Boiler Control Market Report

Published Date: 22 January 2026 | Report Code: boiler-control

Boiler Control Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Boiler Control market, offering insights into market trends, size, technology advancements, segmentation, and regional dynamics over the forecast period from 2023 to 2033.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

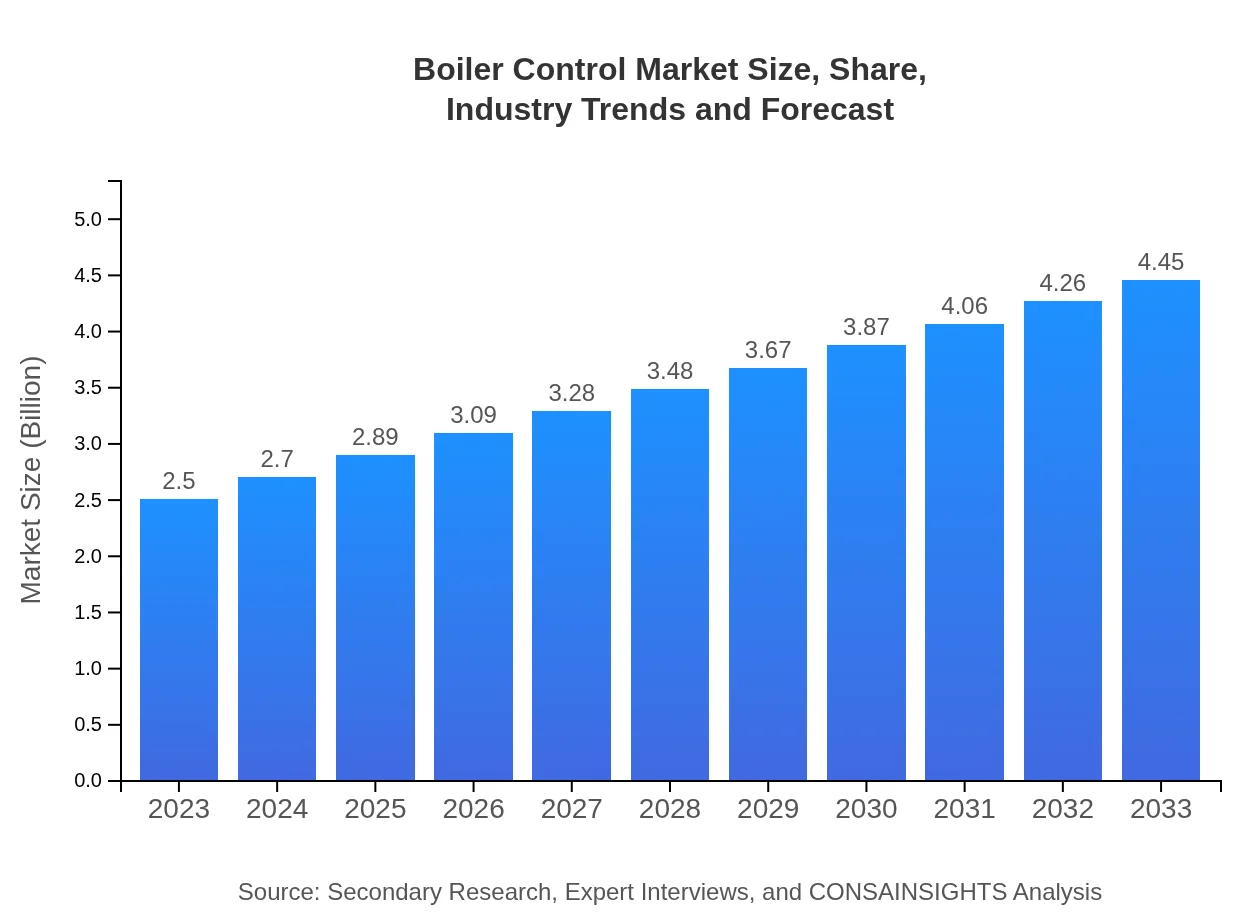

| 2023 Market Size | $2.50 Billion |

| CAGR (2023-2033) | 5.8% |

| 2033 Market Size | $4.45 Billion |

| Top Companies | Emerson Electric Co., Honeywell International Inc., Siemens AG, General Electric, Valeo |

| Last Modified Date | 22 January 2026 |

Boiler Control Market Overview

Customize Boiler Control Market Report market research report

- ✔ Get in-depth analysis of Boiler Control market size, growth, and forecasts.

- ✔ Understand Boiler Control's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Boiler Control

What is the Market Size & CAGR of Boiler Control market in 2023?

Boiler Control Industry Analysis

Boiler Control Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Boiler Control Market Analysis Report by Region

Europe Boiler Control Market Report:

With a market size of $0.65 billion in 2023, Europe is expected to expand to $1.15 billion by 2033. The EU's commitment to reducing carbon emissions and promoting advanced technological solutions act as primary growth factors.Asia Pacific Boiler Control Market Report:

In 2023, the Asia Pacific region holds a market size of approximately $0.53 billion, which is projected to reach $0.94 billion by 2033. Factors driving this growth include rapid industrialization, urbanization, and increased investments in renewable energy sources.North America Boiler Control Market Report:

North America represents a significant segment with a market size of $0.90 billion in 2023, anticipated to grow to $1.60 billion by 2033. The region's advanced industries and stringent safety regulations are key drivers in promoting the use of sophisticated boiler control systems.South America Boiler Control Market Report:

In South America, the Boiler Control market size is estimated at $0.24 billion in 2023, growing to $0.43 billion by 2033. Legislative initiatives focused on energy efficiency and environmental sustainability are pivotal to this region's growth.Middle East & Africa Boiler Control Market Report:

The market in the Middle East and Africa is currently valued at $0.18 billion in 2023 and is expected to reach $0.33 billion by 2033. Growing energy demands and investments in modern industrial infrastructures fuel the Boiler Control market's advancement.Tell us your focus area and get a customized research report.

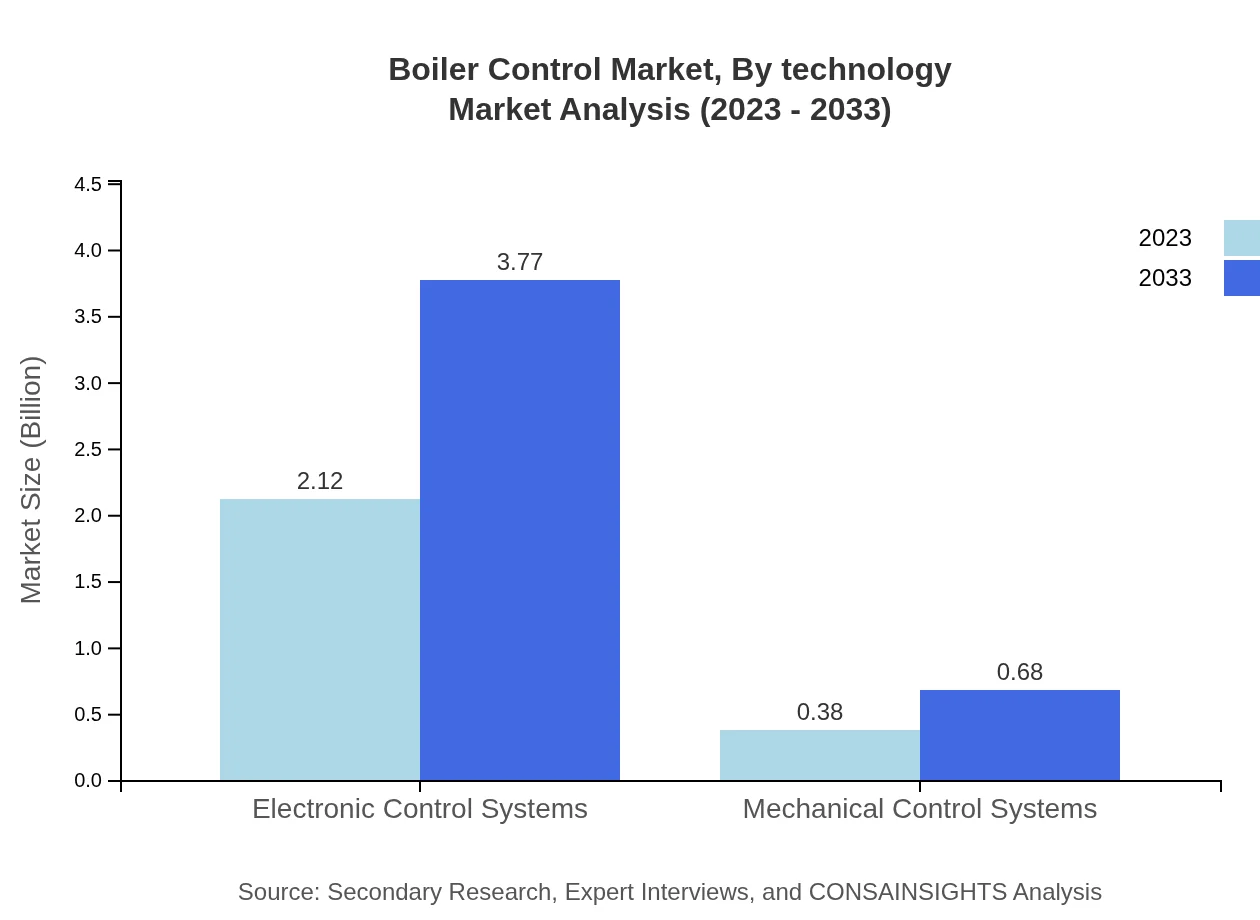

Boiler Control Market Analysis By Technology

The Boiler Control market is significantly influenced by technology advancements. Hardware solutions dominate the market with a size of $2.12 billion in 2023, reaching $3.77 billion by 2033, accounting for 84.7% share. Software solutions, although smaller, are developing rapidly at a size of $0.38 billion in 2023 and $0.68 billion by 2033, representing 15.3% share.

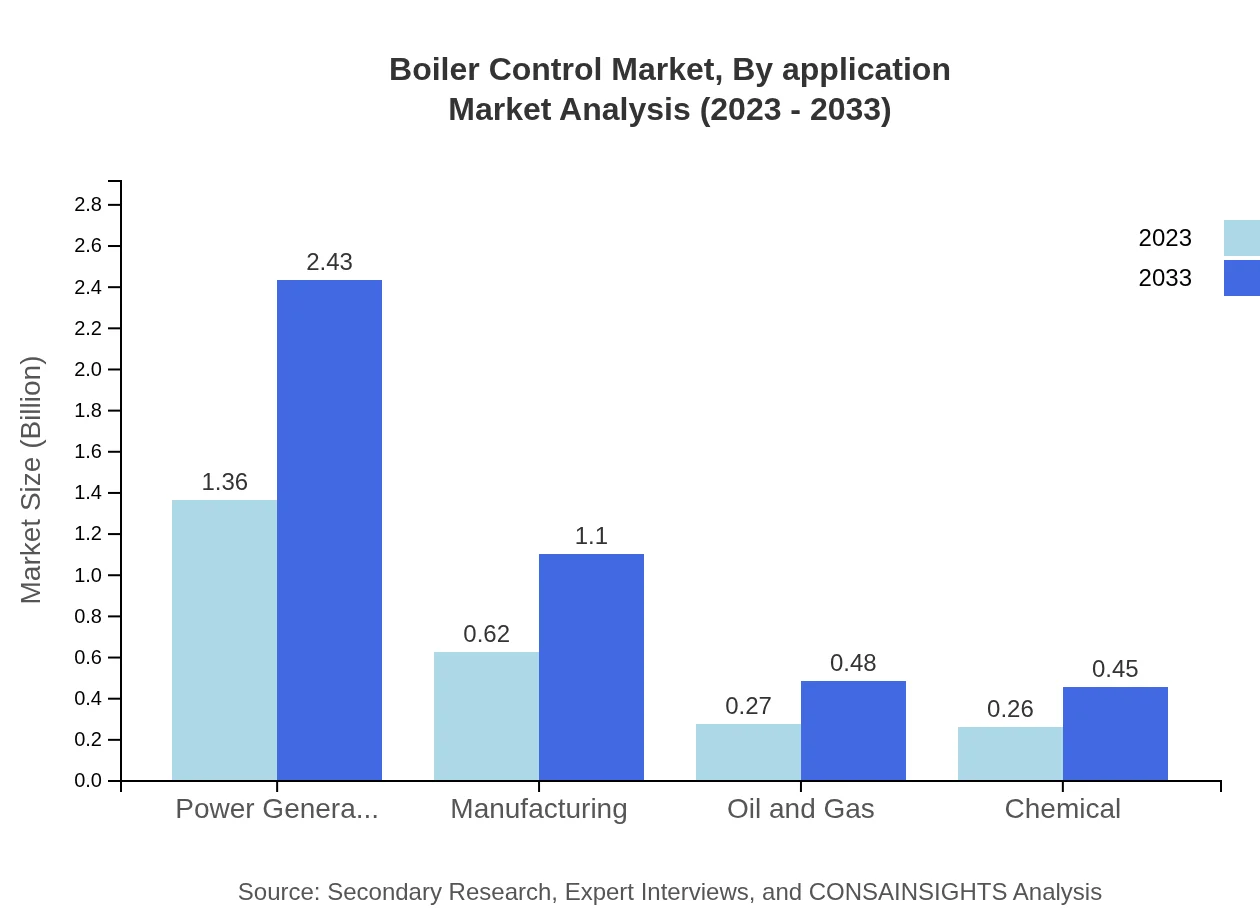

Boiler Control Market Analysis By Application

Among various applications, Power Generation remains a key segment, with an anticipated market size of $1.36 billion in 2023, projected to grow to $2.43 billion by 2033 (54.51% share). Manufacturing follows closely, with a market size of $0.62 billion in 2023, projected to rise to $1.10 billion by 2033 (24.61% share).

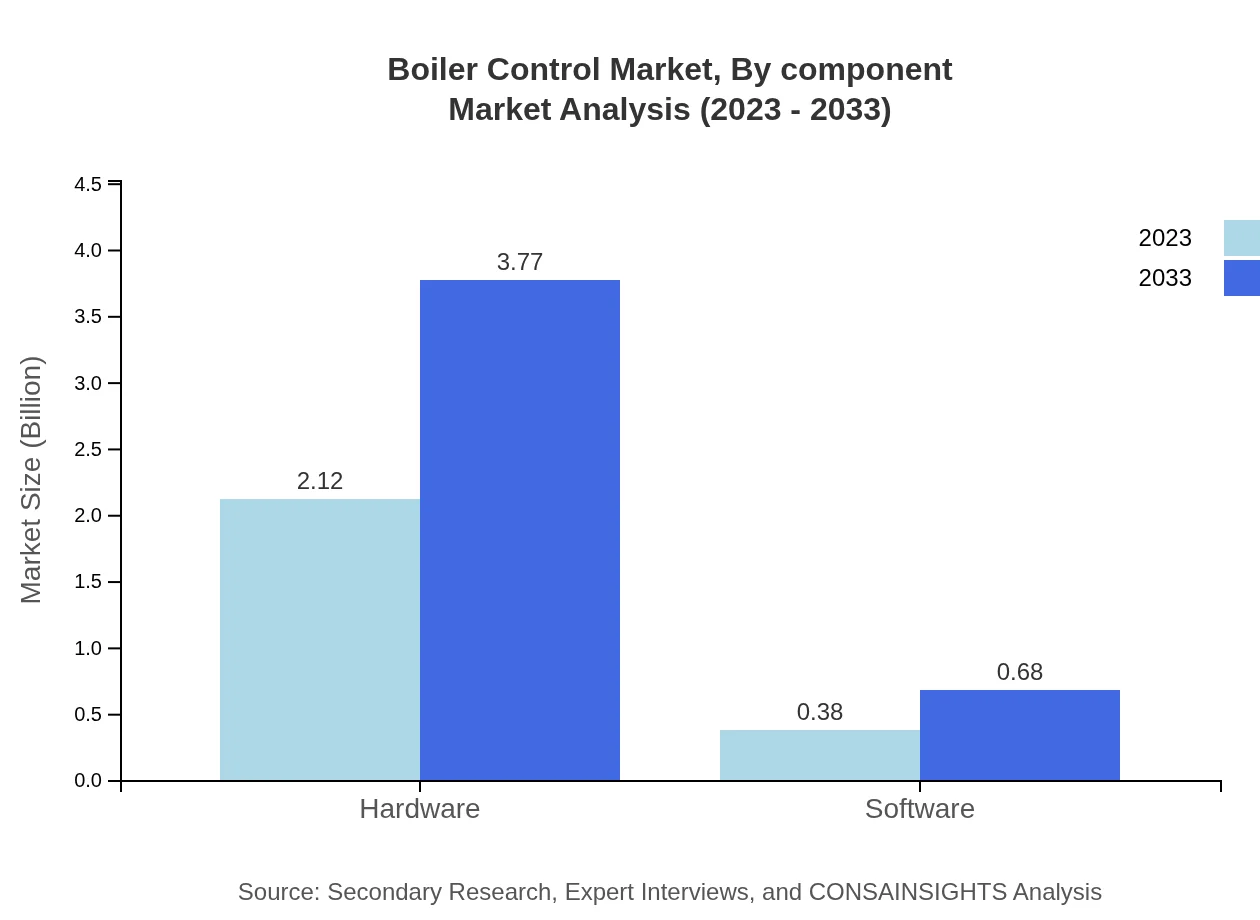

Boiler Control Market Analysis By Component

Components of boiler control systems comprise hardware (Electrical and Mechanical Control Systems) and software solutions. The significant growth in hardware components underscores their pivotal role, projected to evolve from $2.12 billion in 2023 to $3.77 billion by 2033, marking essential features in operational safety and efficiency.

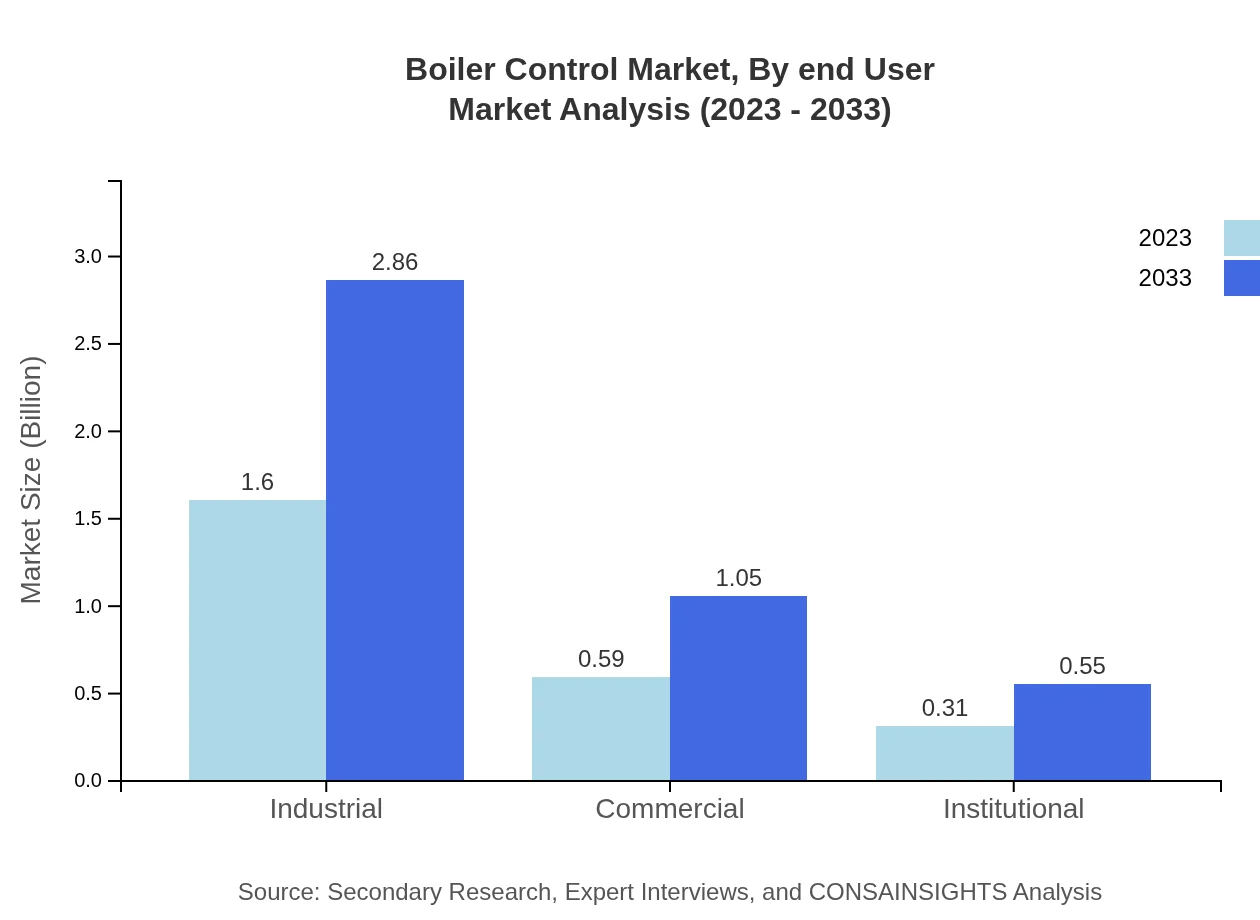

Boiler Control Market Analysis By End User

The industrial sector remains the largest end-user of boiler control systems, representing a market size of $1.60 billion in 2023, anticipated to increase to $2.86 billion by 2033 (64.12% share). Moreover, the commercial segment is projected to reach $1.05 billion by 2033 from $0.59 billion in 2023.

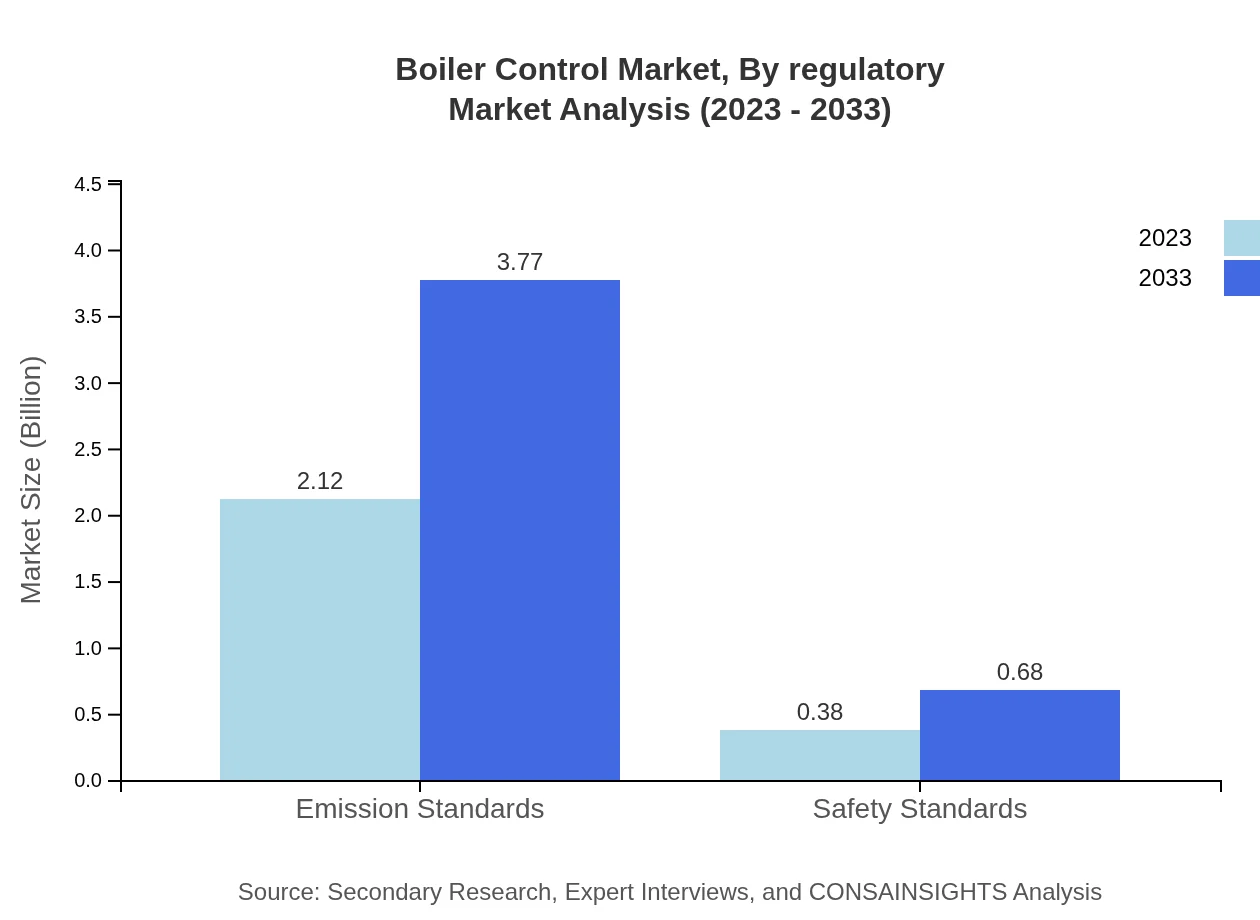

Boiler Control Market Analysis By Regulatory

Compliance with emission and safety standards is increasingly driving the Boiler Control market. Regulations concerning emissions lead to a predicted market size for Emission Standards of $2.12 billion in 2023, set to grow to $3.77 billion by 2033 (84.7% share). Safety regulations are also gaining traction, with sizes of $0.38 billion in 2023, projected to rise to $0.68 billion by 2033 (15.3% share).

Boiler Control Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Boiler Control Industry

Emerson Electric Co.:

A global leader in automation technologies, Emerson provides advanced boiler control solutions, optimizing both energy efficiency and operational reliability.Honeywell International Inc.:

Honeywell offers comprehensive boiler control systems with innovative technologies, focusing on enhancing safety standards and performance in industrial applications.Siemens AG:

Siemens specializes in digital automation through smart boiler control systems, emphasizing IoT integration to drive efficiencies across various sectors.General Electric:

With a strong heritage in energy solutions, GE develops advanced boiler control systems that enhance combustion efficiency and reduce environmental impact.Valeo:

Valeo is known for its high-performance boiler control systems tailored to meet the needs of the automotive and manufacturing sectors.We're grateful to work with incredible clients.

FAQs

What is the market size of boiler Control?

The global boiler control market is currently valued at approximately $2.5 billion and is projected to grow at a CAGR of 5.8%. By 2033, the market is expected to expand significantly, reflecting the rising demand for efficient heating solutions.

What are the key market players or companies in the boiler Control industry?

Key players in the boiler control market include Siemens AG, Honeywell International Inc., and Schneider Electric. These companies lead the way in providing advanced control solutions tailored to various industrial and commercial applications, driving innovation and market growth.

What are the primary factors driving the growth in the boiler control industry?

The growth in the boiler control industry is primarily driven by the increasing emphasis on energy efficiency, stringent safety standards, and the rising adoption of automation in industrial processes. Additionally, the growing demand for reliable heating systems contributes to market expansion.

Which region is the fastest Growing in the boiler control market?

The Asia Pacific region is poised to become the fastest-growing market for boiler controls, with market size projected to grow from $0.53 billion in 2023 to $0.94 billion in 2033, fueled by rapid industrialization and urbanization in countries such as China and India.

Does Consainsights provide customized market report data for the boiler control industry?

Yes, Consainsights offers customized market report data tailored to client needs in the boiler control industry. These reports can provide detailed insights into specific segments, competitive landscape, and regional analysis to support strategic decision-making.

What deliverables can I expect from this boiler control market research project?

Deliverables from the boiler control market research project include comprehensive market analysis, trend forecasting, segment data, and competitor insights. Clients can also expect tailored recommendations to navigate the evolving market landscape effectively.

What are the market trends of boiler control?

Current market trends in the boiler control sector include increased digitization and automation, rising adoption of cloud-based solutions, and a focus on compliance with emissions regulations. Additionally, advancements in smart technologies are shaping the future of boiler control systems.