Capacitive Ceramic Pressure Sensors Market Report

Published Date: 31 January 2026 | Report Code: capacitive-ceramic-pressure-sensors

Capacitive Ceramic Pressure Sensors Market Size, Share, Industry Trends and Forecast to 2033

This report presents a detailed analysis of the Capacitive Ceramic Pressure Sensors market, focusing on market trends, size, growth projections, and regional insights from 2023 to 2033.

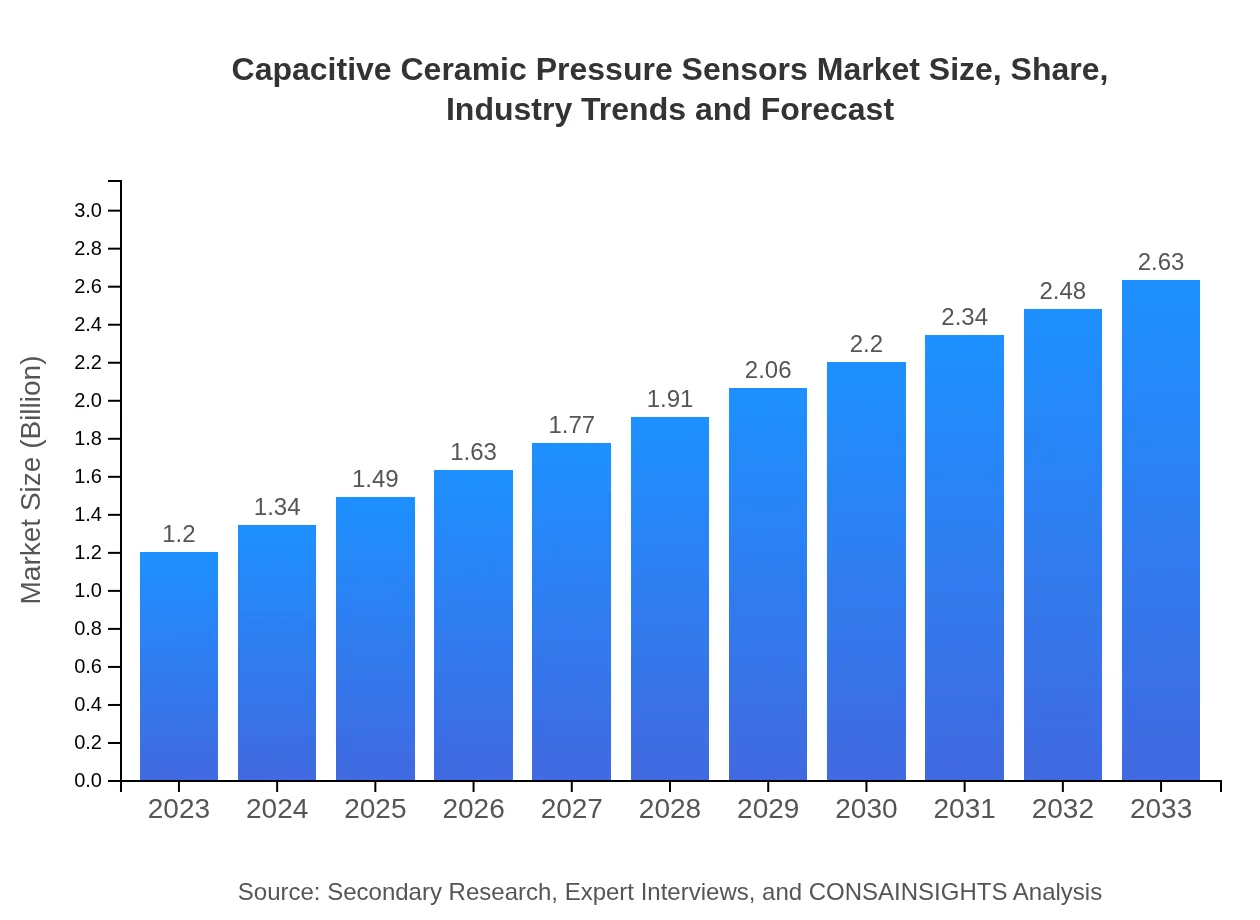

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $1.20 Billion |

| CAGR (2023-2033) | 7.9% |

| 2033 Market Size | $2.63 Billion |

| Top Companies | Honeywell International Inc., Siemens AG, Texas Instruments, Emerson Electric Co., Kistler Instrumente AG |

| Last Modified Date | 31 January 2026 |

Capacitive Ceramic Pressure Sensors Market Overview

Customize Capacitive Ceramic Pressure Sensors Market Report market research report

- ✔ Get in-depth analysis of Capacitive Ceramic Pressure Sensors market size, growth, and forecasts.

- ✔ Understand Capacitive Ceramic Pressure Sensors's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Capacitive Ceramic Pressure Sensors

What is the Market Size & CAGR of Capacitive Ceramic Pressure Sensors market in 2023?

Capacitive Ceramic Pressure Sensors Industry Analysis

Capacitive Ceramic Pressure Sensors Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Capacitive Ceramic Pressure Sensors Market Analysis Report by Region

Europe Capacitive Ceramic Pressure Sensors Market Report:

Europe’s market will increase from $0.38 billion in 2023 to $0.83 billion in 2033. The region is a hub for innovations, with stringent regulatory standards necessitating high-precision sensors.Asia Pacific Capacitive Ceramic Pressure Sensors Market Report:

The Asia Pacific region is expected to see significant growth, with the market size growing from $0.22 billion in 2023 to $0.49 billion in 2033. Rising industrialization in countries like China and India, alongside increased adoption of advanced manufacturing technologies, underpins this growth.North America Capacitive Ceramic Pressure Sensors Market Report:

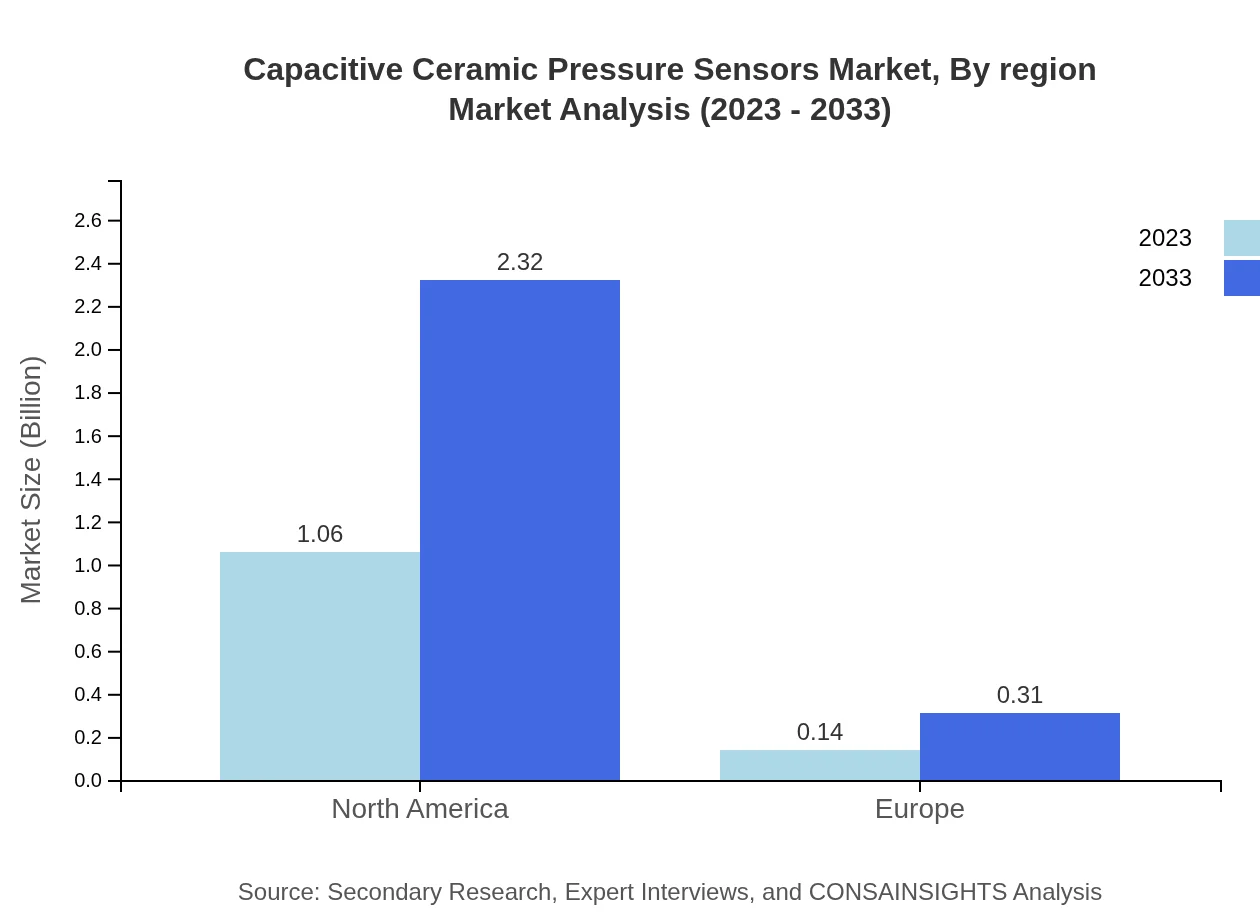

North America is set to dominate the market, expanding from $0.42 billion in 2023 to approximately $0.93 billion in 2033. High rates of industrial automation and significant presence of key players solidify this region’s leading status.South America Capacitive Ceramic Pressure Sensors Market Report:

In South America, the market is projected to expand from $0.02 billion in 2023 to $0.04 billion by 2033. Economic recovery and investments in industrial automation will drive demand for capacitive sensors in the region.Middle East & Africa Capacitive Ceramic Pressure Sensors Market Report:

In the Middle East and Africa, the market is expected to grow from $0.15 billion in 2023 to $0.34 billion by 2033, driven by increasing investments in infrastructure and oil, and gas industries.Tell us your focus area and get a customized research report.

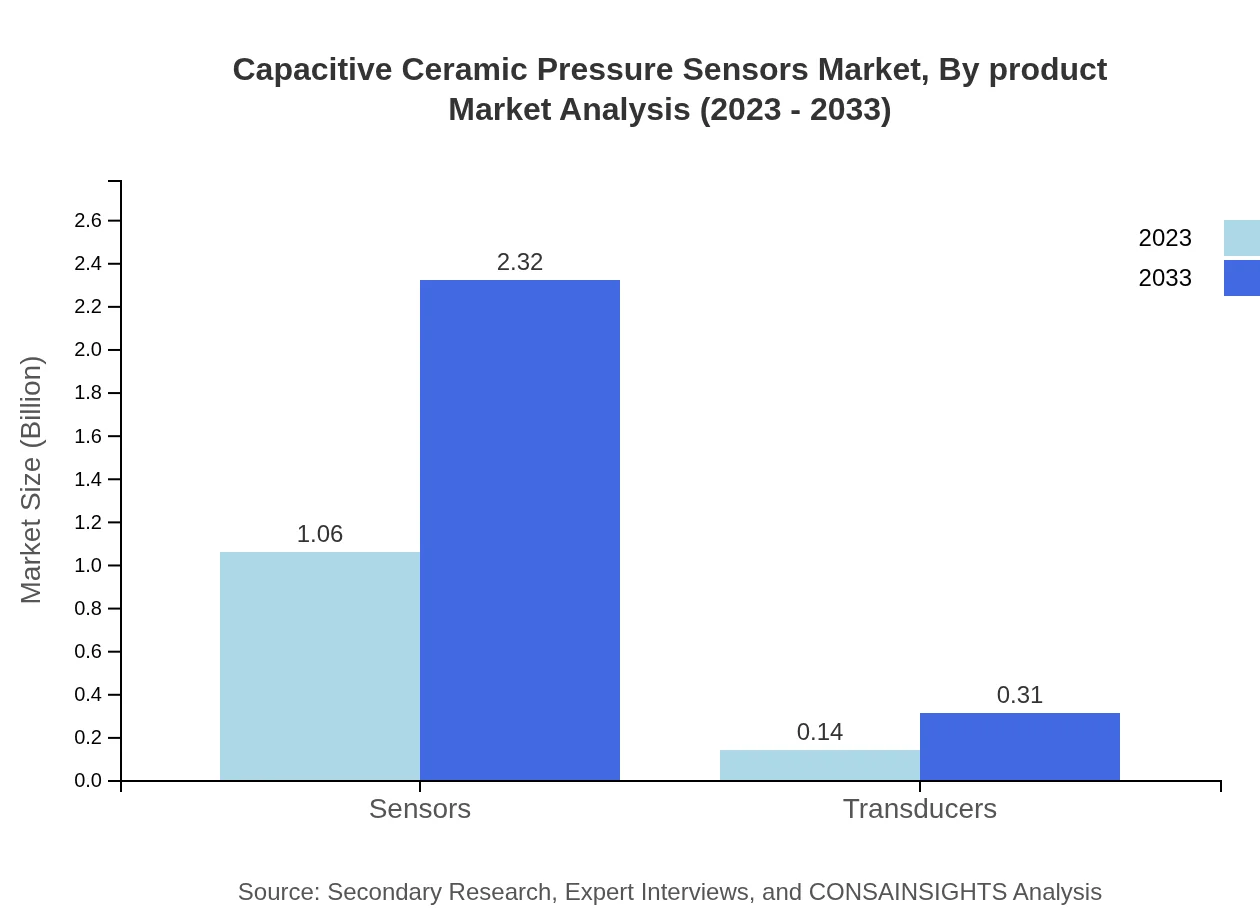

Capacitive Ceramic Pressure Sensors Market Analysis By Product

The market reflects a strong preference for sensors, projecting a value increase from $1.06 billion in 2023 to $2.32 billion in 2033. Transducers follow with growth prospects, moving from $0.14 billion to $0.31 billion in the same timeframe.

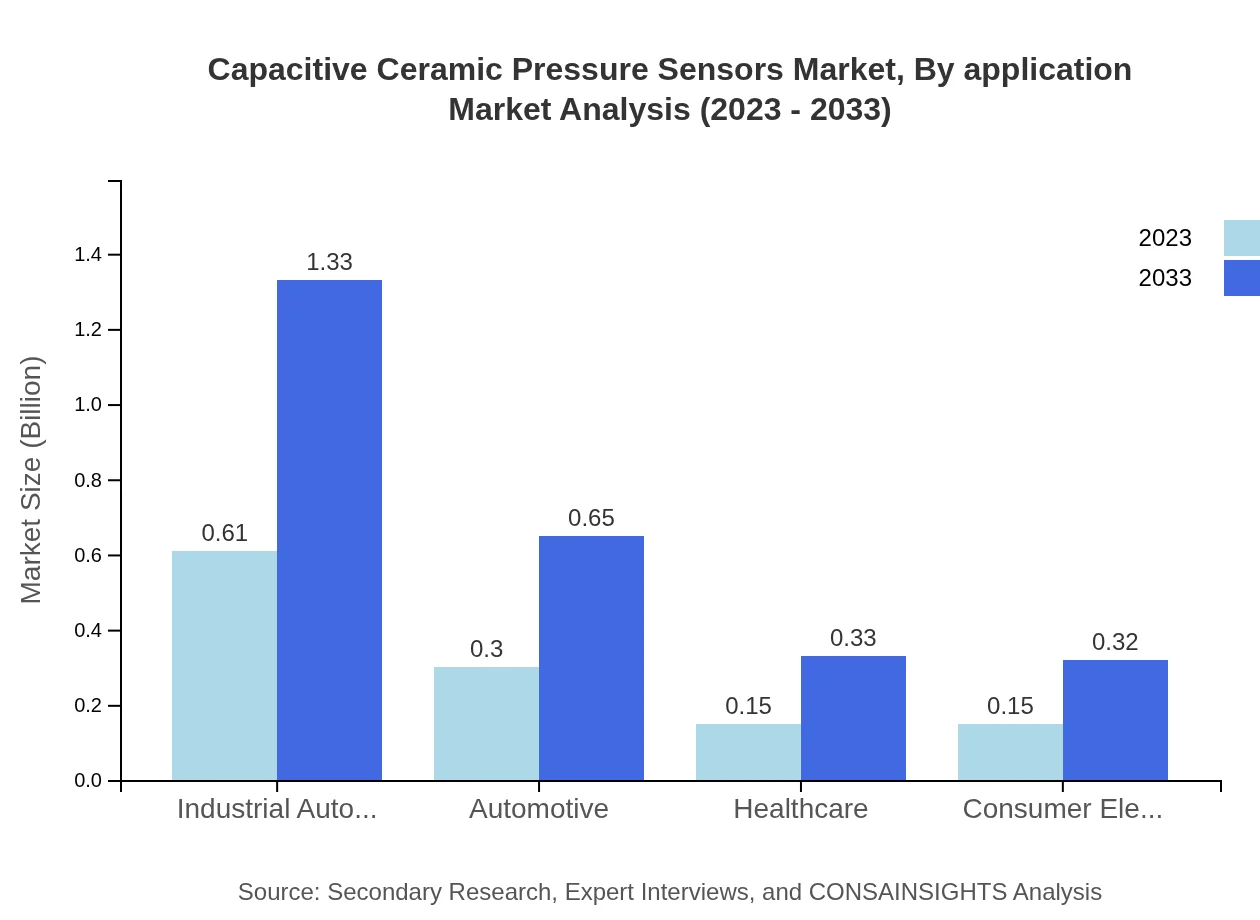

Capacitive Ceramic Pressure Sensors Market Analysis By Application

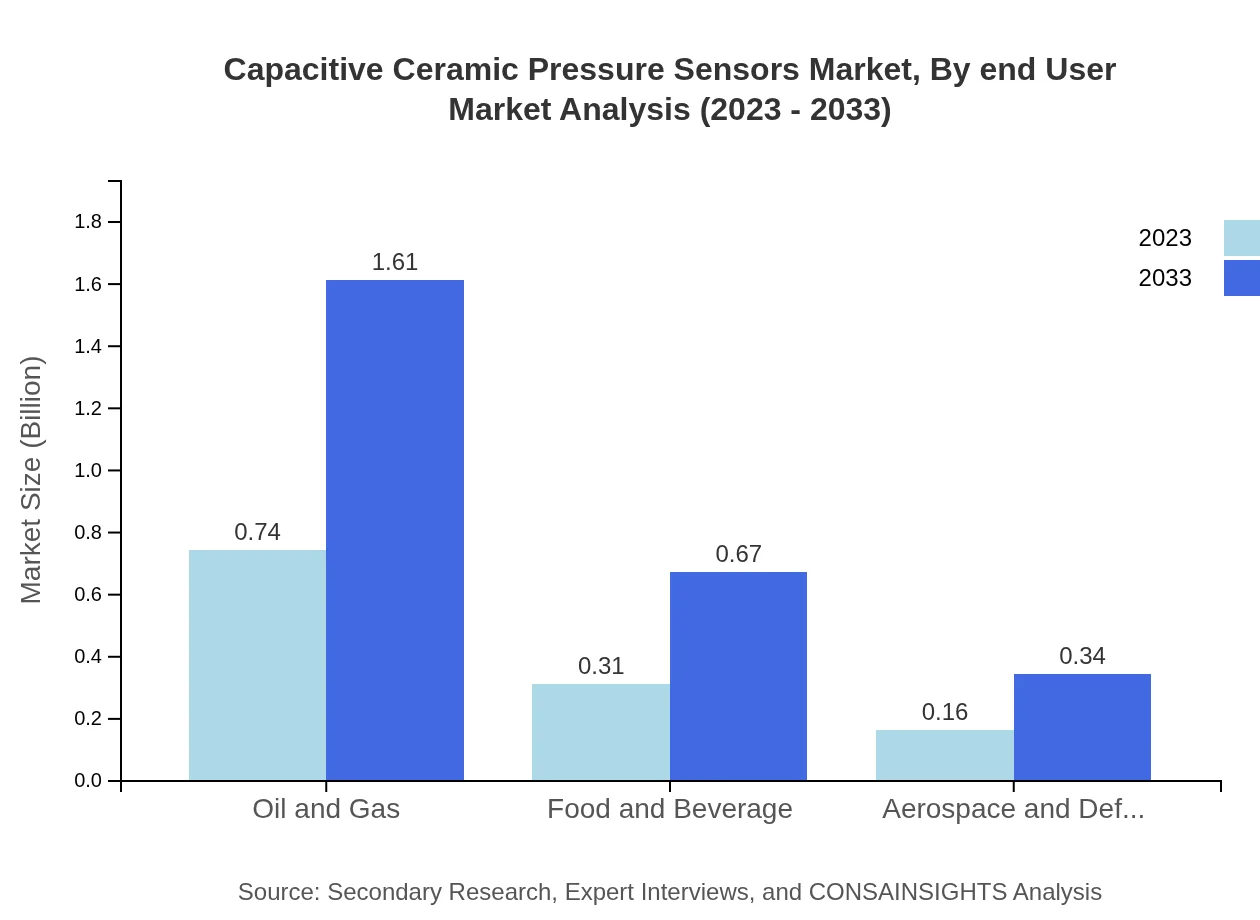

Key applications include oil and gas (projected growth from $0.74 billion to $1.61 billion), food and beverage, which will rise from $0.31 billion to $0.67 billion. Each sector underscores their critical role in evolving market dynamics.

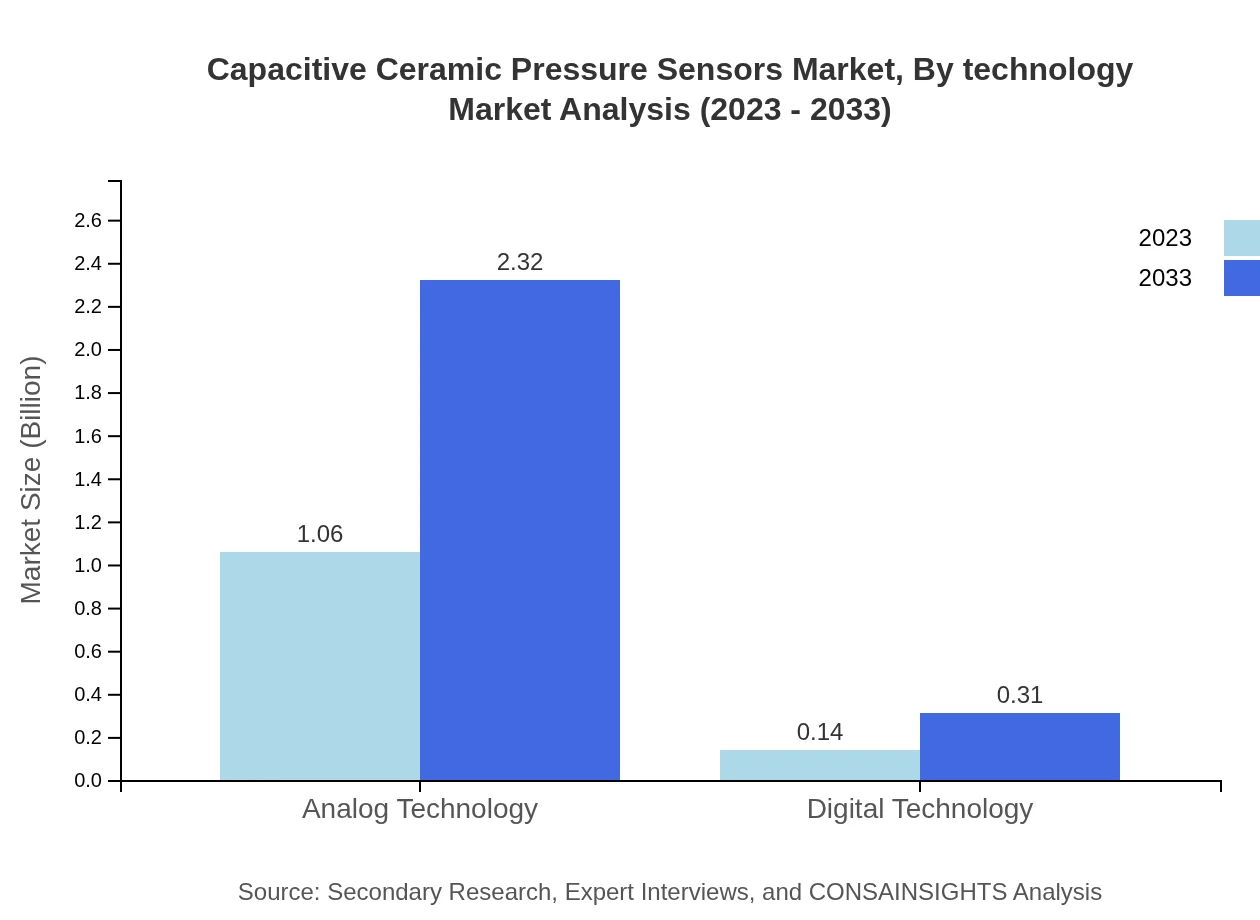

Capacitive Ceramic Pressure Sensors Market Analysis By Technology

The capacitive ceramic pressure sensors are divided mainly into analog (growing from $1.06 billion to $2.32 billion) and digital technologies (forecasted growth from $0.14 billion to $0.31 billion). Dominance of analog technology reflects maturity and robustness, whereas digital technology indicates an innovation pathway.

Capacitive Ceramic Pressure Sensors Market Analysis By End User

Sectors such as industrial automation and automotive are projected to together grow from a combined size of $0.91 billion in 2023 to $1.98 billion in 2033, emphasizing their importance in driving demand for capacitive sensors.

Capacitive Ceramic Pressure Sensors Market Analysis By Region

Comprehensive regional insights reveal that North America and Europe lead in adoption rates, while Asia Pacific showcases rapid growth, particularly in emerging economies increasing their industrial bases.

Capacitive Ceramic Pressure Sensors Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Capacitive Ceramic Pressure Sensors Industry

Honeywell International Inc.:

A leader in providing technology and manufacturing solutions, Honeywell's sensors are renowned for their reliability and accuracy in various industrial applications.Siemens AG:

Siemens, known for its innovations in automation and smart solutions, also excels in supply of capacitive pressure sensors, supporting various industries in their modernization efforts.Texas Instruments:

A prominent player in electronics manufacturing, Texas Instruments designs capacitive sensors that contribute to advanced pressure measurement techniques.Emerson Electric Co.:

Emerson specializes in automation products and services; their capacitive sensors serve critical functions in diverse applications like oil and gas.Kistler Instrumente AG:

Kistler is noted for precision measurement systems and contributes significantly to the capacitive technology sector with high-performance sensors.We're grateful to work with incredible clients.

FAQs

What is the market size of capacitive Ceramic Pressure Sensors?

The capacitive ceramic pressure sensors market is valued at approximately $1.2 billion in 2023, with a projected compound annual growth rate (CAGR) of 7.9%, potentially reaching new heights by 2033.

What are the key market players or companies in this capacitive Ceramic Pressure Sensors industry?

Key players in the capacitive ceramic pressure sensors market include renowned manufacturers and innovators, focusing on advanced sensor technologies, accuracy, and reliability, to meet diverse industrial needs.

What are the primary factors driving the growth in the capacitive Ceramic Pressure Sensors industry?

The growth in the capacitive ceramic pressure sensors market is driven by increased demand in industries such as oil and gas, automotive, and healthcare. Innovations in sensor technology and rising automation also contribute significantly.

Which region is the fastest Growing in the capacitive Ceramic Pressure Sensors?

The fastest-growing region in the capacitive ceramic pressure sensors market is North America, expected to expand from $0.42 billion in 2023 to $0.93 billion by 2033, showcasing strong market dynamics.

Does ConsaInsights provide customized market report data for the capacitive Ceramic Pressure Sensors industry?

Yes, ConsaInsights offers tailored market report data for the capacitive ceramic pressure sensors industry, adapting insights and analysis based on client specifications and industry trends.

What deliverables can I expect from this capacitive Ceramic Pressure Sensors market research project?

Deliverables include comprehensive market analysis reports, segmented data insights, growth forecasts, competitive landscape evaluations, and recommendations for strategic investments in the capacitive ceramic pressure sensors market.

What are the market trends of capacitive Ceramic Pressure Sensors?

Current trends in the capacitive ceramic pressure sensors market include advancements in digital technology integration, increased focus on industrial automation, and the rise of multifunctional sensors catering to diverse applications.