Conveyor Monitoring Market Report

Published Date: 22 January 2026 | Report Code: conveyor-monitoring

Conveyor Monitoring Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Conveyor Monitoring market, covering market size, trends, regional analyses, and forecasts for the years 2023 to 2033. Key insights and data are provided to facilitate informed decision-making in this rapidly developing sector.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

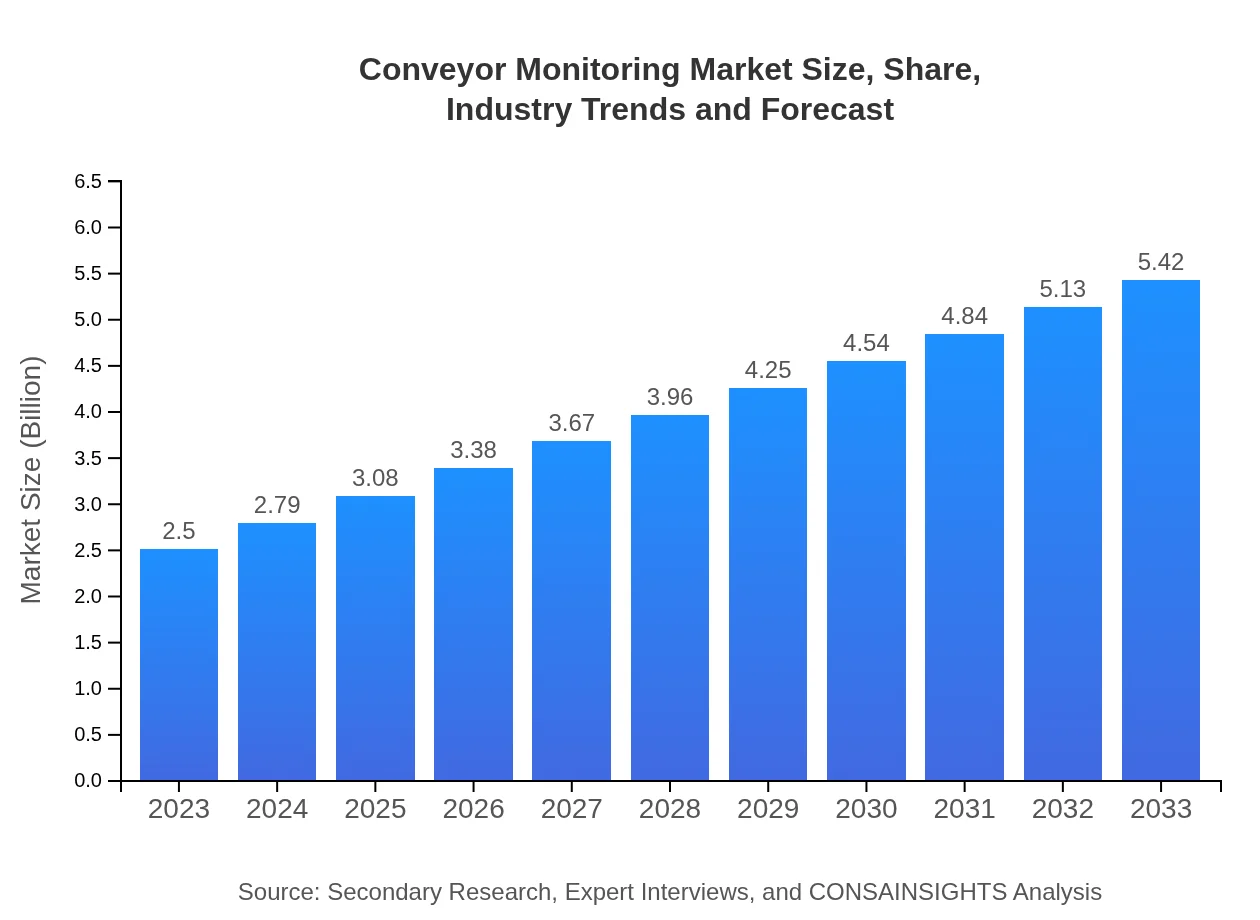

| 2023 Market Size | $2.50 Billion |

| CAGR (2023-2033) | 7.8% |

| 2033 Market Size | $5.42 Billion |

| Top Companies | Siemens AG, Rockwell Automation, Honeywell International Inc., Schneider Electric, Emerson Electric Co. |

| Last Modified Date | 22 January 2026 |

Conveyor Monitoring Market Overview

Customize Conveyor Monitoring Market Report market research report

- ✔ Get in-depth analysis of Conveyor Monitoring market size, growth, and forecasts.

- ✔ Understand Conveyor Monitoring's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Conveyor Monitoring

What is the Market Size & CAGR of Conveyor Monitoring market in 2023?

Conveyor Monitoring Industry Analysis

Conveyor Monitoring Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Conveyor Monitoring Market Analysis Report by Region

Europe Conveyor Monitoring Market Report:

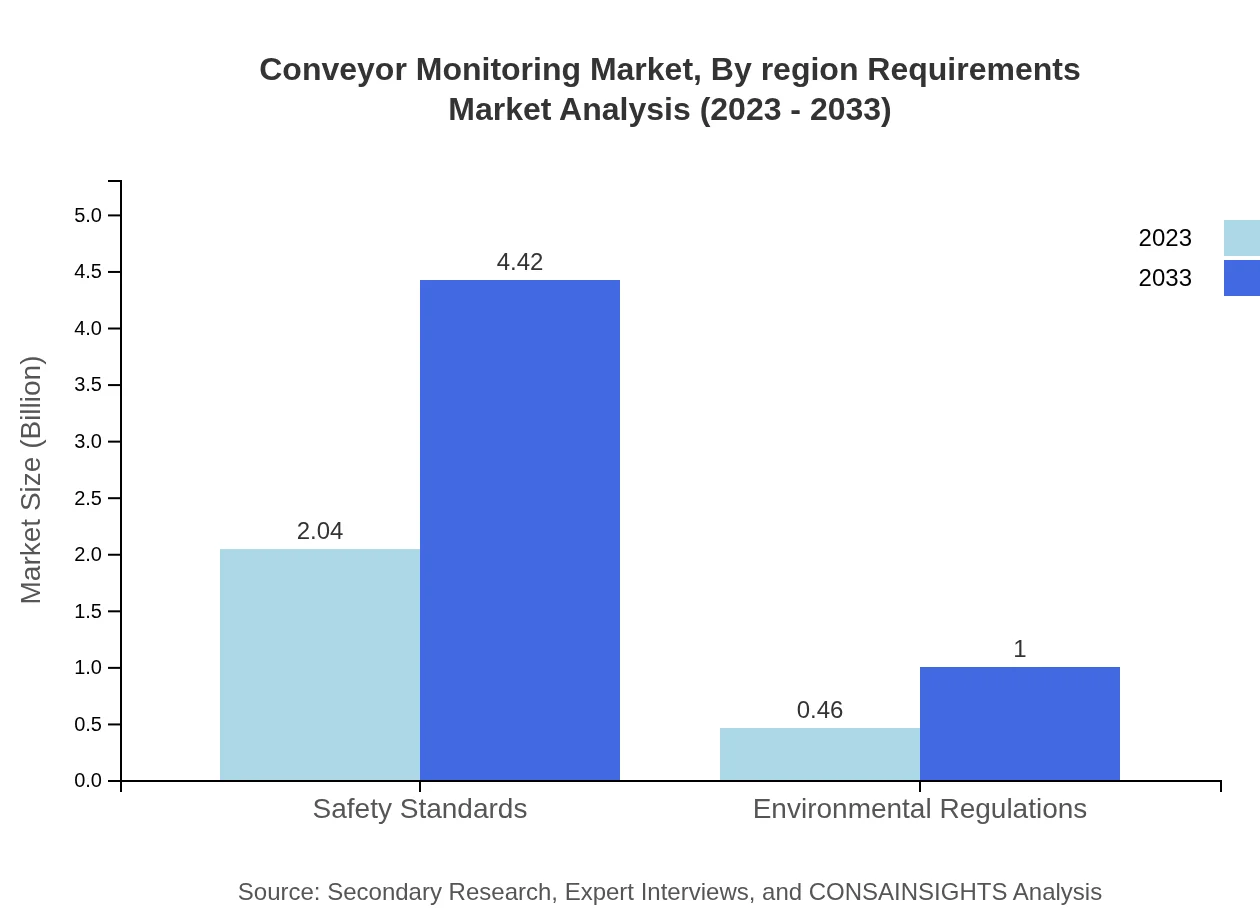

Europe's Conveyor Monitoring market is anticipated to increase from USD 0.77 billion in 2023 to USD 1.67 billion by 2033. The region is proactive in adopting stringent safety standards and environmental regulations, which in turn drives the adoption of innovative conveyor monitoring solutions. Key industries such as automotive and food processing are leading the charge in automation.Asia Pacific Conveyor Monitoring Market Report:

In the Asia Pacific region, the Conveyor Monitoring market is expected to grow from USD 0.47 billion in 2023 to USD 1.03 billion by 2033. Rapid industrialization, especially in countries like China and India, and the expansion of manufacturing hubs are driving demand for advanced conveyor monitoring solutions. The emphasis on automation and operational efficiency has led to increased investments in monitoring technologies.North America Conveyor Monitoring Market Report:

North America holds a significant share of the Conveyor Monitoring market, projected to grow from USD 0.93 billion in 2023 to USD 2.03 billion by 2033. The region's advanced manufacturing infrastructure, combined with a strong focus on automation and smart technologies, positions it well for continued expansion in this sector.South America Conveyor Monitoring Market Report:

The South American Conveyor Monitoring market, while smaller, shows potential growth from USD 0.02 billion in 2023 to USD 0.04 billion by 2033. This growth is largely attributed to the mining and agricultural sectors where conveyor systems are vital. Adapting new technologies is critical for improving productivity and keeping up with global standards.Middle East & Africa Conveyor Monitoring Market Report:

The Middle East and Africa are expected to see their Conveyor Monitoring market grow from USD 0.30 billion in 2023 to USD 0.66 billion by 2033. Factors such as infrastructural development in the logistics and mining sectors contribute to this growth as countries seek to modernize their operational capabilities.Tell us your focus area and get a customized research report.

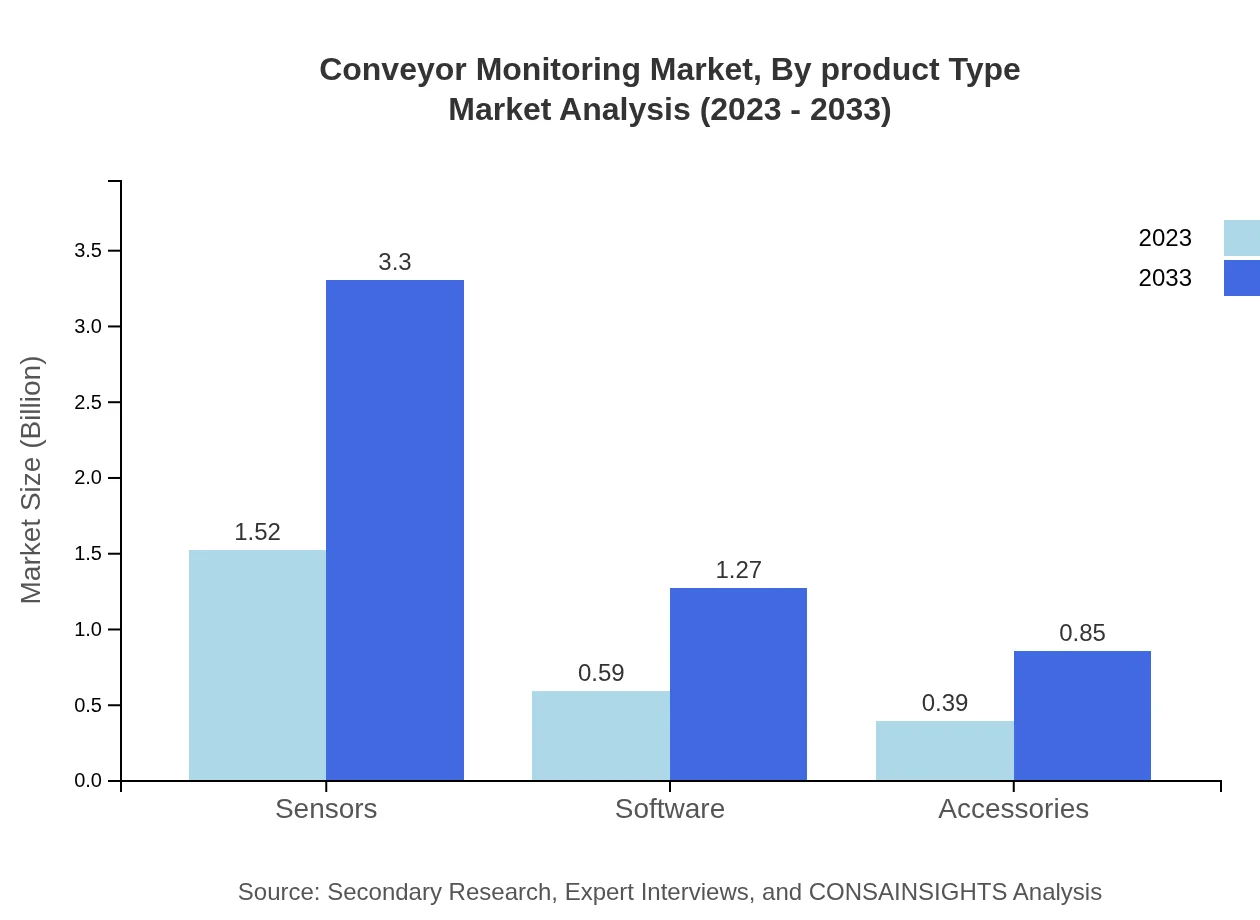

Conveyor Monitoring Market Analysis By Product Type

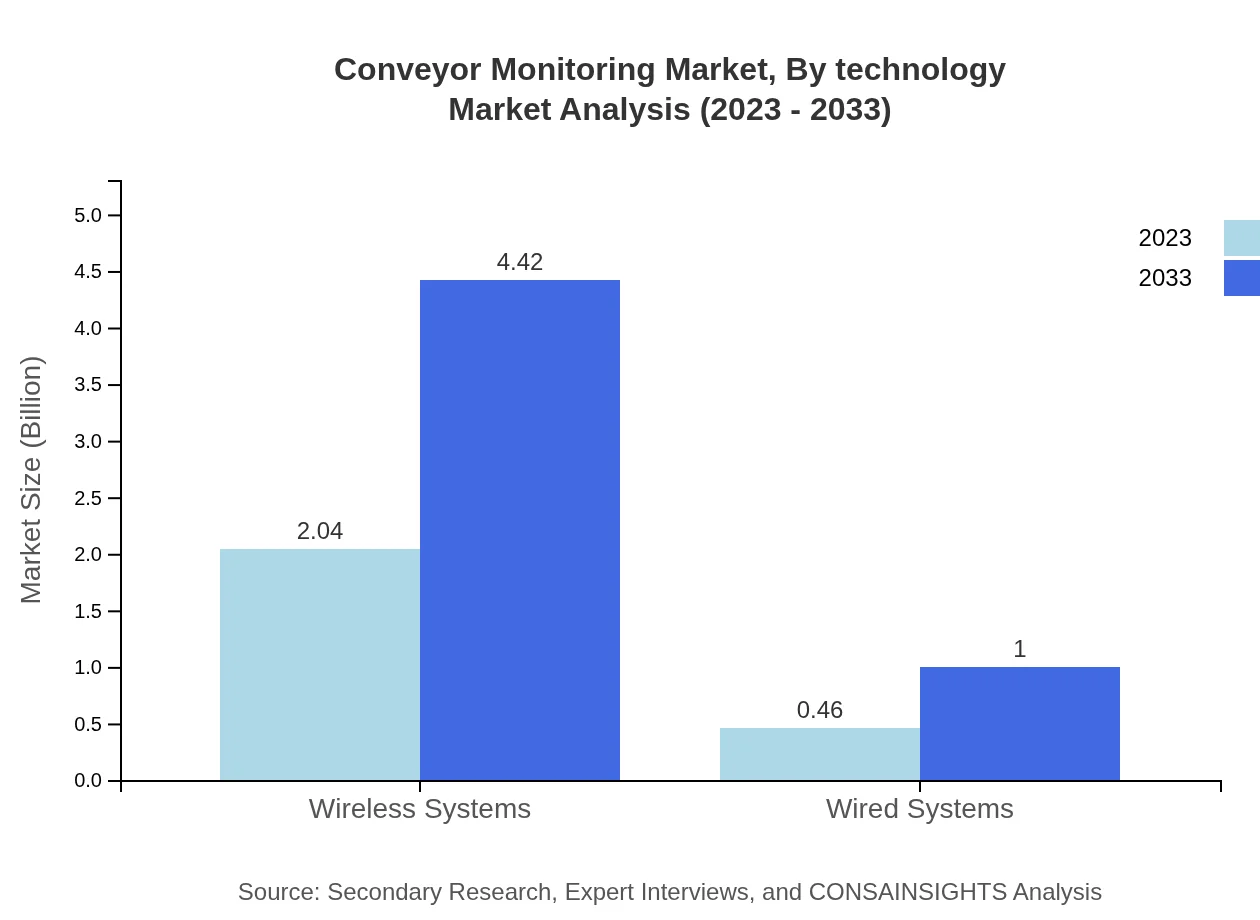

The market by product type indicates strong performance for Sensors, which are expected to expand from USD 1.52 billion in 2023 to USD 3.30 billion by 2033, capturing 60.98% of the market share. Wireless systems also play a dominant role, expected to grow from USD 2.04 billion in 2023 to USD 4.42 billion by 2033, holding 81.52% of the share.

Conveyor Monitoring Market Analysis By Technology

Market analysis by technology reveals a significant inclination towards Wireless Systems, projected to grow remarkably. Trends in IoT integration and advancements in software analytics are reshaping conveyor monitoring, providing robust data insights and predictive maintenance solutions.

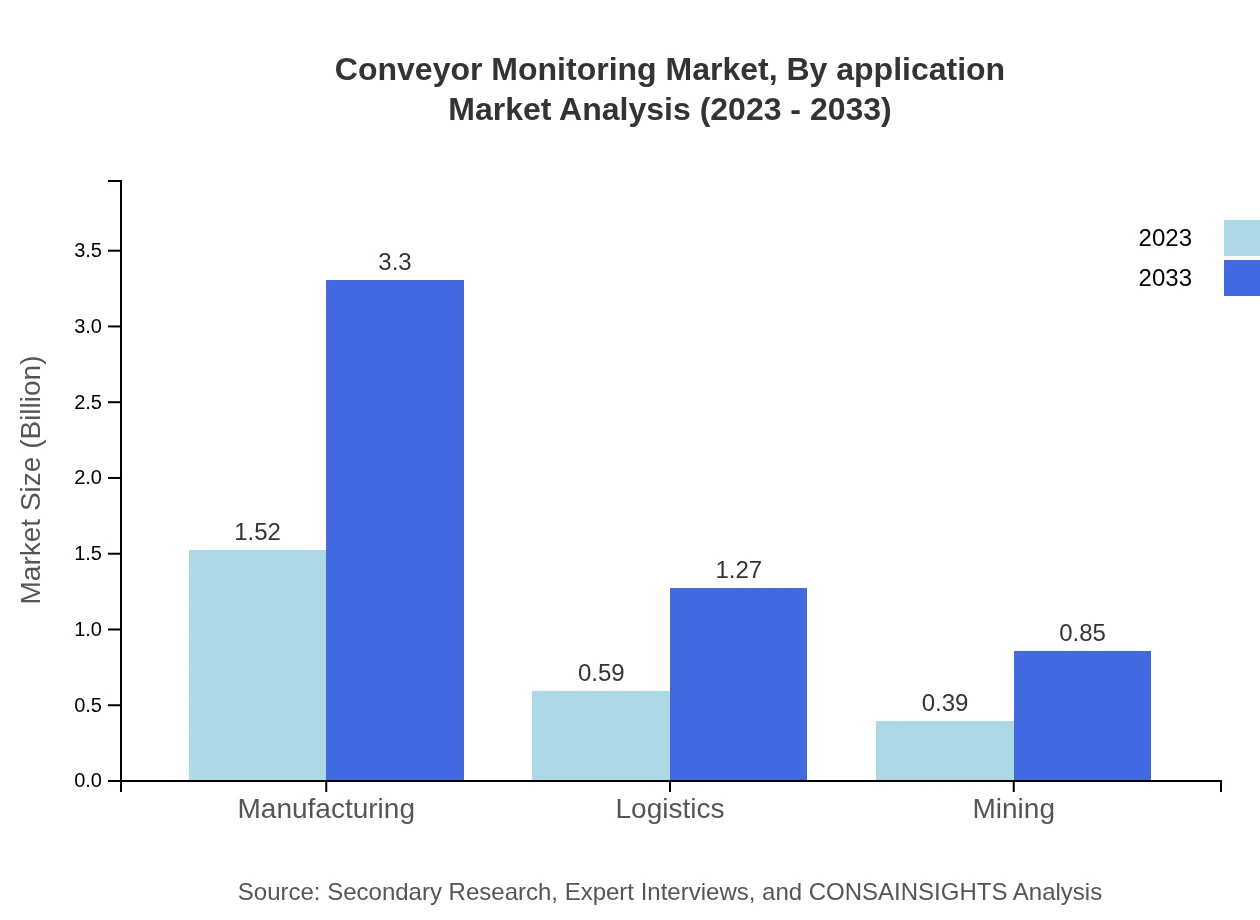

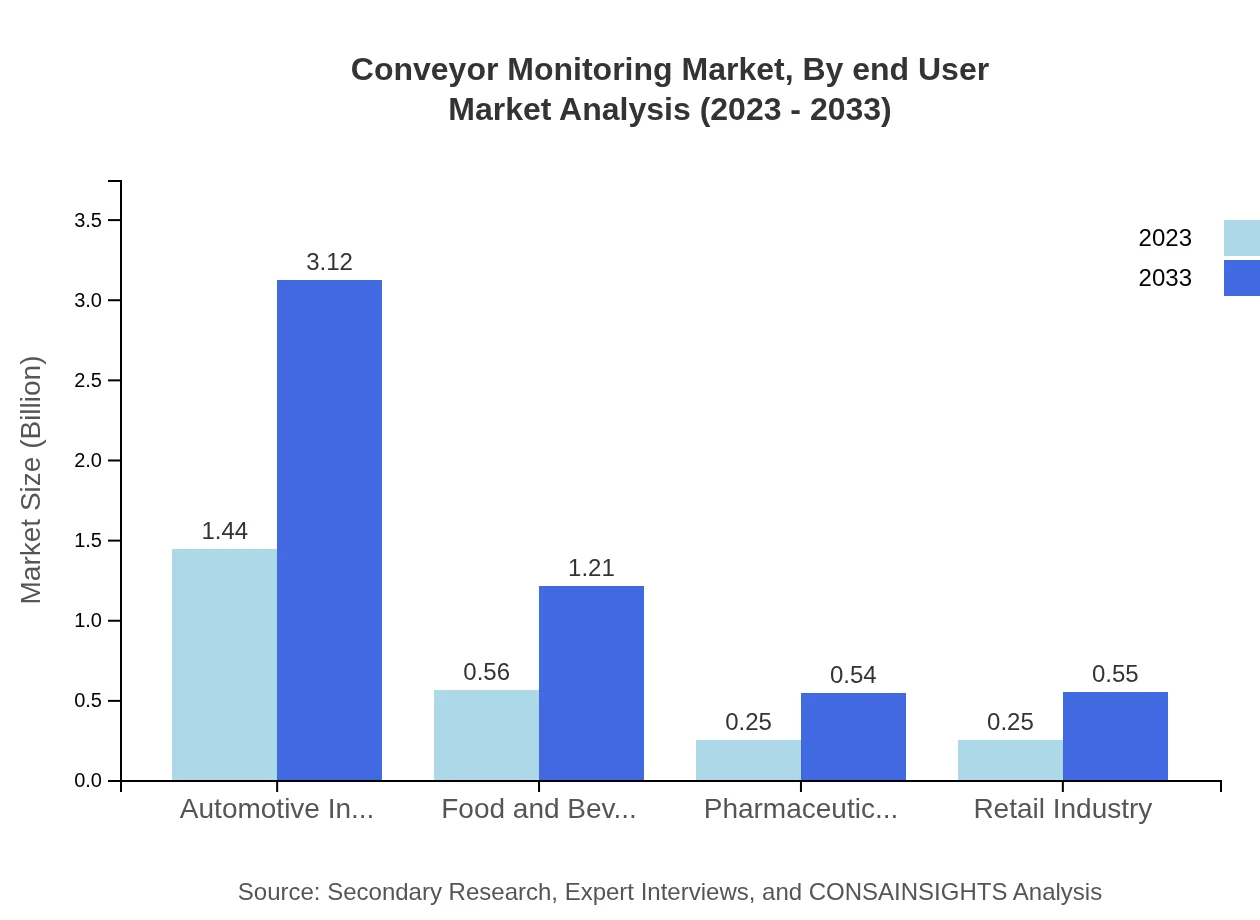

Conveyor Monitoring Market Analysis By Application

Application-wise, the Automotive Industry commands the largest market share, reaching USD 1.44 billion in 2023 and anticipated to more than double to USD 3.12 billion by 2033. Other industries like Food and Beverage and Pharmaceutical are also witnessing increased investments in monitoring technologies, driven by the need for enhanced operational efficiencies.

Conveyor Monitoring Market Analysis By End User

End-user analysis highlights the Manufacturing sector as a key driver of growth, representing 60.98% share in 2023. The sector is expected to expand significantly, emphasizing operational reliability through advanced conveyor monitoring technologies. Logistics and Mining sectors are also critical end users, contributing substantially to market progress.

Conveyor Monitoring Market Analysis By Region Requirements

Regulatory requirements are increasingly shaping the Conveyor Monitoring market. Strict safety standards drive the adoption of advanced monitoring systems, particularly in North America and Europe. Ensuring compliance with environmental regulations also promotes investment in sustainable monitoring solutions.

Conveyor Monitoring Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Conveyor Monitoring Industry

Siemens AG:

Siemens is a global leader in automation and digitalization, providing advanced conveyor monitoring and automation solutions that enhance operational efficiency across various industries.Rockwell Automation:

Rockwell Automation specializes in industrial automation, offering solutions that optimize conveyor operations and ensure seamless integration of monitoring systems into existing processes.Honeywell International Inc.:

Honeywell provides a range of monitoring solutions that enhance safety and efficiency, particularly in logistics and manufacturing environments, leveraging advanced sensor technology.Schneider Electric:

Schneider Electric focuses on energy management and automation, offering innovative solutions for conveyor monitoring that improve system reliability and productivity.Emerson Electric Co.:

Emerson is known for its automation technology and process management solutions, contributing to the efficient operation of conveyor systems through advanced monitoring capabilities.We're grateful to work with incredible clients.

FAQs

What is the market size of conveyor Monitoring?

The conveyor monitoring market is projected to grow from $2.5 billion in 2023 with a CAGR of 7.8%, reaching $4.95 billion by 2033, as industries increasingly adopt advanced monitoring technologies.

What are the key market players or companies in this conveyor Monitoring industry?

Key players in the conveyor monitoring industry include major technology firms specializing in automation, integrated control systems, and IoT solutions, contributing significantly to advancements and product innovations.

What are the primary factors driving the growth in the conveyor Monitoring industry?

Growth is primarily driven by increasing automation across industries, heightened safety regulations, demand for real-time monitoring, and technological advancement in sensor and communication technologies.

Which region is the fastest Growing in the conveyor Monitoring?

Asia Pacific is the fastest-growing region, expanding from $0.47 billion in 2023 to $1.03 billion by 2033, driven by rapid industrialization and investments in smart manufacturing technologies.

Does ConsaInsights provide customized market report data for the conveyor Monitoring industry?

Yes, ConsaInsights offers customized market report data tailored to specific requirements in the conveyor monitoring industry, focusing on particular sectors, regions, or technological advancements.

What deliverables can I expect from this conveyor Monitoring market research project?

Deliverables include detailed market analysis reports, segmentation insights, competitive landscape evaluations, growth forecasts, and actionable recommendations to enhance strategic decision-making.

What are the market trends of conveyor Monitoring?

Current market trends include increased adoption of AI and IoT for predictive maintenance, integration of advanced sensor technology, and a shift towards wireless monitoring solutions in various industries.