Conical Dryer Market Report

Published Date: 22 January 2026 | Report Code: conical-dryer

Conical Dryer Market Size, Share, Industry Trends and Forecast to 2033

This market report offers a comprehensive analysis of the Conical Dryer market, covering key insights, trends, and data forecasts from 2023 to 2033. It delves into market size, growth rates, regional dynamics, and technological advancements affecting the industry's landscape.

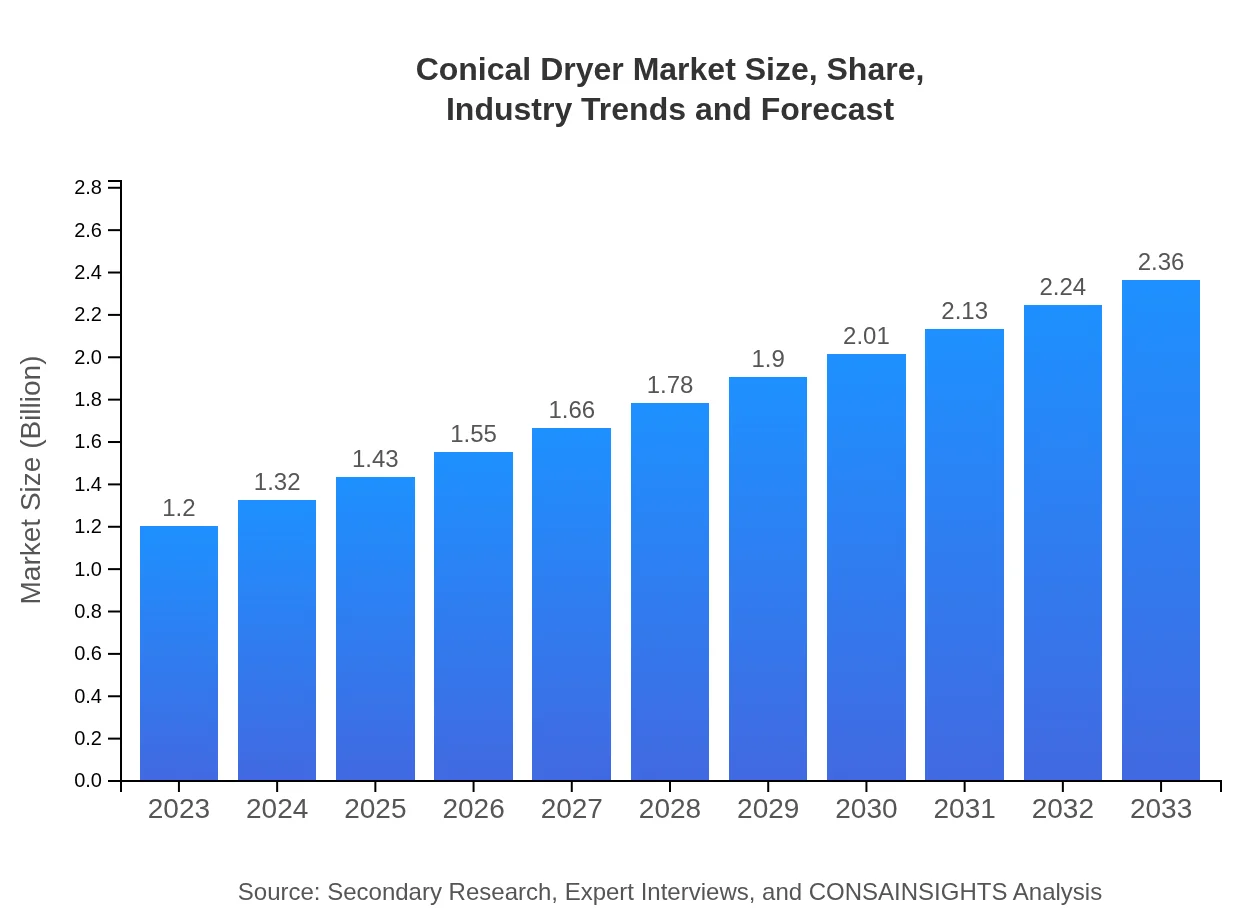

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $1.20 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $2.36 Billion |

| Top Companies | GEA Group AG, Mikro Pulverizer Company, Inc., Schenck Process, Miele, Bühler Group |

| Last Modified Date | 22 January 2026 |

Conical Dryer Market Overview

Customize Conical Dryer Market Report market research report

- ✔ Get in-depth analysis of Conical Dryer market size, growth, and forecasts.

- ✔ Understand Conical Dryer's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Conical Dryer

What is the Market Size & CAGR of the Conical Dryer market in 2023?

Conical Dryer Industry Analysis

Conical Dryer Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Conical Dryer Market Analysis Report by Region

Europe Conical Dryer Market Report:

The European Conical Dryer market is anticipated to grow from USD 0.31 billion in 2023 to USD 0.61 billion by 2033. The region's emphasis on sustainability and energy-efficient processes is promoting the adoption of innovative dryer technologies in various industries.Asia Pacific Conical Dryer Market Report:

The Asia-Pacific region is projected to witness robust growth in the Conical Dryer market, increasing from USD 0.24 billion in 2023 to USD 0.48 billion by 2033. This growth is driven by rapid industrialization, increased pharmaceutical production, and rising demand for food processing technologies.North America Conical Dryer Market Report:

North America holds a significant share of the Conical Dryer market, with growth projected to rise from USD 0.41 billion in 2023 to USD 0.81 billion by 2033. The pharmaceutical sector's rigorous standards for product quality and safety continue to drive investments in advanced drying technologies.South America Conical Dryer Market Report:

In South America, the market size is expected to expand from USD 0.10 billion in 2023 to USD 0.20 billion by 2033, supported by the growth of the food and beverage sector. The region's focus on enhancing manufacturing efficiency is also contributing to increased investments in drying technologies.Middle East & Africa Conical Dryer Market Report:

In the Middle East and Africa, the market is expected to grow from USD 0.13 billion in 2023 to USD 0.26 billion by 2033. The rise in manufacturing activities and a strong focus on modernizing infrastructure are the main drivers for Conical Dryer adoption in this region.Tell us your focus area and get a customized research report.

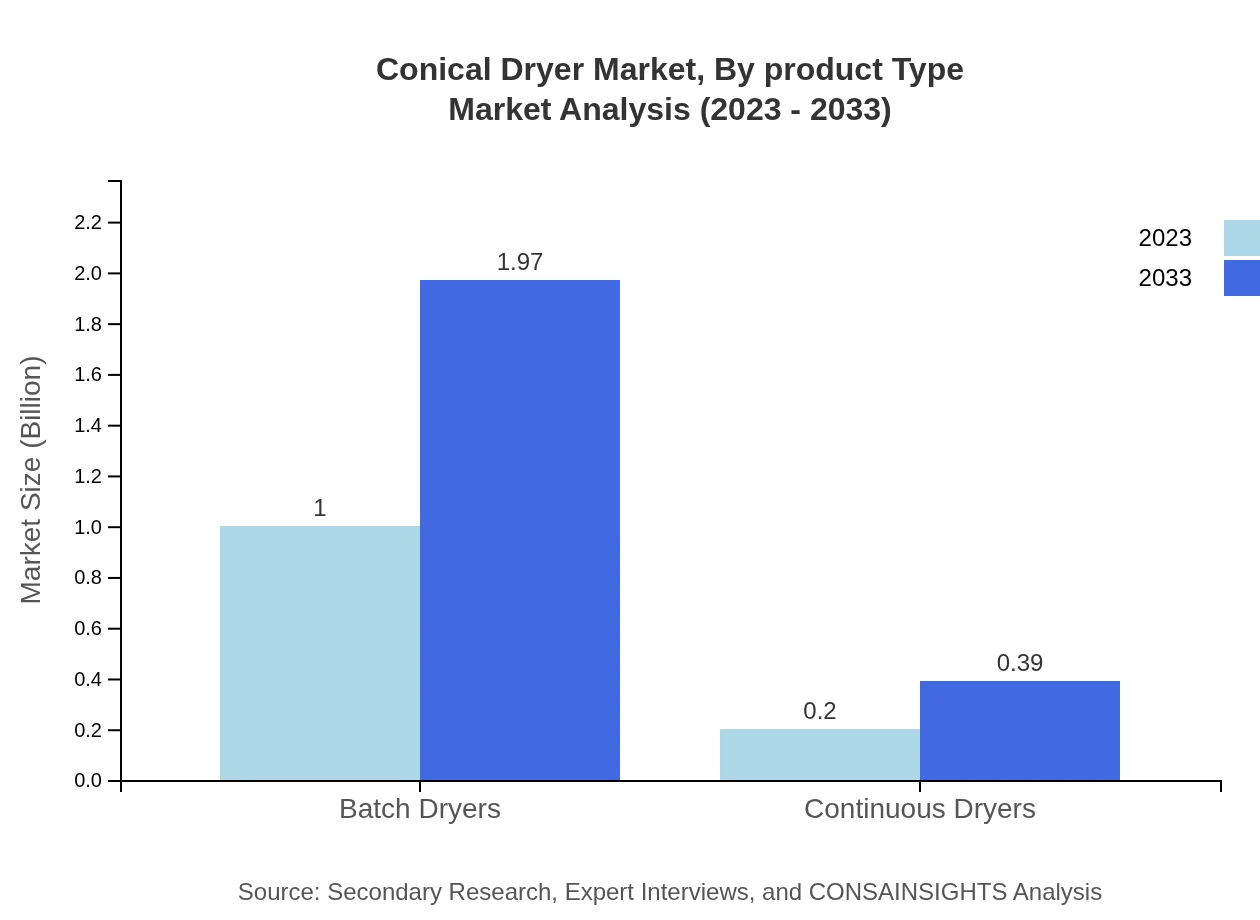

Conical Dryer Market Analysis By Product Type

The Conical Dryer market, segmented by product type, includes batch dryers and continuous dryers. Batch dryers dominate with a market size of USD 1.00 billion in 2023, forecasted to reach USD 1.97 billion by 2033, holding a share of 83.66%. Continuous dryers, on the other hand, are projected to grow from USD 0.20 billion in 2023 to USD 0.39 billion by 2033, accounting for 16.34% of the market. The versatility and efficiency of batch dryers make them highly favored in industries requiring varied drying processes.

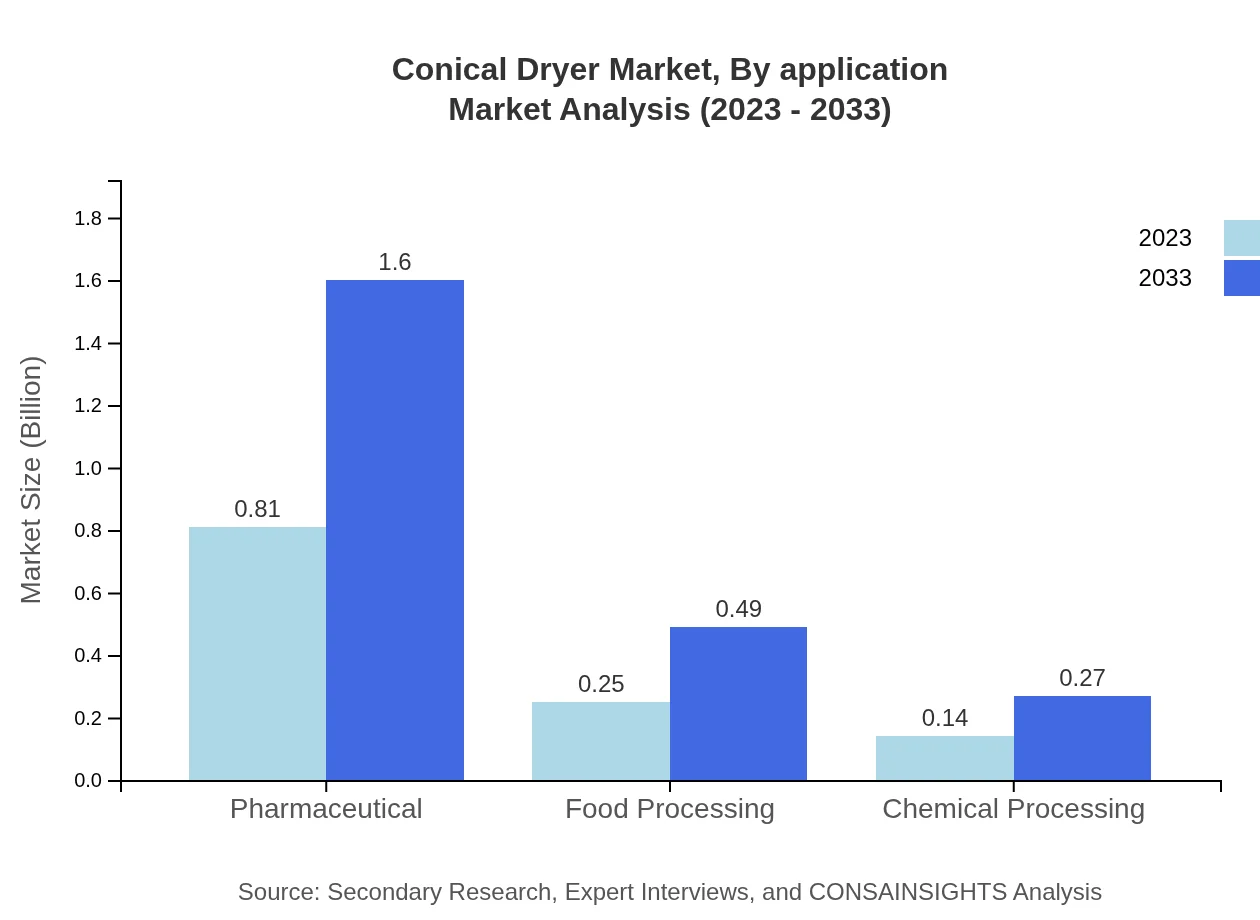

Conical Dryer Market Analysis By Application

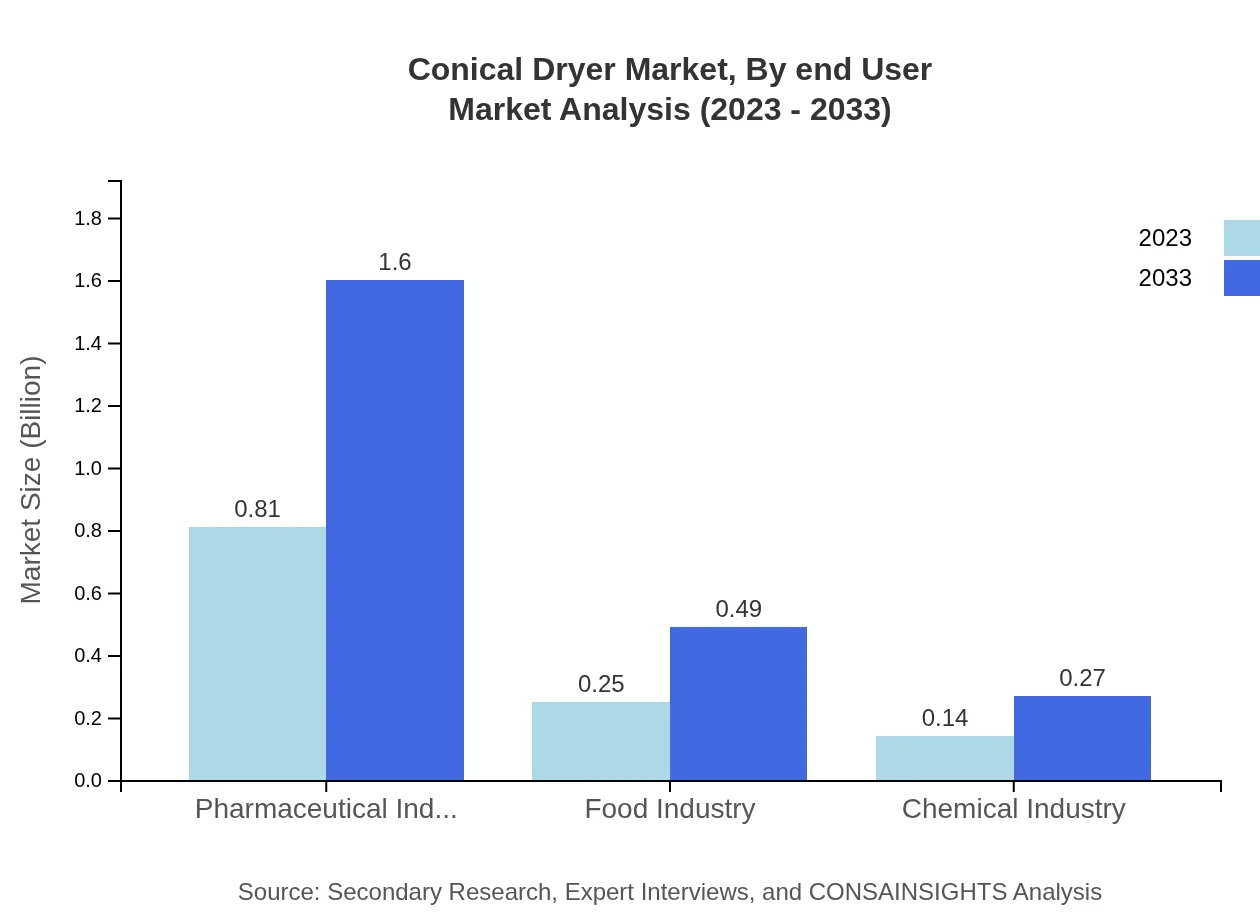

Within the application segment, the pharmaceutical industry is a major player, with a market size of USD 0.81 billion in 2023, expected to grow to USD 1.60 billion by 2033, dominating the market share at 67.78%. The food processing industry follows, with a size of USD 0.25 billion, projected to expand to USD 0.49 billion by 2033, capturing 20.64% of the market. The chemicals segment also shows a growing presence, with a size increase from USD 0.14 billion to USD 0.27 billion, holding 11.58% of the market share.

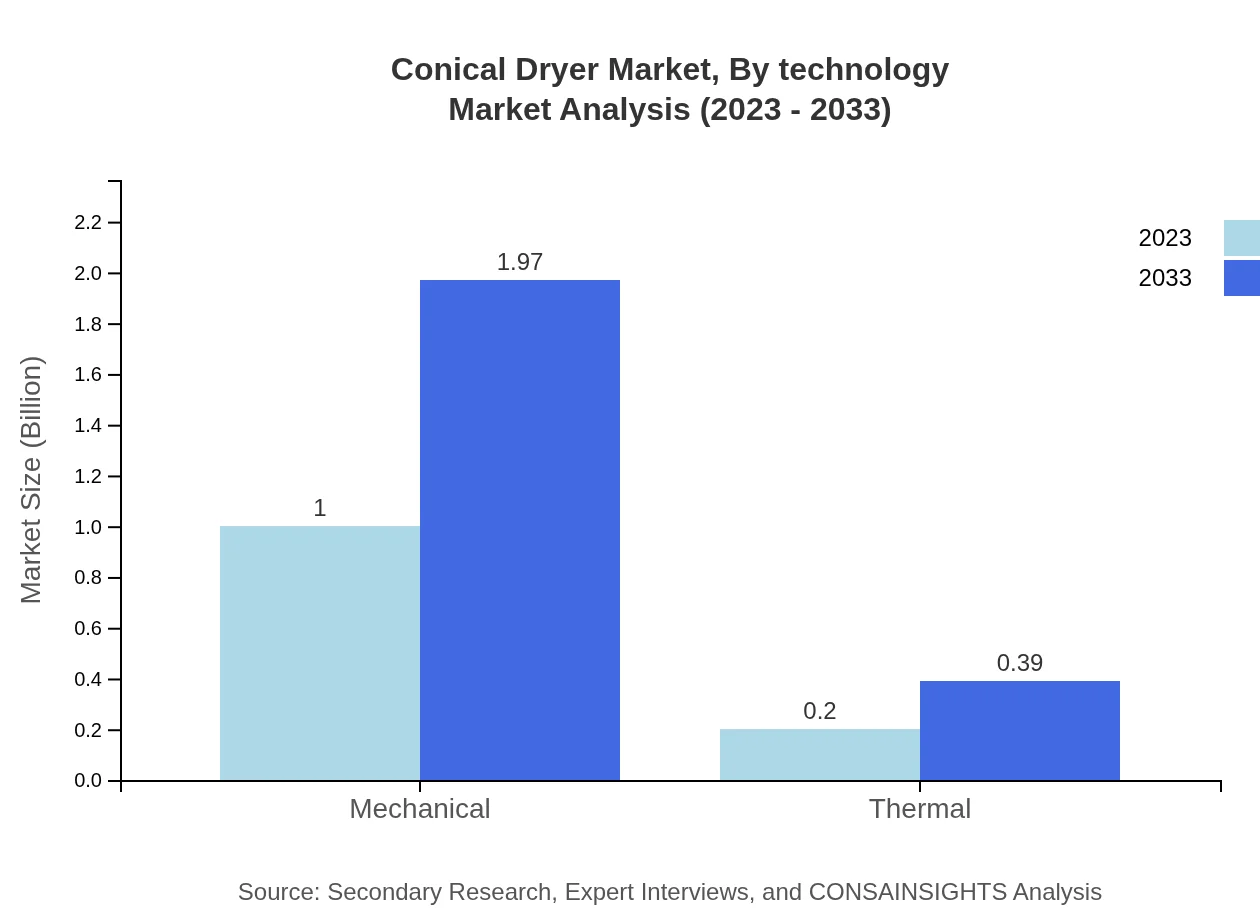

Conical Dryer Market Analysis By Technology

The analysis of technology in the Conical Dryer market highlights the advancement in automation and control technologies. Automating the drying process significantly reduces operational costs and enhances production efficiency. New technologies such as IoT integration and remote monitoring capabilities are becoming prevalent, allowing for better precision in controlling drying parameters, ultimately improving product quality in many sectors.

Conical Dryer Market Analysis By End User

In terms of end-user industries, the pharmaceutical and food processing sectors are the most significant contributors to the Conical Dryer market. The pharmaceutical industry emphasizes product contamination prevention and efficiency, leading to increased investments in Conical Dryers. The food processing industry focuses on maintaining flavor and nutritional values, driving the need for effective drying solutions.

Conical Dryer Market Analysis By Material

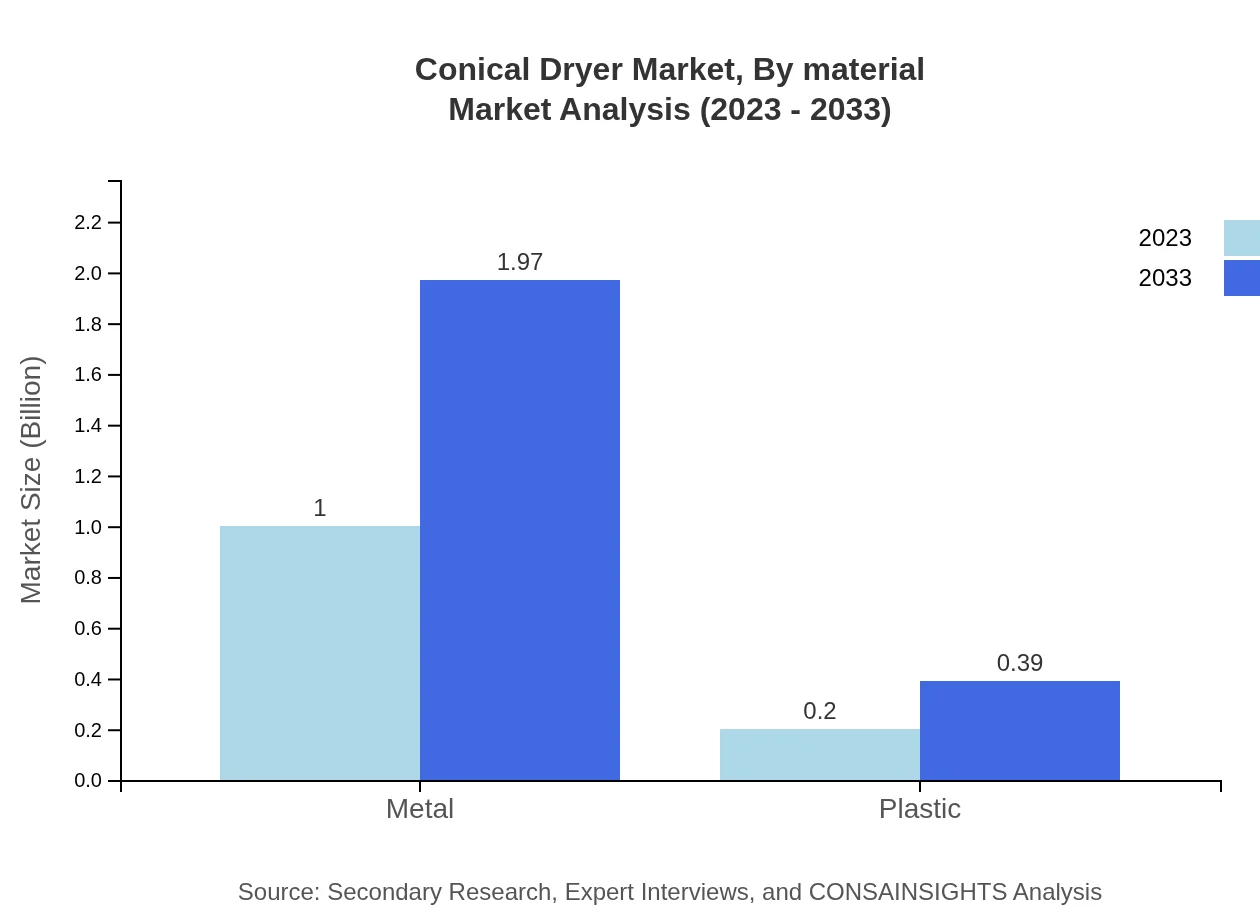

The market is segmented by materials, showing varying performance levels across different industries. For instance, metal materials dominate the segment with a size of USD 1.00 billion in 2023, growing to USD 1.97 billion by 2033, with an 83.66% market share. On the other hand, plastic materials show growth proportions from USD 0.20 billion to USD 0.39 billion, securing a 16.34% share, reflecting the increasing adoption of lightweight materials in manufacturing processes.

Conical Dryer Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in the Conical Dryer Industry

GEA Group AG:

GEA Group AG is a global leader in the technology of food processing and pharmaceuticals, specializing in developing innovative drying technologies, including Conical Dryers.Mikro Pulverizer Company, Inc.:

Mikro Pulverizer Company, Inc. is renowned for manufacturing advanced drying solutions and systems that meet the needs of various industries, supporting the efficient use of Conical Dryers.Schenck Process:

Schenck Process specializes in providing solutions for bulk material handling and processing, including Conical Dryers, focusing on efficiency and sustainability.Miele:

Miele is recognized for its high-quality appliances, including Conical Dryers that cater to both industrial and household needs, emphasizing energy efficiency and performance.Bühler Group:

Bühler Group offers innovative solutions for food processing and chemical production, incorporating advanced drying techniques to enhance manufacturing processes.We're grateful to work with incredible clients.

FAQs

What is the market size of conical dryer?

The global conical dryer market is valued at approximately $1.2 billion in 2023, with a projected CAGR of 6.8% from 2023 to 2033, indicating robust growth trends within the industry.

What are the key market players or companies in the conical dryer industry?

Key market players in the conical dryer industry include major manufacturers and suppliers who specialize in drying technology, contributing significantly to market innovation and expansion efforts.

What are the primary factors driving the growth in the conical dryer industry?

The growth of the conical dryer industry is driven by rising demand in pharmaceuticals, food processing, and chemical industries, as businesses seek efficient drying solutions to enhance production processes.

Which region is the fastest Growing in the conical dryer market?

The Asia Pacific region is the fastest-growing market for conical dryers, with projected growth from $0.24 billion in 2023 to $0.48 billion in 2033, highlighted by increasing industrialization.

Does ConsaInsights provide customized market report data for the conical dryer industry?

Yes, ConsaInsights offers customized market report data for the conical dryer industry, catering to specific client needs and helping businesses make informed decisions based on tailored insights.

What deliverables can I expect from this conical dryer market research project?

Deliverables from the conical dryer market research project include detailed market analysis, growth forecasts, competitive landscape assessments, and insights on regional trends and industry segments.

What are the market trends of conical dryer?

Current market trends in the conical dryer industry indicate a shift towards automation and sustainability, with increasing investments in advanced drying technologies aiming to improve efficiency and reduce energy consumption.