Commercial Aircraft Floor Panels Market Report

Published Date: 03 February 2026 | Report Code: commercial-aircraft-floor-panels

Commercial Aircraft Floor Panels Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Commercial Aircraft Floor Panels market from 2023 to 2033, detailing market size, growth trends, regional insights, and competitive landscape, along with future forecasts and technological advancements.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

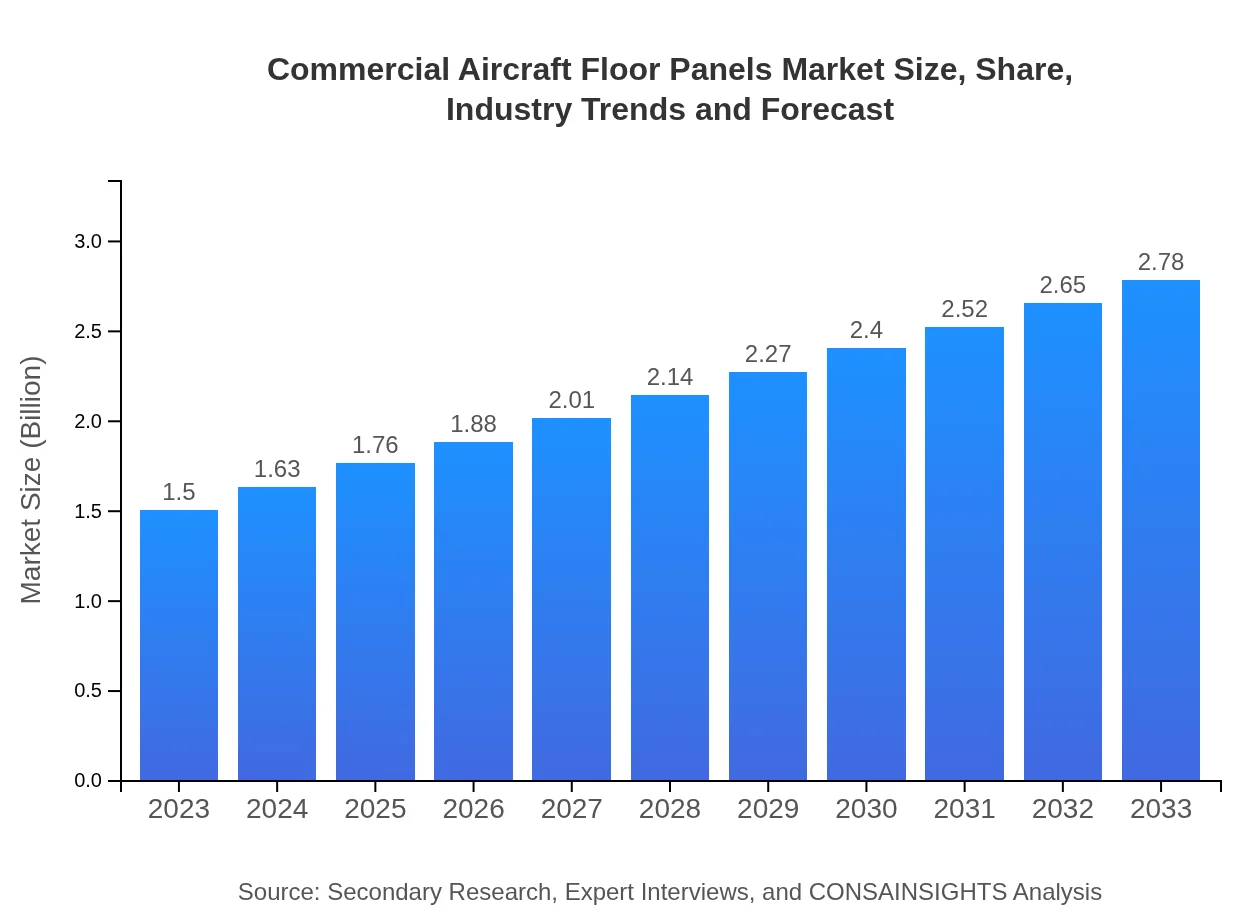

| 2023 Market Size | $1.50 Billion |

| CAGR (2023-2033) | 6.2% |

| 2033 Market Size | $2.78 Billion |

| Top Companies | Boeing , Airbus, Hexcel Corporation, Mitsubishi Chemical |

| Last Modified Date | 03 February 2026 |

Commercial Aircraft Floor Panels Market Overview

Customize Commercial Aircraft Floor Panels Market Report market research report

- ✔ Get in-depth analysis of Commercial Aircraft Floor Panels market size, growth, and forecasts.

- ✔ Understand Commercial Aircraft Floor Panels's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Commercial Aircraft Floor Panels

What is the Market Size & CAGR of Commercial Aircraft Floor Panels market in 2023?

Commercial Aircraft Floor Panels Industry Analysis

Commercial Aircraft Floor Panels Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Commercial Aircraft Floor Panels Market Analysis Report by Region

Europe Commercial Aircraft Floor Panels Market Report:

In 2023, Europe holds a market value of $0.36 billion, with a forecasted growth to $0.67 billion by 2033, propelled by stringent regulations with respect to safety standards and sustainability, along with a strong focus on enhancing passenger experience.Asia Pacific Commercial Aircraft Floor Panels Market Report:

In 2023, the Asia Pacific market is valued at $0.30 billion, expecting to reach $0.55 billion by 2033, driven by a growing number of commercial aircraft orders and increasing air travel demand within the region. Companies are initiating more local partnerships, enhancing manufacturing capabilities, and focusing on innovation and lightweight materials.North America Commercial Aircraft Floor Panels Market Report:

With 2023 market value at $0.48 billion growing to $0.89 billion by 2033, the North American region remains a significant player due to the presence of major aircraft manufacturers, a robust airline industry, and high spending on aircraft upgrades.South America Commercial Aircraft Floor Panels Market Report:

The South American market is valued at $0.15 billion in 2023, projected to grow to $0.28 billion by 2033. Economic growth in countries like Brazil and Chile, alongside increasing connectivity and enhancements in regional airlines, contributes to this market expansion.Middle East & Africa Commercial Aircraft Floor Panels Market Report:

The Middle East and Africa market, valued at $0.21 billion in 2023, is expected to reach $0.39 billion by 2033, driven by the region's burgeoning tourism and commerce requiring increased capacity in aviation and upgraded aircraft interiors.Tell us your focus area and get a customized research report.

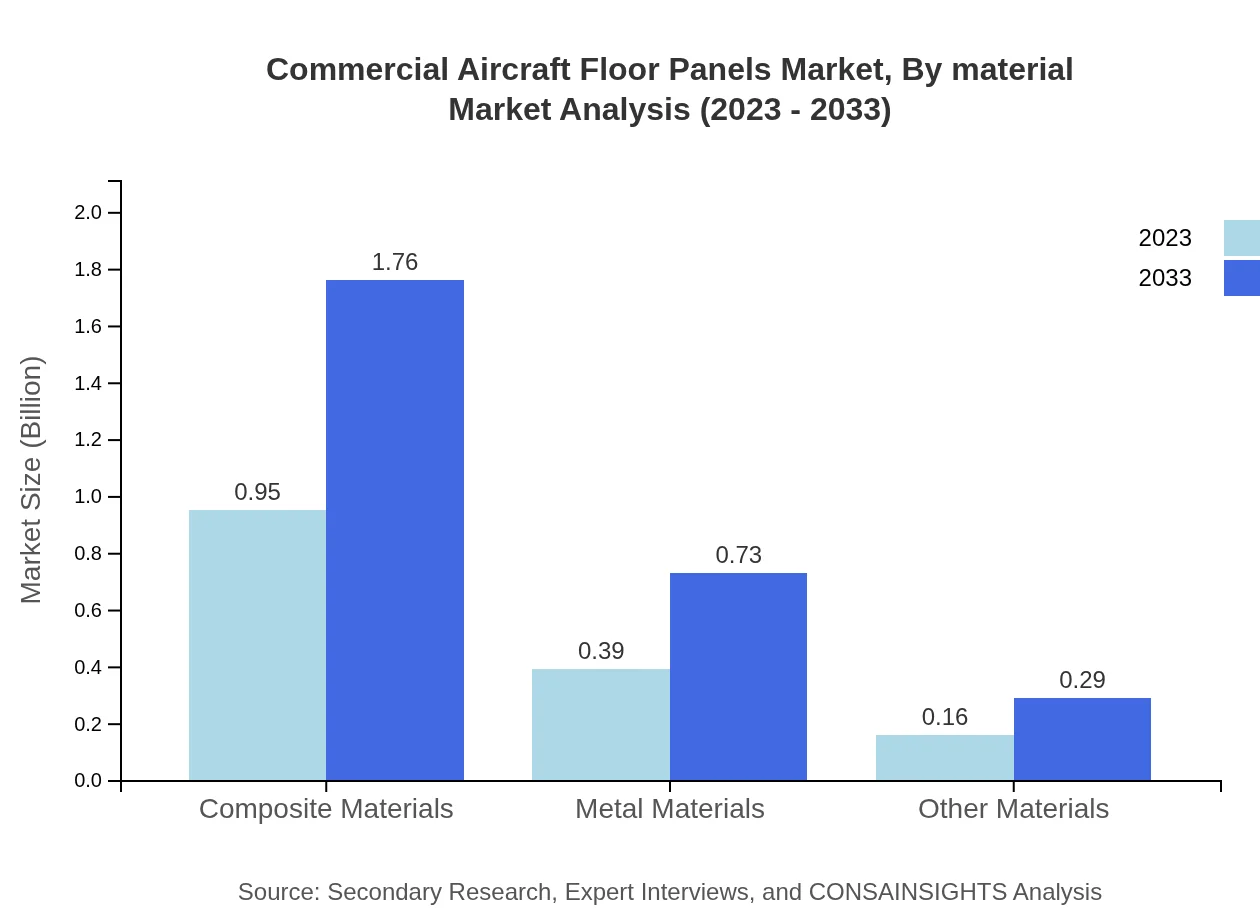

Commercial Aircraft Floor Panels Market Analysis By Material

In terms of materials, the composite segment dominates with a market size of $0.95 billion in 2023, estimated to grow to $1.76 billion in 2033. Metal materials follow with a market forecast from $0.39 billion to $0.73 billion. The functionality, weight savings, and performance of composite materials are primary drivers in this category.

Commercial Aircraft Floor Panels Market Analysis By Application

Global Commercial Aircraft Floor Panels Market, By Application Market Analysis (2023 - 2033)

Cargo areas contribute significantly to the market with a share of 53.67% in 2023. This area is expected to expand from $0.81 billion to $1.49 billion by 2033. The passenger areas follow closely with 22.52% share, growing steadily due to increasing air travel, demanding better comfort and aesthetics.

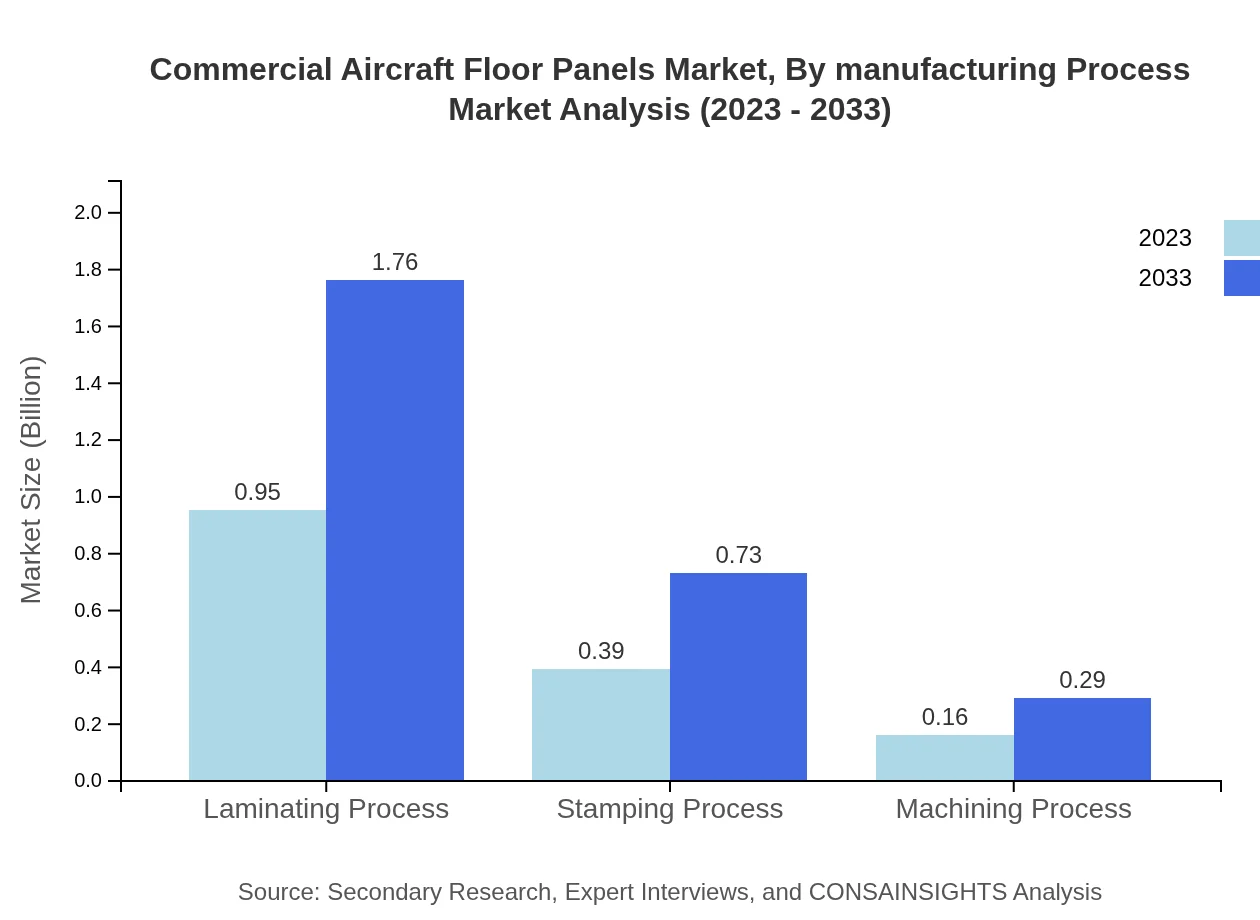

Commercial Aircraft Floor Panels Market Analysis By Manufacturing Process

Laminating processes dominate with a market size of $0.95 billion in 2023, growing to $1.76 billion by 2033, while stamping and machining processes also play critical roles in manufacturing efficiency and cost competitiveness in the industry.

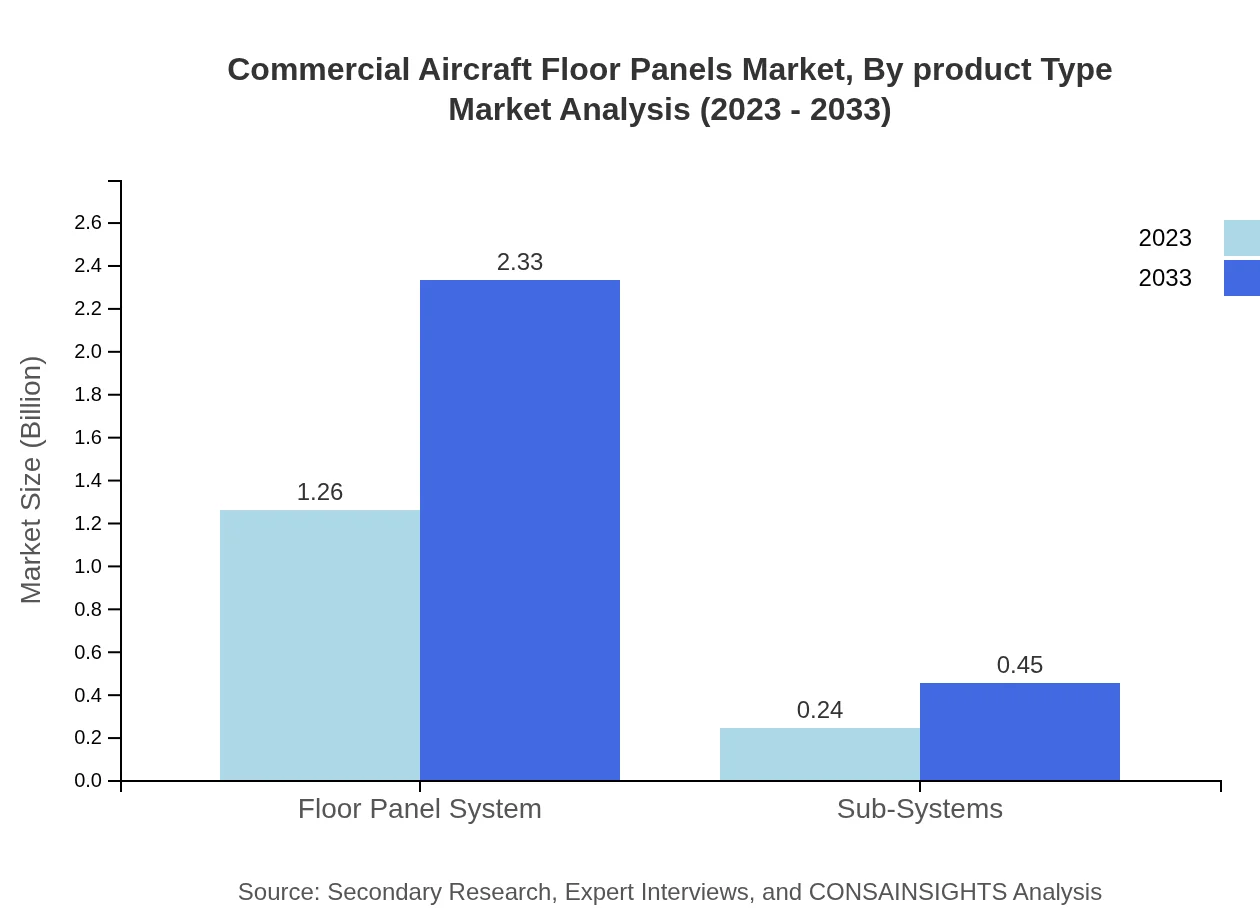

Commercial Aircraft Floor Panels Market Analysis By Product Type

Floor panel systems lead the market with a growth from $1.26 billion in 2023 to $2.33 billion in 2033, attributed to their essential role in aircraft structures while sub-systems contribute as well, showing steady demand across applications.

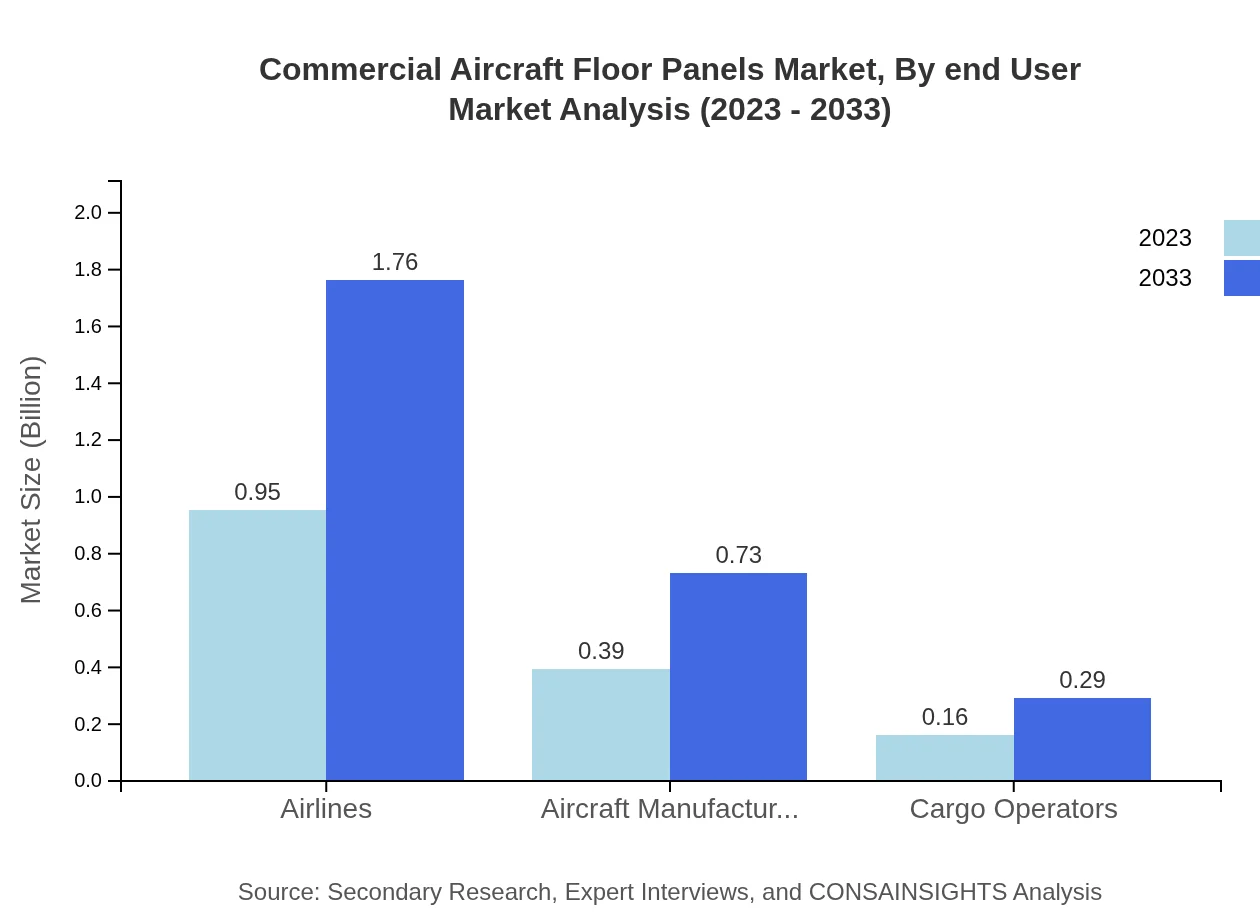

Commercial Aircraft Floor Panels Market Analysis By End User

Airlines account for a substantial share of the market at 63.27% in 2023, highlighting their dependence on efficient operational models that rely on modernized and safe aircraft interiors resulting in growth from $0.95 billion to $1.76 billion by 2033.

Commercial Aircraft Floor Panels Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Commercial Aircraft Floor Panels Industry

Boeing :

A leading global aerospace company known for its innovative designs and manufacturing of commercial aircraft, including high-quality floor panels that meet stringent industry standards.Airbus:

A major player in the aerospace industry, Airbus designs and manufactures commercial aircraft with advanced floor panel technologies, focusing on weight reduction and passenger comfort.Hexcel Corporation:

Specializes in advanced composites and engineered materials, providing lightweight floor panel solutions by leveraging innovative technology in the aviation sector.Mitsubishi Chemical:

Known for high-performance materials, Mitsubishi Chemical delivers advanced floor panel products that cater to the evolving demands of the aviation industry.We're grateful to work with incredible clients.

FAQs

What is the market size of commercial Aircraft Floor Panels?

The commercial aircraft floor panels market is valued at approximately $1.5 billion in 2023 and is projected to grow at a CAGR of 6.2% through to 2033.

What are the key market players or companies in this commercial Aircraft Floor Panels industry?

Key players in the commercial aircraft floor panels market include major aircraft manufacturers, aftermarket suppliers, and companies specializing in advanced material technologies. They drive innovation and compete for market share.

What are the primary factors driving the growth in the commercial Aircraft Floor Panels industry?

Growth factors include increasing air travel demand, advancements in lightweight materials, and regulatory compliance for safety and efficiency. The need for modernized aircraft interiors also fuels market expansion.

Which region is the fastest Growing in the commercial Aircraft Floor Panels?

North America is the fastest-growing region, with the market expected to rise from $0.48 billion in 2023 to $0.89 billion by 2033, highlighting significant investment in aircraft technology and upgrades.

Does ConsaInsights provide customized market report data for the commercial Aircraft Floor Panels industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs within the commercial aircraft floor panels industry, ensuring comprehensive insights for stakeholder decision-making.

What deliverables can I expect from this commercial Aircraft Floor Panels market research project?

Expect in-depth analysis reports, market size forecasts, competitive landscape insights, regional data breakdown, and trend analysis focusing on key segments within the commercial aircraft floor panels market.

What are the market trends of commercial Aircraft Floor Panels?

Current trends include a shift towards lightweight and durable materials, sustainability considerations in manufacturing, integration of advanced technologies, and increased investment in aircraft modernization post-pandemic.