Condition Monitoring Equipment Market Report

Published Date: 31 January 2026 | Report Code: condition-monitoring-equipment

Condition Monitoring Equipment Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Condition Monitoring Equipment market, including insights into market size, trends, and forecasts from 2023 to 2033. Key segments, regional dynamics, and leading industry players are examined to inform stakeholders of potential opportunities and challenges in this evolving market.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

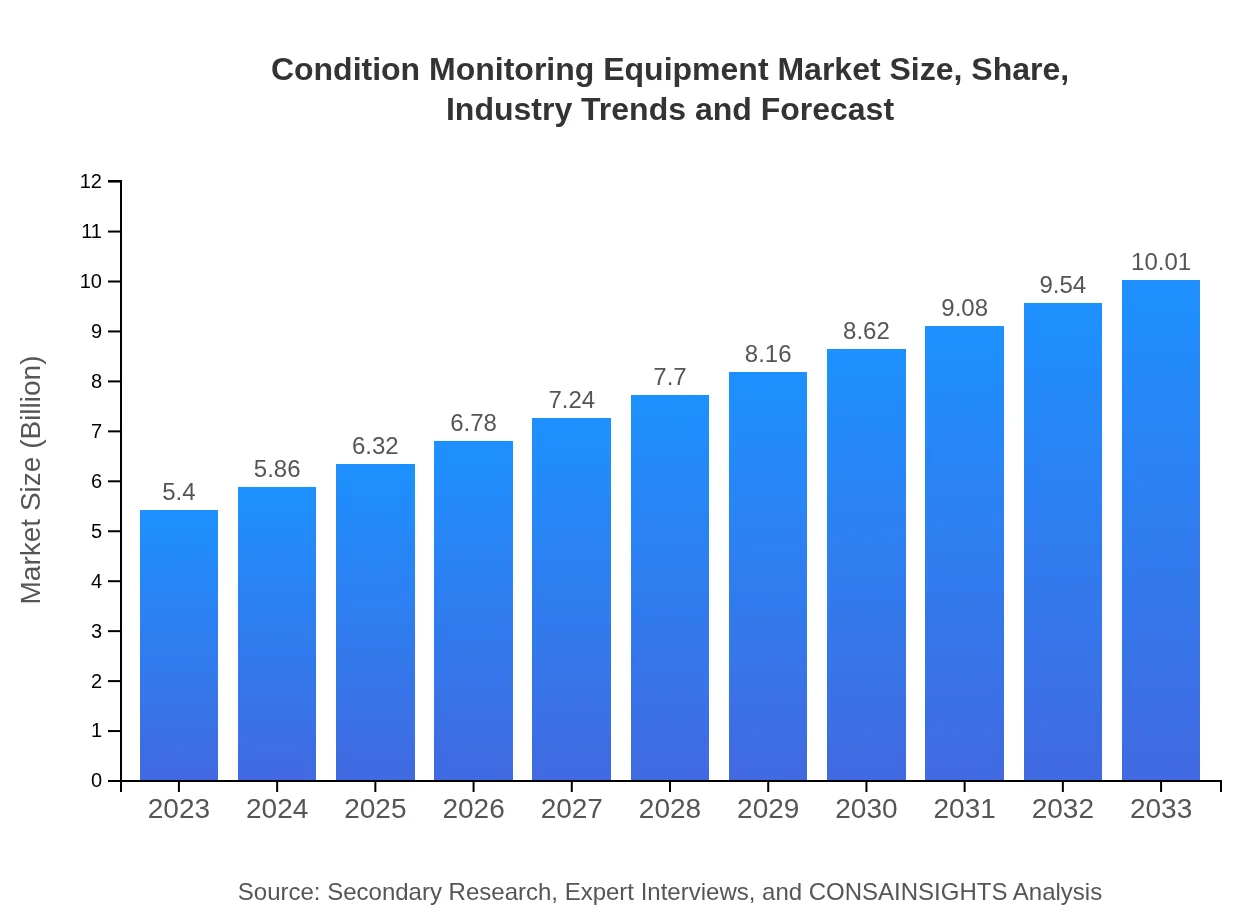

| 2023 Market Size | $5.40 Billion |

| CAGR (2023-2033) | 6.2% |

| 2033 Market Size | $10.01 Billion |

| Top Companies | Emerson Electric Co., Rockwell Automation, Inc., Siemens AG, Honeywell International Inc., SKF Group |

| Last Modified Date | 31 January 2026 |

Condition Monitoring Equipment Market Overview

Customize Condition Monitoring Equipment Market Report market research report

- ✔ Get in-depth analysis of Condition Monitoring Equipment market size, growth, and forecasts.

- ✔ Understand Condition Monitoring Equipment's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Condition Monitoring Equipment

What is the Market Size & CAGR of Condition Monitoring Equipment market in 2023?

Condition Monitoring Equipment Industry Analysis

Condition Monitoring Equipment Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Condition Monitoring Equipment Market Analysis Report by Region

Europe Condition Monitoring Equipment Market Report:

Europe's Condition Monitoring Equipment market is expected to increase from $1.59 billion in 2023 to $2.95 billion in 2033. The region's stringent regulations on machinery health and safety standards coupled with a shift towards digitalization in manufacturing underline its substantial market growth.Asia Pacific Condition Monitoring Equipment Market Report:

In the Asia-Pacific region, the Condition Monitoring Equipment market is projected to grow from $1.06 billion in 2023 to $1.96 billion in 2033. This growth can be attributed to the rapid industrialization, increased manufacturing activities, and investments in smart manufacturing technologies.North America Condition Monitoring Equipment Market Report:

North America stands as a significant market player, anticipated to grow from $1.91 billion in 2023 to $3.54 billion by 2033. The region's technological advancements, focus on industrial automation, and presence of leading manufacturing companies are pivotal in driving this growth.South America Condition Monitoring Equipment Market Report:

The South American market for Condition Monitoring Equipment is expected to rise from $0.49 billion in 2023 to $0.91 billion in 2033. The growth is fueled by rising demand for efficient monitoring systems in industries such as mining and oil & gas.Middle East & Africa Condition Monitoring Equipment Market Report:

In the Middle East and Africa, the market is set to rise from $0.35 billion in 2023 to $0.65 billion by 2033. The growth in oil and gas exploration and an increase in infrastructure projects are key motivators for the adoption of condition monitoring technologies in this region.Tell us your focus area and get a customized research report.

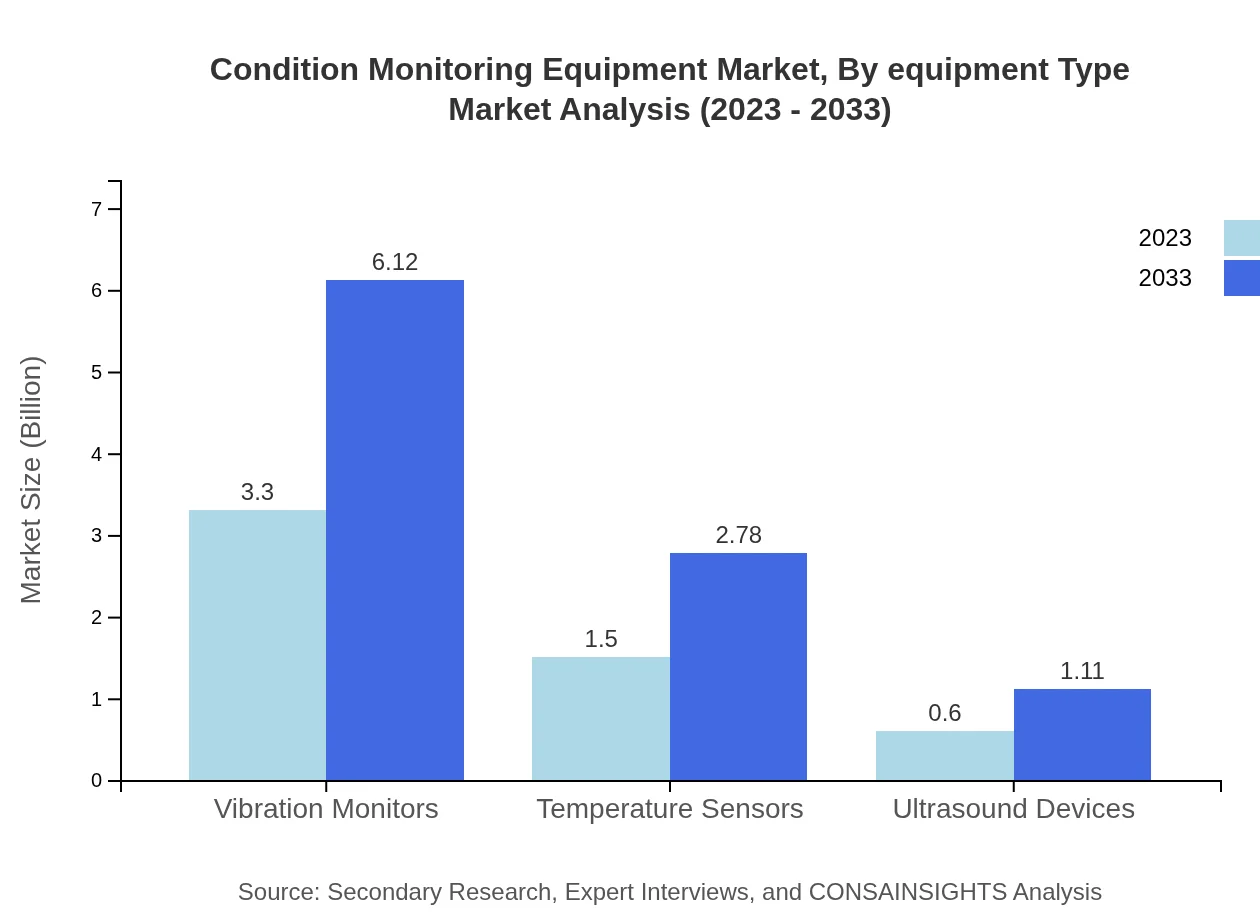

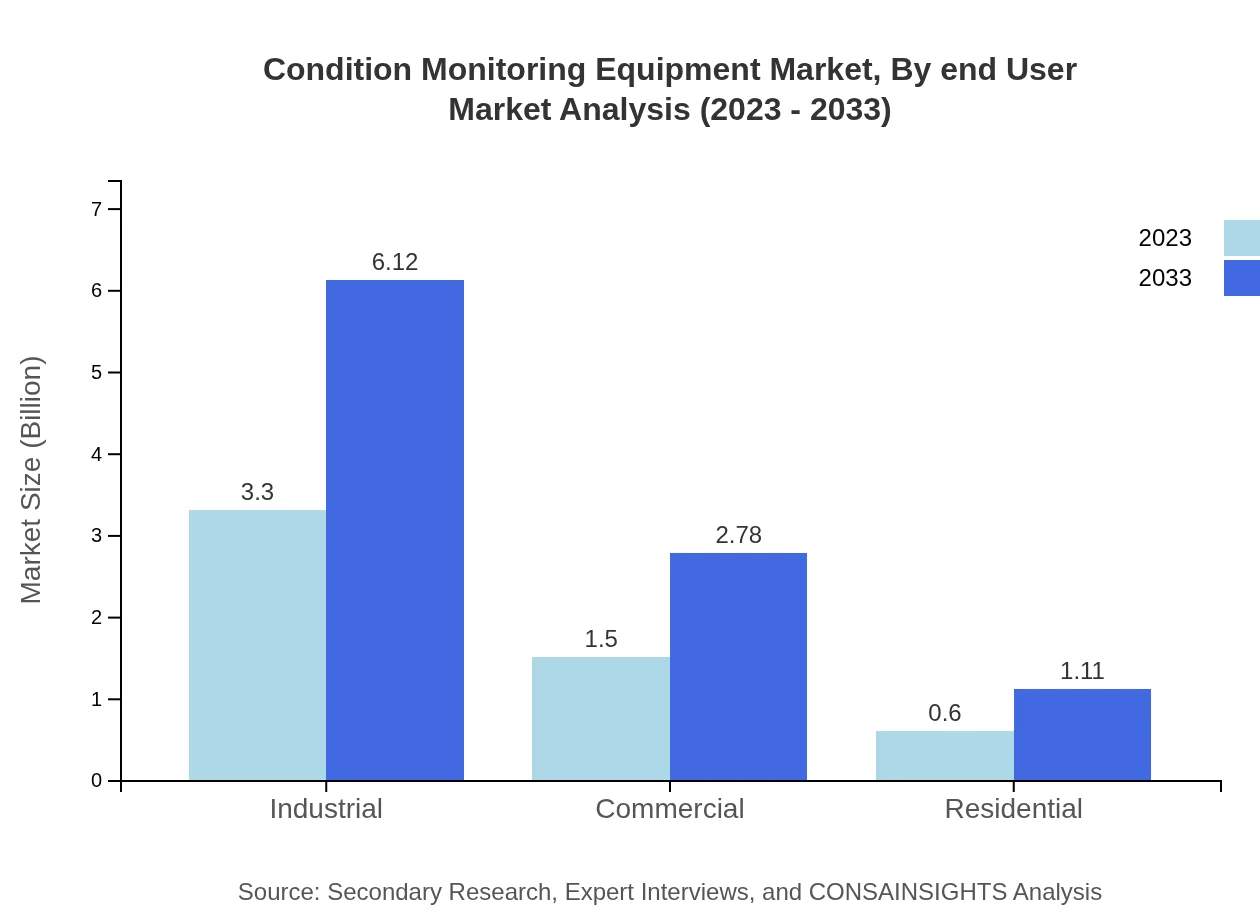

Condition Monitoring Equipment Market Analysis By Equipment Type

The Condition Monitoring Equipment market is sizeable, with its primary segment being industrial equipment, expected to reach $3.30 billion in 2023 and $6.12 billion in 2033. This segment accounts for 61.15% of total market share in both years, underlining its significance. Commercial applications follow with sizes of $1.50 billion in 2023 and $2.78 billion in 2033, representing 27.75% market share. Residential applications contribute a smaller share with projections of $0.60 billion in 2023 and $1.11 billion in 2033, highlighting a niche but growing market.

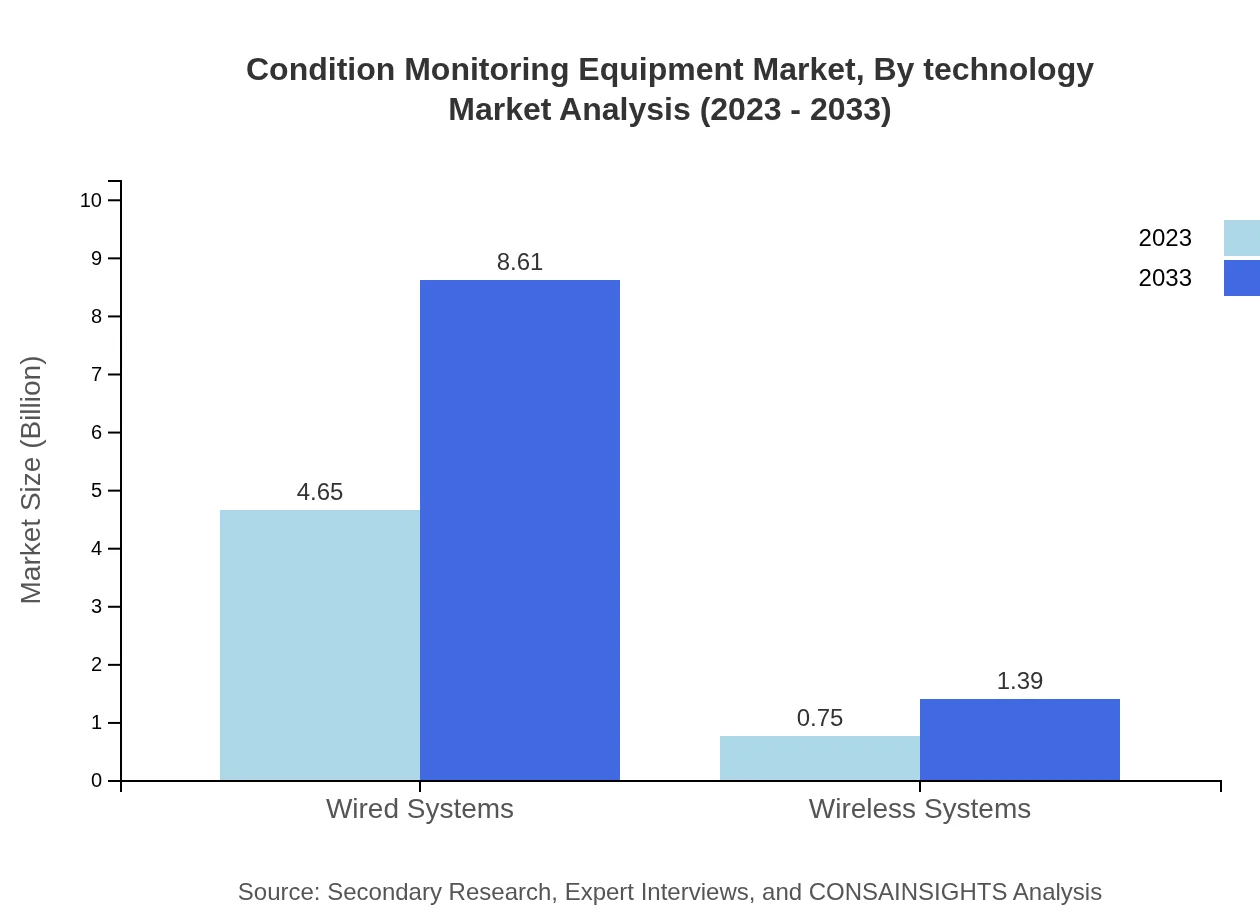

Condition Monitoring Equipment Market Analysis By Technology

In terms of technology, the wired systems segment leads with a market size of $4.65 billion in 2023, expanding to $8.61 billion by 2033 and maintaining an 86.1% market share. Wireless systems, while smaller, are witnessing growth from $0.75 billion to $1.39 billion, focusing on flexibility and ease of installation.

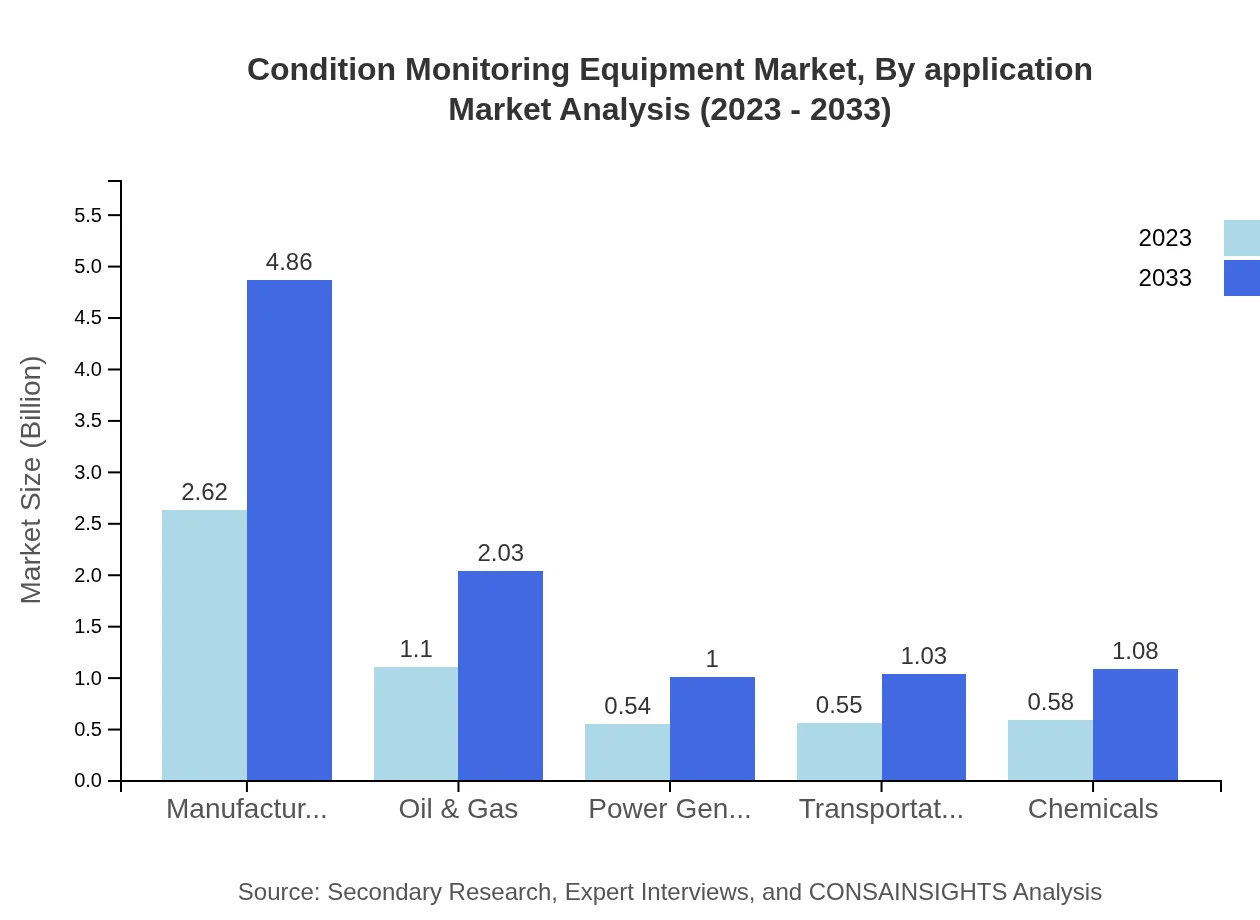

Condition Monitoring Equipment Market Analysis By Application

For applications, manufacturing remains dominant, expected to grow from $2.62 billion in 2023 to $4.86 billion in 2033, holding 48.59% of the market share. The oil & gas sector is also significant, with a projected increase from $1.10 billion to $2.03 billion, while other sectors like power generation and transportation contribute to the diversified demand for condition monitoring equipment.

Condition Monitoring Equipment Market Analysis By End User

End-user segmentation shows that industries like manufacturing, oil & gas, and power generation are key adopters of condition monitoring technologies. With their complex machinery and high operational costs, these sectors benefit greatly from predictive maintenance technologies, ensuring operational efficiency.

Condition Monitoring Equipment Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Condition Monitoring Equipment Industry

Emerson Electric Co.:

Emerson provides advanced monitoring solutions integrating IoT and AI technologies to enhance predictive maintenance across industries.Rockwell Automation, Inc.:

Rockwell focuses on automation solutions, providing condition monitoring equipment that helps optimize processes in manufacturing.Siemens AG:

Siemens offers comprehensive condition monitoring solutions that enhance operational reliability in diverse sectors.Honeywell International Inc.:

Honeywell provides integrated monitoring systems, focusing on safety and efficiency for industrial operations.SKF Group:

SKF specializes in providing lubrication solutions and condition monitoring sensors that enhance machinery performance.We're grateful to work with incredible clients.

FAQs

What is the market size of condition Monitoring Equipment?

The global condition-monitoring equipment market is valued at approximately $5.4 billion in 2023 and is projected to achieve a compound annual growth rate (CAGR) of 6.2%, reaching substantial growth by 2033.

What are the key market players or companies in this condition Monitoring Equipment industry?

Key players in the condition-monitoring equipment market include major corporations like SKF, Siemens, and Honeywell. These companies lead in innovation, providing cutting-edge solutions that enhance equipment reliability and performance across various industries.

What are the primary factors driving the growth in the condition Monitoring Equipment industry?

The growth of the condition-monitoring equipment industry is driven by increasing industrial automation, the need for predictive maintenance, and advancements in IoT technologies. These factors collectively enhance operational efficiency and reduce downtime.

Which region is the fastest Growing in the condition Monitoring Equipment?

North America is currently the fastest-growing region in the condition-monitoring equipment market, with a market size projected to increase from $1.91 billion in 2023 to approximately $3.54 billion by 2033.

Does Cons Insights provide customized market report data for the condition Monitoring Equipment industry?

Yes, Cons Insights offers customized market report data tailored to specific needs in the condition-monitoring equipment industry, enabling businesses to obtain targeted insights and strategies.

What deliverables can I expect from this condition Monitoring Equipment market research project?

Deliverables from the condition-monitoring equipment market research project typically include comprehensive reports, market analysis, competitive landscapes, and forecasts tailored to your business requirements.

What are the market trends of condition Monitoring Equipment?

Current trends in the condition-monitoring equipment market include the growing integration of IoT, the shift towards wireless monitoring systems, and increased demand for vibration monitoring technologies, indicating a dynamic evolution in maintenance methodologies.