Compressor Control System Market Report

Published Date: 22 January 2026 | Report Code: compressor-control-system

Compressor Control System Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Compressor Control System market, covering its size, segmentation, regional insights, and trends through 2023 to 2033, aimed at informing industry stakeholders of potential opportunities and challenges.

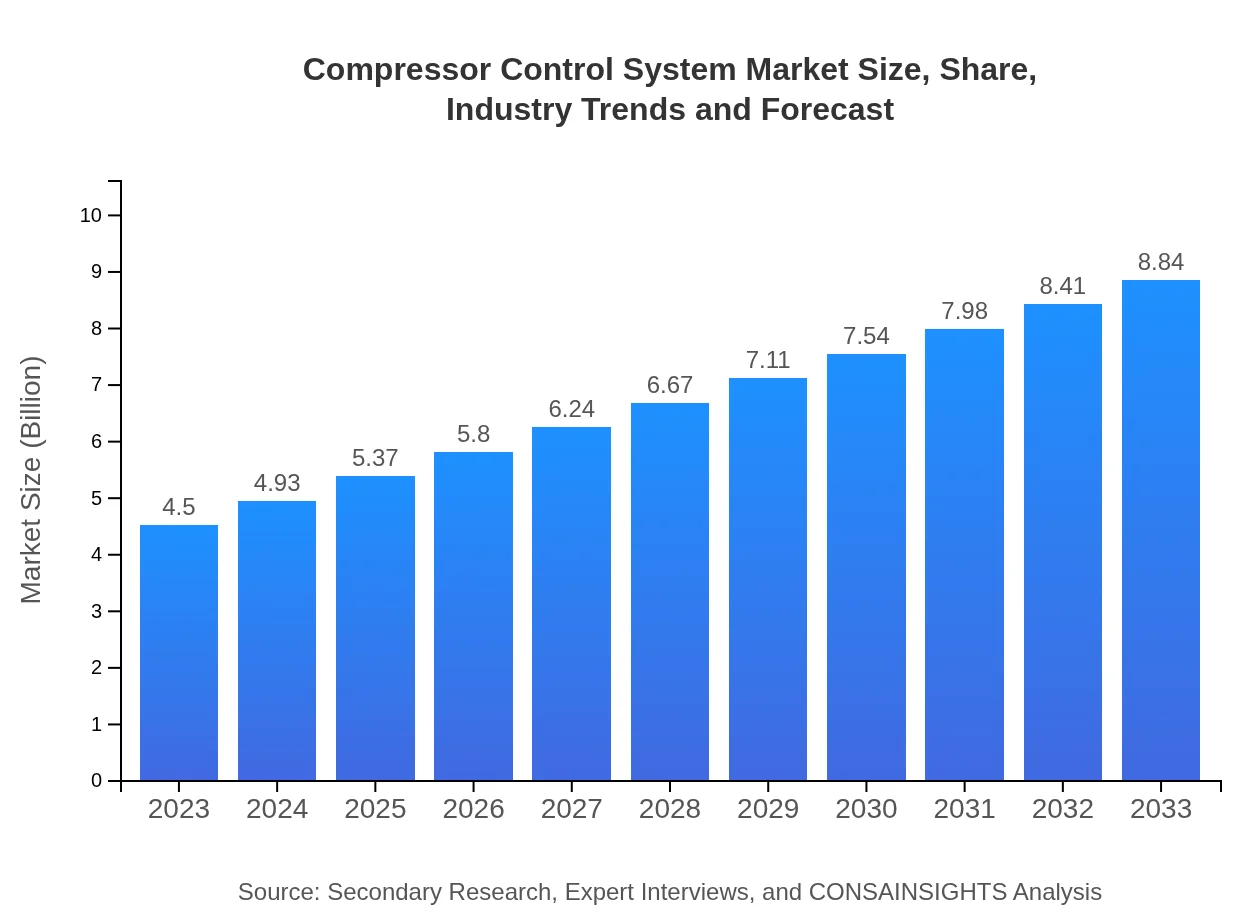

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $4.50 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $8.84 Billion |

| Top Companies | Siemens AG, Honeywell International Inc., Emerson Electric Co., Rockwell Automation Inc., Atlas Copco |

| Last Modified Date | 22 January 2026 |

Compressor Control System Market Overview

Customize Compressor Control System Market Report market research report

- ✔ Get in-depth analysis of Compressor Control System market size, growth, and forecasts.

- ✔ Understand Compressor Control System's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Compressor Control System

What is the Market Size & CAGR of Compressor Control System market in 2023?

Compressor Control System Industry Analysis

Compressor Control System Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Compressor Control System Market Analysis Report by Region

Europe Compressor Control System Market Report:

Europe currently holds a market value of USD 1.28 billion, anticipated to grow to USD 2.52 billion by 2033, buoyed by stringent environmental regulations, which are pushing industries to adopt smarter control systems and improve energy efficiency.Asia Pacific Compressor Control System Market Report:

In the Asia-Pacific region, the Compressor Control System market was valued at USD 0.94 billion in 2023, expected to grow to USD 1.85 billion by 2033. This growth is supported by rapid industrialization, especially in China and India, and the rising demand for automation in factories.North America Compressor Control System Market Report:

North America has a market size of USD 1.58 billion in 2023, growing to USD 3.11 billion by 2033. The U.S. leads in market share owing to advanced infrastructure, regulatory pressures for energy conservation, and significant investments in technology and research.South America Compressor Control System Market Report:

The South American market is smaller, with a size of USD 0.17 billion in 2023, projected to reach USD 0.34 billion by 2033. The growth is primarily driven by increasing investments in oil and gas and manufacturing sectors, along with government initiatives for energy efficiency.Middle East & Africa Compressor Control System Market Report:

The Middle East and Africa market size is USD 0.53 billion in 2023, projected to grow to USD 1.03 billion by 2033, driven by the oil and gas industry’s demand for efficient equipment and technological advances.Tell us your focus area and get a customized research report.

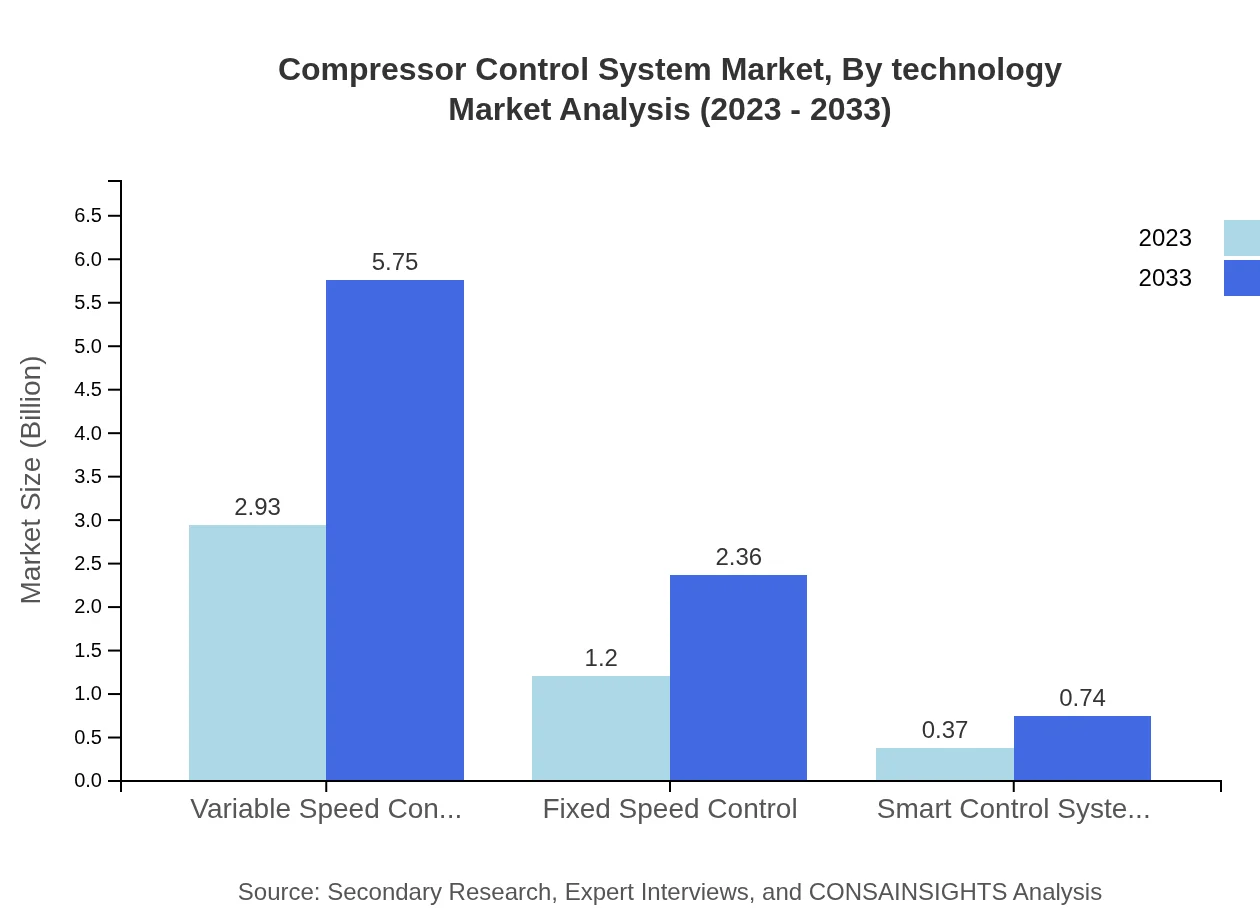

Compressor Control System Market Analysis By Technology

The market segments include variable speed control, fixed speed control, and smart control systems. Variable speed control dominates the market with a share of 65%, reflecting a growing trend towards energy efficiency and reduced wear and tear on compressor components. Fixed speed control maintains a significant share of 26.64%, primarily in legacy systems. Smart control systems are emerging, capturing 8.33% due to increasing market preferences for IoT integration.

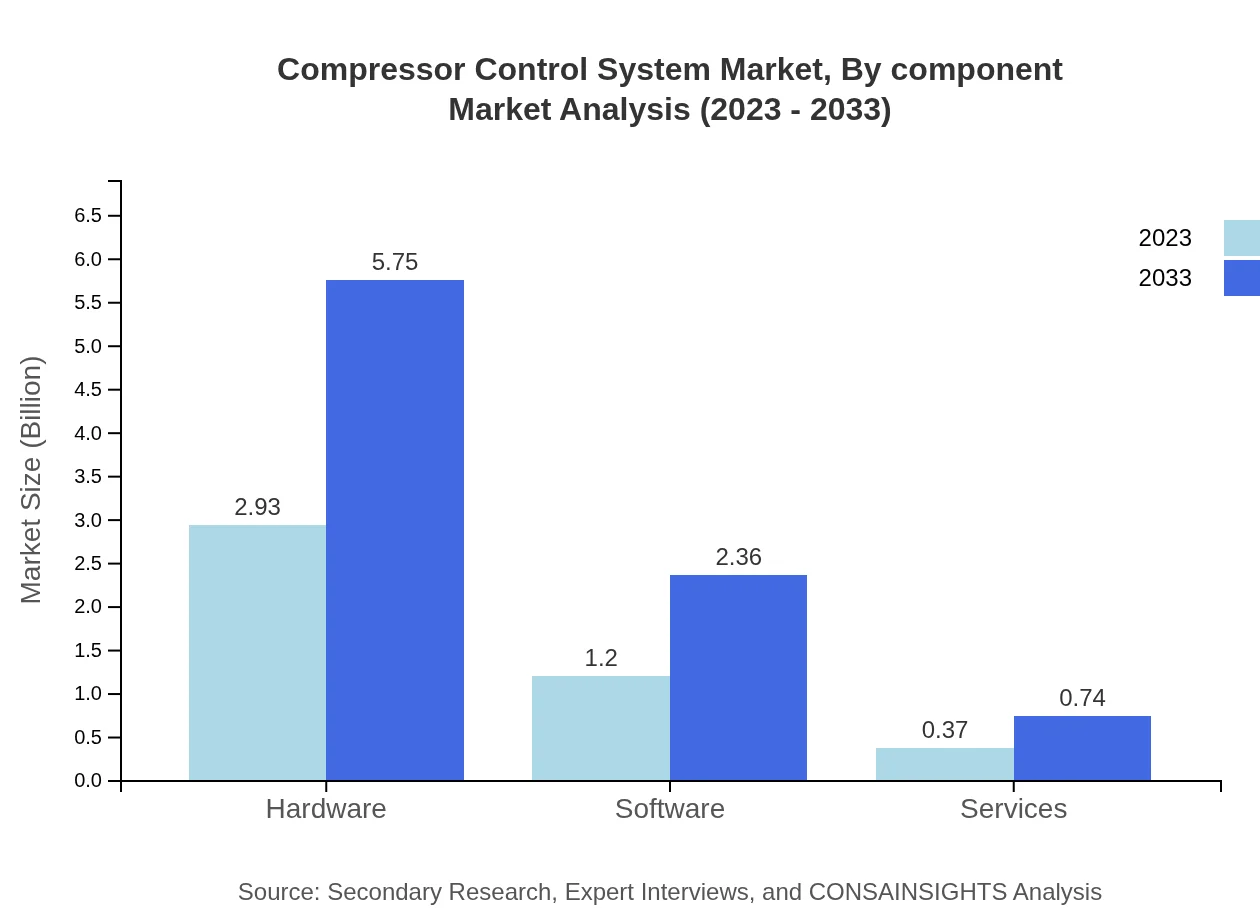

Compressor Control System Market Analysis By Component

The product types are segmented into hardware and software solutions. Hardware, which encompasses compressors, sensors, and controllers, represented 65% of the market in 2023. Software solutions, integral for monitoring and analytics, held a share of 26.64%, with a growing emphasis on predictive analytics and operational flexibility.

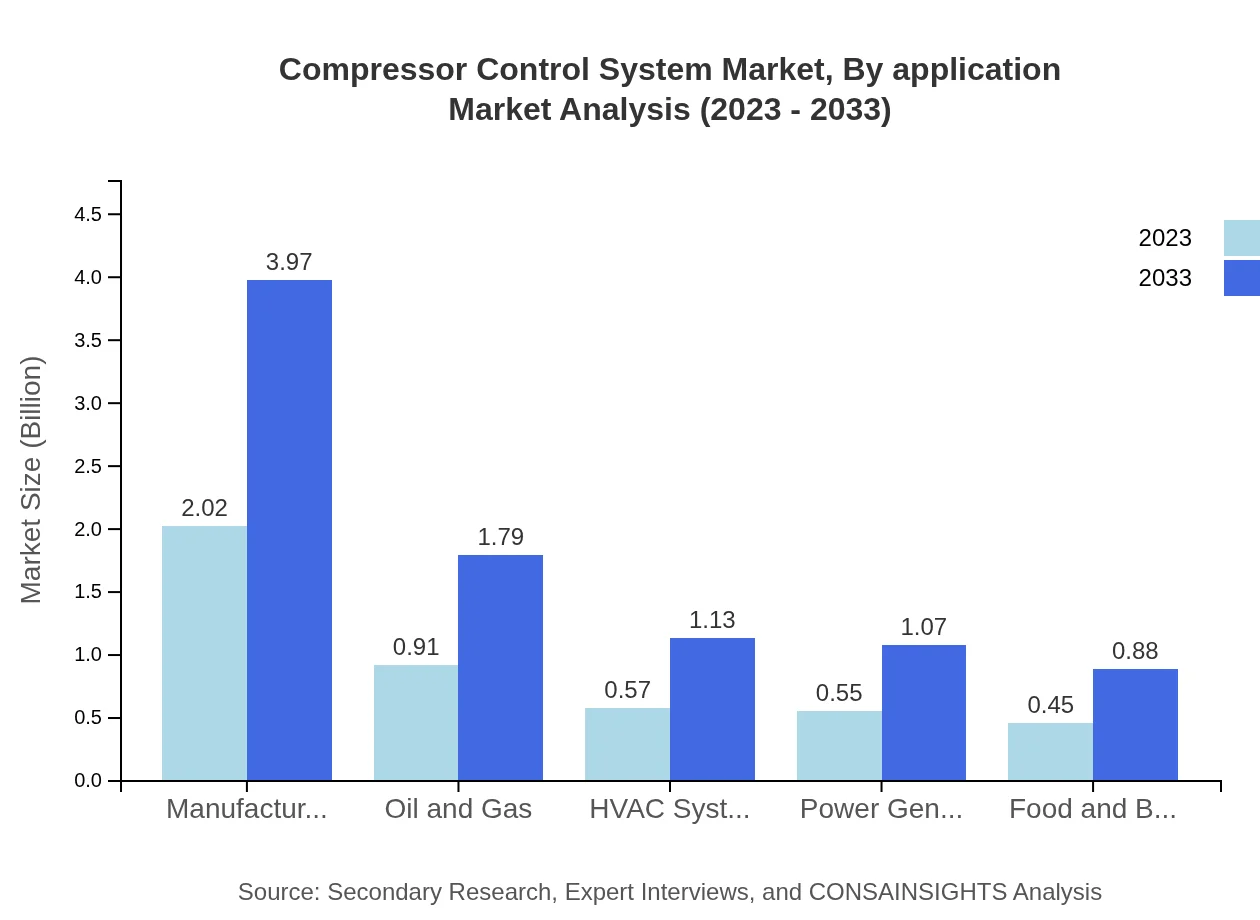

Compressor Control System Market Analysis By Application

The market spans various applications including manufacturing, oil and gas, HVAC systems, and power generation. Manufacturing remains the largest segment, constituting 44.84% of the market, driven by high demands for reliability and efficiency. The oil and gas sector accounts for 20.26%, while HVAC systems hold a share of 12.76%.

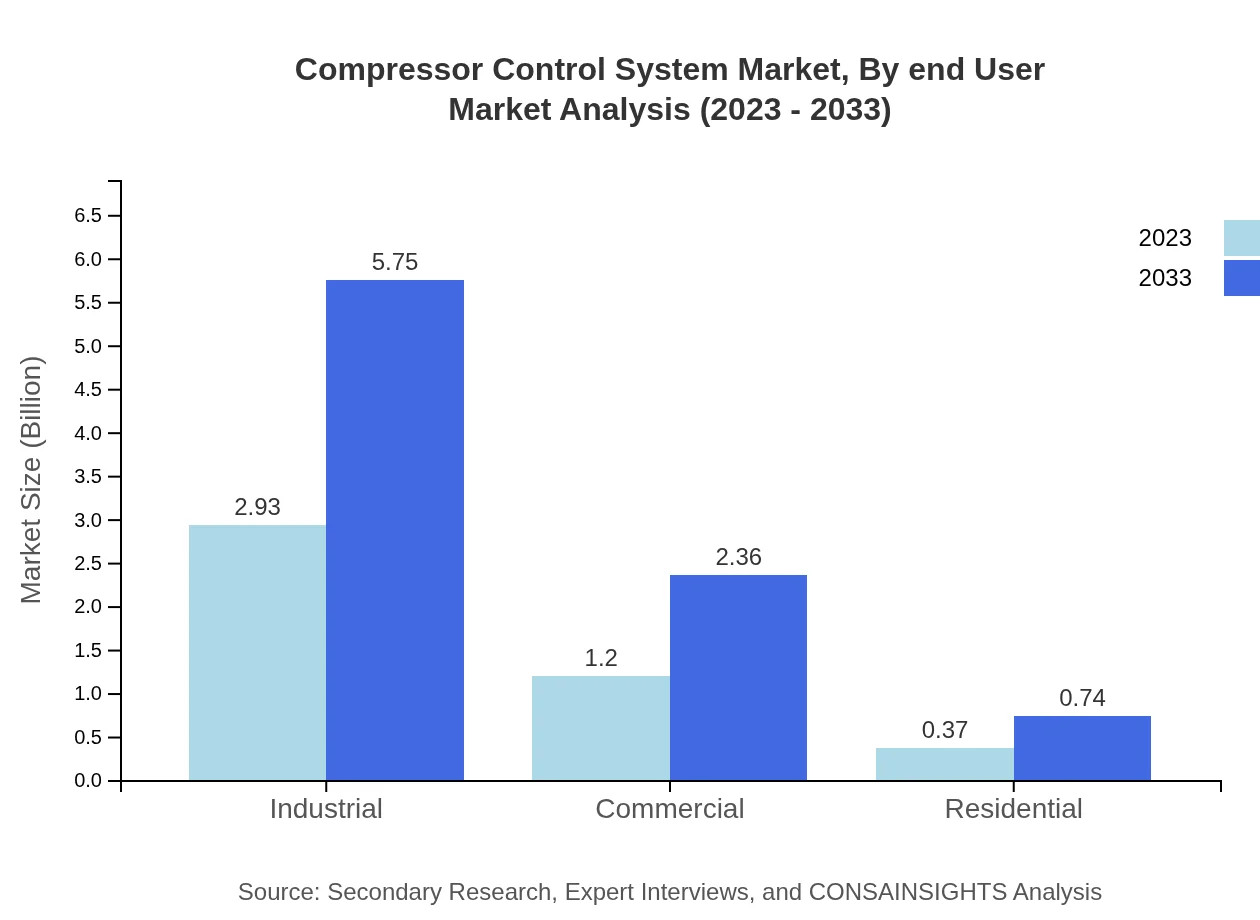

Compressor Control System Market Analysis By End User

Key end-user industries include manufacturing, oil and gas, HVAC systems, and food and beverage. Their demands for efficiency and operational reliability make them pivotal to the market's growth, with manufacturing leading in market share at 44.84%.

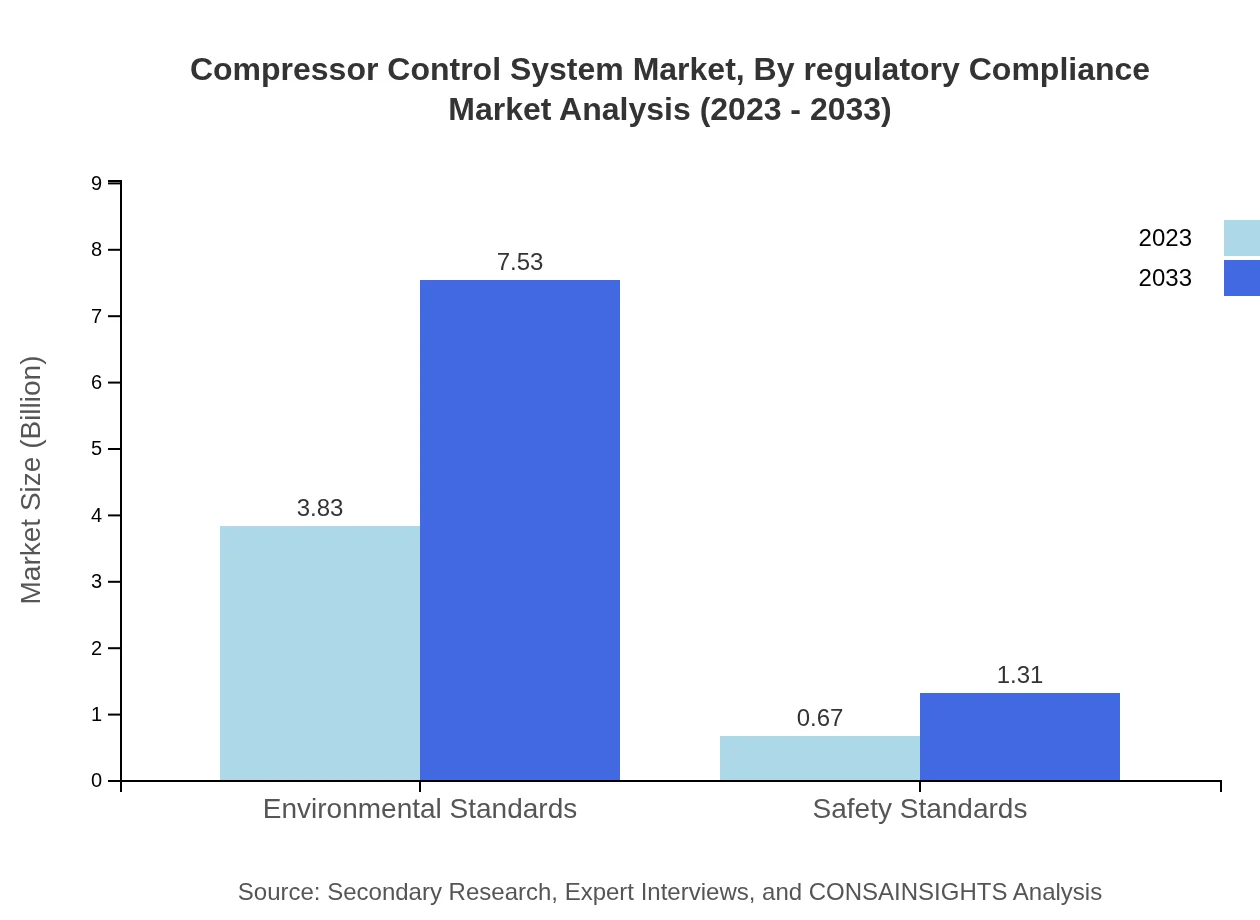

Compressor Control System Market Analysis By Regulatory Compliance

Market shares regarding compliance are bifurcated between environmental and safety standards. Environmental standards demand rigorous energy efficiency measures, constituting a hefty 85.19% of market compliance needs, while safety standards account for 14.81%.

Compressor Control System Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Compressor Control System Industry

Siemens AG:

Siemens is a global leader in industrial automation and digitalization, providing advanced compressor control technologies that enhance energy efficiency and reliability across sectors.Honeywell International Inc.:

Honeywell specializes in manufacturing technologies for diverse industries, focusing on eco-friendly and smart control systems that optimize compressor operations.Emerson Electric Co.:

Emerson is known for its innovative automation solutions, helping industries improve efficiency and compliance through state-of-the-art compressor control systems.Rockwell Automation Inc.:

Rockwell Automation provides comprehensive solutions in industrial automation and information, including sophisticated compressor control systems that ensure operational excellence.Atlas Copco:

Atlas Copco delivers sustainable productivity solutions through their advancements in air compressor technologies, focusing on energy-efficient control systems.We're grateful to work with incredible clients.

FAQs

What is the market size of compressor Control System?

The global compressor control system market size is projected to reach USD 4.5 billion by 2033, growing at a CAGR of 6.8% from its current value in 2023. The expanding industrial applications underscore the increasing demand for these systems.

What are the key market players or companies in this compressor Control System industry?

The key players in the compressor control system industry include major corporations such as Siemens AG, Honeywell International Inc., Emerson Electric Co., and Rockwell Automation, all of which contribute significantly to technology innovations and market growth.

What are the primary factors driving the growth in the compressor Control System industry?

Major growth factors in the compressor control system market include rising industrial automation, stringent environmental regulations, and the increasing emphasis on energy efficiency in various sectors, including manufacturing and HVAC systems.

Which region is the fastest Growing in the compressor Control System?

The North American region is the fastest-growing market for compressor control systems, projected to grow from USD 1.58 billion in 2023 to USD 3.11 billion by 2033, reflecting strong investments in technology and industrial infrastructure.

Does ConsaInsights provide customized market report data for the compressor Control System industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs within the compressor control system industry, ensuring clients receive relevant insights and comprehensive market analytics for informed decision-making.

What deliverables can I expect from this compressor Control System market research project?

Clients can expect detailed market analysis reports, segment-wise breakdown, growth forecasts, competitive landscape assessments, and actionable insights tailored for strategic planning and execution within the compressor control system market.

What are the market trends of compressor Control System?

Current trends in the compressor control system market involve advancements in smart control technologies, increasing adoption of variable speed drives, and a focus on sustainability, shaped by environmental regulations and energy efficiency initiatives.