Chemical Protective Clothing Market Report

Published Date: 22 January 2026 | Report Code: chemical-protective-clothing

Chemical Protective Clothing Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Chemical Protective Clothing market from 2023 to 2033. It covers key insights, market size, industry trends, regional analyses, technology impacts, product performance, and predictions for future growth.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

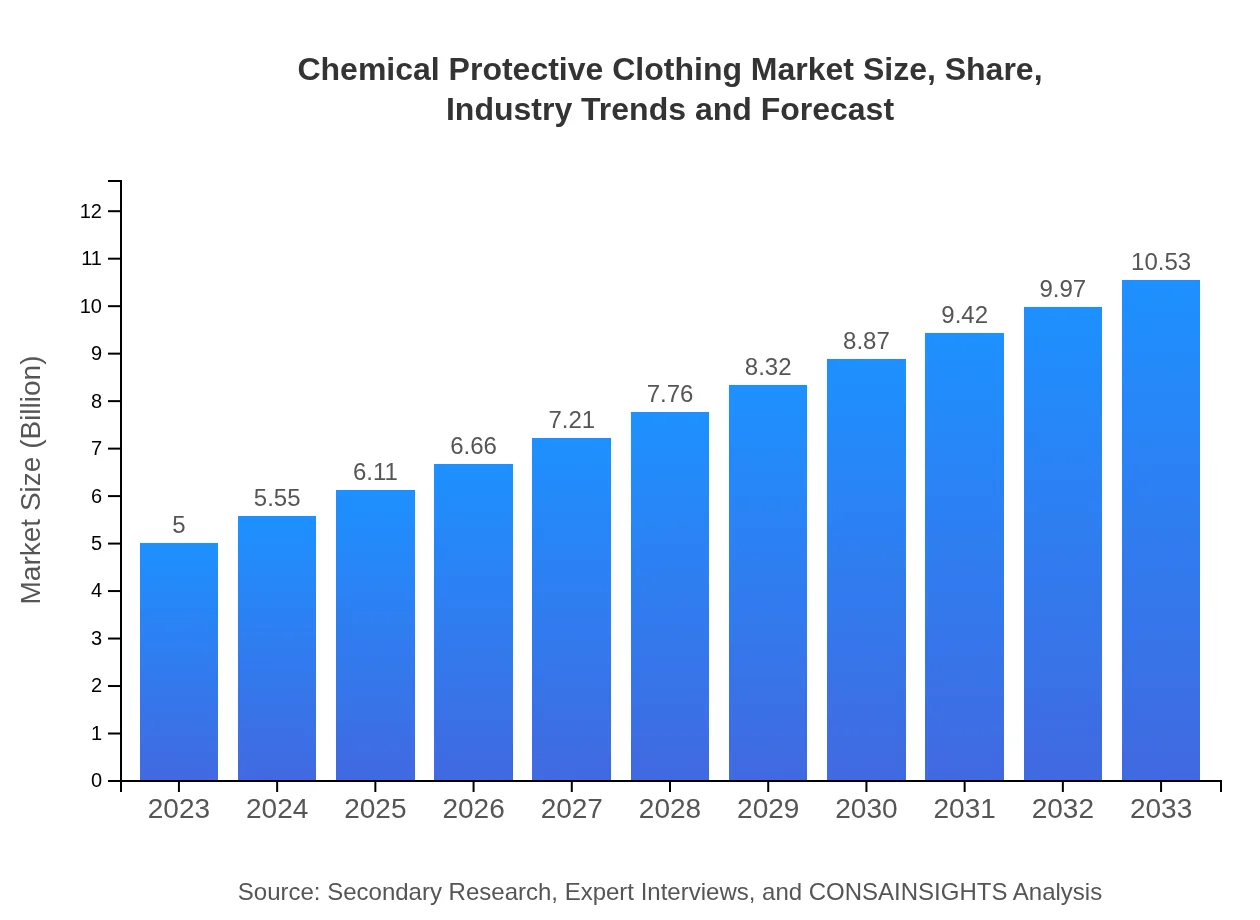

| 2023 Market Size | $5.00 Billion |

| CAGR (2023-2033) | 7.5% |

| 2033 Market Size | $10.53 Billion |

| Top Companies | 3M Company, DuPont, Honeywell International Inc. |

| Last Modified Date | 22 January 2026 |

Chemical Protective Clothing Market Overview

Customize Chemical Protective Clothing Market Report market research report

- ✔ Get in-depth analysis of Chemical Protective Clothing market size, growth, and forecasts.

- ✔ Understand Chemical Protective Clothing's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Chemical Protective Clothing

What is the Market Size & CAGR of Chemical Protective Clothing market in 2033?

Chemical Protective Clothing Industry Analysis

Chemical Protective Clothing Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Chemical Protective Clothing Market Analysis Report by Region

Europe Chemical Protective Clothing Market Report:

Europe is anticipated to maintain a robust market landscape for Chemical Protective Clothing, expanding from $1.30 billion in 2023 to $2.74 billion by 2033. The implementation of stringent regulations regarding chemical handling has led to an increased demand for protective gear, significantly affecting market dynamics.Asia Pacific Chemical Protective Clothing Market Report:

The Asia Pacific region is expected to exhibit robust growth in the Chemical Protective Clothing market, driven by increasing manufacturing activities and growing regulatory pressures regarding workplace safety. The market is projected to grow from $1.04 billion in 2023 to $2.19 billion by 2033. Countries like China and India are at the forefront of this growth with escalating industrial sectors that demand enhanced protective gear.North America Chemical Protective Clothing Market Report:

North America holds a significant share of the Chemical Protective Clothing market, with expectations of growth from $1.64 billion in 2023 to $3.46 billion in 2033. This growth is supported by strict regulatory frameworks and a strong emphasis on workplace safety across industries such as manufacturing and healthcare.South America Chemical Protective Clothing Market Report:

In South America, the Chemical Protective Clothing market is set to increase from $0.48 billion in 2023 to $1.02 billion by 2033. The growth is largely influenced by expanding industries, particularly agriculture and mining, which necessitate stringent health and safety measures to protect workers from hazardous chemicals.Middle East & Africa Chemical Protective Clothing Market Report:

In the Middle East and Africa, the market is projected to grow from $0.53 billion in 2023 to $1.12 billion by 2033. The growth is propelled by increased industrial activities, particularly in the oil and gas sector, where protective clothing is paramount for worker safety.Tell us your focus area and get a customized research report.

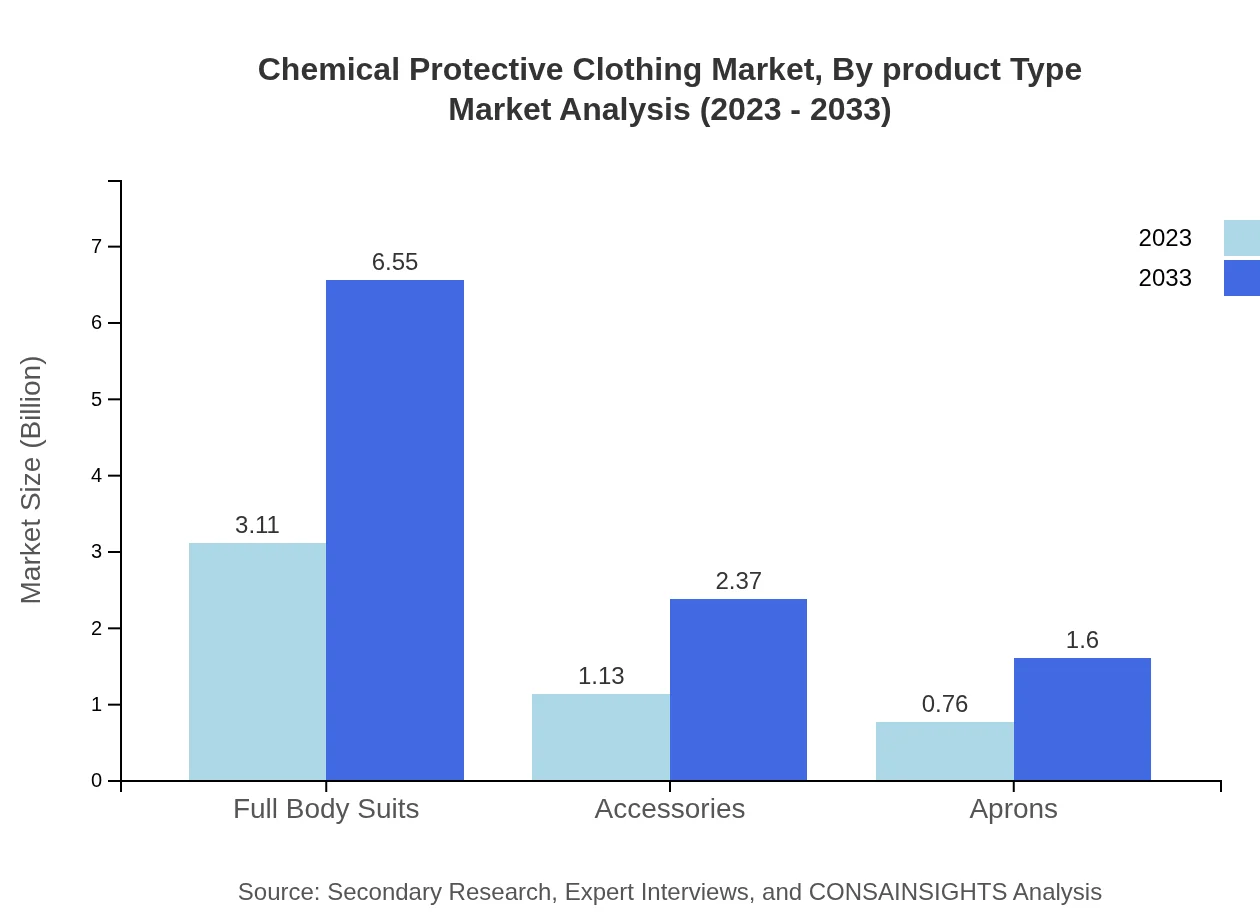

Chemical Protective Clothing Market Analysis By Product Type

The product types dominate the Chemical Protective Clothing market, with full body suits leading the category. In 2023, the market for full body suits is projected at $3.11 billion and is expected to grow to $6.55 billion by 2033, holding a share of 62.24%. Accessories and aprons also contribute significantly, with respective shares of 22.55% and 15.21%. Such segmentation highlights the importance of comprehensive protective solutions.

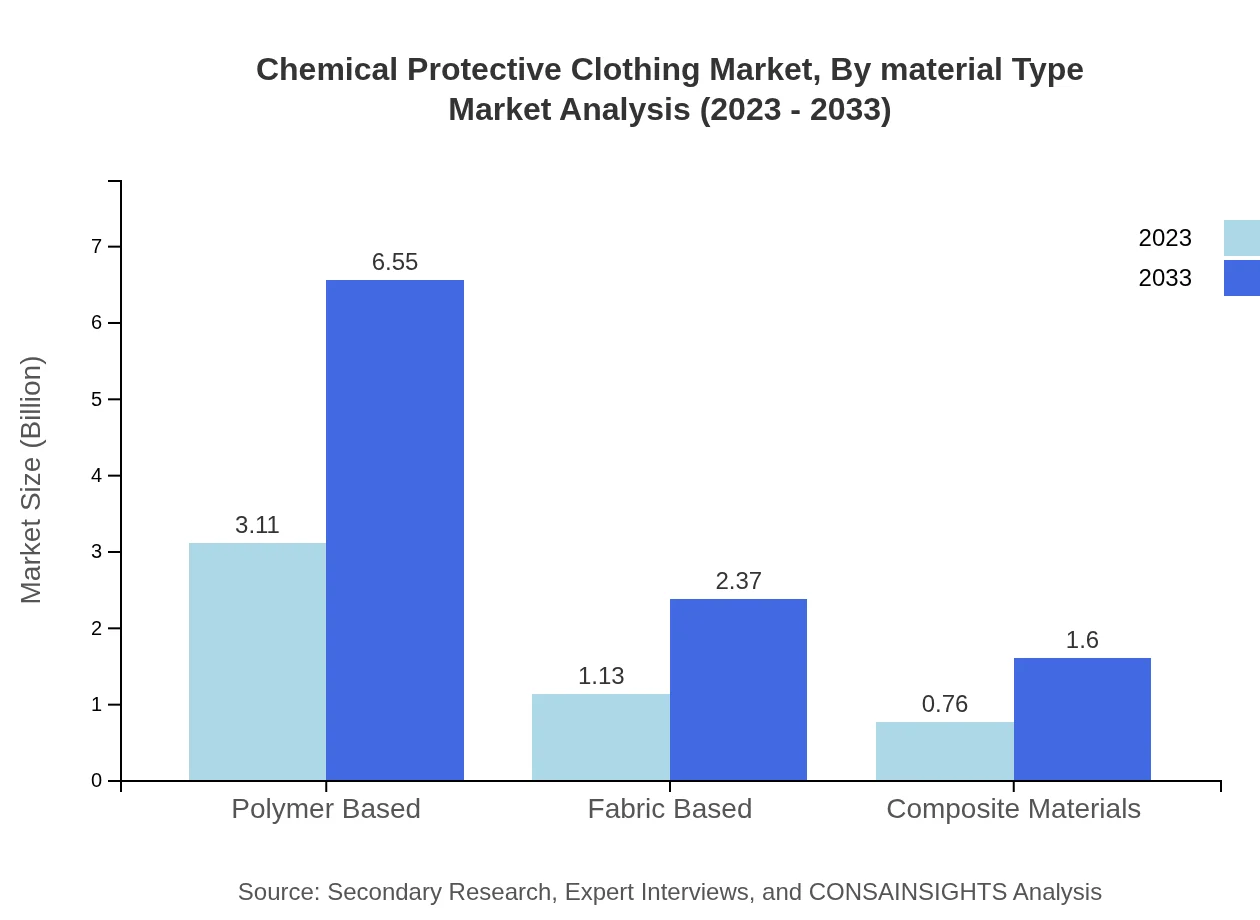

Chemical Protective Clothing Market Analysis By Material Type

Material types in the market include polymer-based, fabric-based, and composite materials. Polymer-based clothing leads the segment with a market size of $3.11 billion in 2023, growing to $6.55 billion by 2033, maintaining a 62.24% share. Fabric-based materials and composite materials also show growth potential, underscoring the industry's drive towards innovation in material science.

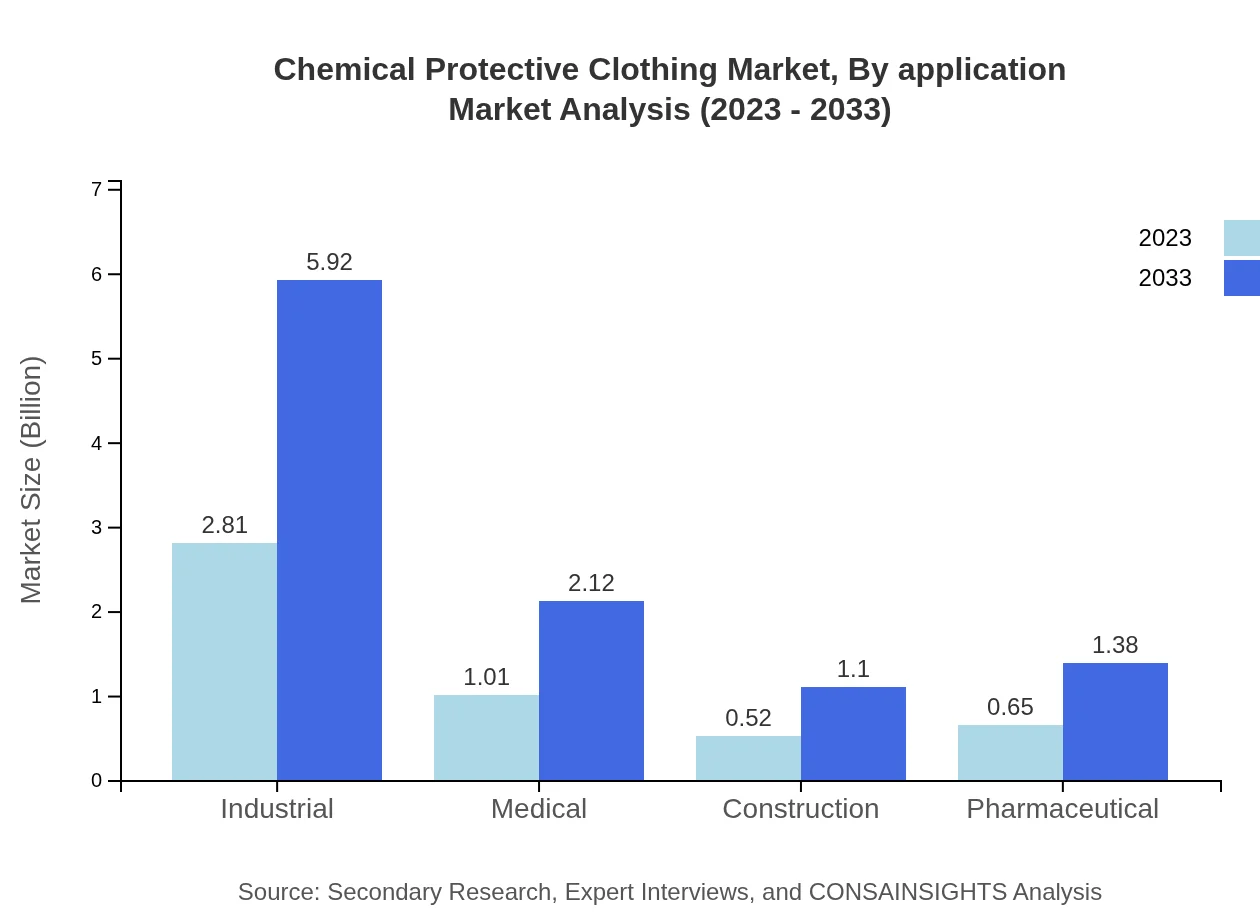

Chemical Protective Clothing Market Analysis By Application

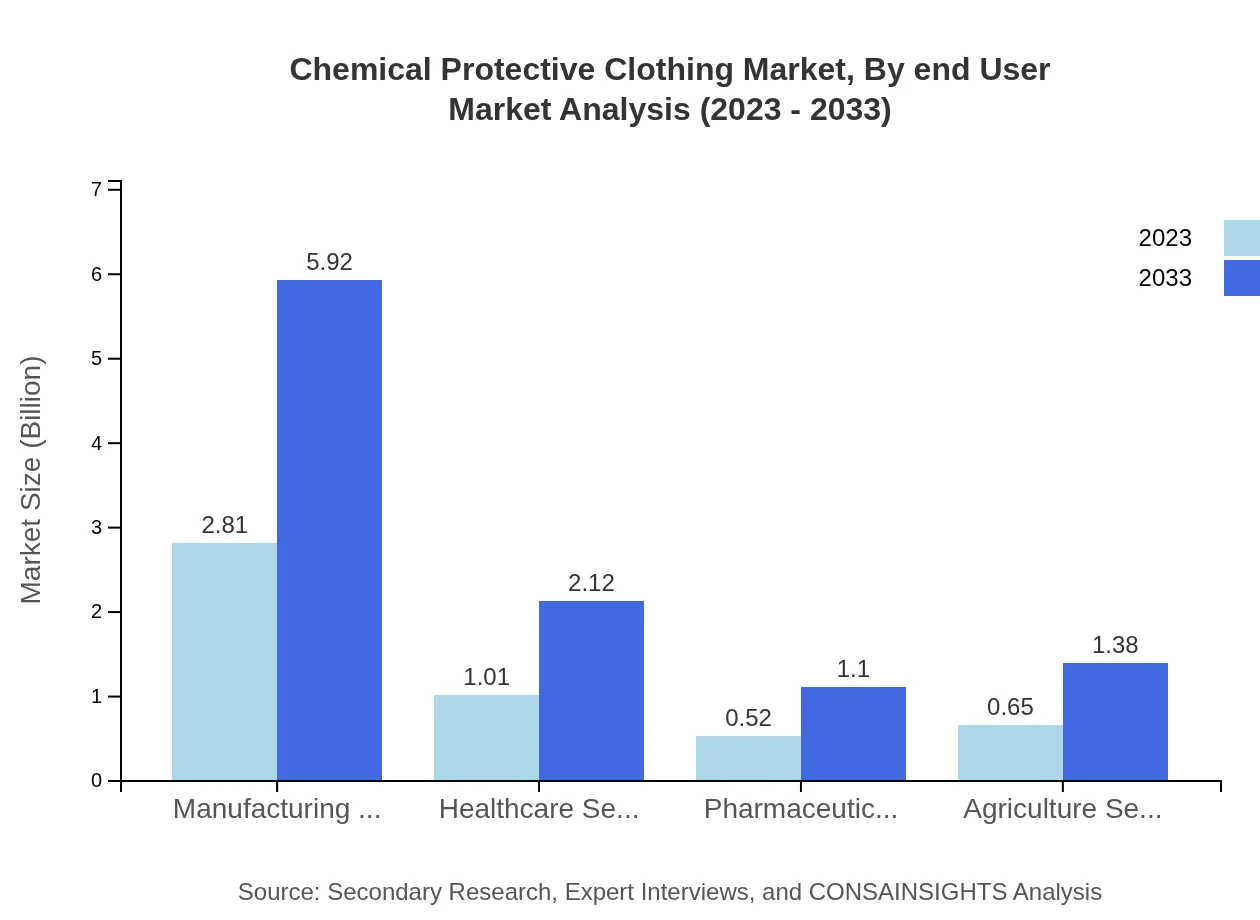

The applications of Chemical Protective Clothing span several sectors, including industrial, medical, agriculture, and construction. The industrial sector accounts for $2.81 billion in 2023, projected to grow to $5.92 billion by 2033. The medical and agricultural sectors also show consistent demand, driven by health and safety regulations which necessitate protective gear.

Chemical Protective Clothing Market Analysis By End User

End-user segmentation reveals that the manufacturing sector plays a crucial role in the demand for protective clothing, accounting for 56.29% of the market share. The healthcare and pharmaceutical sectors also have significant contributions, with shares of 20.17% and 10.45%, respectively. This segmentation illustrates the targeted market strategies employed by companies to address specific sector needs.

Chemical Protective Clothing Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Chemical Protective Clothing Industry

3M Company:

3M is a global leader in safety equipment, offering a wide range of chemical protective clothing and safety solutions designed for various industries, emphasizing quality and advanced material technology.DuPont:

DuPont is known for its superior protective clothing solutions, focusing on innovative fabric technologies to create durable gear that meets stringent safety standards in industries such as healthcare and manufacturing.Honeywell International Inc.:

Honeywell is a prominent player in the safety gear market, producing an extensive portfolio of chemical protective clothing tailored to meet the diverse needs of industrial applications.We're grateful to work with incredible clients.

FAQs

What is the market size of chemical Protective Clothing?

The global chemical protective clothing market is currently valued at $5 billion, with a projected CAGR of 7.5% over the next decade, indicating substantial growth as industries increasingly prioritize worker safety.

What are the key market players or companies in this chemical Protective Clothing industry?

Key players in the chemical protective clothing market include DuPont, 3M, Honeywell, and Lakeland Industries, each contributing to innovation and advancements in protective gear across various sectors.

What are the primary factors driving the growth in the chemical Protective Clothing industry?

Growth in the chemical protective clothing industry is largely driven by regulatory policies focused on worker safety, increased industrial activities, and rising awareness of the health hazards associated with chemical exposure.

Which region is the fastest Growing in the chemical Protective Clothing?

The fastest-growing region in the chemical protective clothing market is North America, with market growth from $1.64 billion in 2023 to $3.46 billion by 2033, reflecting heightened safety regulations and demand.

Does ConsaInsights provide customized market report data for the chemical Protective Clothing industry?

Yes, ConsaInsights offers customized market report data tailored to client specifications for the chemical protective clothing industry, enabling businesses to make informed strategic decisions based on unique needs.

What deliverables can I expect from this chemical Protective Clothing market research project?

Deliverables from the chemical protective clothing market research project include comprehensive reports, segmented market analysis, competitor assessments, and insights on regional growth trends and future forecasts.

What are the market trends of chemical Protective Clothing?

Key market trends in chemical protective clothing include a shift towards advanced materials such as fabric-based and polymer-based products, and an increasing focus on sustainability practices in manufacturing.