Chemical Mechanical Planarization Market Report

Published Date: 31 January 2026 | Report Code: chemical-mechanical-planarization

Chemical Mechanical Planarization Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Chemical Mechanical Planarization (CMP) market from 2023 to 2033, focusing on market size, growth trends, segmentation, technological advancements, and regional insights.

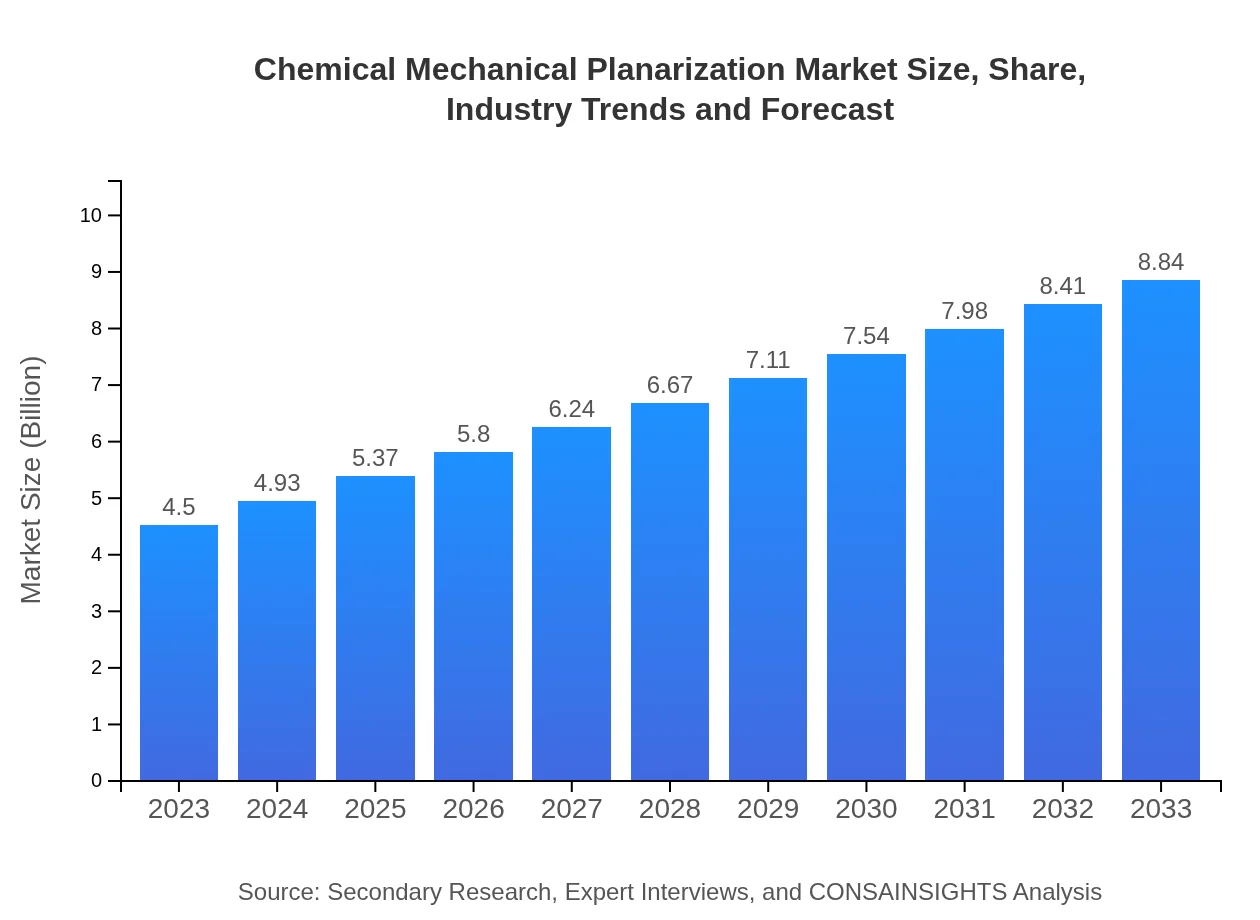

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $4.50 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $8.84 Billion |

| Top Companies | Applied Materials Inc., GlobalFoundries, KLA Corporation, Lam Research Corporation |

| Last Modified Date | 31 January 2026 |

Chemical Mechanical Planarization Market Overview

Customize Chemical Mechanical Planarization Market Report market research report

- ✔ Get in-depth analysis of Chemical Mechanical Planarization market size, growth, and forecasts.

- ✔ Understand Chemical Mechanical Planarization's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Chemical Mechanical Planarization

What is the Market Size & CAGR of Chemical Mechanical Planarization market in 2023?

Chemical Mechanical Planarization Industry Analysis

Chemical Mechanical Planarization Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Chemical Mechanical Planarization Market Analysis Report by Region

Europe Chemical Mechanical Planarization Market Report:

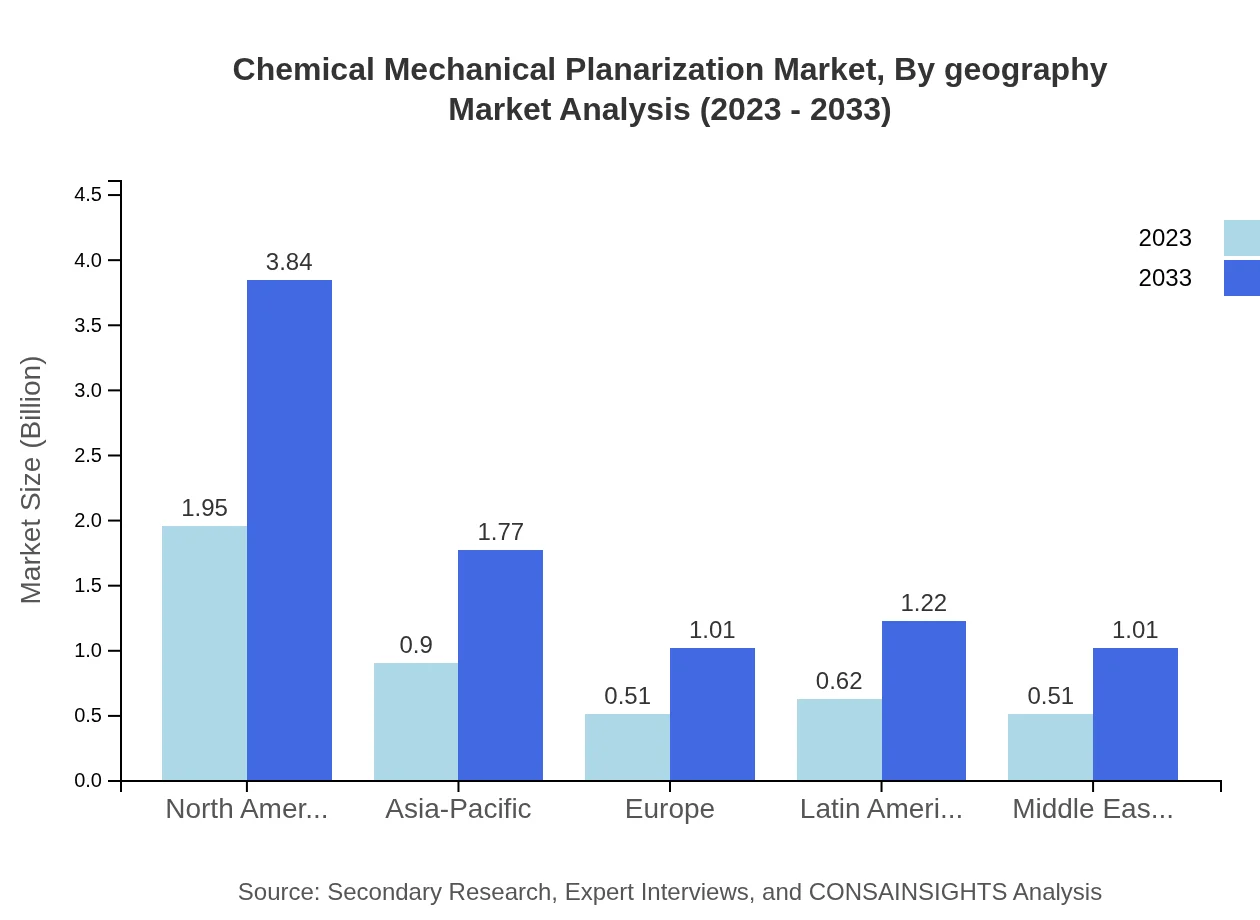

In Europe, the CMP market is currently valued at $1.22 billion in 2023, with expectations to reach $2.40 billion by 2033. The growth is led by increasing investments in renewable energy technologies and advancements in optoelectronic devices.Asia Pacific Chemical Mechanical Planarization Market Report:

In 2023, the Asia Pacific Chemical Mechanical Planarization market is valued at approximately $0.87 billion and is projected to grow to $1.70 billion by 2033. The region is driven by major semiconductor manufacturing hubs like China, Taiwan, and South Korea, along with increasing investments in technology and infrastructure.North America Chemical Mechanical Planarization Market Report:

North America is a vital region for the CMP market, with a valuation of $1.67 billion in 2023, projected to grow to $3.29 billion by 2033. The presence of leading semiconductor manufacturers and technology firms drives demand in this region.South America Chemical Mechanical Planarization Market Report:

The South American CMP market is valued at $0.31 billion in 2023 and is expected to reach $0.62 billion by 2033. The region's growth is significantly attributable to increasing technological adoption in electronics and the telecom sectors.Middle East & Africa Chemical Mechanical Planarization Market Report:

The CMP market in the Middle East and Africa is valued at $0.42 billion in 2023, expected to reach $0.83 billion by 2033. Growth is anticipated as technological advancements and government initiatives promote the semiconductor industry.Tell us your focus area and get a customized research report.

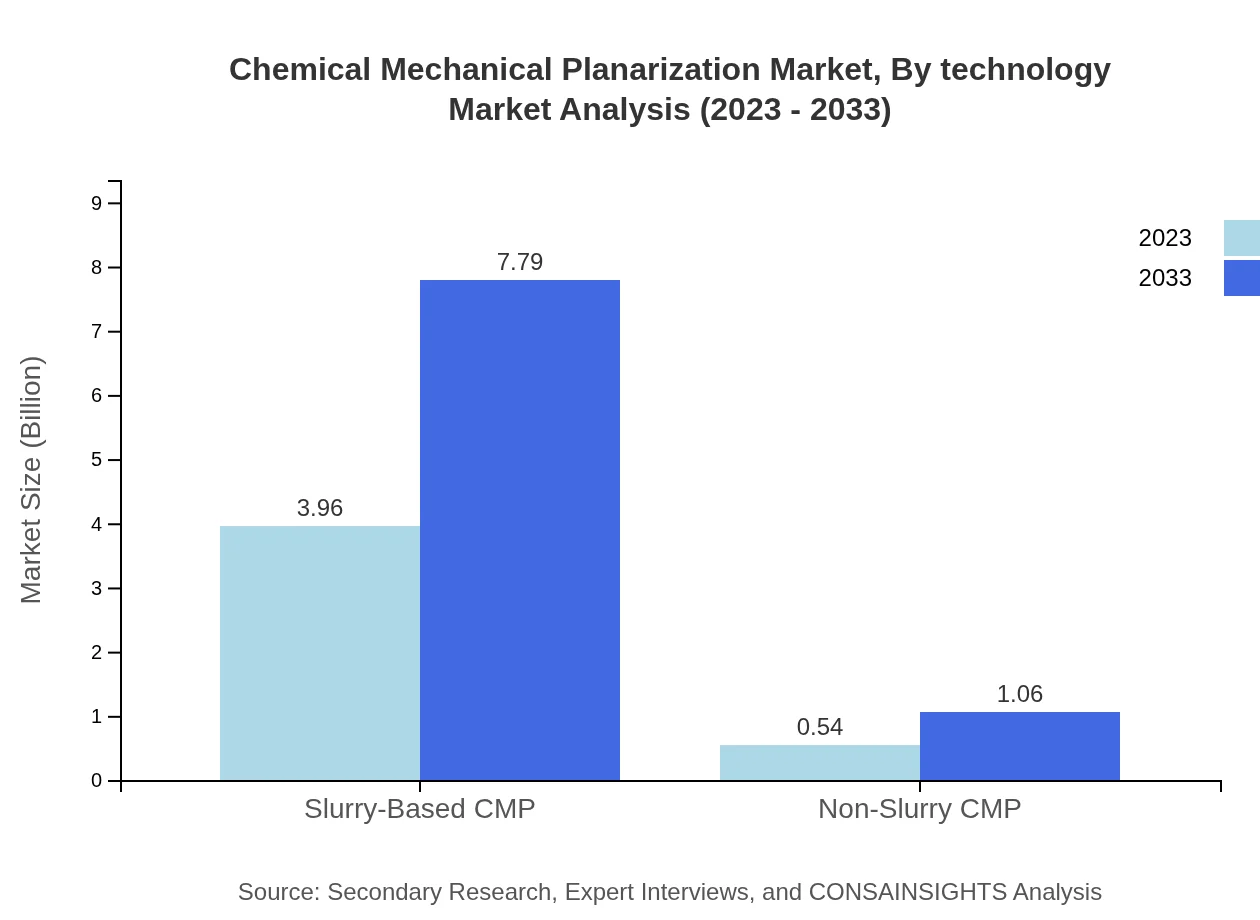

Chemical Mechanical Planarization Market Analysis By Technology

The CMP market is primarily divided into slurry-based and non-slurry CMP technologies. Slurry-based CMP dominates, accounting for 88.04% of the market in 2023, with robust growth expected due to the demand for high-quality surface finish in semiconductor devices. Non-slurry CMP, which is gaining traction due to its cost-effectiveness and environmental benefits, is projected to grow steadily.

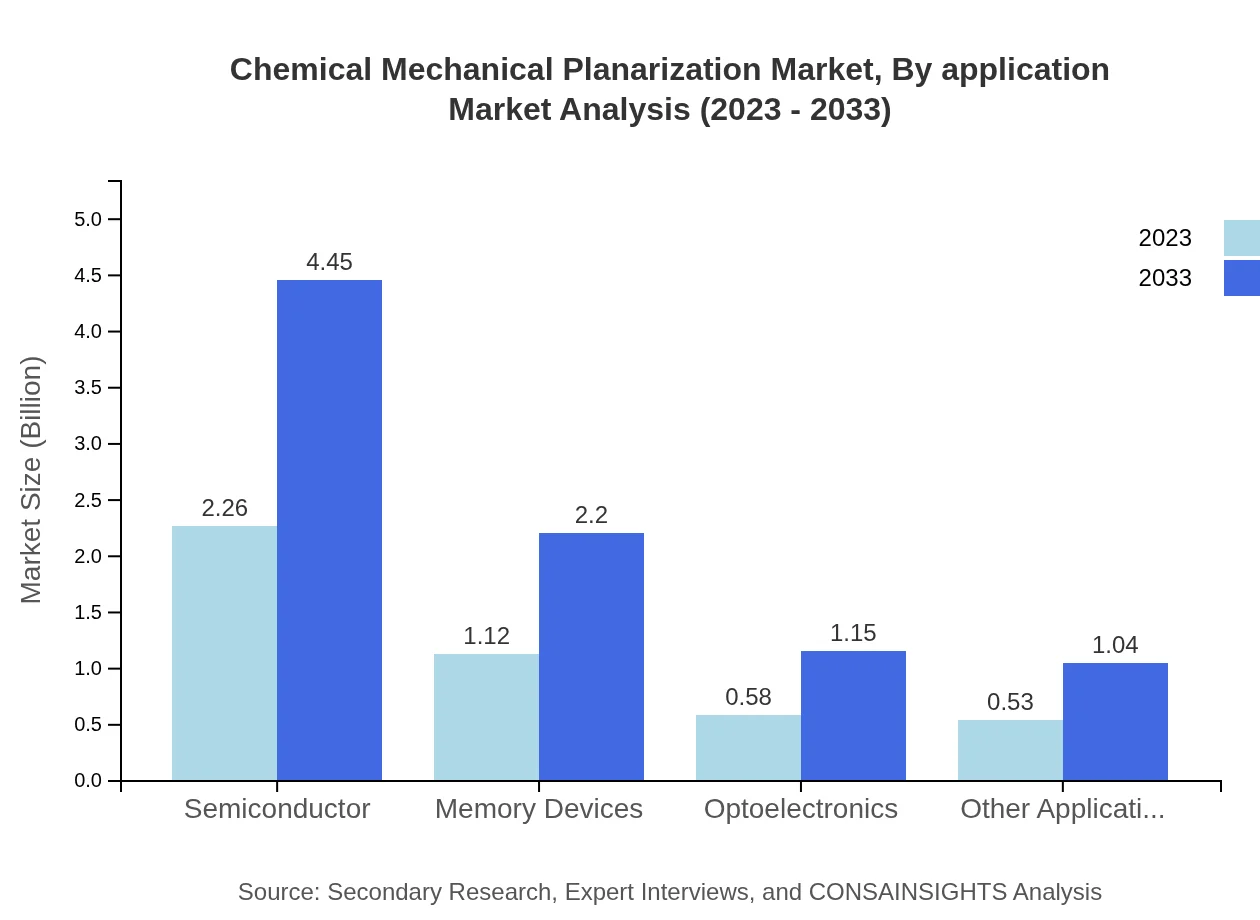

Chemical Mechanical Planarization Market Analysis By Application

CMP applications span various sectors including semiconductors, memory devices, optoelectronics, and other applications. The semiconductor segment is the largest, representing 50.32% of the market in 2023, driven by innovations in microchip design and the push for more advanced chips.

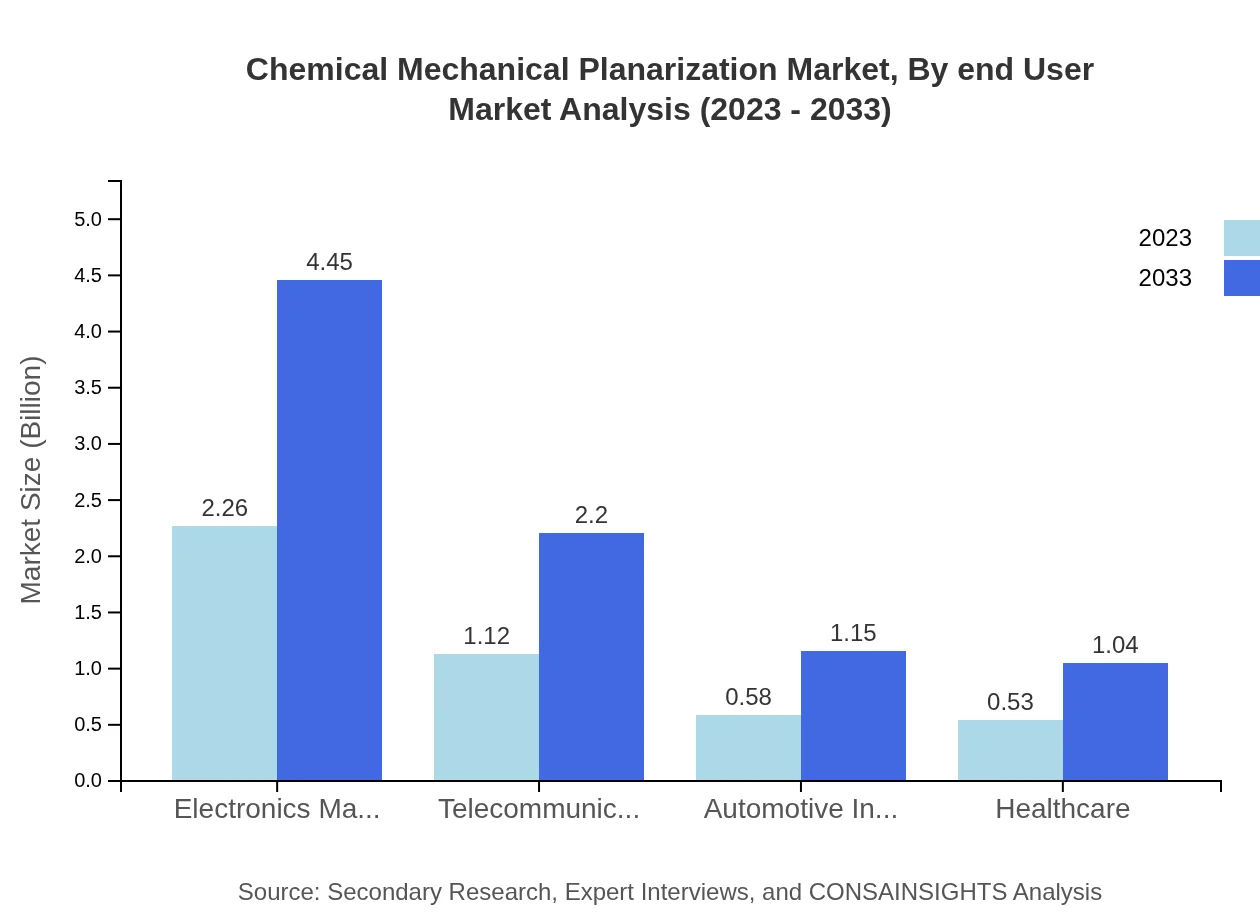

Chemical Mechanical Planarization Market Analysis By End User

The key end-user industries for CMP include electronics manufacturers, telecommunications, automotive, and healthcare sectors. Electronics manufacturers account for the largest segment, contributing 50.32% to the market in 2023, indicating the critical role of CMP in achieving desired surface finishes for advanced electronics.

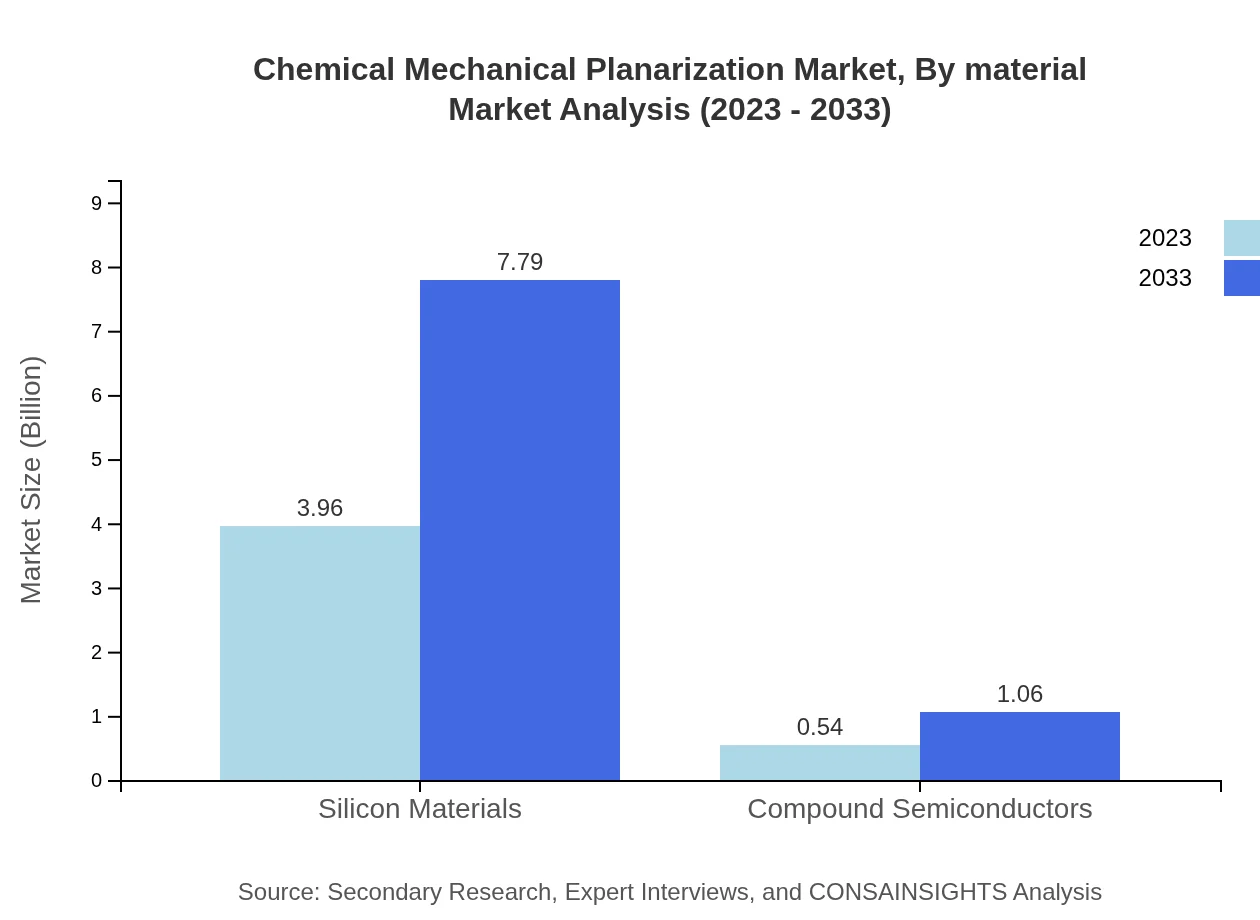

Chemical Mechanical Planarization Market Analysis By Material

CMP employs various materials, with silicon materials representing 88.04% of the material market share in 2023. The demand for silicon materials is driven by their essential role in semiconductor manufacturing, particularly in integrated circuits and memory chips.

Chemical Mechanical Planarization Market Analysis By Geography

Geographically, North America and Asia Pacific lead the CMP market, attributed to their robust electronics manufacturing industries and concentration of semiconductor fabs. Europe follows, with growth propelled by technological innovations and increased demand for advanced optoelectronic devices.

Chemical Mechanical Planarization Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Chemical Mechanical Planarization Industry

Applied Materials Inc.:

A leader in materials engineering solutions and advanced manufacturing technology for semiconductor manufacturing, Applied Materials provides innovative CMP solutions that enhance semiconductor fabrication.GlobalFoundries:

GlobalFoundries specializes in semiconductor manufacturing and provides advanced CMP processes and solutions for integrated circuits, focusing on efficiency and performance.KLA Corporation:

KLA is known for its advanced process control and yield management solutions, including CMP technology, aiding semiconductor manufacturers in achieving precise surface finishes.Lam Research Corporation:

Lam Research offers essential technology for semiconductor fabrication, including CMP systems that support developments in a diverse range of applications.We're grateful to work with incredible clients.

FAQs

What is the market size of chemical Mechanical Planarization?

The Chemical Mechanical Planarization market is currently valued at approximately $4.5 billion in 2023 and is projected to grow at a CAGR of 6.8%, aiming to achieve significant growth by 2033.

What are the key market players or companies in this chemical Mechanical Planarization industry?

Key players in the Chemical Mechanical Planarization industry include major semiconductor equipment manufacturers and material suppliers, focusing on innovation and efficient solutions for the microelectronics sector.

What are the primary factors driving the growth in the chemical Mechanical Planarization industry?

Growth in the CMP market is driven by advancements in semiconductor technology, increasing demand for high-performance electronics, and the proliferation of smart devices and IoT applications globally.

Which region is the fastest Growing in the chemical Mechanical Planarization?

The fastest-growing region in the CMP market is North America, projected to grow from $1.67 billion in 2023 to $3.29 billion by 2033, led by technological innovations in semiconductor manufacturing.

Does ConsaInsights provide customized market report data for the chemical Mechanical Planarization industry?

Yes, ConsaInsights offers customized market reports on chemical mechanical planarization, tailored to specific client needs and covering various aspects such as market trends, competitive analysis and forecasts.

What deliverables can I expect from this chemical Mechanical Planarization market research project?

Deliverables from the CMP research project include detailed market analysis reports, segmentation data, competitor insights, and growth forecasts, helping stakeholders make informed decisions.

What are the market trends of chemical Mechanical Planarization?

Current trends in the CMP market include increasing adoption of advanced materials, evolution in process technology, and a shift towards eco-friendly options, all supporting sustainable manufacturing practices.