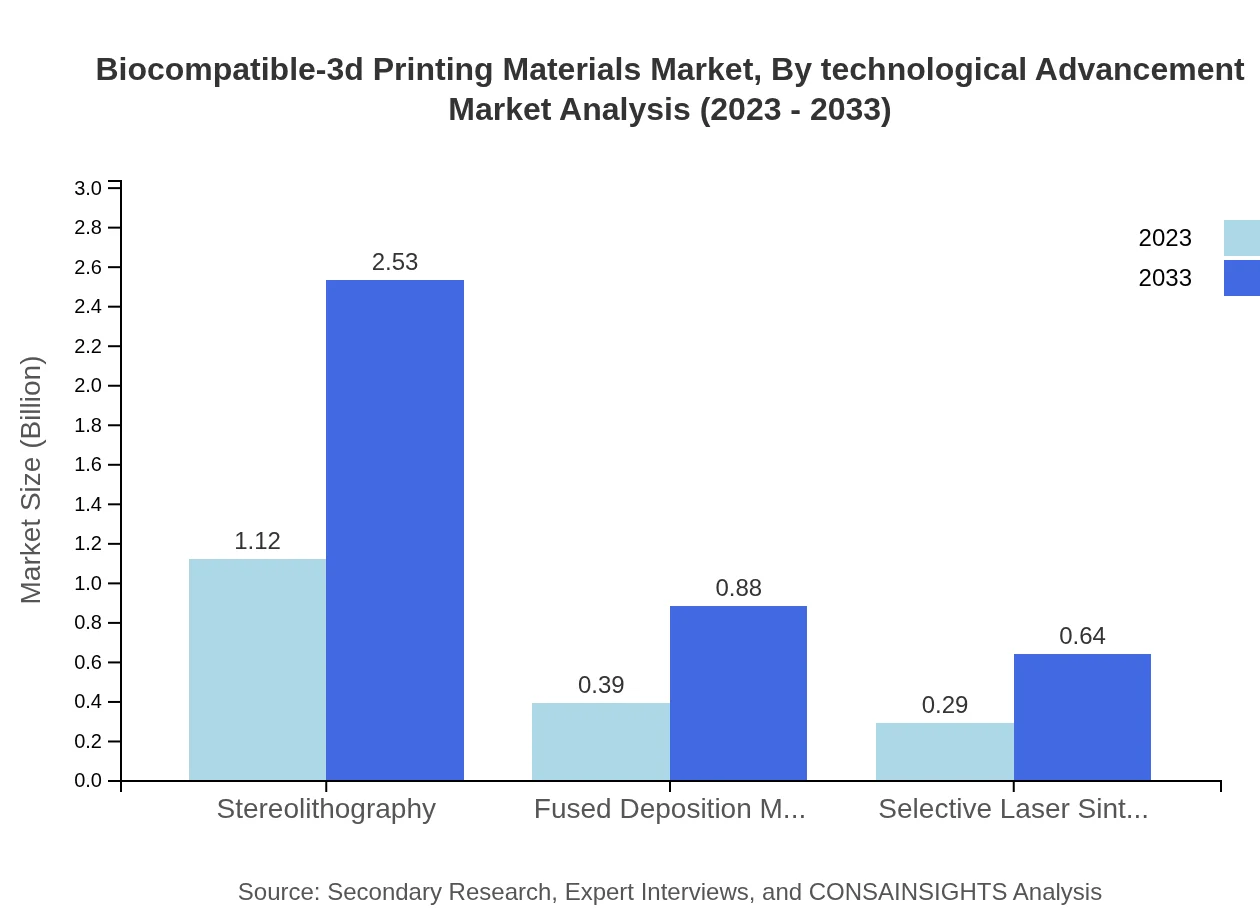

Biocompatible-3d Printing Materials Market Analysis By Technological Advancement

Technological advancements are pivotal in driving the biocompatible 3D printing materials market. Innovations such as stereolithography, fused deposition modeling, and selective laser sintering have redefined material capabilities. Stereolithography is leading the market with a share of 62%, while fused deposition modeling and selective laser sintering hold 21.77% and 15.86% market shares respectively, showcasing their growing adoption in clinical applications.

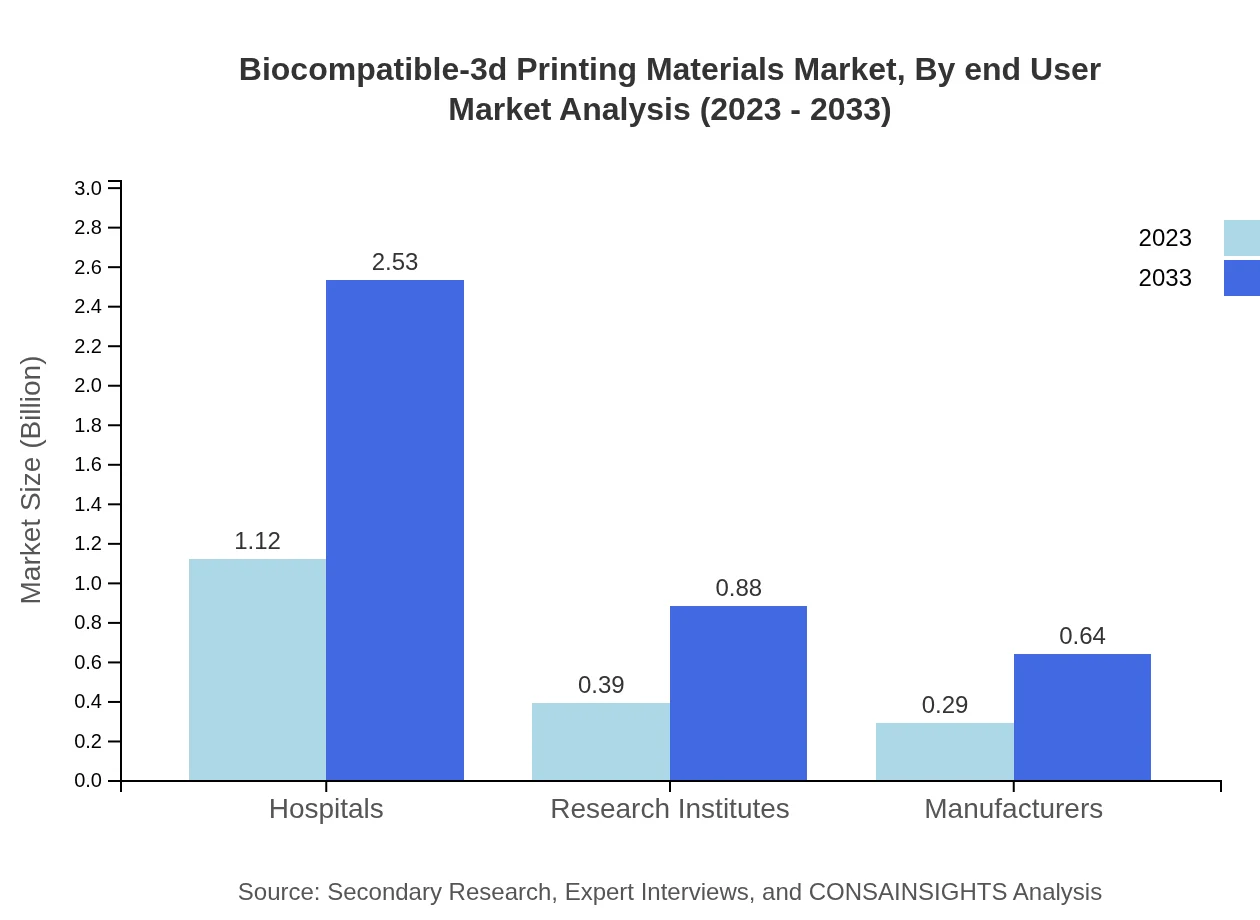

Biocompatible-3d Printing Materials Market Analysis By End User

The primary end-users of biocompatible 3D printing materials include hospitals and research institutes, collectively accounting for over 80% market share. Hospitals, with a market size of $1.12 billion, are increasingly adopting 3D printing technologies for custom patient solutions, while research institutes are exploring novel applications to advance medical science, anticipated to grow from $0.39 billion to $0.88 billion.

Biocompatible-3d Printing Materials Market Analysis By Geography

Geographically, the North American region leads the market share, presenting significant opportunities due to early technological adoption and strong investment in healthcare R&D. Europe follows closely, supported by regulatory backing. The Asia Pacific market is rapidly gaining traction due to population growth and demand for affordable healthcare solutions.

Biocompatible-3d Printing Materials Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Biocompatible-3d Printing Materials Industry

Stratasys Ltd.:

Stratasys is a leader in the 3D printing industry, providing innovative solutions, including biocompatible materials for medical applications, helping revolutionize healthcare through quality manufacturing.3D Systems Corporation:

3D Systems is one of the pioneers in 3D printing technology, offering a wide range of biocompatible materials aimed at enhancing personalized healthcare solutions.Materialise NV:

Materialise specializes in 3D printing software and services, with a strong emphasis on medical technology, offering biocompatible materials for surgical planning and patient-specific implants.We're grateful to work with incredible clients.

FAQs

What is the market size of biocompatible-3d Printing Materials?

The biocompatible 3D printing materials market is valued at approximately $1.8 billion in 2023, with a projected Compound Annual Growth Rate (CAGR) of 8.2%. This growth is indicative of increasing demand in the healthcare sector.

What are the key market players or companies in the biocompatible-3d Printing Materials industry?

Key players in the biocompatible 3D printing materials market include leading companies such as 3D Systems, Stratasys, and Materialise. These firms focus on innovation to enhance their product offerings and capture market share.

What are the primary factors driving the growth in the biocompatible-3d Printing Materials industry?

Growth in the biocompatible 3D printing materials industry is driven by rising demand for customized medical implants, advancements in 3D printing technology, and increasing investments in healthcare innovation, leading to significant market expansion.

Which region is the fastest Growing in the biocompatible-3d Printing Materials?

The Asia-Pacific region is the fastest-growing in the biocompatible 3D printing materials market. By 2033, its market size is expected to reach approximately $0.41 billion, reflecting strong development in healthcare infrastructure.

Does ConsaInsights provide customized market report data for the biocompatible-3d Printing Materials industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs within the biocompatible 3D printing materials industry, allowing clients to gain insights suited to their unique operational goals.

What deliverables can I expect from this biocompatible-3d Printing Materials market research project?

Deliverables from the biocompatible 3D printing materials market research project typically include comprehensive market analysis, trend forecasts, competitor assessments, and actionable insights to inform strategic decision-making.

What are the market trends of biocompatible-3d Printing Materials?

Current trends in the biocompatible 3D printing materials market include increased adoption of polymers due to their versatility, rising interest in personalized medicine, and investments in emerging technologies such as bioprinting.