Clean Room Robot Market Report

Published Date: 31 January 2026 | Report Code: clean-room-robot

Clean Room Robot Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Clean Room Robot market from 2023 to 2033, including market trends, size projections, regional insights, segmentation analysis, and forecasts. It aims to equip stakeholders with pertinent data to make informed strategic decisions.

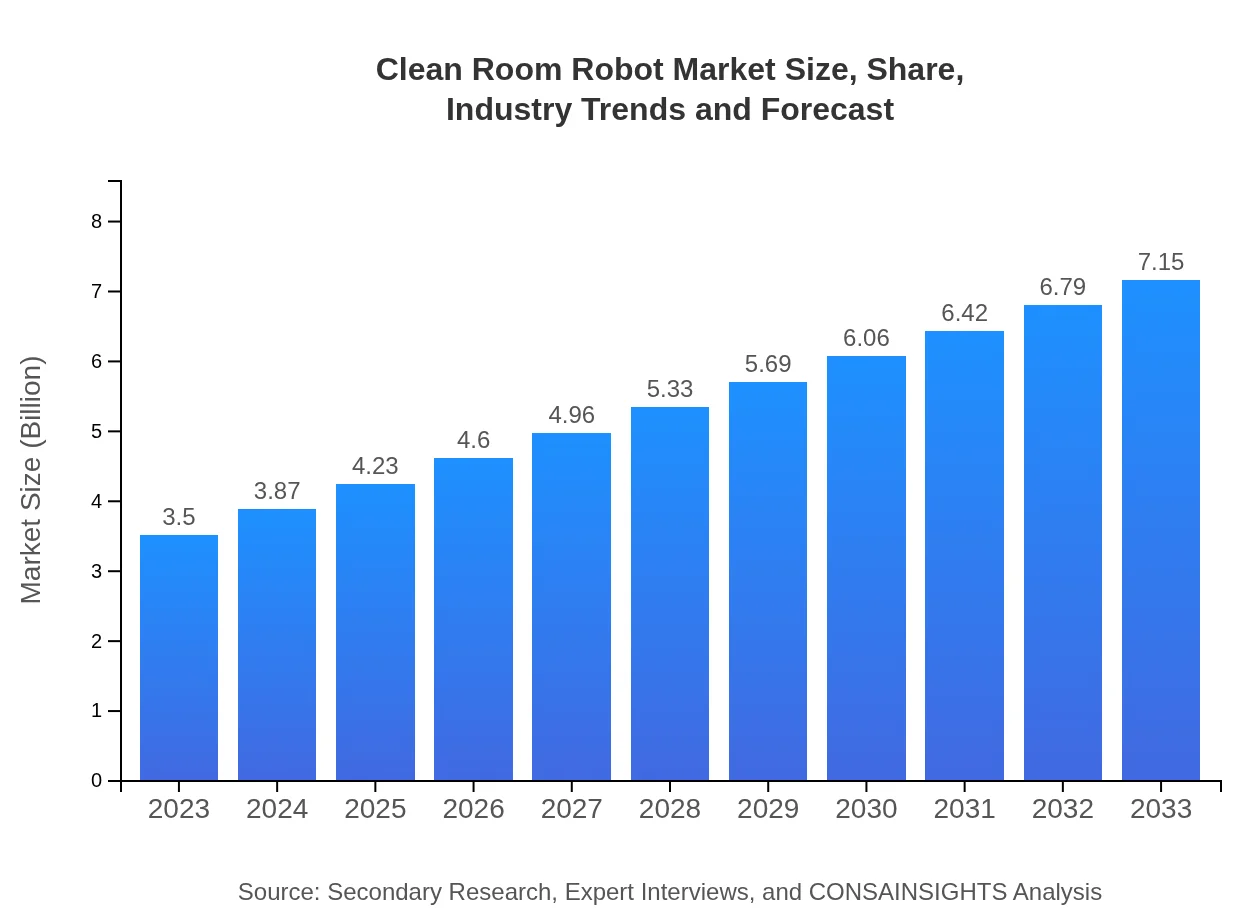

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $3.50 Billion |

| CAGR (2023-2033) | 7.2% |

| 2033 Market Size | $7.15 Billion |

| Top Companies | Fanuc Corporation, KUKA AG, Yaskawa Electric Corporation |

| Last Modified Date | 31 January 2026 |

Clean Room Robot Market Overview

Customize Clean Room Robot Market Report market research report

- ✔ Get in-depth analysis of Clean Room Robot market size, growth, and forecasts.

- ✔ Understand Clean Room Robot's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Clean Room Robot

What is the Market Size & CAGR of Clean Room Robot market in 2033?

Clean Room Robot Industry Analysis

Clean Room Robot Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Clean Room Robot Market Analysis Report by Region

Europe Clean Room Robot Market Report:

Europe is expected to increase from $0.99 billion in 2023 to $2.03 billion by 2033. The region has a strong regulatory framework promoting the use of clean room robotics, especially in manufacturing and research sectors focused on pharmaceuticals and biotechnology.Asia Pacific Clean Room Robot Market Report:

The Asia Pacific region, with a market size of $0.73 billion in 2023 projected to grow to $1.48 billion by 2033, shows substantial growth driven by rapid industrialization and increased demand in pharmaceutical and electronics sectors. Countries like China and Japan lead in robotics adoption, with a focus on enhancing manufacturing capabilities.North America Clean Room Robot Market Report:

The North American market, growing from approximately $1.17 billion in 2023 to $2.40 billion in 2033, is driven by high demand for automated solutions in the pharmaceutical and biotech industries, coupled with advanced technologies in robotics enhancing production processes.South America Clean Room Robot Market Report:

In South America, the Clean Room Robot market is anticipated to expand from $0.18 billion in 2023 to $0.36 billion by 2033. The growth is primarily attributed to the pharmaceutical industry, where stringent regulations are necessitating automation for compliance with cleanliness standards.Middle East & Africa Clean Room Robot Market Report:

The Clean Room Robot market in the Middle East and Africa, estimated to grow from $0.43 billion in 2023 to $0.88 billion by 2033, is expected to benefit from enhancements in the healthcare sector, particularly in medical device manufacturing and pharmaceutical production.Tell us your focus area and get a customized research report.

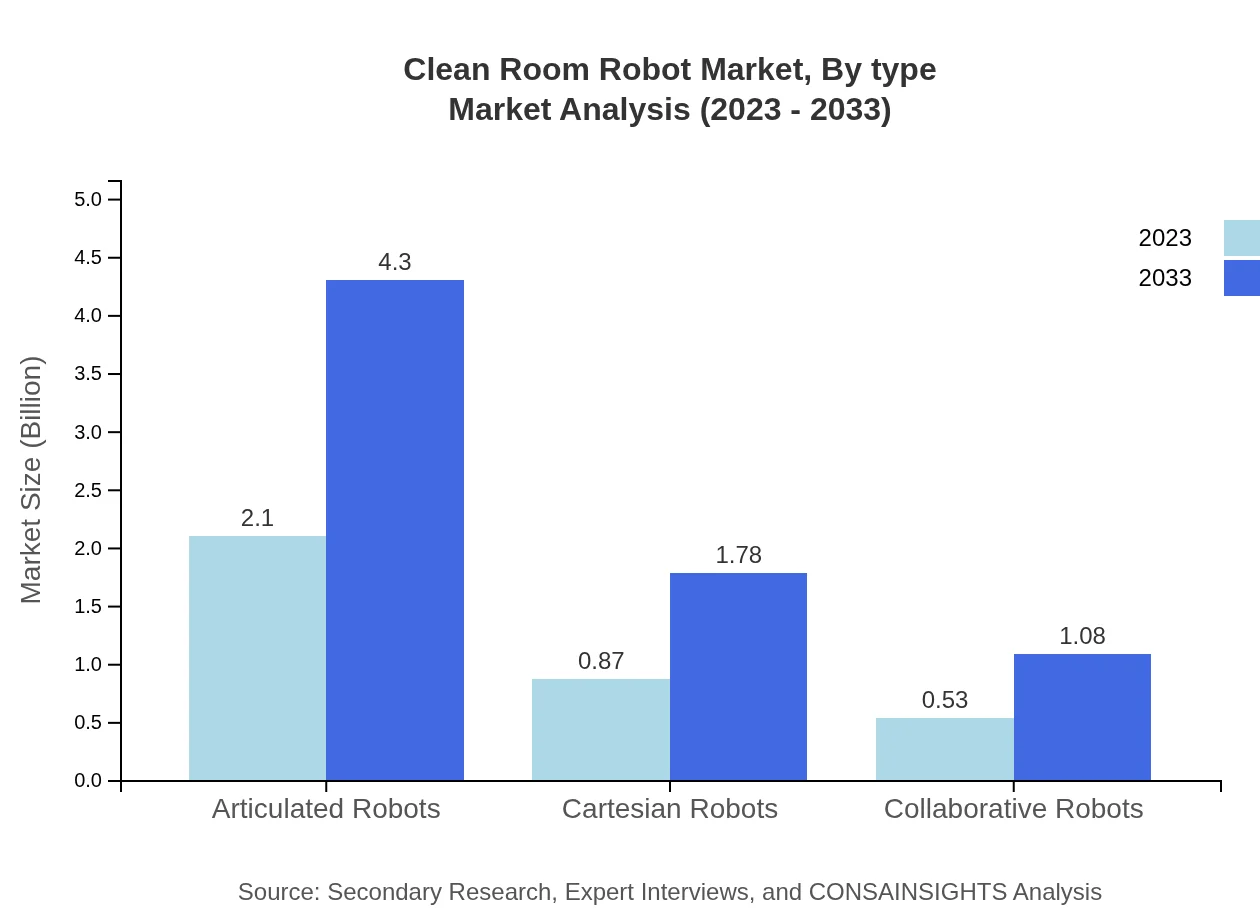

Clean Room Robot Market Analysis By Type

The Clean Room Robot market is segmented into articulated robots, cartesian robots, and collaborative robots. Articulated robots command a significant share, growing from $2.10 billion in 2023 to $4.30 billion by 2033, representing 60.04% market share. Cartesian robots also show robust growth, expanding from $0.87 billion to $1.78 billion and holding a 24.85% share. Collaborative robots, vital for enhancing human-robot interaction, are expected to grow from $0.53 billion to $1.08 billion, capturing 15.11% of the market.

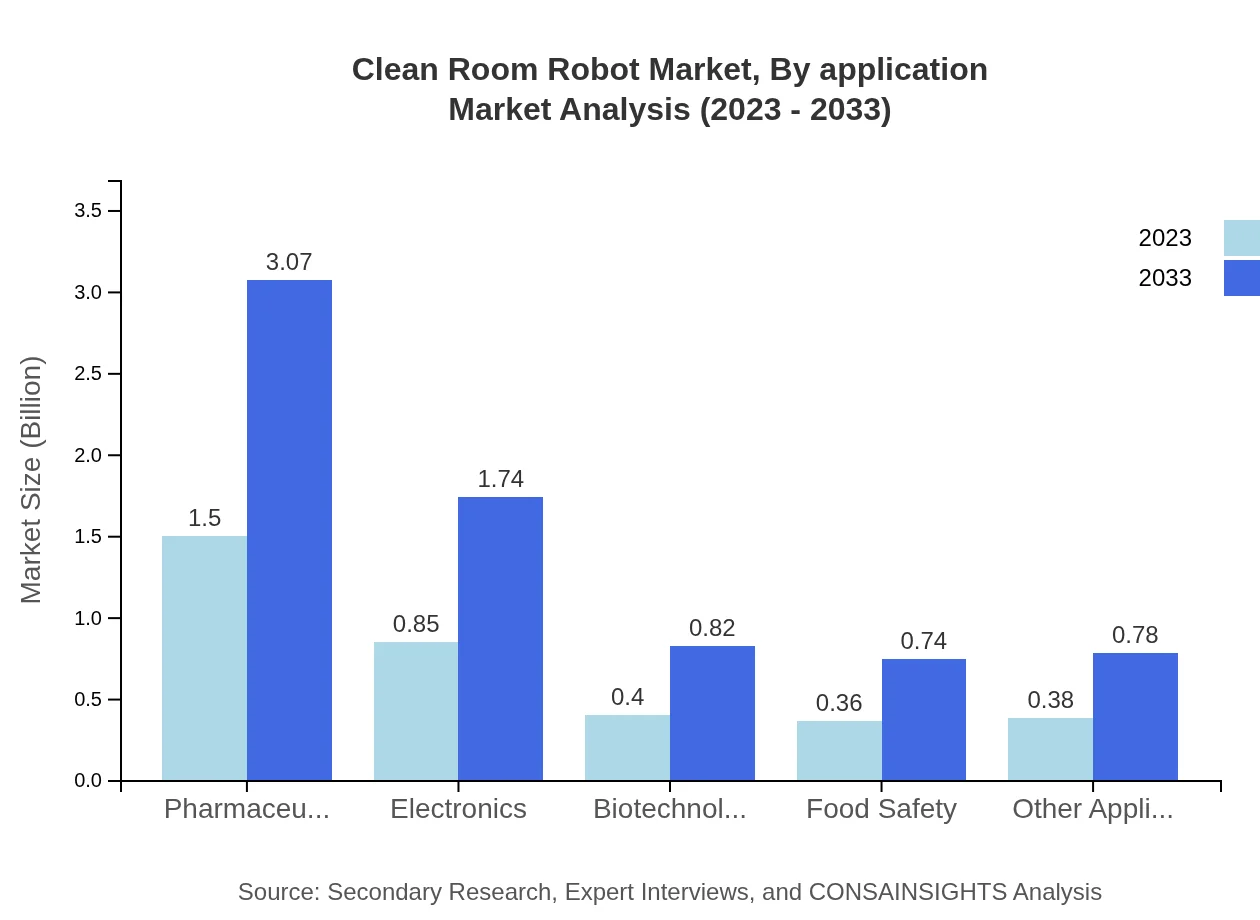

Clean Room Robot Market Analysis By Application

In terms of application, the Clean Room Robot market is significantly driven by sectors such as pharmaceuticals, where it is projected to grow from $2.10 billion to $4.30 billion through 2033. The electronics sector will also grow notably, reaching $1.78 billion from $0.87 billion. Other applications include biotechnology and medical devices, emphasizing the diverse use of clean room robotics across industries that require high cleanliness standards.

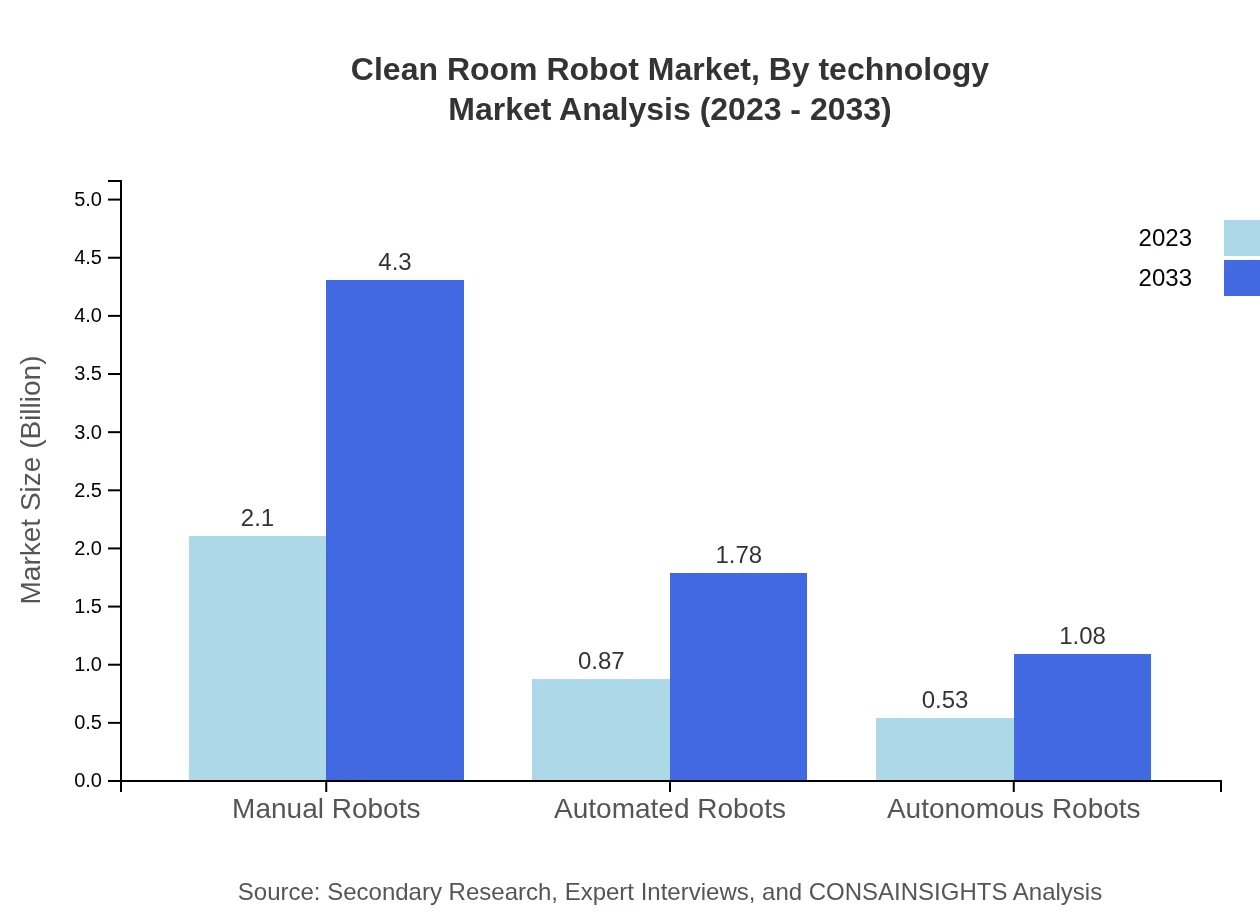

Clean Room Robot Market Analysis By Technology

The technology segment includes advancements in artificial intelligence, machine learning, and sensor integration that enhance the operational efficiency of clean room robots. Innovations such as autonomous operations and smart connectivity are expected to drive market growth, fostering more sophisticated applications in various industries.

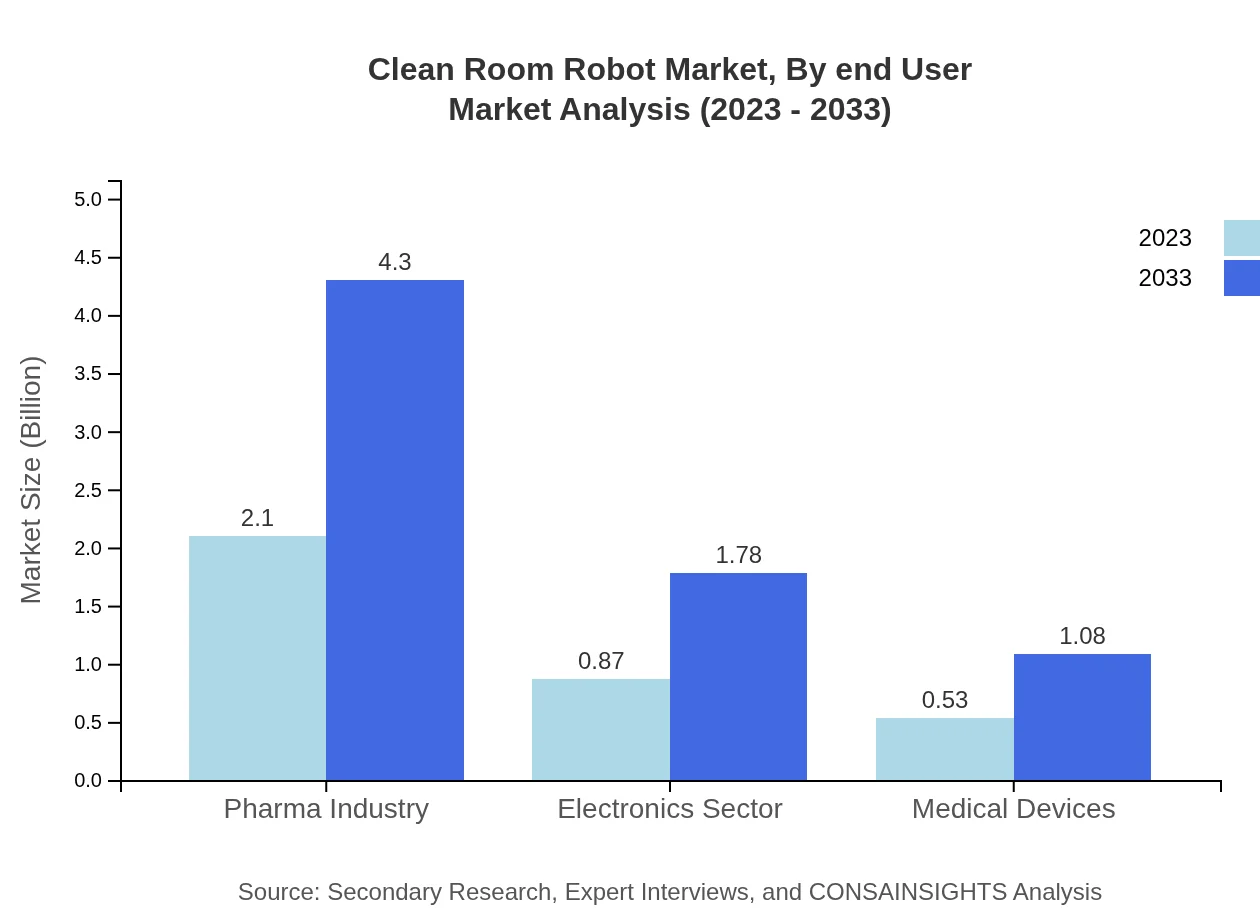

Clean Room Robot Market Analysis By End User

The end-user segment of Clean Room Robots encompasses industries such as pharmaceuticals, electronics, biotechnology, and food safety. The pharmaceutical industry leads with significant investments in automation due to the need for stringent compliance and efficiency, followed by electronics manufacturing, which increasingly demands automation to maintain product integrity.

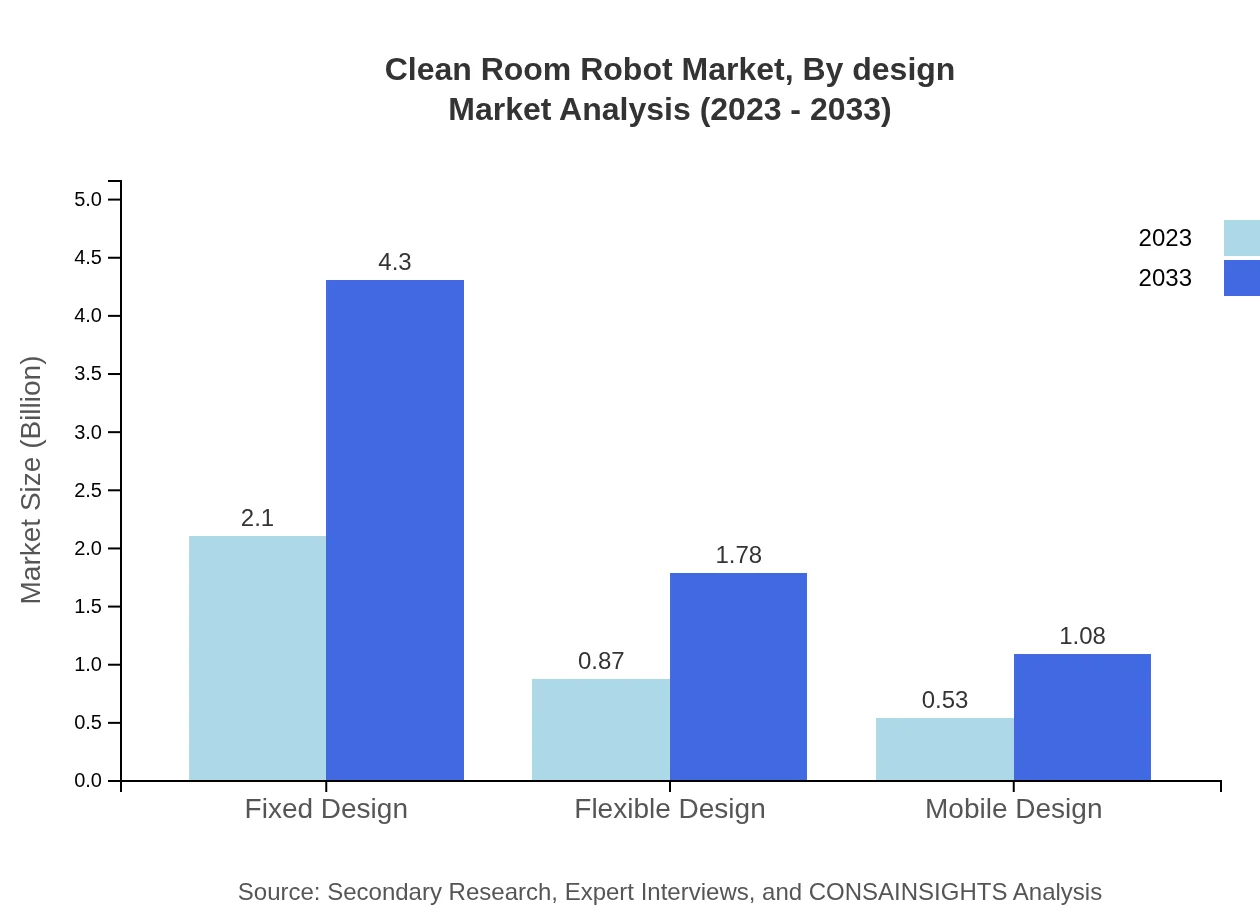

Clean Room Robot Market Analysis By Design

Clean Room Robots can be classified into fixed, flexible, and mobile designs. Fixed designs cover a substantial market share, particularly in manufacturing processes that require high precision and reliability. Flexible and mobile designs will grow significantly, offering adaptability in production environments and thereby enhancing overall operational competencies.

Clean Room Robot Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Clean Room Robot Industry

Fanuc Corporation:

A leading manufacturer of industrial robots, Fanuc specializes in automation solutions for clean environments, enhancing productivity while ensuring stringent cleanliness standards are met.KUKA AG:

KUKA is renowned for its innovative robotics solutions, offering cutting-edge clean room robots designed for precision tasks across various applications, particularly in the pharmaceuticals and electronics sectors.Yaskawa Electric Corporation:

Yaskawa is a pioneering robotics company that provides advanced clean room automation solutions, focusing on increasing efficiency and reducing contamination risks in manufacturing processes.We're grateful to work with incredible clients.

FAQs

What is the market size of clean Room Robot?

The clean-room robot market is projected to reach approximately $3.5 billion by 2033, growing at a CAGR of 7.2%. This growth reflects increasing adoption in various sectors, driven by heightened demand for automation and maintenance of sterile environments.

What are the key market players or companies in this clean Room Robot industry?

Key players in the clean-room robot industry include established robotics manufacturers, automation technology firms, and suppliers of specialized equipment. Companies are increasingly collaborating to enhance product offerings, thereby expanding their market presence.

What are the primary factors driving the growth in the clean Room robot industry?

The growth in the clean-room robot industry is primarily driven by advancements in automation technology, increasing regulatory compliance for cleanliness in manufacturing, and a rising demand for improved efficiency in sterile operations across various sectors.

Which region is the fastest Growing in the clean Room robot market?

The fastest-growing region in the clean-room robot market is Europe, expected to grow from $0.99 billion in 2023 to $2.03 billion by 2033. This growth is fueled by stringent regulatory standards for cleanliness in pharmaceuticals and electronics.

Does ConsaInsights provide customized market report data for the clean Room robot industry?

Yes, Consainsights provides customized market report data tailored to specific needs in the clean-room robot industry. Clients can obtain detailed insights and forecasts that encompass various aspects of the market.

What deliverables can I expect from this clean Room robot market research project?

Expected deliverables from the clean-room robot market research project include comprehensive market analysis, segment data, regional insights, competitor analysis, and detailed forecasts spanning different timelines and market behaviors.

What are the market trends of clean Room robots?

Current trends in the clean-room robot market include increased integration of AI and machine learning technologies, the shift towards collaborative robotic systems, and growing investments in research and development aimed at enhancing efficiency and reducing operational costs.