Control Valves Market Report

Published Date: 22 January 2026 | Report Code: control-valves

Control Valves Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Control Valves market, including market size, growth trends, segment performance, and regional insights for the period of 2023 to 2033.

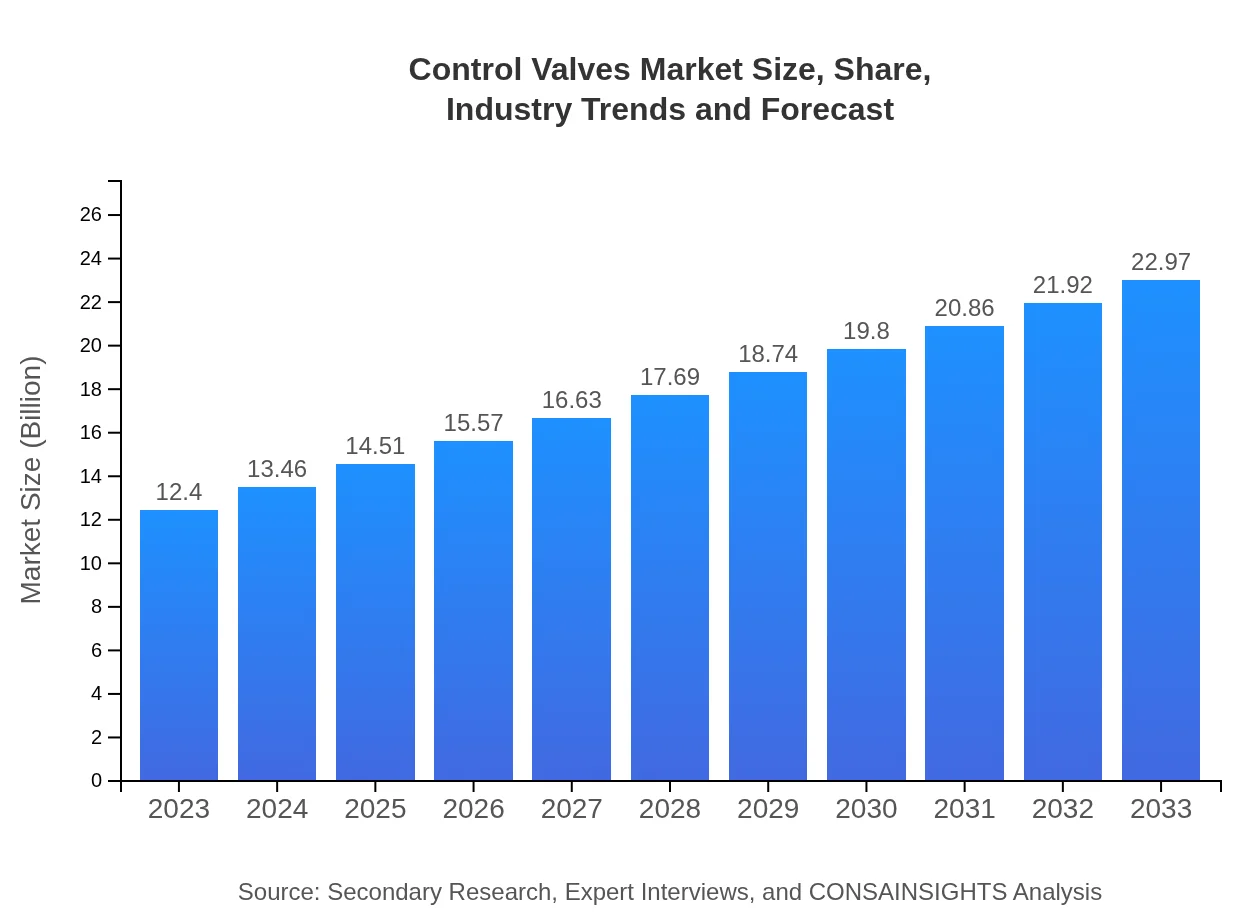

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $12.40 Billion |

| CAGR (2023-2033) | 6.2% |

| 2033 Market Size | $22.97 Billion |

| Top Companies | Emerson Electric Co., Flowserve Corporation, Honeywell International Inc., Siemens AG |

| Last Modified Date | 22 January 2026 |

Control Valves Market Overview

Customize Control Valves Market Report market research report

- ✔ Get in-depth analysis of Control Valves market size, growth, and forecasts.

- ✔ Understand Control Valves's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Control Valves

What is the Market Size & CAGR of Control Valves market in 2023?

Control Valves Industry Analysis

Control Valves Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Control Valves Market Analysis Report by Region

Europe Control Valves Market Report:

Europe's Control Valves market is forecasted to grow from $4.07 billion in 2023 to $7.54 billion by 2033. The region is focusing on sustainable practices and energy efficiency, which is propelling investments in automated control valve systems.Asia Pacific Control Valves Market Report:

In the Asia Pacific region, the Control Valves market is anticipated to grow from $2.25 billion in 2023 to $4.17 billion by 2033. This growth is fueled by rapid industrialization and urbanization in countries like China and India, coupled with increased investments in infrastructure development.North America Control Valves Market Report:

North America holds a significant share of the Control Valves market, expected to rise from $4.27 billion in 2023 to $7.91 billion in 2033. Growth in this region is driven primarily by the increasing adoption of automation technologies in industries such as oil & gas and manufacturing.South America Control Valves Market Report:

The South American market is projected to expand from $0.94 billion in 2023 to $1.75 billion by 2033. The region continues to see growth in sectors such as oil and gas and water treatment as countries seek improved efficiency in resource management.Middle East & Africa Control Valves Market Report:

The market in the Middle East and Africa is expected to expand from $0.87 billion in 2023 to $1.62 billion by 2033. This growth is attributed to the surge in oil and gas exploration activities and the need for efficient water resource management.Tell us your focus area and get a customized research report.

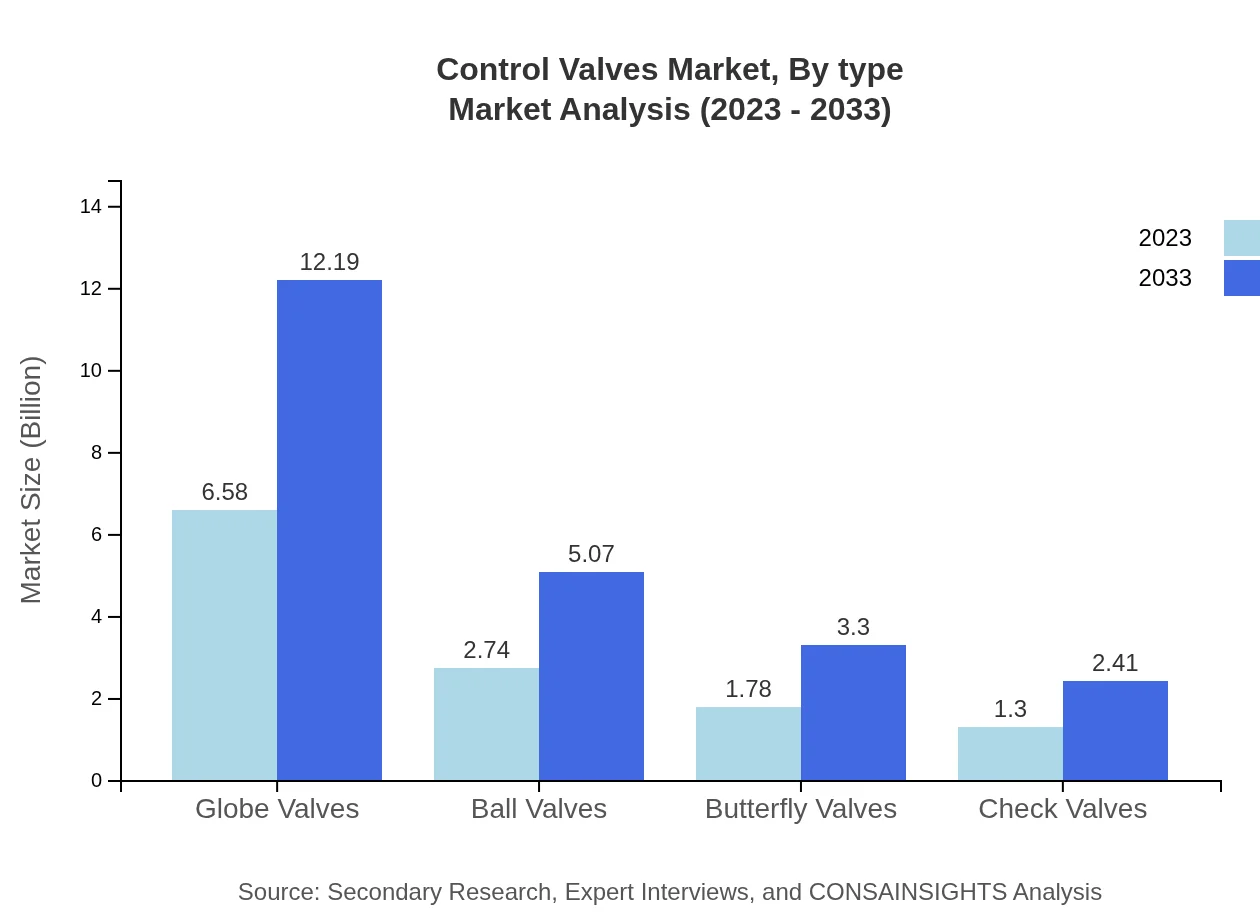

Control Valves Market Analysis By Type

The Control Valves market by type comprises several categories, including: - Globe Valves: Market size of $6.58 billion in 2023, expected to reach $12.19 billion by 2033. - Ball Valves: Market size of $2.74 billion in 2023, expected to reach $5.07 billion by 2033. - Butterfly Valves: Market size of $1.78 billion in 2023, projected to grow to $3.30 billion by 2033. - Check Valves: Starting at $1.30 billion in 2023, anticipated to rise to approximately $2.41 billion by 2033.

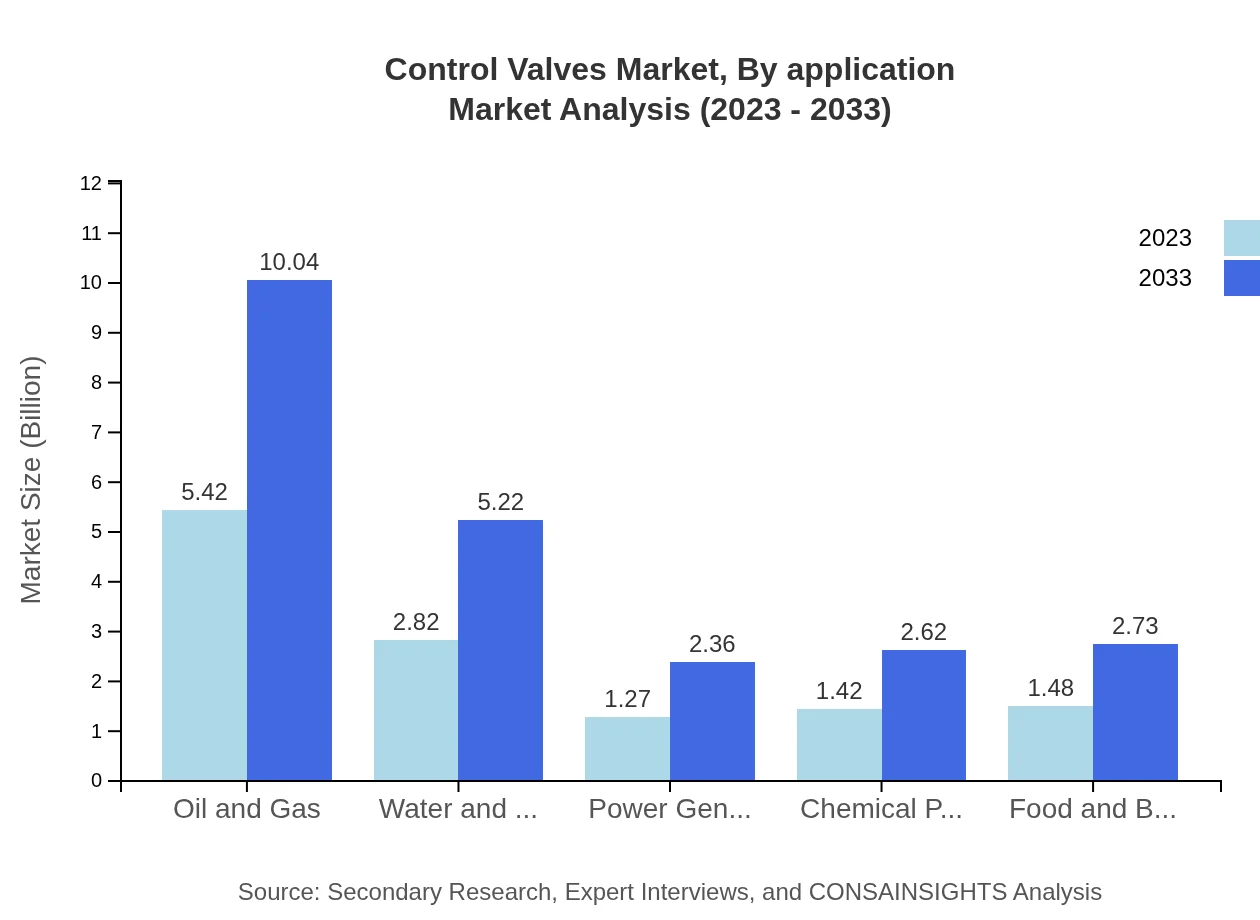

Control Valves Market Analysis By Application

The applications of control valves are diverse, impacting key industries: - Oil and Gas: Market size of $5.42 billion in 2023, projected to reach $10.04 billion by 2033. - Water and Wastewater Treatment: Growth from $2.82 billion to $5.22 billion over the same period. - Power Generation: Expected to grow from $1.27 billion to $2.36 billion, given its relevance in energy sectors.

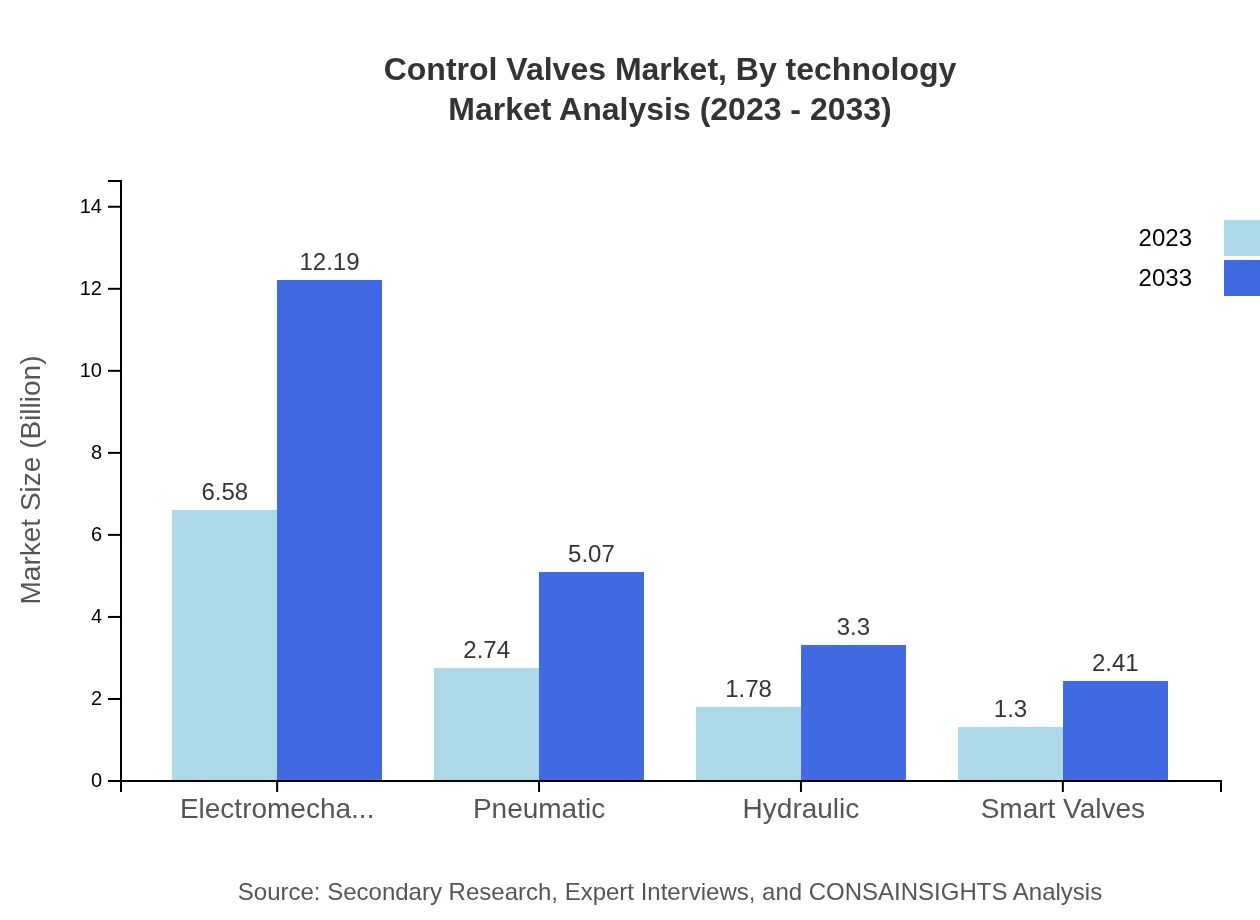

Control Valves Market Analysis By Technology

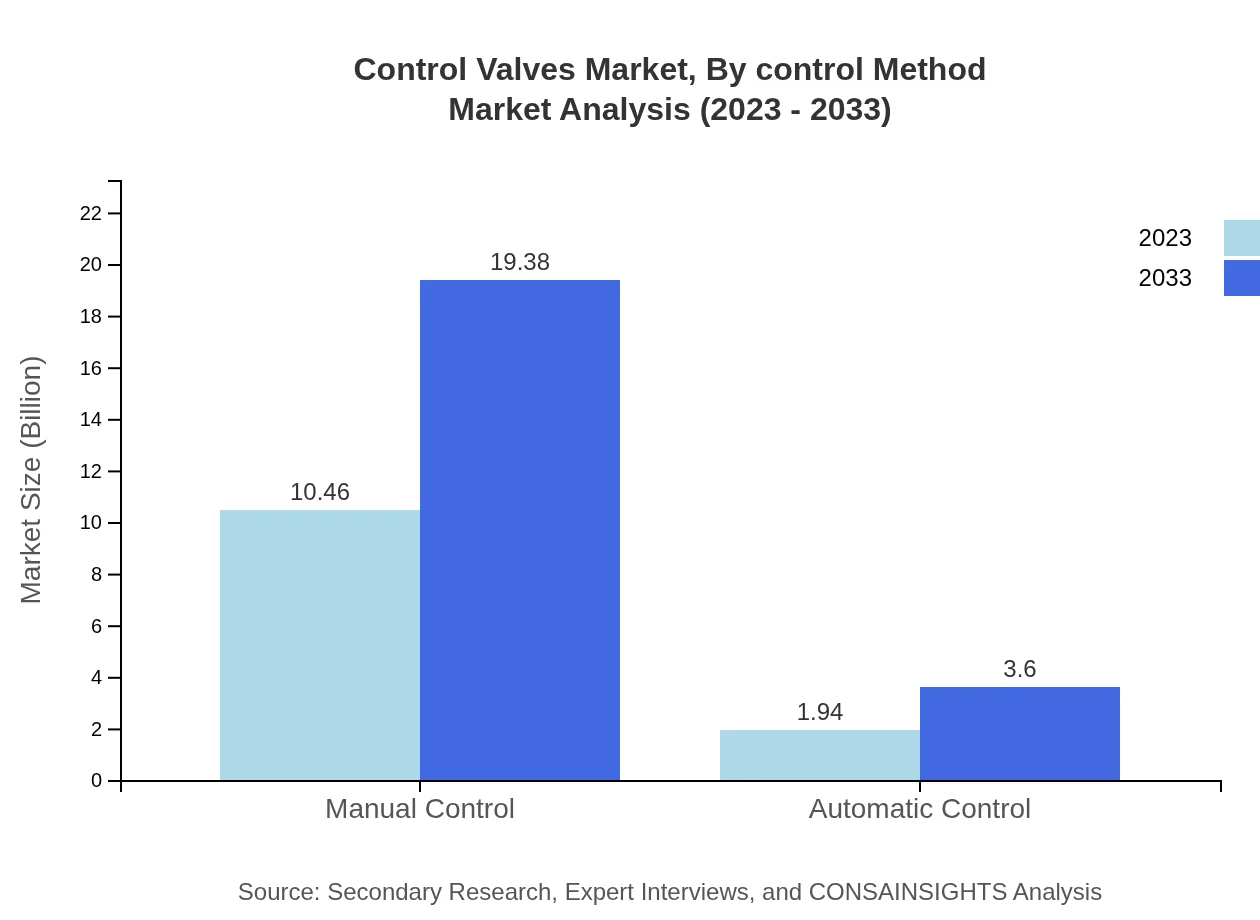

The Control Valves market by technology includes: - Manual Control: Significant market size of $10.46 billion in 2023, projected to grow to $19.38 billion by 2033. - Automatic Control: Anticipated growth from $1.94 billion to $3.60 billion, driven by trend towards automation.

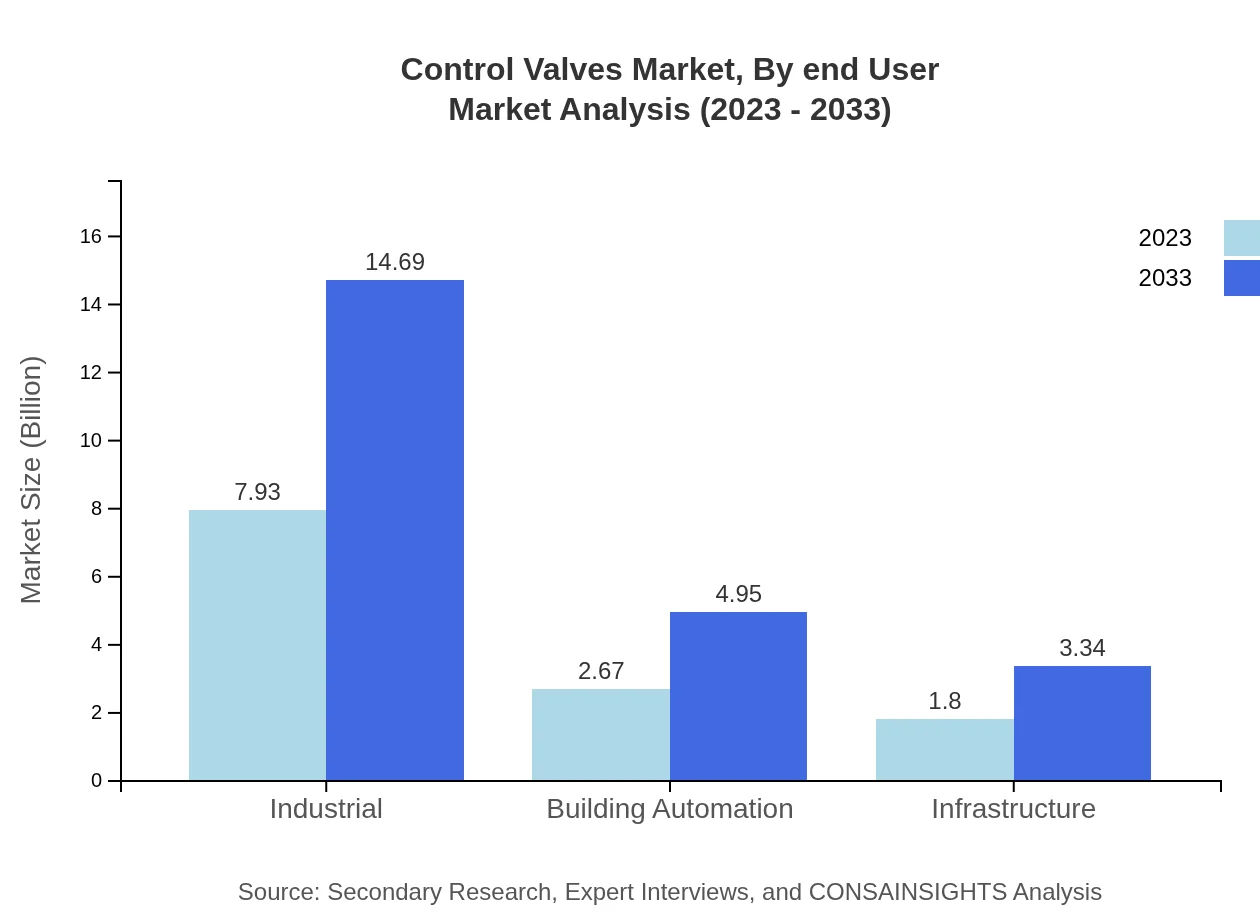

Control Valves Market Analysis By End User

End-users of control valves span across various sectors, including: - Industrial applications, taking up a market share of 63.92% in 2023 with expected growth correlating with industrial recovery. - Food and Beverage, Chemical Processing, and others playing critical roles with moderate shares and growing demand.

Control Valves Market Analysis By Control Method

The Control Valves market by control method illustrates: - Manual Control continues to dominate with 84.34% market share in 2023, while Automatic Control, although smaller at 15.66%, is seeing more adoption in advanced applications.

Control Valves Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Control Valves Industry

Emerson Electric Co.:

A global leader in automation technology, Emerson offers a wide range of control valves known for their precision and reliability in industries such as oil and gas and food processing.Flowserve Corporation:

Flowserve specializes in manufacturing flow control products and provides control valves that cater to various applications, enhancing productivity and efficiency in industrial settings.Honeywell International Inc.:

Honeywell integrates innovative technologies into its control valves, promoting automation across sectors such as building management and process industries.Siemens AG:

Siemens is renowned for its advancements in digital technologies and provides cutting-edge control valve solutions that meet the growing demand for efficiency and automation.We're grateful to work with incredible clients.

FAQs

What is the market size of control Valves?

The global control valves market is projected to reach $12.4 billion by 2033, expanding from $6.2 billion in 2023, with a CAGR of 6.2% during this period.

What are the key market players or companies in this control Valves industry?

Key players in the control valves industry include major companies such as Emerson Electric Co., Flowserve Corporation, and Honeywell International Inc., recognized for their innovative solutions and extensive market reach.

What are the primary factors driving the growth in the control Valves industry?

The control valves market growth is primarily driven by the increasing demand for automation in industrial applications, advancements in smart valve technology, and initiatives for sustainable energy management.

Which region is the fastest Growing in the control Valves?

Asia Pacific exhibits the fastest growth in the control valves market, expected to grow from $2.25 billion in 2023 to $4.17 billion by 2033, reflecting a robust CAGR due to industrial expansions.

Does ConsaInsights provide customized market report data for the control Valves industry?

Yes, ConsaInsights offers customized market reports tailored to specific clients' needs in the control valves industry, ensuring relevant insights and data required for strategic decisions.

What deliverables can I expect from this control Valves market research project?

Deliverables from the control valves market research project include comprehensive market analysis reports, segmentation data, regional forecasts, and competitive landscape assessments.

What are the market trends of control Valves?

Market trends in control valves include a shift towards automation and smart valves, growing integration of IoT technologies, and increased emphasis on energy efficiency across various industries.