Cement Bonded Particle Board Market Report

Published Date: 22 January 2026 | Report Code: cement-bonded-particle-board

Cement Bonded Particle Board Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Cement Bonded Particle Board market, offering insights into market size, growth forecasts, industry trends, and regional analysis from 2023 to 2033.

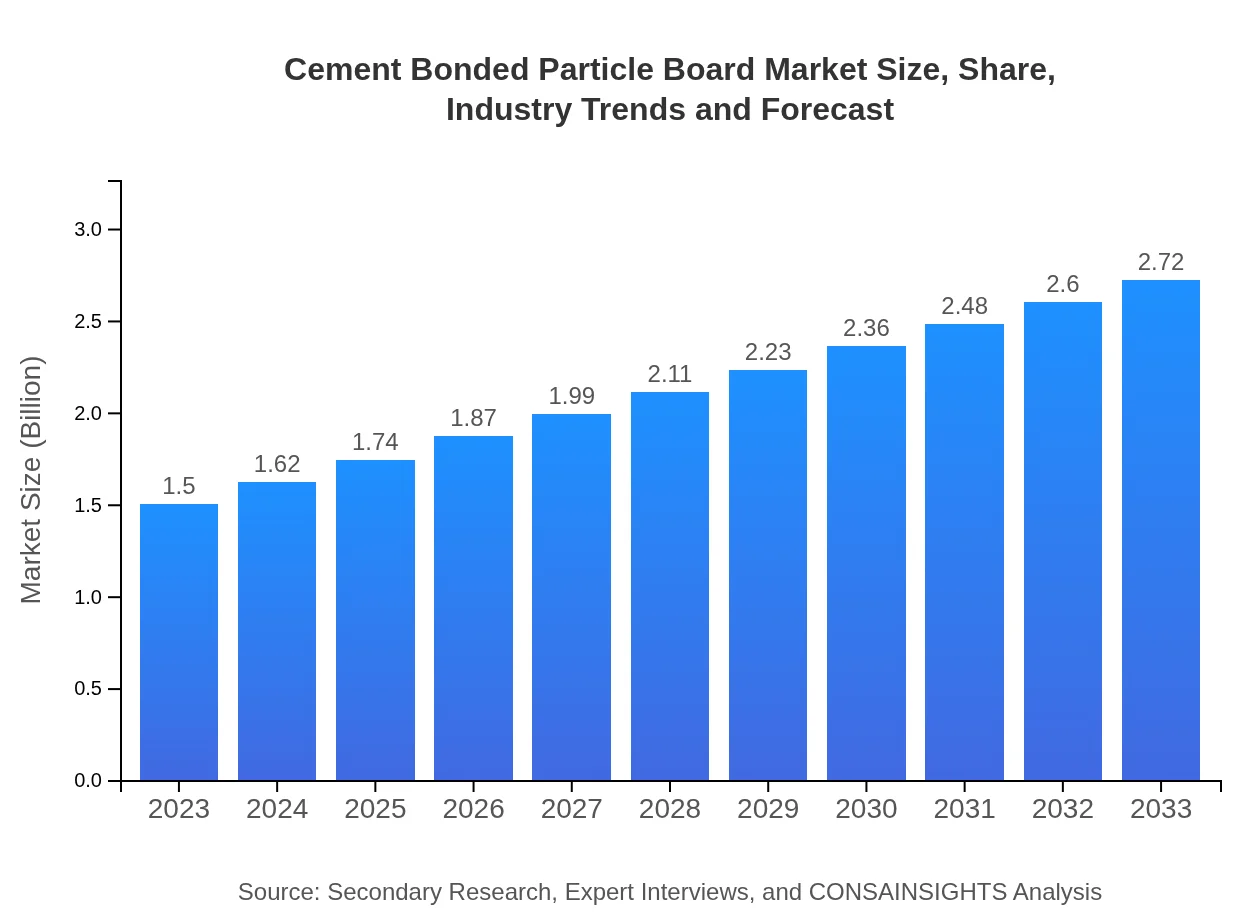

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $1.50 Billion |

| CAGR (2023-2033) | 6.0% |

| 2033 Market Size | $2.72 Billion |

| Top Companies | Saint-Gobain, MDF (Medium Density Fiberboard) Corporation, GMS Inc. |

| Last Modified Date | 22 January 2026 |

Cement Bonded Particle Board Market Overview

Customize Cement Bonded Particle Board Market Report market research report

- ✔ Get in-depth analysis of Cement Bonded Particle Board market size, growth, and forecasts.

- ✔ Understand Cement Bonded Particle Board's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Cement Bonded Particle Board

What is the Market Size & CAGR of Cement Bonded Particle Board market in 2023?

Cement Bonded Particle Board Industry Analysis

Cement Bonded Particle Board Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Cement Bonded Particle Board Market Analysis Report by Region

Europe Cement Bonded Particle Board Market Report:

The European market for Cement Bonded Particle Board is anticipated to grow significantly from $0.53 billion in 2023 to $0.97 billion by 2033. The emphasis on green building practices and remodeling existing structures is shaping this growth, with countries like Germany and France leading the charge.Asia Pacific Cement Bonded Particle Board Market Report:

In the Asia Pacific region, the Cement Bonded Particle Board market is projected to grow from $0.26 billion in 2023 to $0.48 billion by 2033. The significant growth is attributed to rapid urbanization, increasing population, and a booming construction industry in countries such as China and India.North America Cement Bonded Particle Board Market Report:

North America is poised to see a jump from $0.51 billion in 2023 to $0.93 billion by 2033. Demand in this region will be primarily fueled by stringent building codes and regulations that favor fire and environmentally resistant materials, especially in the United States.South America Cement Bonded Particle Board Market Report:

The South American market for Cement Bonded Particle Board is expected to increase from $0.14 billion in 2023 to $0.26 billion by 2033, driven by increasing construction activities and an emphasis on utilizing sustainable materials, particularly in Brazil and Argentina.Middle East & Africa Cement Bonded Particle Board Market Report:

In the Middle East and Africa, the market is small but expected to expand from $0.05 billion in 2023 to $0.09 billion by 2033 due to growing investment in infrastructure and an increase in housing projects, particularly in the UAE and South Africa.Tell us your focus area and get a customized research report.

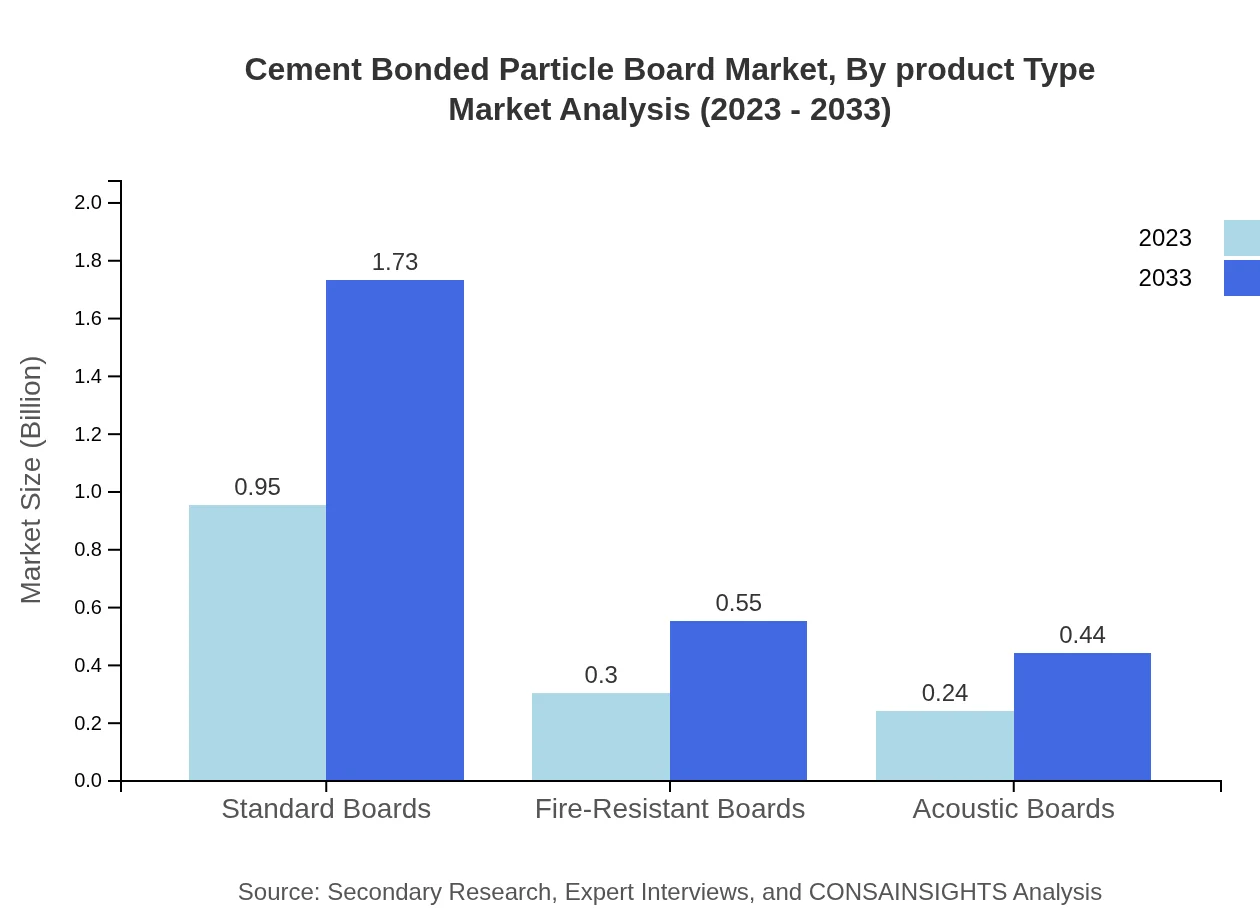

Cement Bonded Particle Board Market Analysis By Product Type

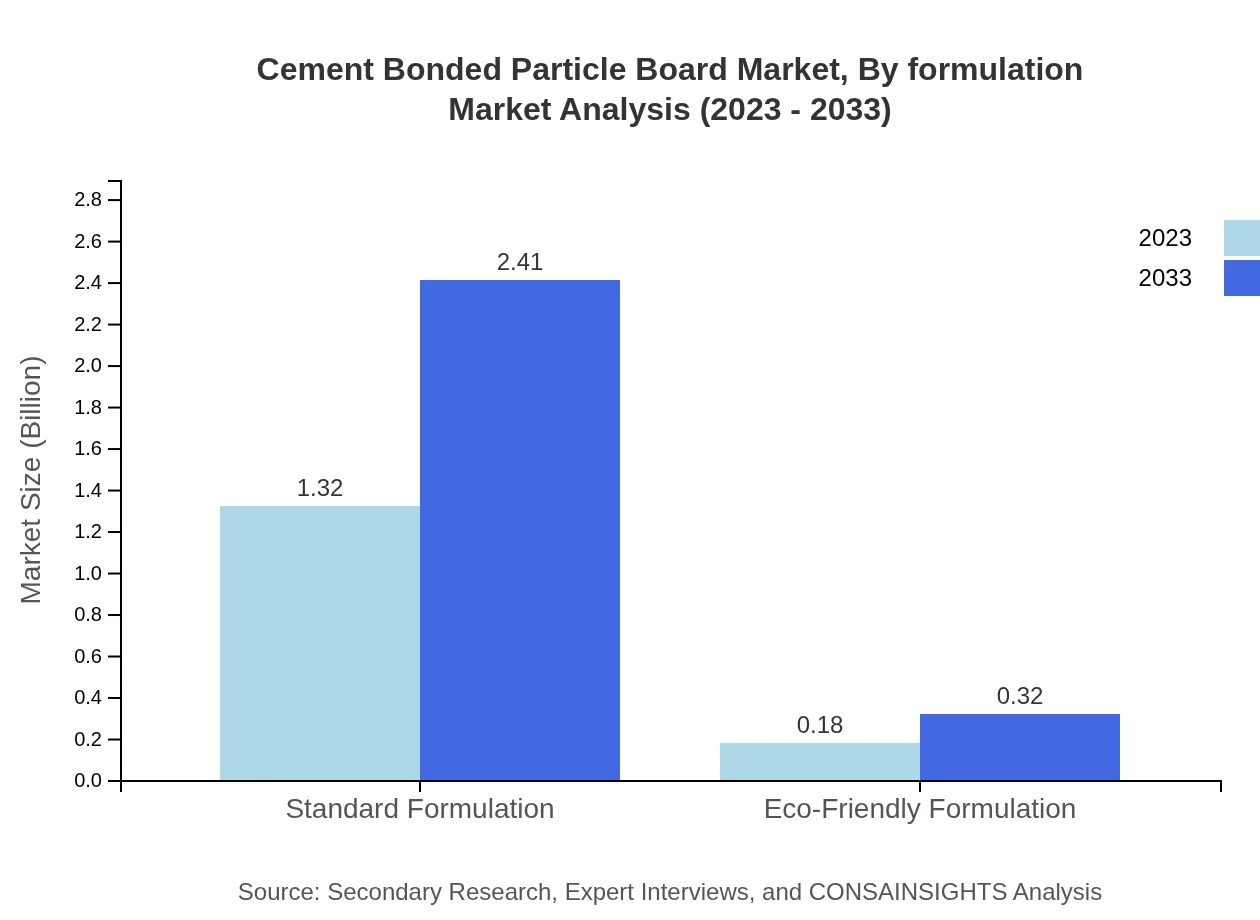

The market is dominated by standard formulations, which represent an 88.3% market share in 2023, significantly outpacing eco-friendly formulations, which capture 11.7% of the market. The trend towards eco-friendly products is gaining traction, but it still remains a smaller portion of total sales. By 2033, both categories are expected to grow equally, reflecting changes in consumer preferences and regulations.

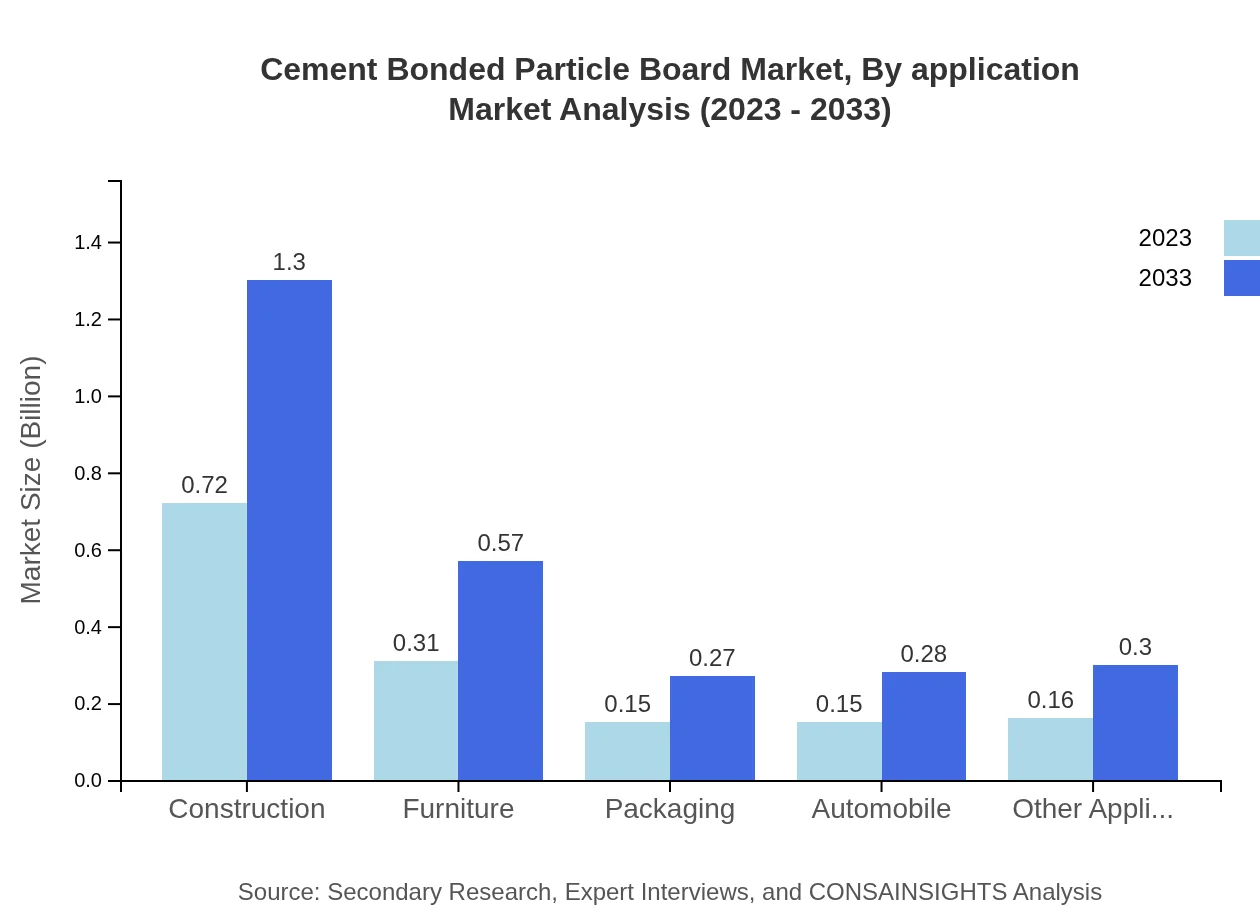

Cement Bonded Particle Board Market Analysis By Application

The largest application segment is construction, accounting for 47.87% of the market in 2023, anticipated to grow to 1.30 billion by 2033. Other applications include residential (53.59% share), commercial (21.47% share), and industrial, highlighting the versatility of CBPB across diverse sectors.

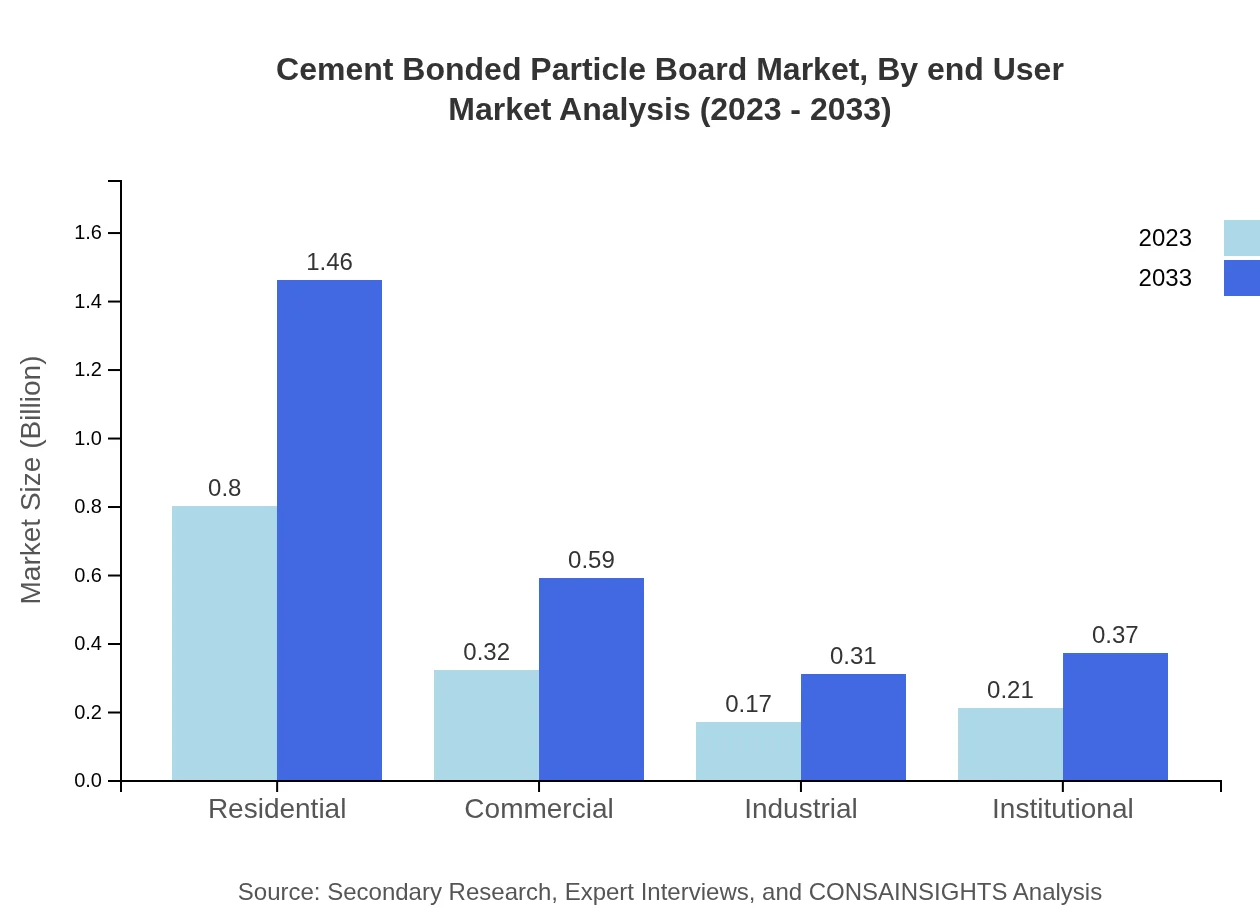

Cement Bonded Particle Board Market Analysis By End User

In terms of end-users, residential construction is the leader, expected to maintain its significant share as urbanization drives new housing projects. The furniture industry also plays a critical role, indicating a diverse application spectrum for CBPB.

Cement Bonded Particle Board Market Analysis By Formulation

Standard boards dominate the formulation segment; however, eco-friendly alternatives are gathering momentum as consumers increasingly prioritize sustainability. The gradual shift to eco-friendly products could change market dynamics substantially by 2033.

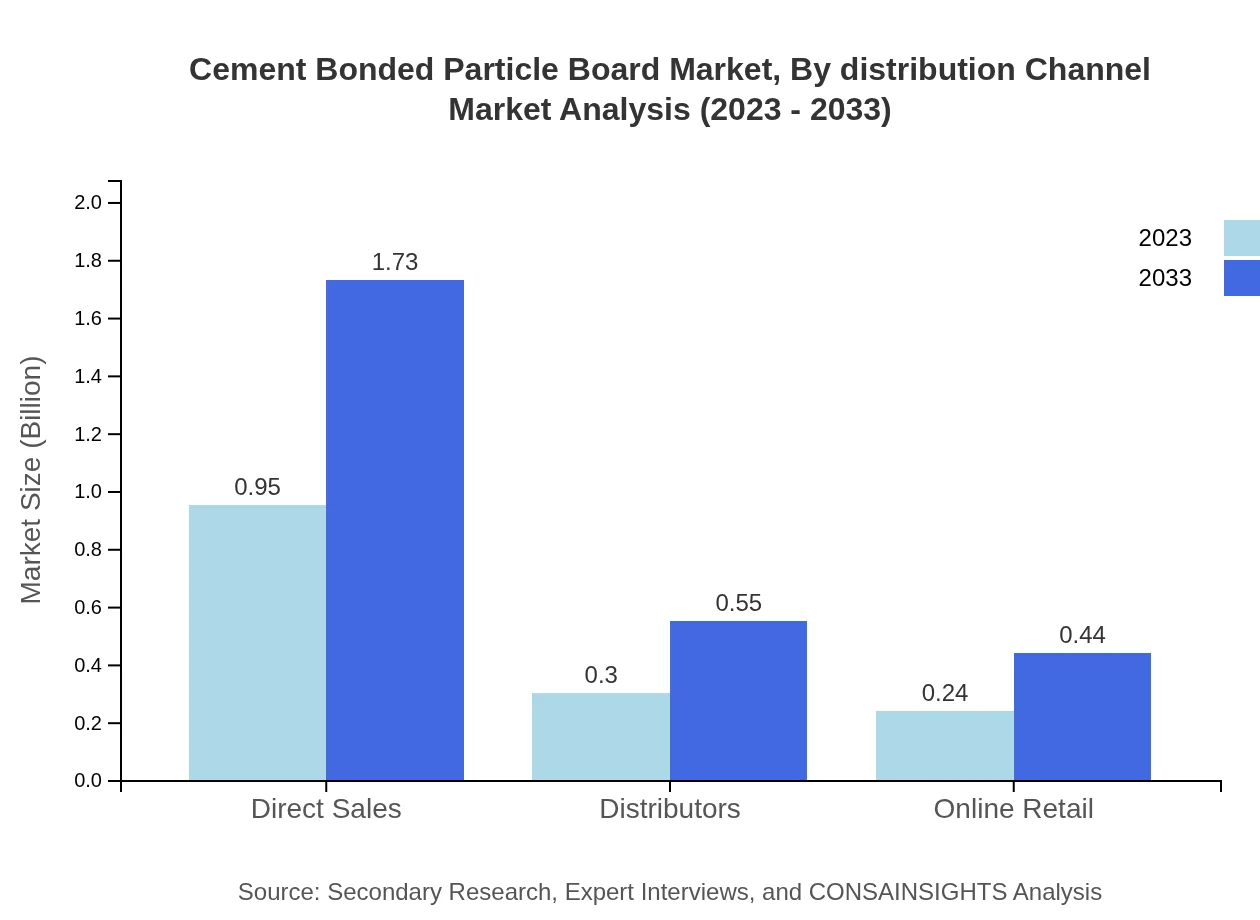

Cement Bonded Particle Board Market Analysis By Distribution Channel

The primary distribution channels are direct sales and distributors, holding substantial market shares. However, the rise of online retail channels is transforming the market landscape as more consumers prefer the convenience of online shopping.

Cement Bonded Particle Board Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Cement Bonded Particle Board Industry

Saint-Gobain:

A leading player in construction materials, offering high-quality cement bonded particle boards that meet international standards.MDF (Medium Density Fiberboard) Corporation:

Known for innovative eco-friendly products in the CBPB segment that cater to the growing demand for sustainable materials.GMS Inc.:

Specializes in diversified building materials, recognized for its superior quality Cement Bonded Particle Boards tailored for various applications.We're grateful to work with incredible clients.

FAQs

What is the market size of cement Bonded Particle Board?

The global cement-bonded particle board market is estimated at $1.5 billion in 2023 with a projected CAGR of 6.0% through 2033. This growth reflects rising demand in various applications, highlighting the material's versatility and durability.

What are the key market players or companies in the cement Bonded Particle Board industry?

The key players in the cement-bonded particle board market include major manufacturers like James Hardie Industries, Louisiana-Pacific Corporation, and UPM-Kymmene Corporation, among others. These companies lead through innovations in product development and sustainable manufacturing practices.

What are the primary factors driving the growth in the cement Bonded Particle Board industry?

Key growth drivers in the cement-bonded particle board industry include increasing demand for eco-friendly building materials, the growth of the construction sector, and heightened awareness of sustainable living practices, fostering innovation in board formulations and applications.

Which region is the fastest Growing in the cement Bonded Particle Board?

In the cement-bonded particle board market, Europe is the fastest-growing region, expanding from $0.53 billion in 2023 to $0.97 billion by 2033. Asia Pacific also shows significant growth, increasing from $0.26 billion to $0.48 billion in the same period.

Does ConsaInsights provide customized market report data for the cement Bonded Particle Board industry?

Yes, ConsaInsights offers customized market report data tailored to specific client needs within the cement-bonded particle board industry. Clients can receive insights focused on regional, segment, and competitive landscapes for strategic decision-making.

What deliverables can I expect from this cement Bonded Particle Board market research project?

Clients can expect comprehensive deliverables from the market research project, including detailed market analysis, trends identification, competitive landscape assessment, and segmented data insights reflecting current and projected market dynamics.

What are the market trends of cement Bonded Particle Board?

Current trends in the cement-bonded particle board market include a shift towards sustainable materials, increased application in both residential and commercial construction, and innovations in formulations such as acoustic and fire-resistant boards, driving higher market penetration.