Cement Mixer Market Report

Published Date: 22 January 2026 | Report Code: cement-mixer

Cement Mixer Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Cement Mixer market, projecting insights from 2023 to 2033. It covers market trends, regional dynamics, competitive landscape, and growth forecasts to inform stakeholders about the evolving industry landscape.

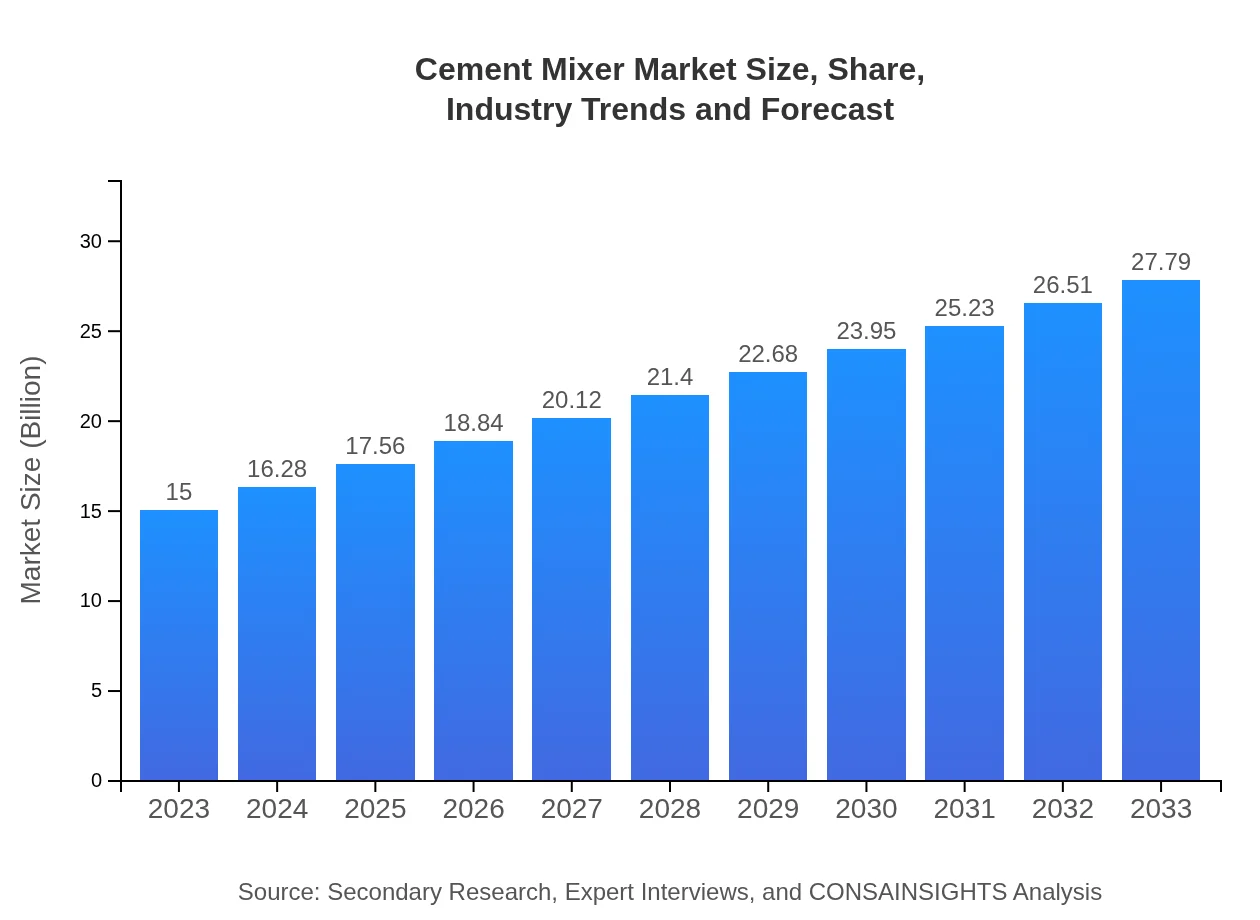

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $15.00 Billion |

| CAGR (2023-2033) | 6.2% |

| 2033 Market Size | $27.79 Billion |

| Top Companies | CEMEX, Liebherr, Schwing Stetter, Terex Corporation, SANY Group |

| Last Modified Date | 22 January 2026 |

Cement Mixer Market Overview

Customize Cement Mixer Market Report market research report

- ✔ Get in-depth analysis of Cement Mixer market size, growth, and forecasts.

- ✔ Understand Cement Mixer's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Cement Mixer

What is the Market Size & CAGR of Cement Mixer market in 2023?

Cement Mixer Industry Analysis

Cement Mixer Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Cement Mixer Market Analysis Report by Region

Europe Cement Mixer Market Report:

In Europe, the Cement Mixer market is forecasted to expand from $3.98 billion in 2023 to $7.38 billion by 2033. Factors influencing this are ongoing infrastructure upgrades, governmental funding for construction projects, and a heightened focus on sustainability in the construction industry.Asia Pacific Cement Mixer Market Report:

The Asia Pacific region is anticipated to see substantial growth in the Cement Mixer market, exhibiting an increase from $2.92 billion in 2023 to $5.40 billion by 2033. Factors driving this growth include increasing investments in infrastructure and urban development in countries like India and China. Availability of affordable labor and the rising trend of prefabricated construction methods further support demand.North America Cement Mixer Market Report:

The North American market is projected to grow from $5.78 billion in 2023 to $10.72 billion by 2033. The region is characterized by a robust construction sector, spurred by residential and commercial developments, alongside an increasing trend towards prefabricated construction, which necessitates innovative mixing solutions.South America Cement Mixer Market Report:

South America's Cement Mixer market is expected to grow from $0.96 billion in 2023 to $1.78 billion by 2033. This growth can be attributed to increased construction activities in Brazil and Argentina, alongside government initiatives aiming to bolster economic growth through infrastructure projects.Middle East & Africa Cement Mixer Market Report:

The Middle East and Africa region is projected to increase from $1.36 billion in 2023 to $2.52 billion by 2033. The growth is driven by a surge in construction activities, especially in countries like the UAE and Saudi Arabia, where large-scale infrastructure projects are ongoing.Tell us your focus area and get a customized research report.

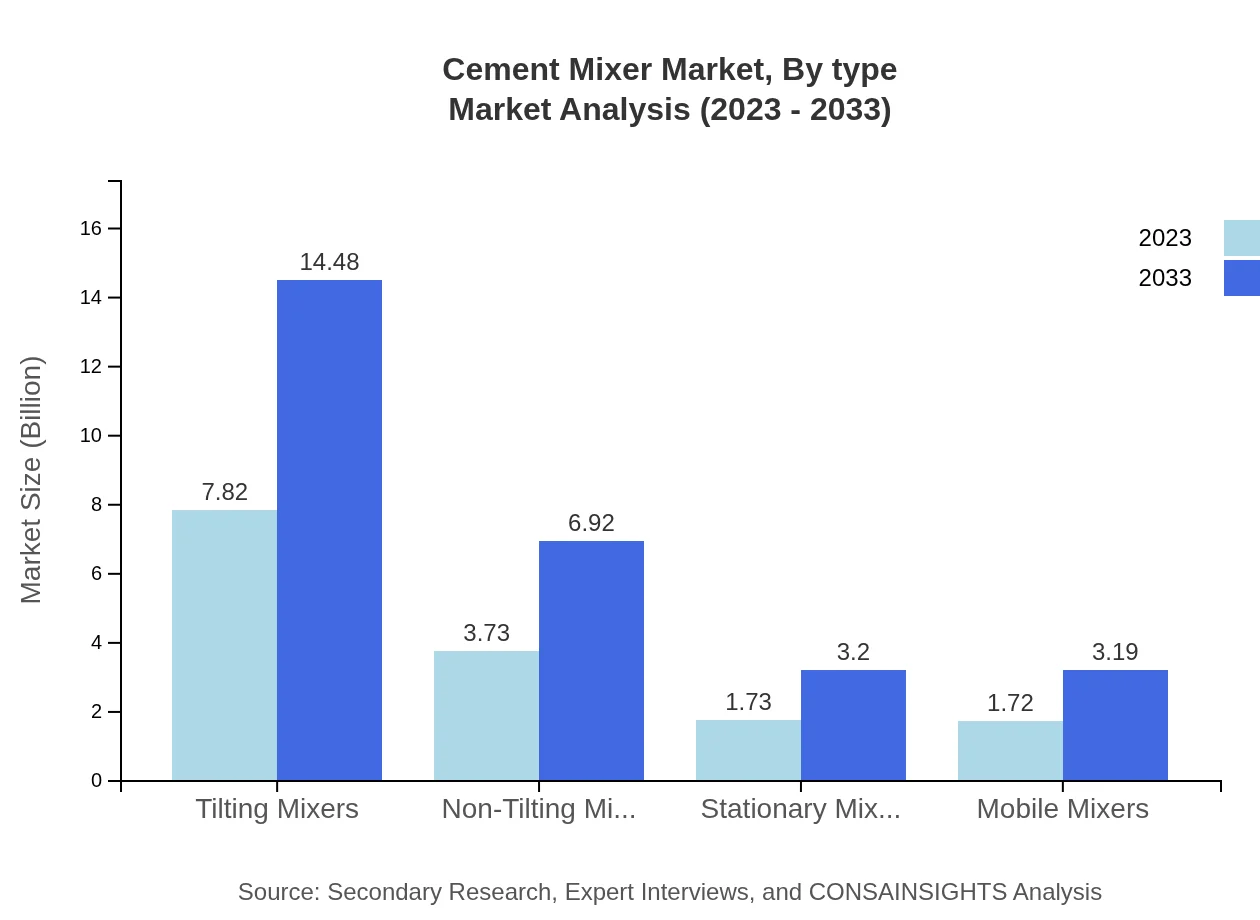

Cement Mixer Market Analysis By Type

The Cement Mixer market can be segmented into different types: Tilting Mixers, Non-Tilting Mixers, Stationary Mixers, and Mobile Mixers. Tilting Mixers lead the market, with a size of $7.82 billion in 2023 projected to grow to $14.48 billion by 2033, holding a 52.1% market share. Non-Tilting Mixers and Stationary Mixers constitute $3.73 billion and $1.73 billion, respectively, in 2023, with expected growth reflecting the diverse project needs across sectors.

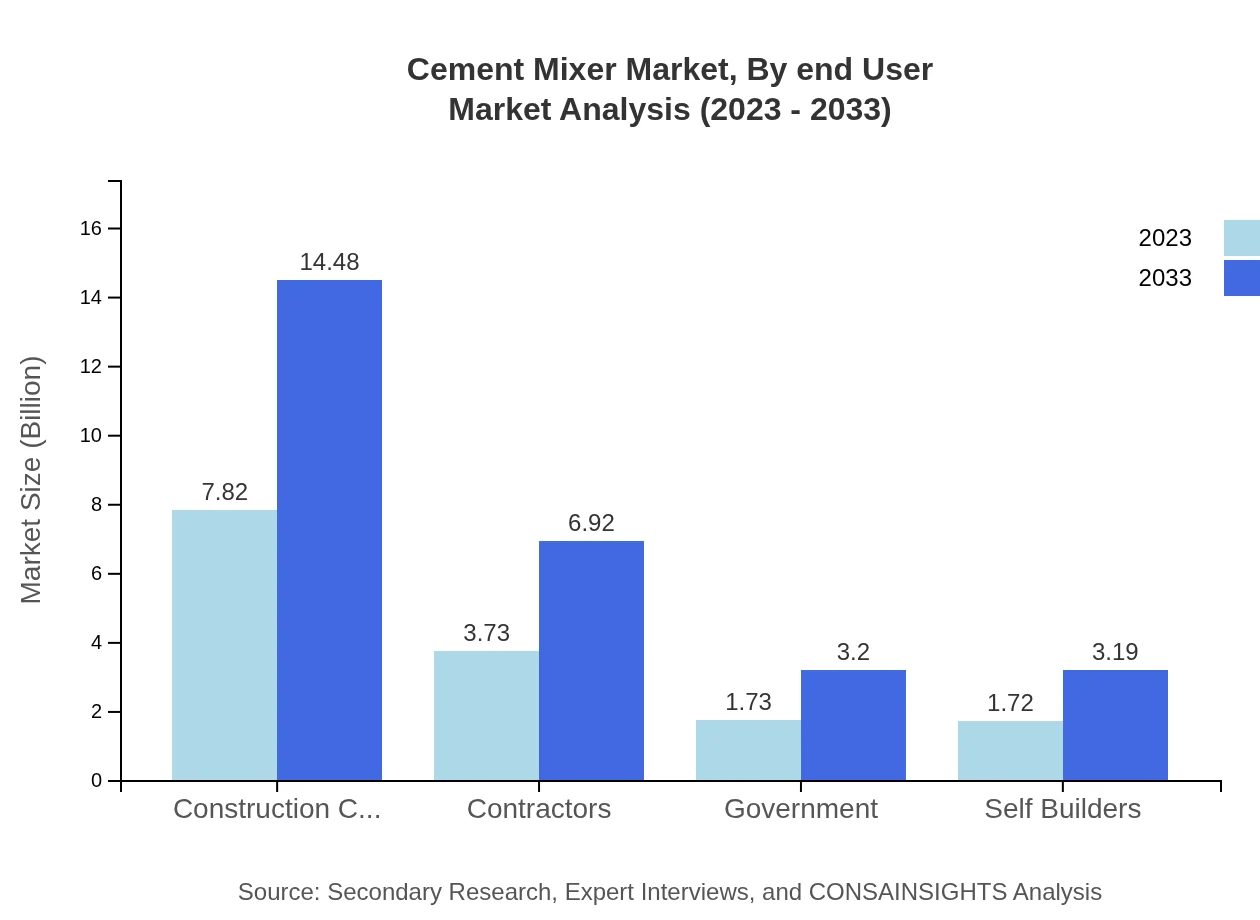

Cement Mixer Market Analysis By Application

Applications of Cement Mixers can be segmented into Construction Companies, Contractors, Government Projects, and Self Builders. The Construction Companies segment leads the market with a size of $7.82 billion in 2023 and is expected to grow significantly to $14.48 billion by 2033, holding a share of 52.1%. Each segment plays a crucial role in driving demand based on various project requirements.

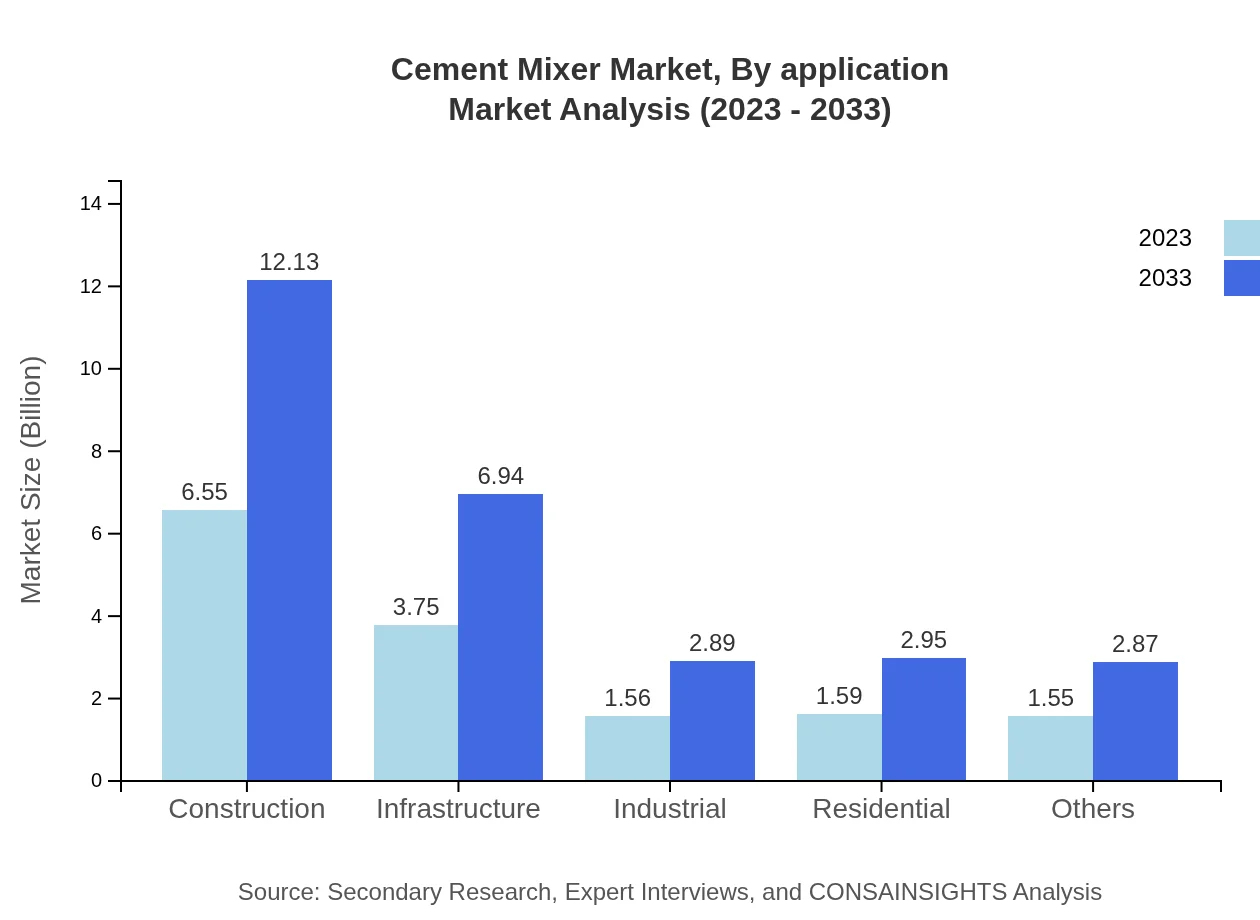

Cement Mixer Market Analysis By End User

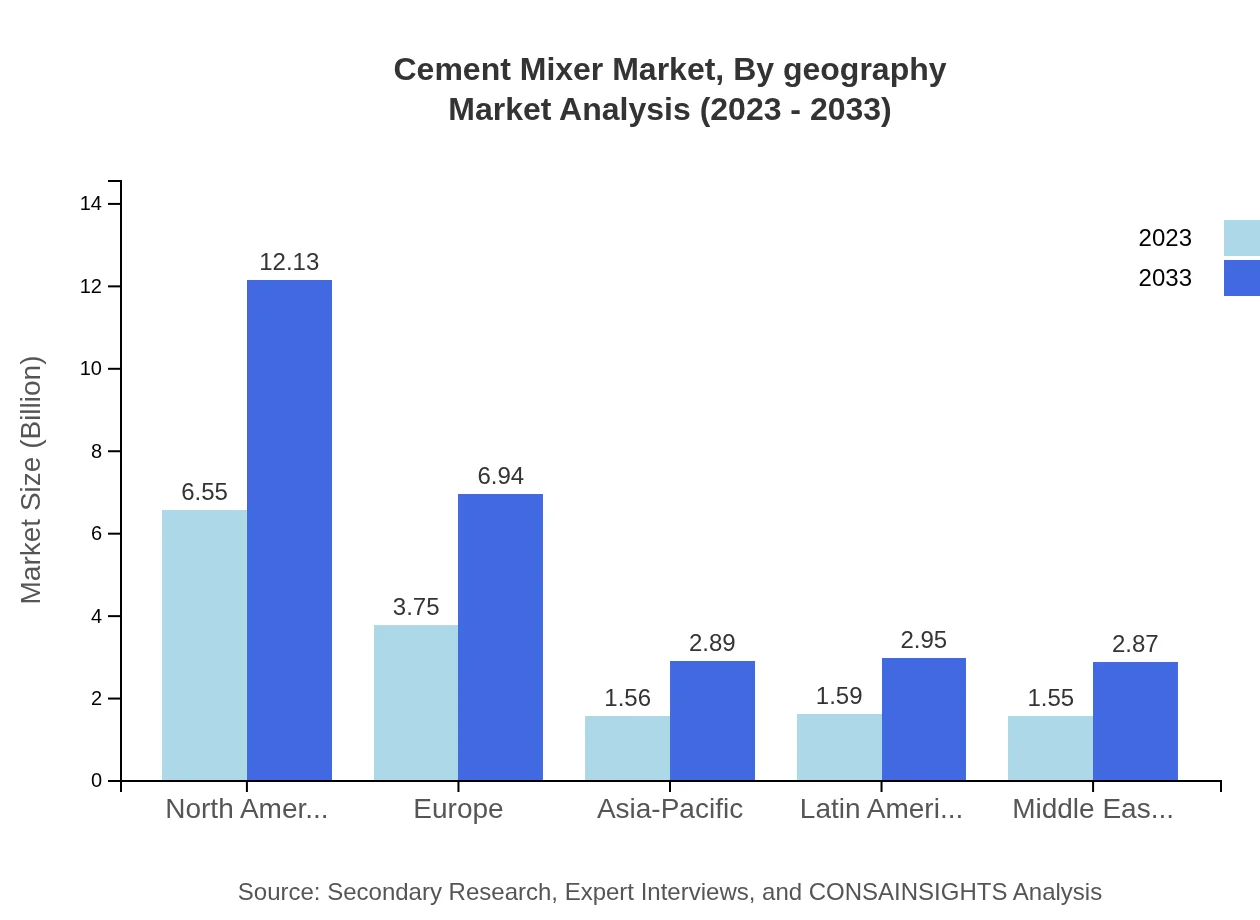

End-user segmentation highlights the contributions of Construction, Infrastructure, Industrial, and Residential sectors. The Construction sector alone consists of a market size of $6.55 billion in 2023, expected to increase to $12.13 billion by 2033, indicating strong growth supported by continuous developments.

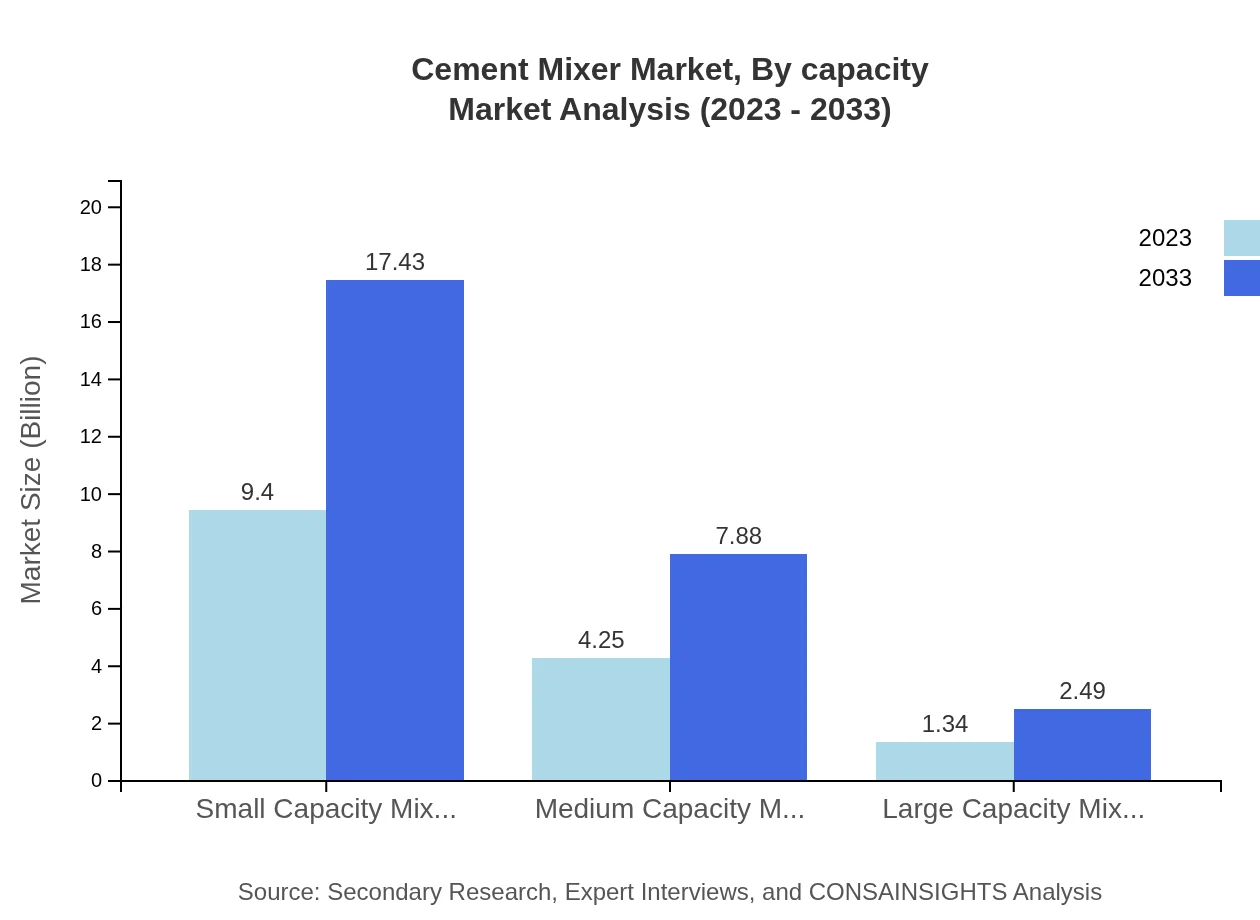

Cement Mixer Market Analysis By Capacity

Cement Mixers are categorized by capacity into Small Capacity Mixers (< 1 cubic meter), Medium Capacity Mixers (1 - 3 cubic meters), and Large Capacity Mixers (> 3 cubic meters). Small Capacity Mixers lead the segment with a market size rising from $9.40 billion in 2023 to $17.43 billion by 2033, capturing a significant share due to their adaptability in various construction projects.

Cement Mixer Market Analysis By Geography

Geographically, the market performance varies with North America leading in revenue followed by Europe, Asia-Pacific, South America, and the Middle East and Africa. Each region presents unique challenges and growth opportunities reflecting local economic conditions and construction sector demands.

Cement Mixer Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Cement Mixer Industry

CEMEX:

CEMEX is a global leader in the building materials industry, providing high-quality construction materials and services, including a variety of Cement Mixers.Liebherr:

Liebherr is known for its high-quality construction equipment and machinery, including innovative cement mixing solutions that cater to a wide range of construction needs.Schwing Stetter:

A prominent player in the concrete technology sector, Schwing Stetter offers a comprehensive range of mixers, including truck-mounted, stationary, and mobile solutions for various applications.Terex Corporation:

Terex Corporation designs and manufactures a wide variety of equipment and machinery, including cement mixers widely used in construction.SANY Group:

Based in China, SANY Group is recognized for its comprehensive machinery solutions that significantly contribute to the Cement Mixer market.We're grateful to work with incredible clients.

FAQs

What is the market size of cement Mixer?

The global cement mixer market is valued at approximately $15 billion in 2023, with a projected CAGR of 6.2% from 2023 to 2033. The market is expected to expand significantly, driven by increasing construction activities and demand for efficient concrete mixing.

What are the key market players or companies in this cement Mixer industry?

Key players in the cement mixer market include major manufacturing companies that produce various types of mixers, catering to construction, infrastructure, and industrial sectors. These companies drive innovation and competition within the market to meet diverse customer needs.

What are the primary factors driving the growth in the cement mixer industry?

The growth of the cement mixer industry is driven by factors such as rising construction activities, urbanization, demand for efficient concrete preparation, technological advancements in mixer design, and government initiatives to enhance infrastructure development across various regions.

Which region is the fastest Growing in the cement mixer market?

North America is the fastest-growing region in the cement mixer market. It is projected to grow from $5.78 billion in 2023 to $10.72 billion by 2033, reflecting significant development in construction and infrastructure projects in this region.

Does ConsaInsights provide customized market report data for the cement mixer industry?

Yes, ConsaInsights offers customized market report data tailored to the specific needs of clients within the cement mixer industry. This includes detailed analyses, forecasts, and actionable insights based on the latest market trends and data.

What deliverables can I expect from this cement mixer market research project?

From the cement mixer market research project, clients can expect various deliverables, including a comprehensive report detailing market size, growth forecasts, segment analysis, competitive landscape, and actionable recommendations for strategy development.

What are the market trends of cement mixer?

Key market trends in the cement mixer industry include increasing adoption of advanced mixer technologies, sustainability practices, and a shift towards mobile and compact mixer models to cater to varied construction needs and space constraints.