Cobot Market Report

Published Date: 31 January 2026 | Report Code: cobot

Cobot Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Cobot market, including insights into market trends, size, growth and future forecasts from 2023 to 2033, segmented analysis by product types and applications.

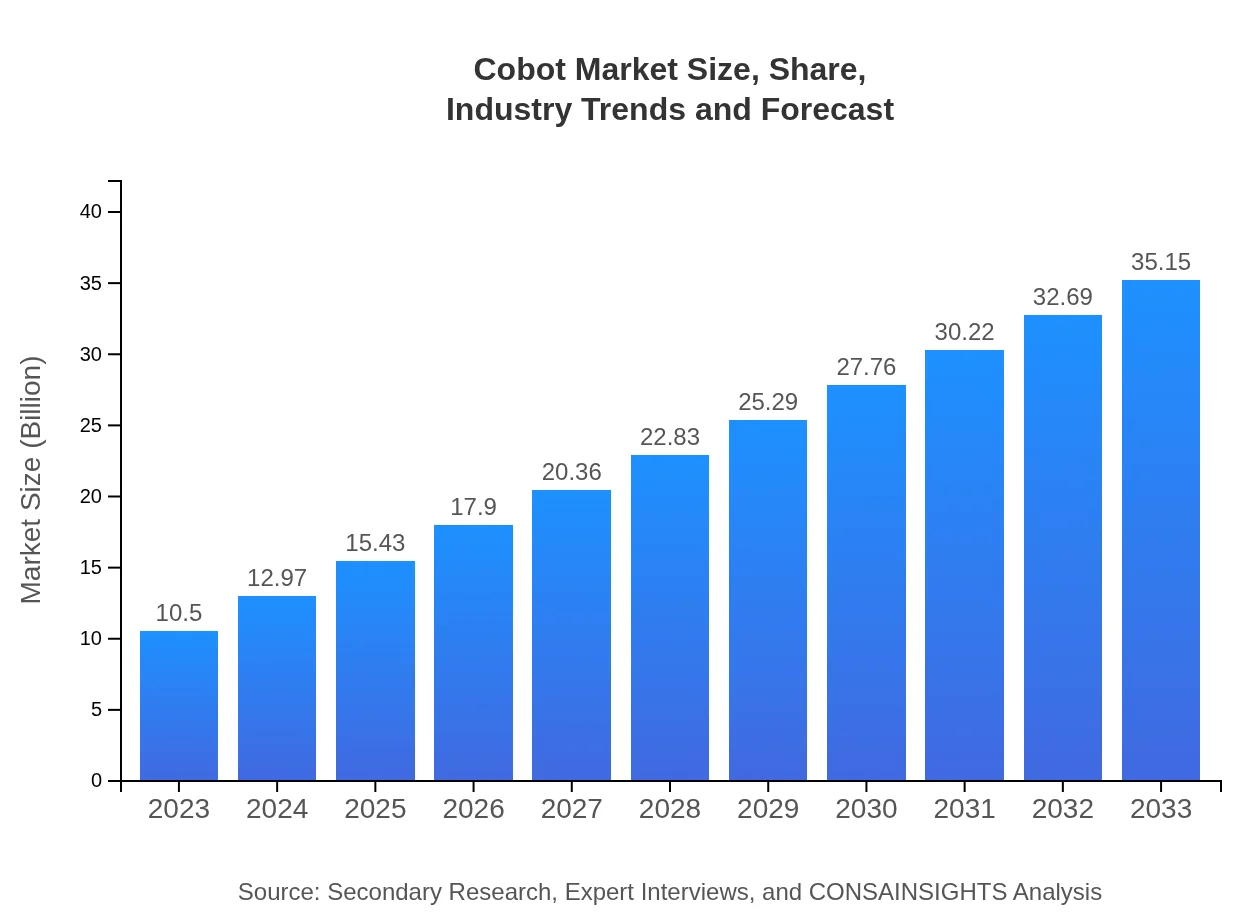

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $10.50 Billion |

| CAGR (2023-2033) | 12.3% |

| 2033 Market Size | $35.15 Billion |

| Top Companies | Universal Robots, KUKA AG, Rethink Robotics, FANUC |

| Last Modified Date | 31 January 2026 |

Cobot Market Overview

Customize Cobot Market Report market research report

- ✔ Get in-depth analysis of Cobot market size, growth, and forecasts.

- ✔ Understand Cobot's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Cobot

What is the Market Size & CAGR of Cobot market in 2023?

Cobot Industry Analysis

Cobot Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Cobot Market Analysis Report by Region

Europe Cobot Market Report:

The European Cobot market size was about $3.19 billion in 2023 and is expected to reach $10.69 billion by 2033. European countries are focusing on increasing their automation capabilities to meet sustainability targets and improve production processes which contributes to significant Cobot adoption.Asia Pacific Cobot Market Report:

In the Asia Pacific region, the Cobot market is expected to grow from $1.95 billion in 2023 to approximately $6.52 billion by 2033. This growth is driven by significant investments in automation technologies and infrastructure development across countries like China and Japan, aiming to enhance manufacturing capabilities.North America Cobot Market Report:

North America leads the Cobot market with a valuation of approximately $3.96 billion in 2023, projected to grow to $13.27 billion by 2033. This region benefits from advanced technological infrastructure and high demand for automation in sectors such as automotive and electronics manufacturing.South America Cobot Market Report:

The South American Cobot market was valued at $0.89 billion in 2023, with projections to reach $2.98 billion in 2033. The drive for automation in industries such as agriculture and manufacturing is propelling the adoption of Cobots, improved efficiency, and productivity.Middle East & Africa Cobot Market Report:

The Middle East and Africa Cobot market, valued at $0.50 billion in 2023, is anticipated to grow to $1.69 billion by 2033. The growth is primarily driven by increased investment in automation and technological innovation in sectors like logistics and healthcare.Tell us your focus area and get a customized research report.

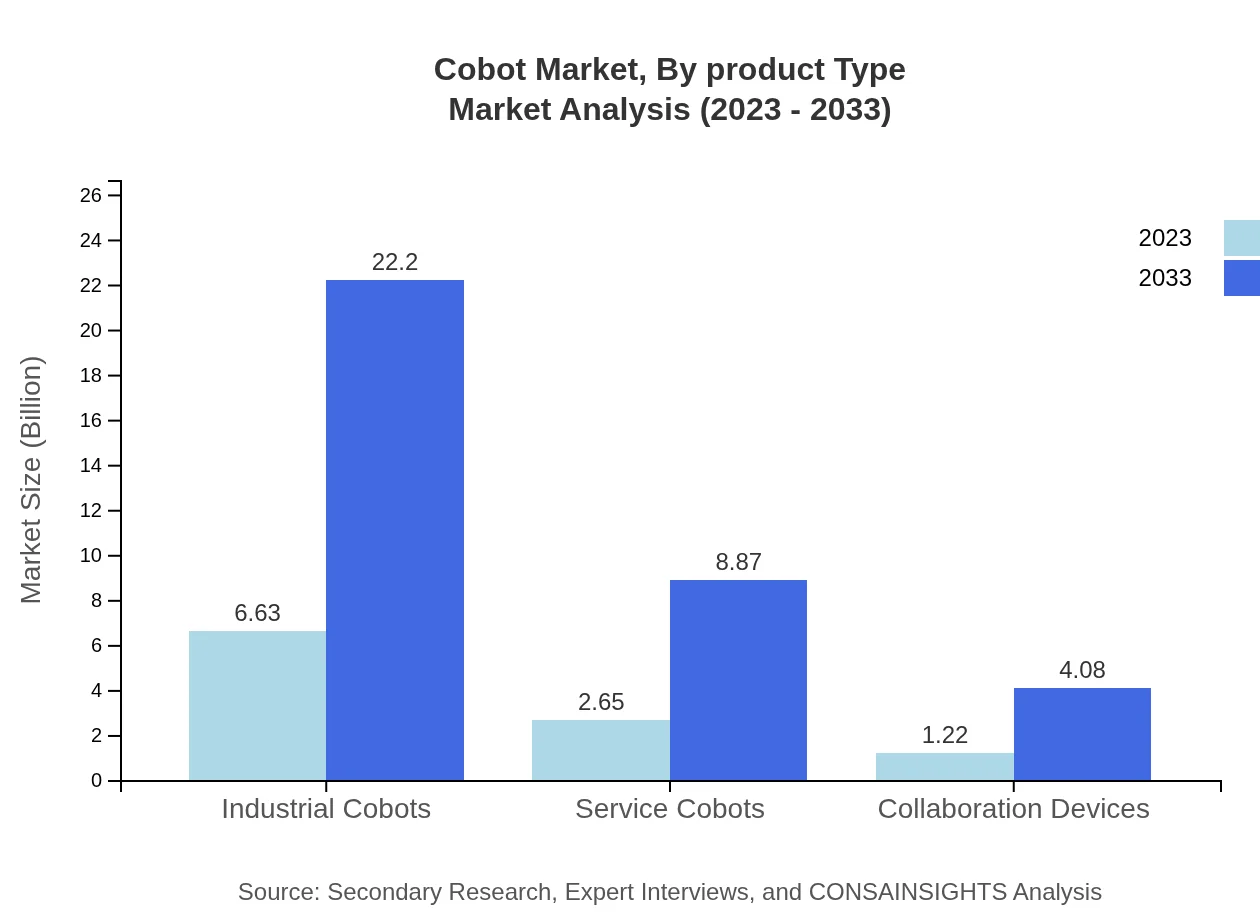

Cobot Market Analysis By Product Type

The Cobot market is dominated by Industrial Cobots, expected to grow from $6.63 billion in 2023 to $22.20 billion by 2033, holding 63.15% market share. Service Cobots follow, displaying significant growth from $2.65 billion to $8.87 billion, representing a 25.23% market share. Both types epitomize the market's versatility and its increasing applicability across various fields.

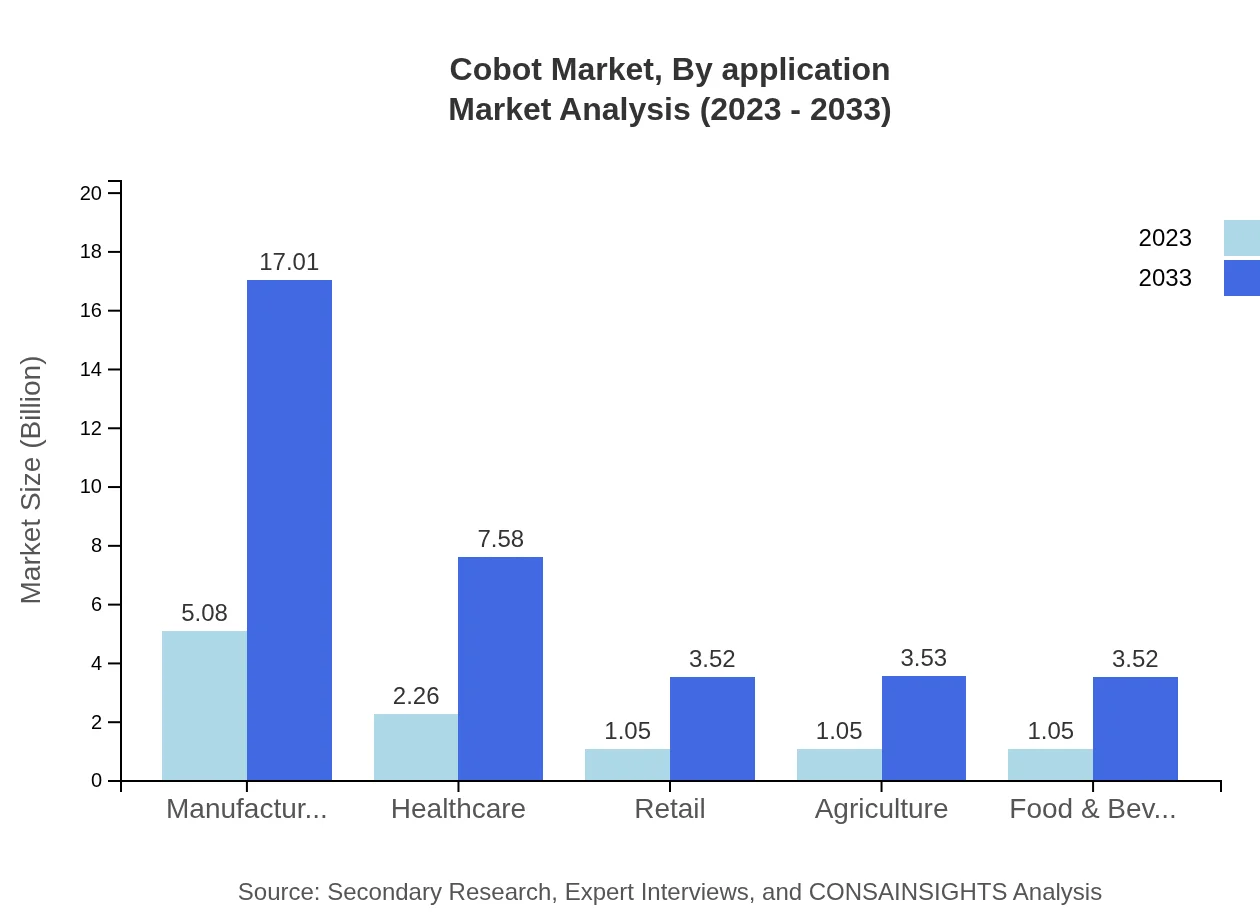

Cobot Market Analysis By Application

Applications of Cobots include Manufacturing, Healthcare, Retail, and others. The manufacturing segment currently commands the largest share at 48.38%, with market size projected to grow substantially from $5.08 billion to $17.01 billion over the forecast period. Healthcare applications are gaining traction, with estimates indicating growth from $2.26 billion to $7.58 billion, thereby representing 21.57% share.

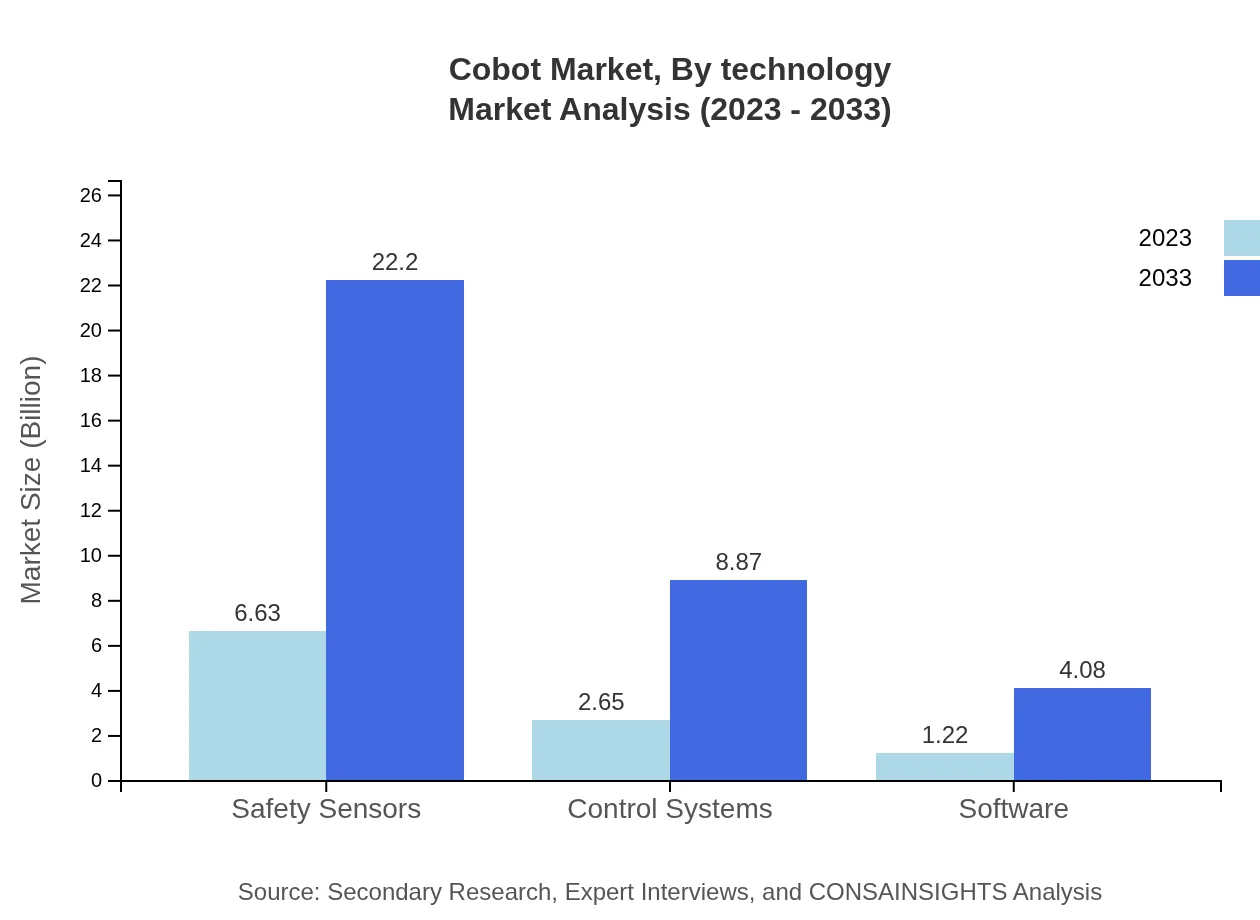

Cobot Market Analysis By Technology

The Cobot market is increasingly characterized by advanced technologies, such as AI and machine learning systems, enhancing Cobots' capabilities. Technologies used include control systems, software for programming and operations, and safety sensors. Safety sensors stand out, growing from $6.63 billion in 2023 to $22.20 billion by 2033, indicating heightened demand for safety-focused Cobots.

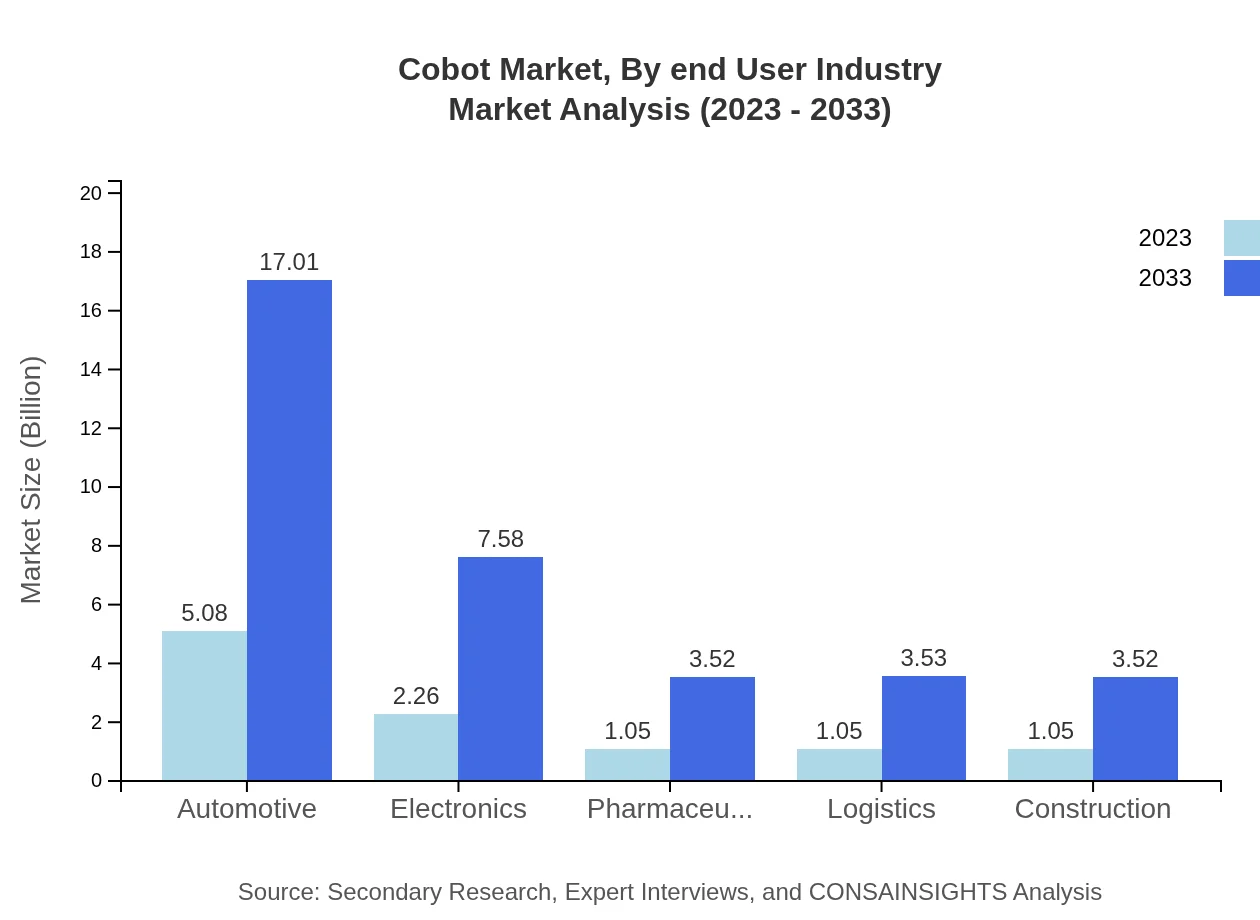

Cobot Market Analysis By End User Industry

Different end-user industries such as Automotive, Electronics, and Pharmaceuticals significantly utilize Cobots. The automotive sector alone accounted for a market size of $5.08 billion in 2023 and is expected to grow to $17.01 billion by 2033. This reflects automotive manufacturers’ innovations to improve assembly line efficiency through Cobots.

Cobot Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Cobot Industry

Universal Robots:

A pioneer in the Cobot space, Universal Robots offers a comprehensive range of flexible, easy-to-use collaborative robots that help companies automate their operations effectively.KUKA AG:

KUKA AG provides innovative Cobot solutions targeting versatile applications in industries such as automotive, healthcare, and logistics, emphasizing efficiency and productivity.Rethink Robotics:

Known for its friendly and intelligent Cobot, Baxter, Rethink Robotics offers user-friendly solutions aimed at streamlining manufacturing processes while safely collaborating with human workers.FANUC:

FANUC delivers top-tier automation and Cobot technologies, focusing on tailored solutions that optimize manufacturing efficiency across various sectors.We're grateful to work with incredible clients.

FAQs

What is the market size of cobot?

The global cobot market is estimated to reach a size of $10.5 billion by 2033, expanding at a CAGR of 12.3% from 2023. This growth reflects the rising adoption of collaborative robots across various industries for automation.

What are the key market players or companies in the cobot industry?

Key players in the cobot market include industry giants such as Universal Robots, KUKA AG, Rethink Robotics, and Fanuc Corporation, all of which are leading the innovation and deployment of cobots in various sectors.

What are the primary factors driving the growth in the cobot industry?

Growth in the cobot industry is driven by increased demand for automation, the need for safety in workplaces, and the rise in labor shortages. Enhanced productivity and efficiency contribute significantly to the adoption of cobots.

Which region is the fastest Growing in the cobot market?

The Asia Pacific region is anticipated to experience the fastest growth in the cobot market, projected to expand from $1.95 billion in 2023 to $6.52 billion by 2033, driven by increased manufacturing activities.

Does ConsaInsights provide customized market report data for the cobot industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs in the cobot industry, ensuring comprehensive insights for stakeholders to inform their strategic decisions.

What deliverables can I expect from this cobot market research project?

From this cobot market research project, you can expect detailed reports, market analysis, growth forecasts, segmented data, and strategic recommendations to better understand the market landscape.

What are the market trends of cobot?

Current trends in the cobot market include a focus on safety and collaboration, advancements in AI and machine learning, and expansion across industries like manufacturing, healthcare, and logistics.