Broaching Machines Market Report

Published Date: 22 January 2026 | Report Code: broaching-machines

Broaching Machines Market Size, Share, Industry Trends and Forecast to 2033

This report offers a comprehensive analysis of the Broaching Machines market, detailing insights on market trends, segmentation, technology advancements, and regional analysis for the period 2023 to 2033.

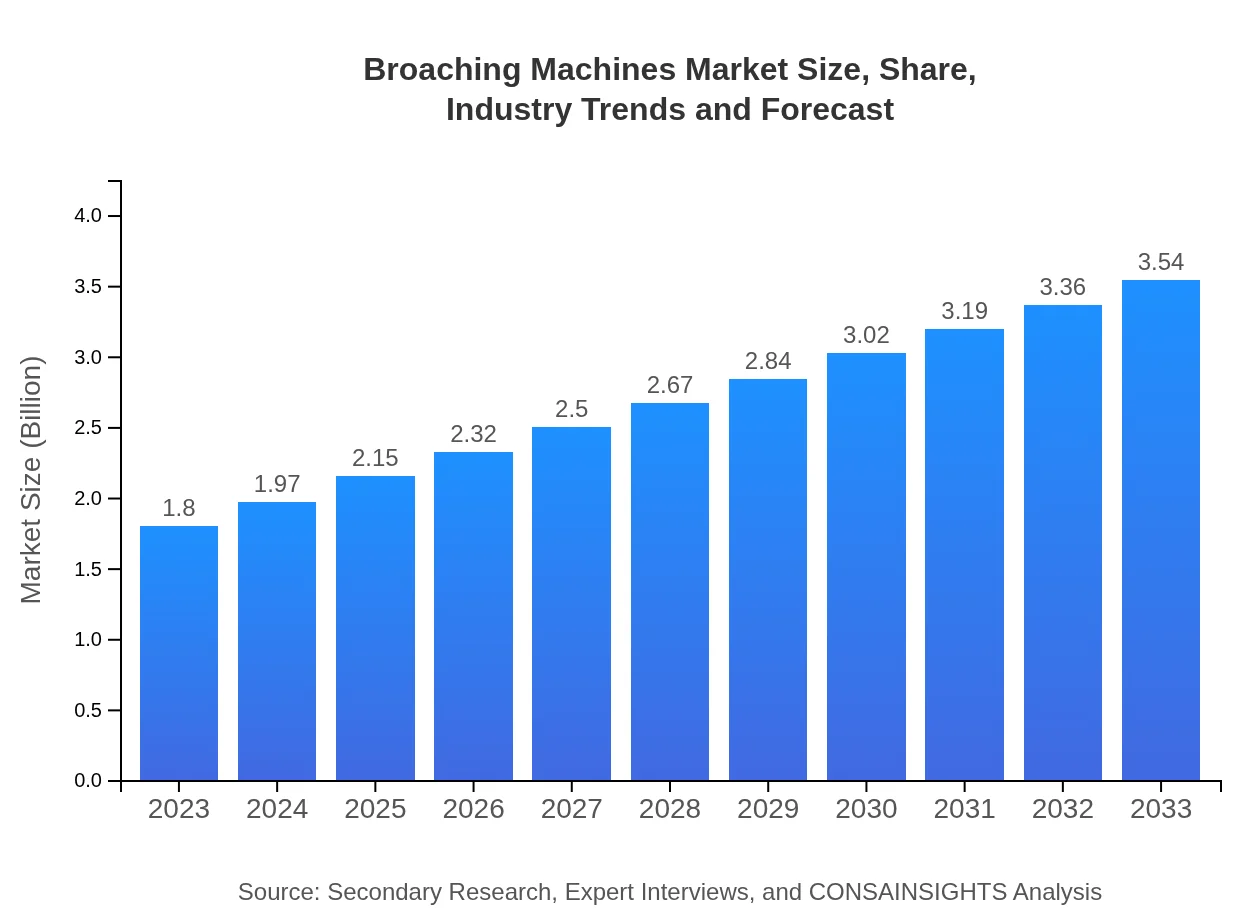

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $1.80 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $3.54 Billion |

| Top Companies | The Mazak Corporation, KUKA AG, Mitsubishi Heavy Industries, Hardinge Inc. |

| Last Modified Date | 22 January 2026 |

Broaching Machines Market Overview

Customize Broaching Machines Market Report market research report

- ✔ Get in-depth analysis of Broaching Machines market size, growth, and forecasts.

- ✔ Understand Broaching Machines's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Broaching Machines

What is the Market Size & CAGR of Broaching Machines market in 2023?

Broaching Machines Industry Analysis

Broaching Machines Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Broaching Machines Market Analysis Report by Region

Europe Broaching Machines Market Report:

European market growth is also significant, expected to reach USD 0.96 billion by 2033 from USD 0.49 billion in 2023, supported by stringent quality standards and increased automation in industries.Asia Pacific Broaching Machines Market Report:

Asia Pacific is anticipated to be a key growth region for the Broaching Machines market, expected to grow from USD 0.36 billion in 2023 to USD 0.71 billion by 2033, driven primarily by booming manufacturing industries in countries like China and India.North America Broaching Machines Market Report:

North America dominates the market with a projected increase from USD 0.65 billion in 2023 to USD 1.29 billion by 2033. The region's manufacturing sector, particularly automotive, combined with technological advancements, will fuel this growth.South America Broaching Machines Market Report:

In South America, the Broaching Machines market is expected to see a modest increase, growing from USD 0.05 billion in 2023 to USD 0.10 billion by 2033, driven by industrial developments and investments in manufacturing infrastructure.Middle East & Africa Broaching Machines Market Report:

The Middle East and Africa are forecasted to see growth from USD 0.24 billion in 2023 to USD 0.48 billion by 2033, driven by infrastructure developments and increased demand for efficient manufacturing processes.Tell us your focus area and get a customized research report.

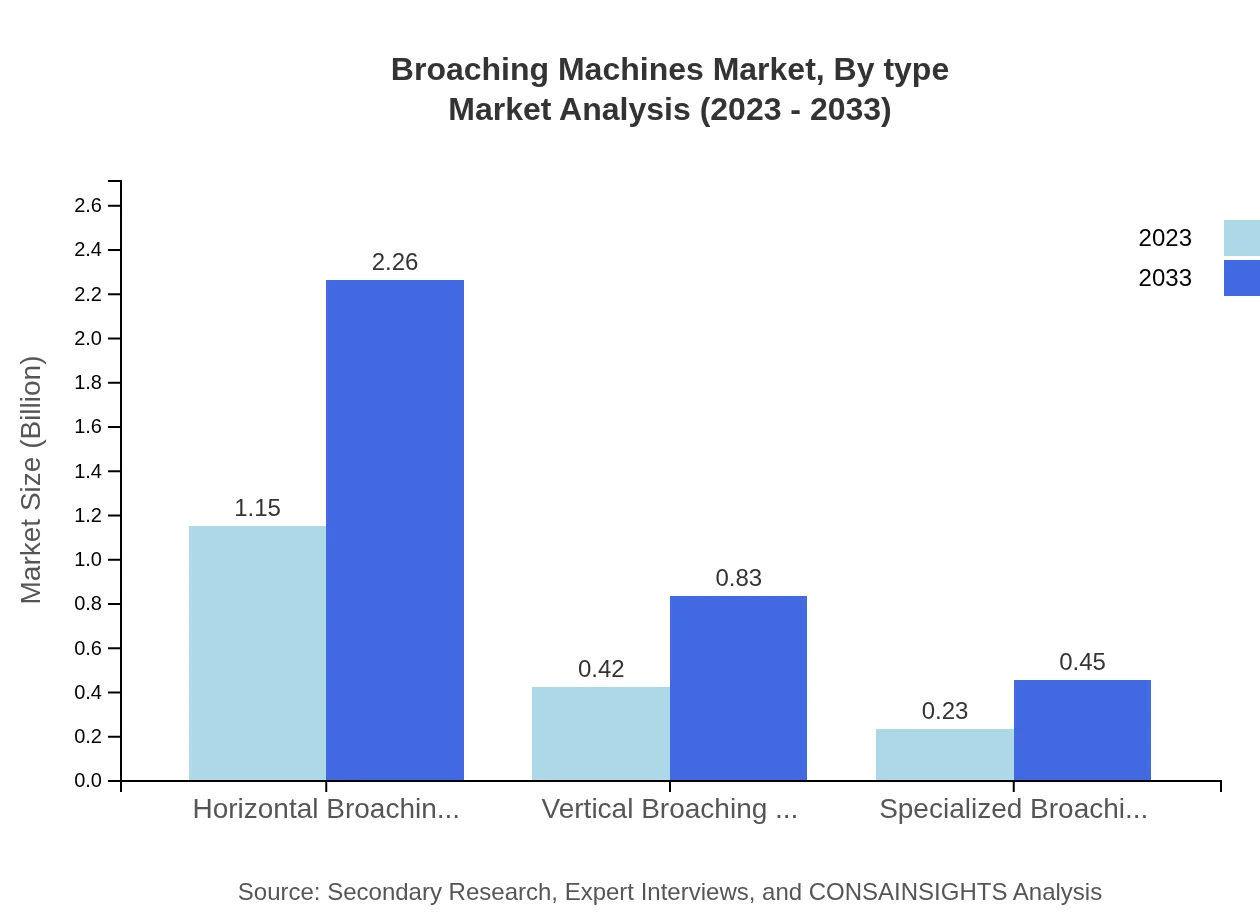

Broaching Machines Market Analysis By Type

In terms of type, Horizontal Broaching Machines continue to dominate the market, holding a significant share. They will grow from USD 1.15 billion in 2023 to USD 2.26 billion by 2033. Vertical and Specialized Broaching Machines, while holding less market share, are also vital for specific applications and will see growth from USD 0.42 billion to USD 0.83 billion, and from USD 0.23 billion to USD 0.45 billion respectively.

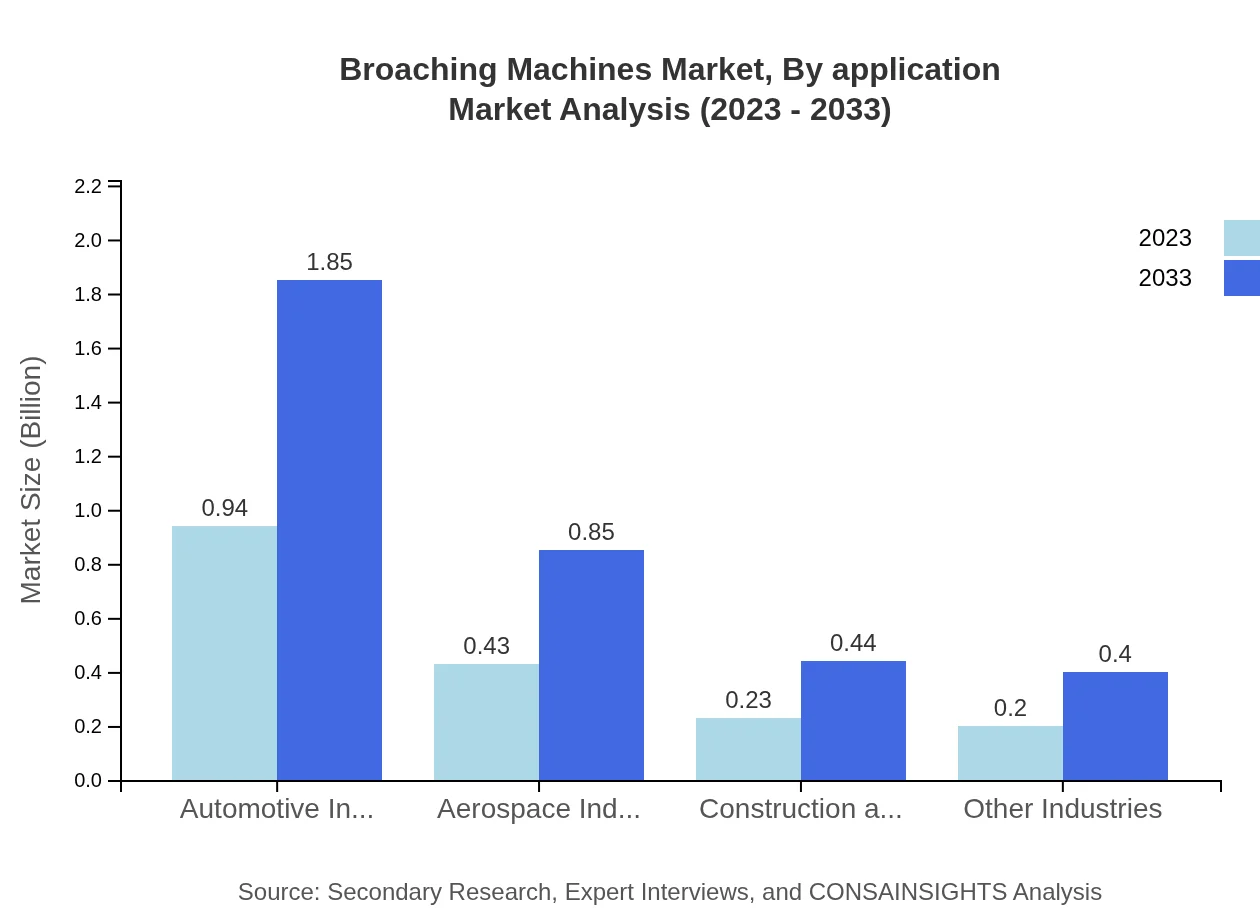

Broaching Machines Market Analysis By Application

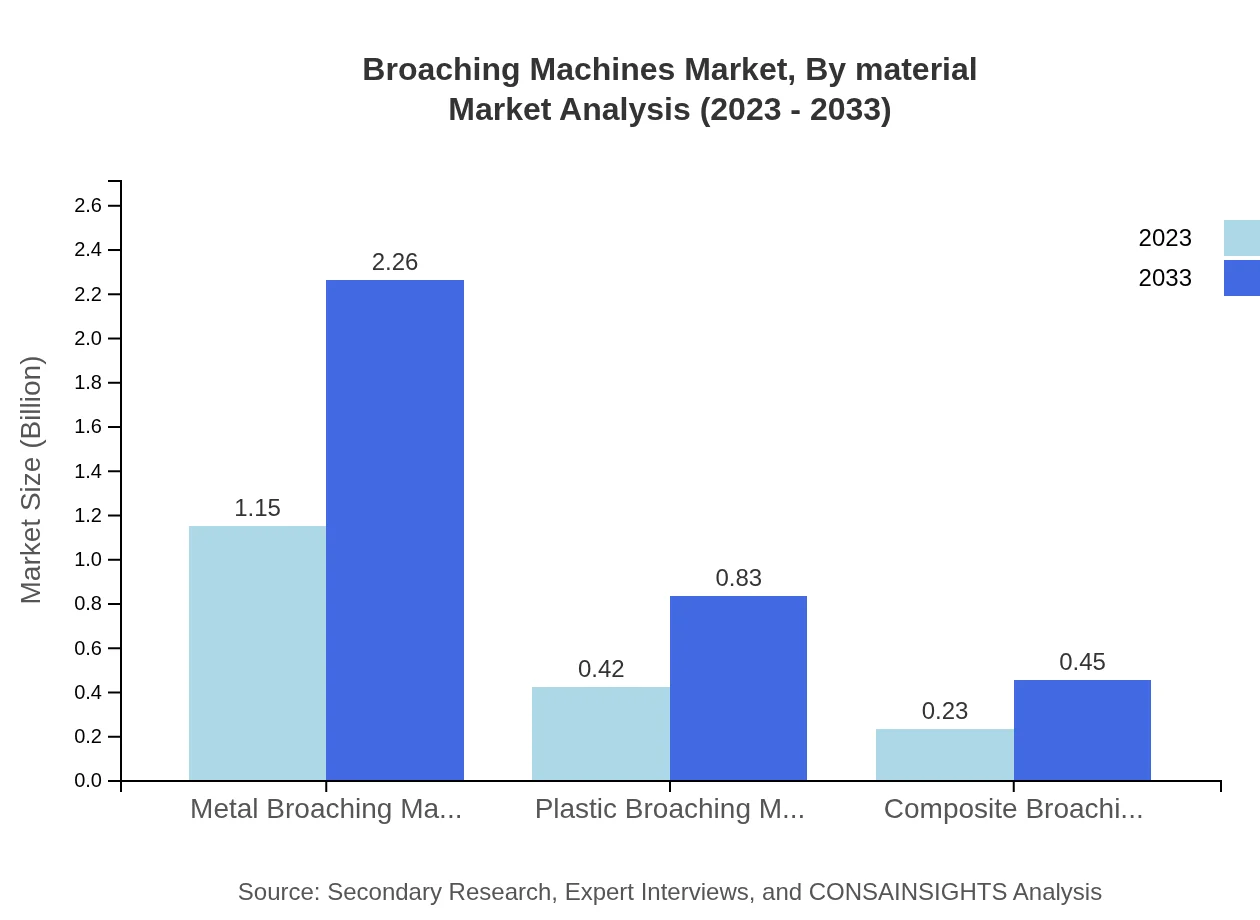

The market for Broaching Machines is segmented by application, where the metal broaching machines are predominant, expected to hold 63.89% of the market share in 2023, growing consistently through 2033. Plastic and composite machines, while smaller in size, are increasingly important for specialized applications, expected to hold 23.38% and 12.73% market shares, respectively.

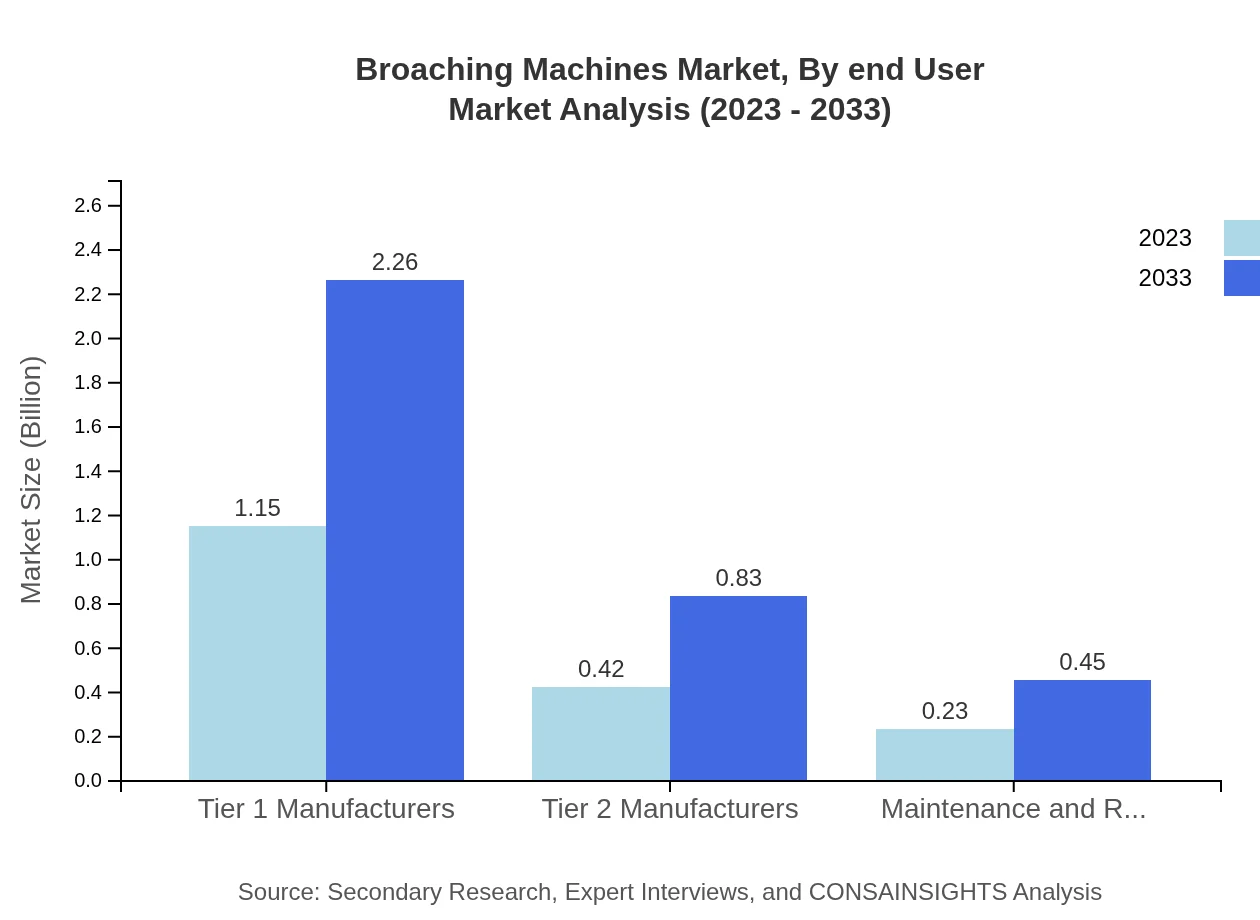

Broaching Machines Market Analysis By End User

The Automotive industry is the leading end-user of Broaching Machines, contributing to over 52% of the market share in 2023, driven by the industry's high demand for precision components. The Aerospace industry holds about 23.94%, showcasing a significant share due to the critical requirements for parts used in aircraft.

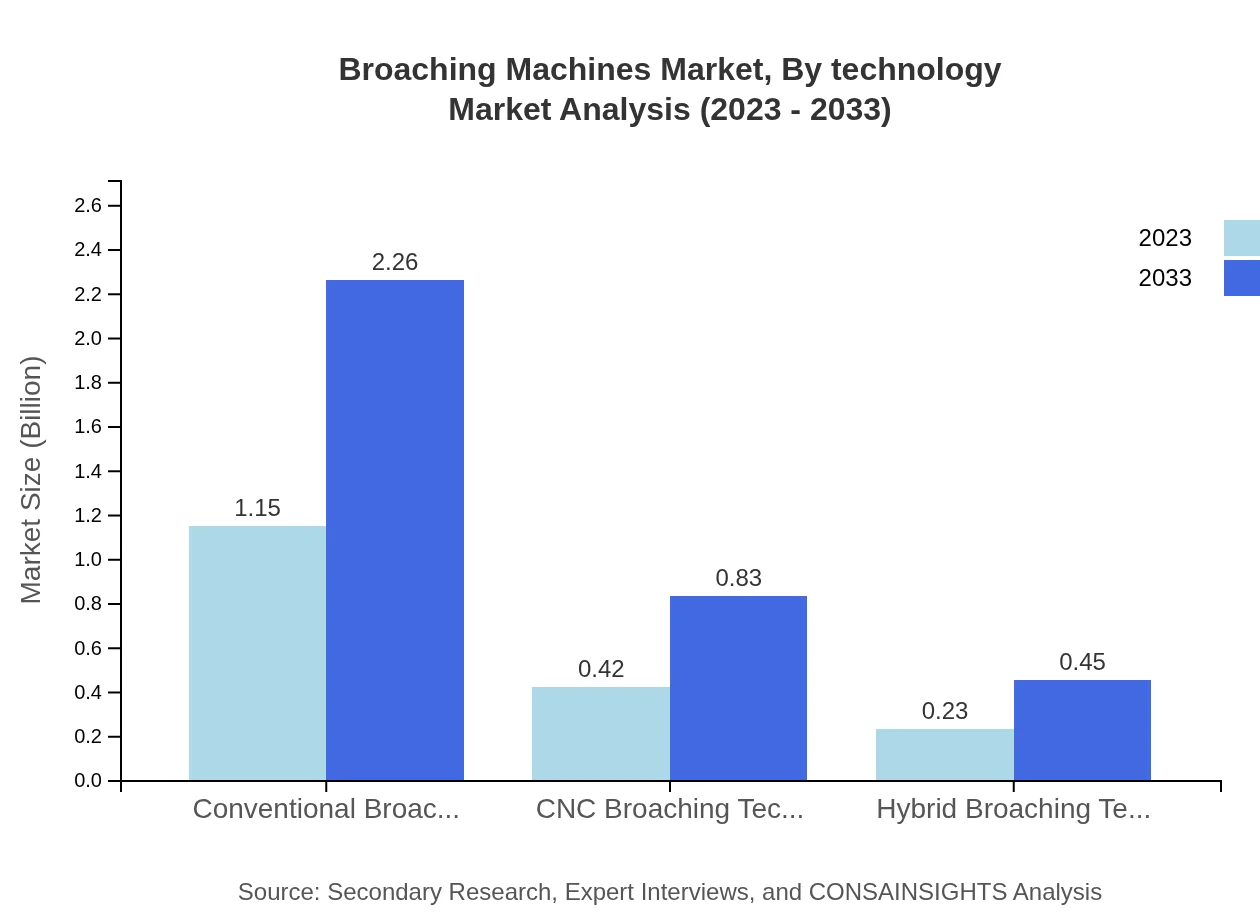

Broaching Machines Market Analysis By Technology

Conventional broaching technology remains prominent, reflecting 63.89% market share in 2023, while CNC broaching technology is growing rapidly with a projected 23.38% share. Innovative Hybrid technologies are emerging, expected to gain attention for their versatility in machining applications, capturing 12.73% of the market.

Broaching Machines Market Analysis By Material

Broaching Machines are highly utilized for metal, with metal broaching holding a significant 63.89% share. The use of plastic and composite materials is gaining traction, attributing to the rising demand for efficiency in the production of lightweight parts, holding 23.38% and 12.73% shares respectively.

Broaching Machines Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Broaching Machines Industry

The Mazak Corporation:

Known for its advanced CNC machines, they provide innovative broaching solutions that enhance productivity and efficiency.KUKA AG:

A global leader in robotics and automated solutions that enrich broaching technologies with automation capabilities.Mitsubishi Heavy Industries:

This company offers high-quality machining solutions, including cutting-edge broaching machinery, addressing various industrial needs.Hardinge Inc.:

A notable player specializing in precision and machining technologies, offering a range of broaching machines designed for high performance.We're grateful to work with incredible clients.

FAQs

What is the market size of broaching machines?

The global broaching machines market is estimated to reach approximately $1.8 billion by 2033, with a compound annual growth rate (CAGR) of 6.8% from 2023 to 2033.

What are the key market players or companies in the broaching machines industry?

Key players in the broaching machines market include major Tier 1 manufacturers delivering innovative solutions, which comprise a significant market share of 63.89% in 2023.

What are the primary factors driving the growth in the broaching machines industry?

Growth factors include increased demand from automotive and aerospace sectors, advancements in automation technologies, and ongoing investments in research and development.

Which region is the fastest Growing in the broaching machines?

North America is projected to be the fastest-growing region, expected to grow from $0.65 billion in 2023 to $1.29 billion by 2033, indicating significant market potential.

Does ConsaInsights provide customized market report data for the broaching machines industry?

Yes, ConsaInsights offers tailored market reports for the broaching machines sector, enabling clients to obtain specific insights that meet their unique business needs.

What deliverables can I expect from this broaching machines market research project?

Deliverables include comprehensive market analyses, insights on key trends, competitive landscapes, and forecasts segmented by region and product type.

What are the market trends of broaching machines?

Current trends include an increase in CNC technology adoption, a shift towards specialized broaching applications, and rising automation levels in manufacturing processes.