Composite Bearings Market Report

Published Date: 22 January 2026 | Report Code: composite-bearings

Composite Bearings Market Size, Share, Industry Trends and Forecast to 2033

This report covers the comprehensive analysis of the Composite Bearings market from 2023 to 2033, offering insights into market trends, size, segmentation, regional analysis, and projected growth opportunities.

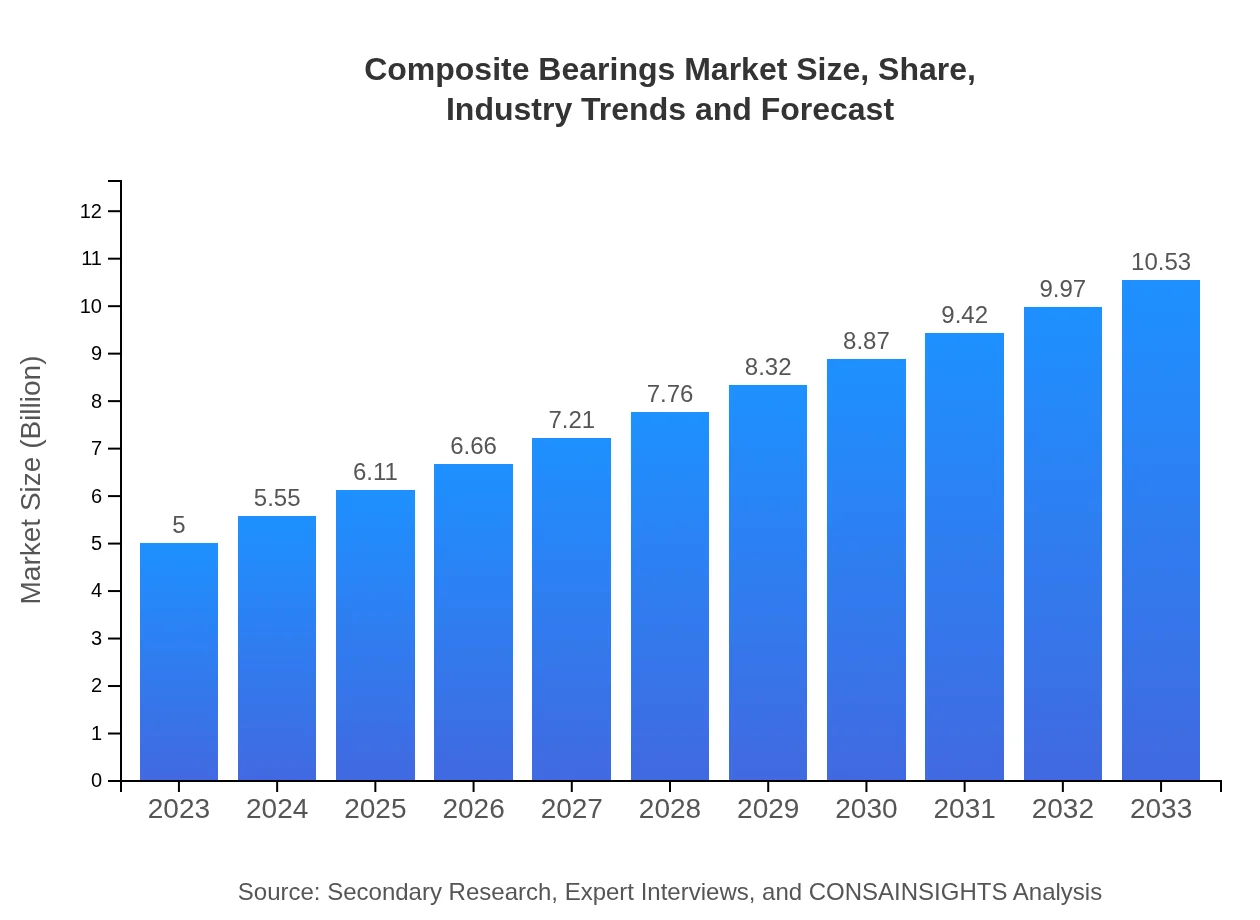

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.00 Billion |

| CAGR (2023-2033) | 7.5% |

| 2033 Market Size | $10.53 Billion |

| Top Companies | SKF Group, JTEKT Corporation, Thordon Bearings |

| Last Modified Date | 22 January 2026 |

Composite Bearings Market Overview

Customize Composite Bearings Market Report market research report

- ✔ Get in-depth analysis of Composite Bearings market size, growth, and forecasts.

- ✔ Understand Composite Bearings's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Composite Bearings

What is the Market Size & CAGR of Composite Bearings market in 2023?

Composite Bearings Industry Analysis

Composite Bearings Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Composite Bearings Market Analysis Report by Region

Europe Composite Bearings Market Report:

Europe’s market for Composite Bearings is poised to see a rise from $1.37 billion in 2023 to $2.89 billion by 2033. Sustainability trends and stringent regulations are pushing manufacturers towards composite materials, particularly in automotive and renewable energy applications.Asia Pacific Composite Bearings Market Report:

In the Asia Pacific region, the Composite Bearings market is expected to grow from $0.94 billion in 2023 to $1.98 billion by 2033. This surge is propelled by the booming automotive and industrial sectors in countries like China and India, with increased investments in infrastructure and manufacturing activities driving demand.North America Composite Bearings Market Report:

Expected to grow substantially from $1.94 billion in 2023 to $4.08 billion by 2033, the North American market is characterized by technological advancements in aerospace and automotive sectors, where high-performance composite bearings are increasingly being adopted.South America Composite Bearings Market Report:

The South American market, although smaller in comparison, shows promising growth from $0.43 billion in 2023 to $0.90 billion in 2033. The regional demand is primarily influenced by growth in the mining and agricultural machinery industries, necessitating robust bearing solutions.Middle East & Africa Composite Bearings Market Report:

The Middle East and Africa region is projected to grow from $0.32 billion in 2023 to $0.67 billion in 2033. The increasing need for durable and efficient bearings in oil and gas industries is expected to drive demand in this region.Tell us your focus area and get a customized research report.

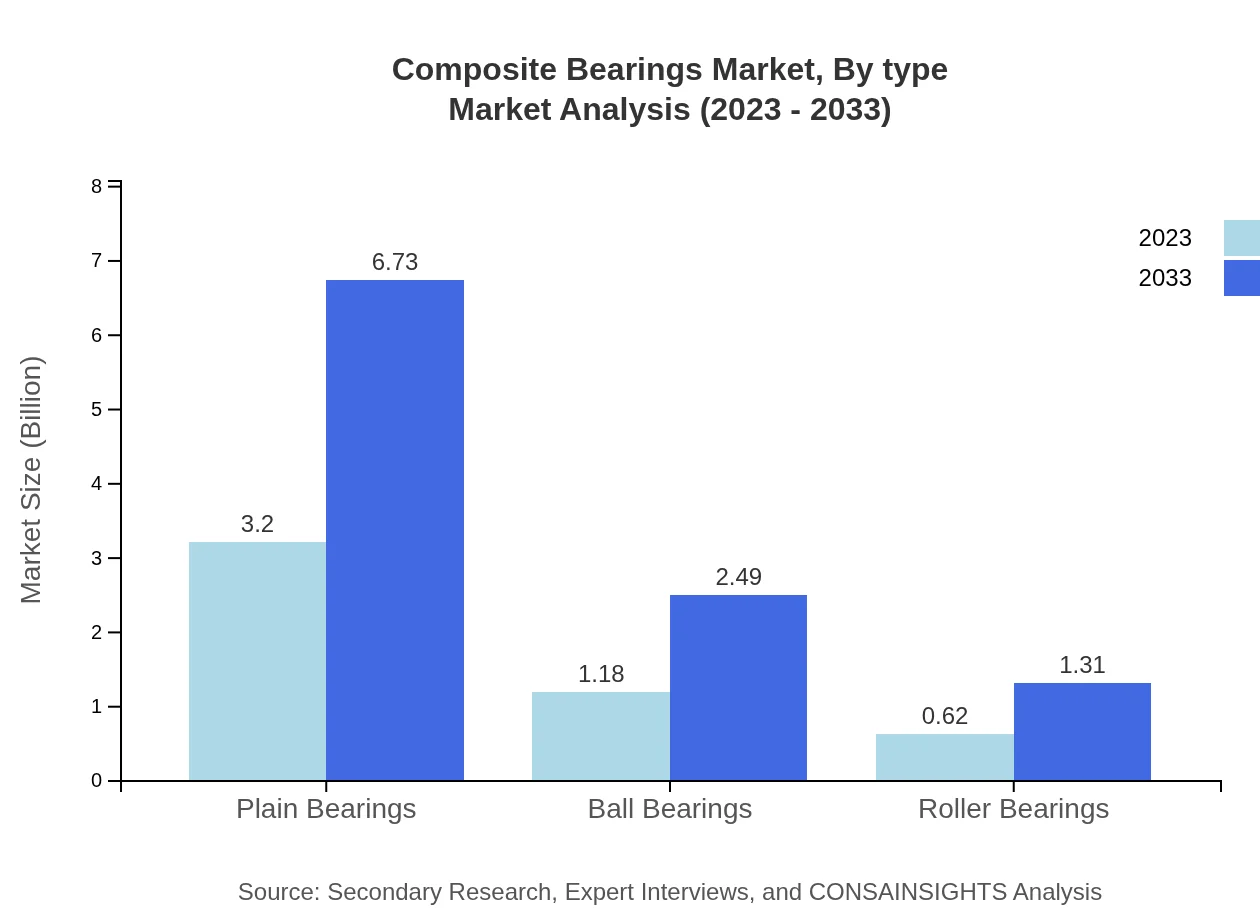

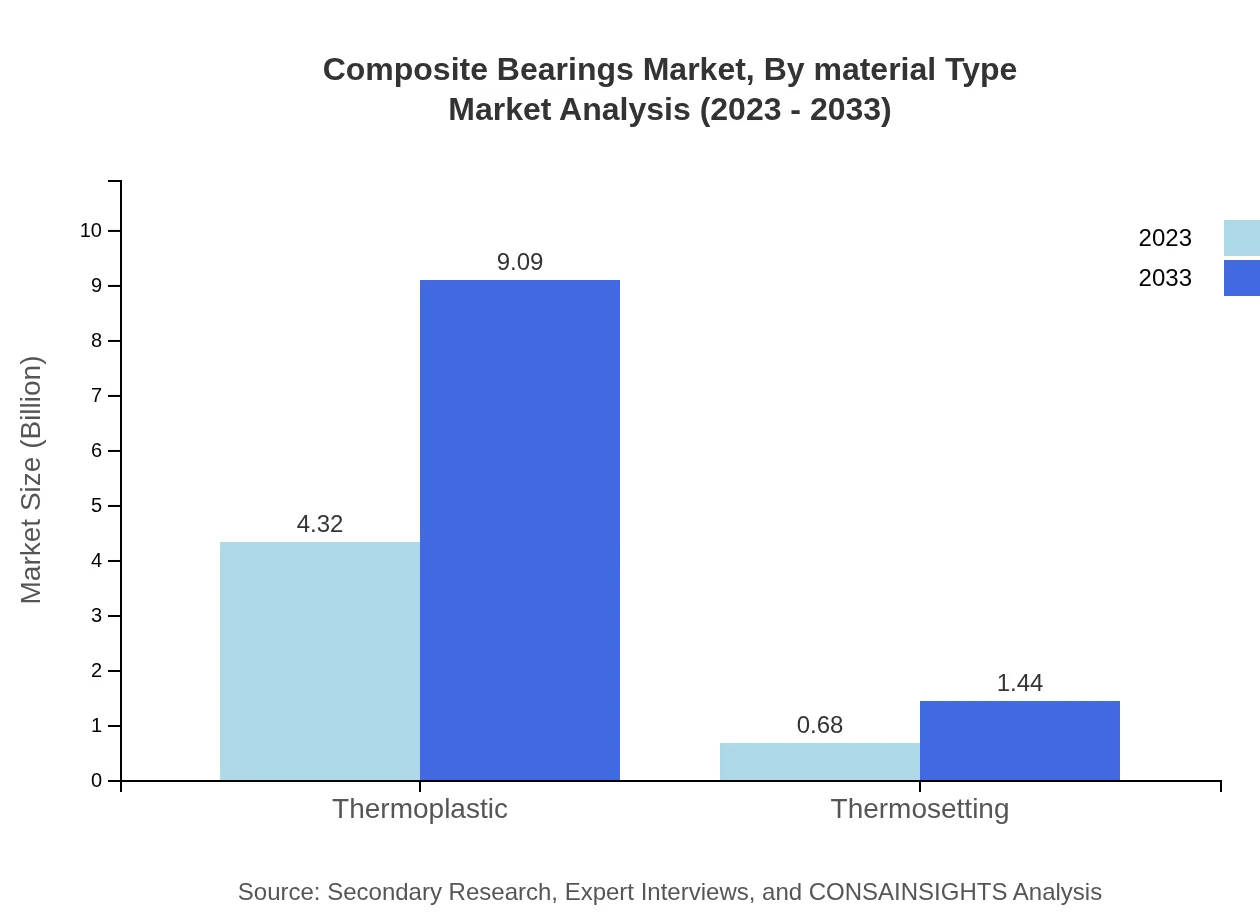

Composite Bearings Market Analysis By Type

The major types in the Composite Bearings market are Thermoplastic and Thermosetting composites. In 2023, Thermoplastic composites hold a substantial market size of $4.32 billion, expected to grow to $9.09 billion by 2033, capturing around 86.33% of the market share. On the other hand, Thermosetting composites, valued at $0.68 billion in 2023, are projected to reach $1.44 billion by 2033, holding 13.67% market share.

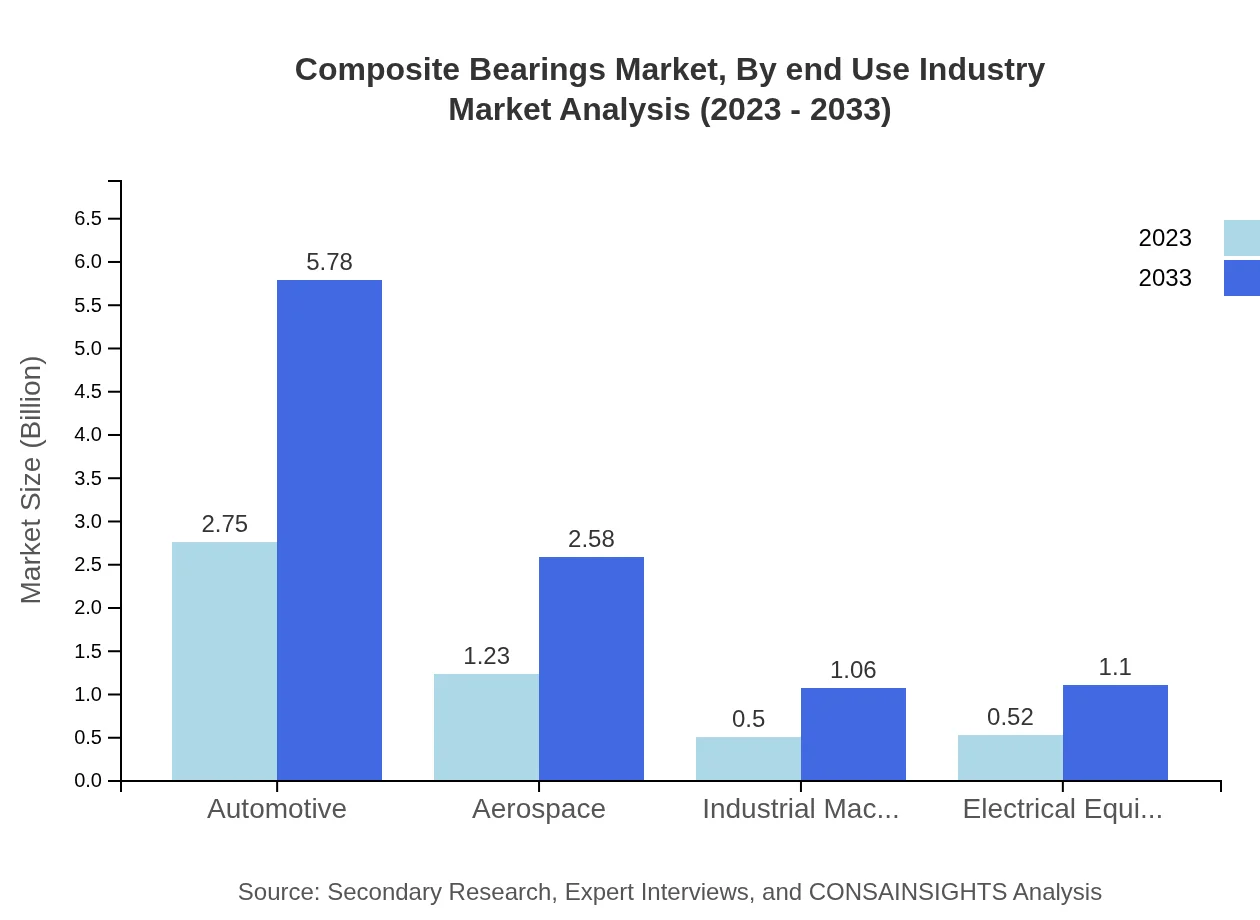

Composite Bearings Market Analysis By End Use Industry

In terms of end-use, the automotive segment is the largest, valued at $2.75 billion in 2023 and expected to reach $5.78 billion by 2033, representing 54.96% market share. Aerospace follows with a size of $1.23 billion in 2023, projected to grow to $2.58 billion by 2033 (24.52% share), while industrial machinery and electrical equipment are also significant contributors.

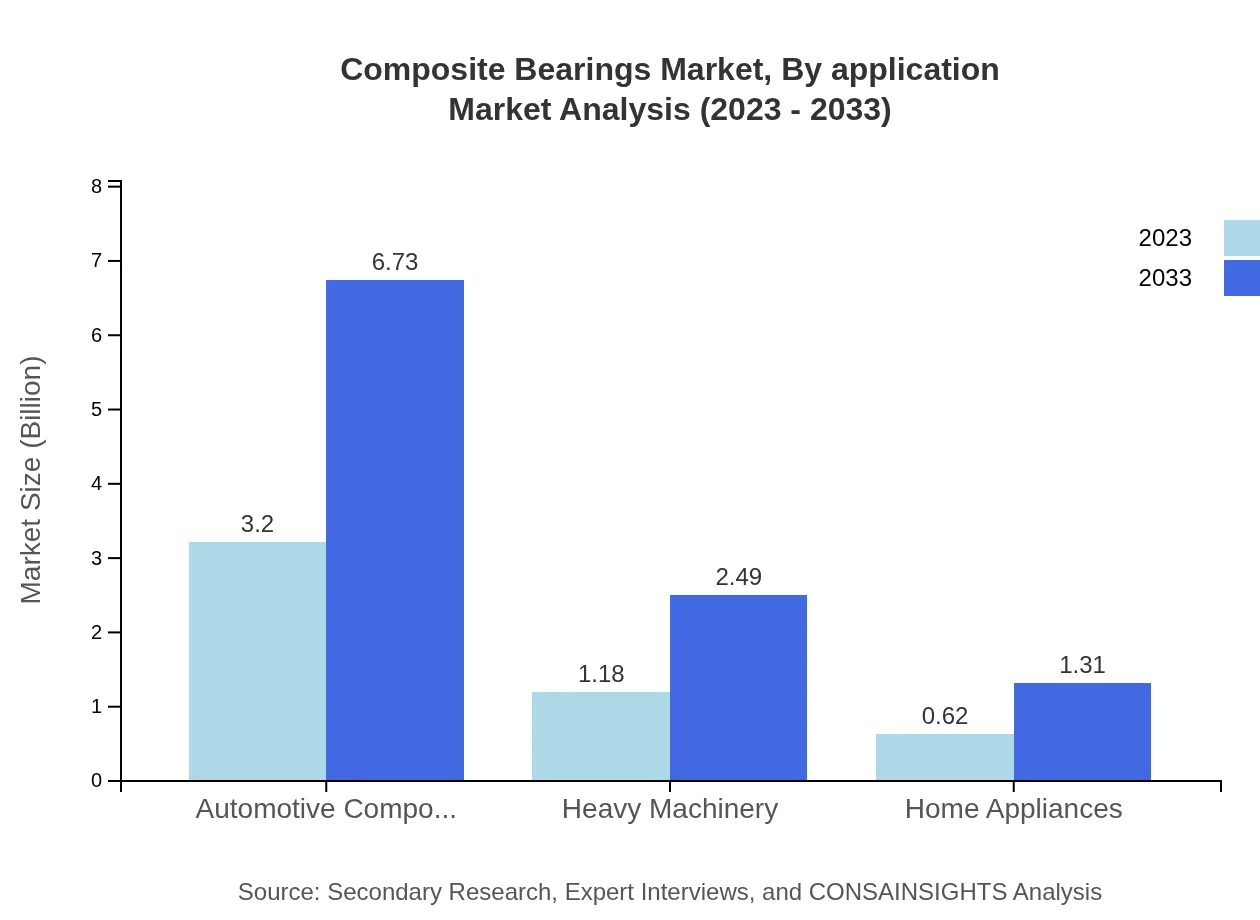

Composite Bearings Market Analysis By Application

The applications of Composite Bearings cut across various sectors, with automotive components leading at a market size of $3.20 billion in 2023, anticipated to increase to $6.73 billion by 2033. Heavy machinery and home appliances also represent vital application sectors.

Composite Bearings Market Analysis By Material Type

The Composite Bearings market bifurcates into Thermoplastic and Thermosetting materials, with Thermochemical materials leading in applications. The durability and performance characteristics of these materials directly influence their acceptance across industries like automotive and aerospace.

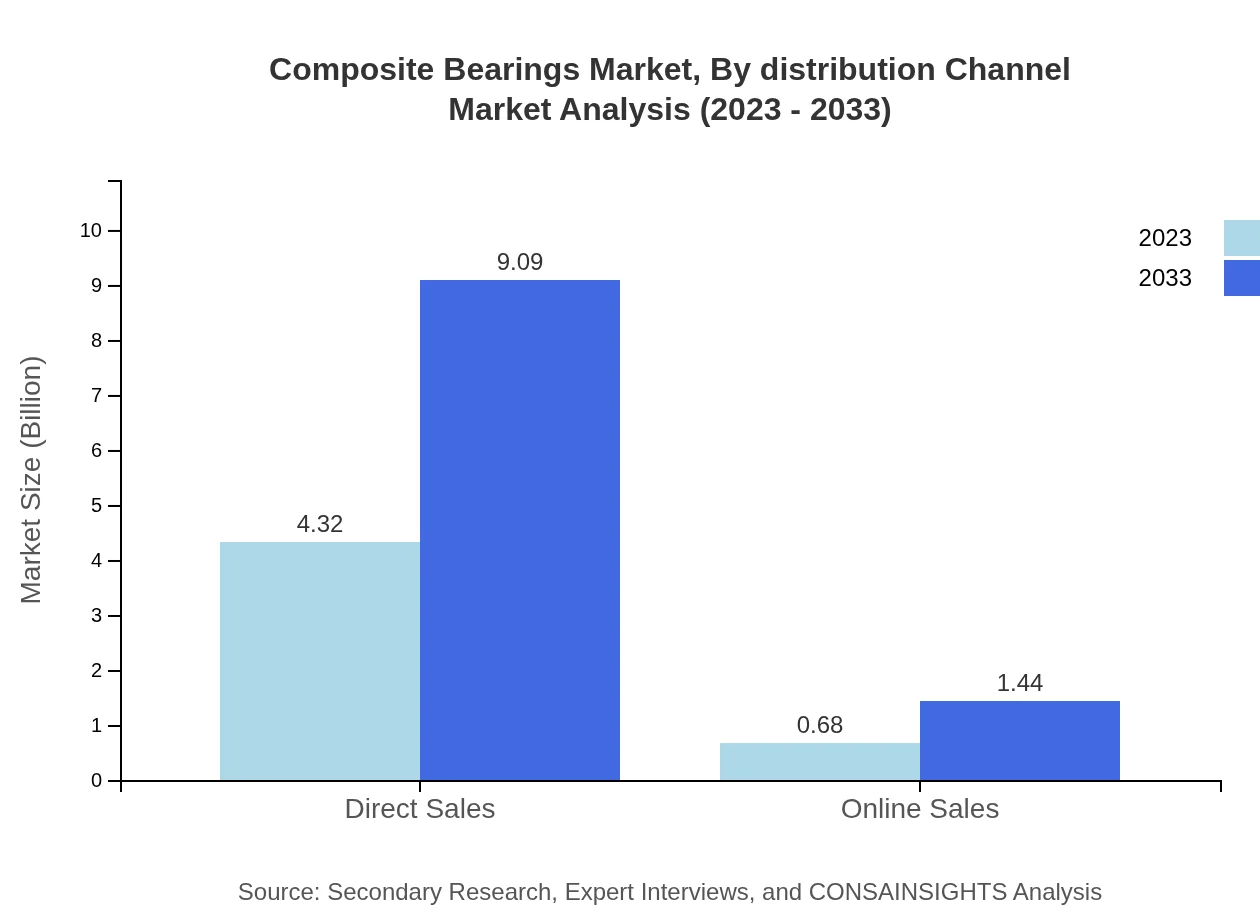

Composite Bearings Market Analysis By Distribution Channel

The distribution landscape highlights direct sales valued at $4.32 billion in 2023, while online sales are predicted to increase from $0.68 billion to $1.44 billion by 2033. The evolution of online platforms has made it easier for manufacturers to reach global audiences and enhance customer engagement.

Composite Bearings Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Composite Bearings Industry

SKF Group:

SKF Group is a leading provider of bearings and seals globally, with a strong portfolio of composite bearing solutions that enhance performance and longevity in various industrial applications.JTEKT Corporation:

JTEKT manufactures a comprehensive range of composite bearings, focusing on innovation and sustainability in the automotive and aerospace sectors, backed by significant R&D investments.Thordon Bearings:

Thordon Bearings specializes in advanced polymer bearings, recognized for their environmentally friendly solutions, primarily used in marine and industrial applications.We're grateful to work with incredible clients.

FAQs

What is the market size of composite Bearings?

The global composite bearings market is valued at approximately 5 billion in 2023, with a projected CAGR of 7.5%. By 2033, the market is expected to expand significantly, reflecting the growing demand for advanced materials in various industries.

What are the key market players or companies in this composite Bearings industry?

Key players in the composite bearings industry include prominent manufacturers and suppliers known for their innovative solutions. These companies focus on research and development to enhance product performance and meet the demands of various sectors such as automotive and aerospace.

What are the primary factors driving the growth in the composite bearings industry?

Growth in the composite bearings industry is primarily driven by increased demand for lightweight and durable materials in automotive and aerospace applications. Additionally, advancements in manufacturing processes and a focus on energy efficiency contribute to the expanding market landscape.

Which region is the fastest Growing in the composite Bearings?

The North American region is currently the fastest-growing area in the composite bearings market, projected to reach approximately 4.08 billion by 2033. This growth is attributed to significant advancements in technology and heightened industrial activity in the region.

Does ConsaInsights provide customized market report data for the composite Bearings industry?

Yes, ConsaInsights offers customized market report data tailored to the specific needs of clients in the composite bearings industry. This includes in-depth analysis and insights relevant to unique market requirements and trends.

What deliverables can I expect from this composite Bearings market research project?

From the composite bearings market research project, you can expect comprehensive reports detailing market size, growth forecasts, competitive analysis, and segmentation data. These deliverables provide valuable insights for strategic decision-making.

What are the market trends of composite Bearings?

Current trends in the composite bearings market include a shift towards environmentally friendly materials, growth in the use of thermoplastics, and increased applications in various sectors such as automotive and industrial machinery, reflecting evolving consumer preferences.