Conveyors Market Report

Published Date: 22 January 2026 | Report Code: conveyors

Conveyors Market Size, Share, Industry Trends and Forecast to 2033

This report provides in-depth analysis of the Conveyors market from 2023 to 2033, focusing on market size, trends, segmentation, and regional insights. It evaluates key factors driving growth and challenges impacting the industry, offering stakeholders a comprehensive outlook.

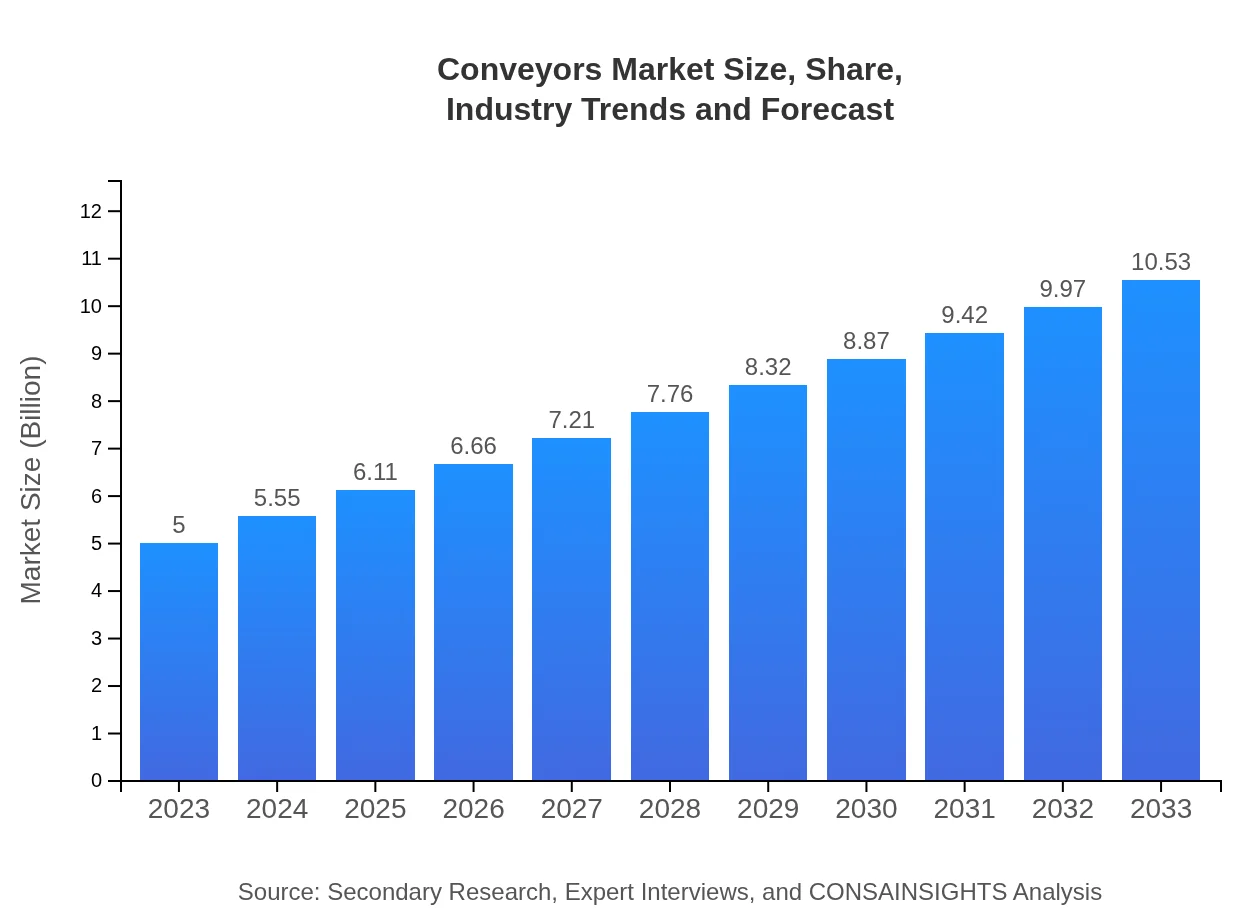

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.00 Billion |

| CAGR (2023-2033) | 7.5% |

| 2033 Market Size | $10.53 Billion |

| Top Companies | Siemens AG, Dorner Mfg. Corp., Fives Group, Honeywell Intelligrated, BEUMER Group |

| Last Modified Date | 22 January 2026 |

Conveyors Market Overview

Customize Conveyors Market Report market research report

- ✔ Get in-depth analysis of Conveyors market size, growth, and forecasts.

- ✔ Understand Conveyors's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Conveyors

What is the Market Size & CAGR of the Conveyors market in 2033?

Conveyors Industry Analysis

Conveyors Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Conveyors Market Analysis Report by Region

Europe Conveyors Market Report:

In Europe, the conveyors market will increase from USD 1.29 billion in 2023 to approximately USD 2.73 billion by 2033. The market is driven by significant investments in automation and smart factory initiatives in Germany and the UK.Asia Pacific Conveyors Market Report:

In the Asia Pacific region, the conveyors market is expected to expand from USD 0.96 billion in 2023 to USD 2.02 billion by 2033, driven by rapid industrialization and growing e-commerce activities. The rise in manufacturing hubs in countries like China and India is also a significant contributor.North America Conveyors Market Report:

North America is projected to see substantial growth, with market size increasing from USD 1.82 billion in 2023 to USD 3.83 billion by 2033. The United States remains a key player due to its advanced manufacturing and logistics sectors.South America Conveyors Market Report:

The South American market is anticipated to grow from USD 0.40 billion in 2023 to USD 0.84 billion by 2033. The boom in construction and mining sectors is driving demand for conveyors, with Brazil and Argentina leading the market.Middle East & Africa Conveyors Market Report:

The Middle East and Africa region is expected to witness growth from USD 0.53 billion in 2023 to USD 1.11 billion by 2033, thanks to growing demand for construction and transportation sectors, with significant contributions from Gulf Cooperation Council (GCC) countries.Tell us your focus area and get a customized research report.

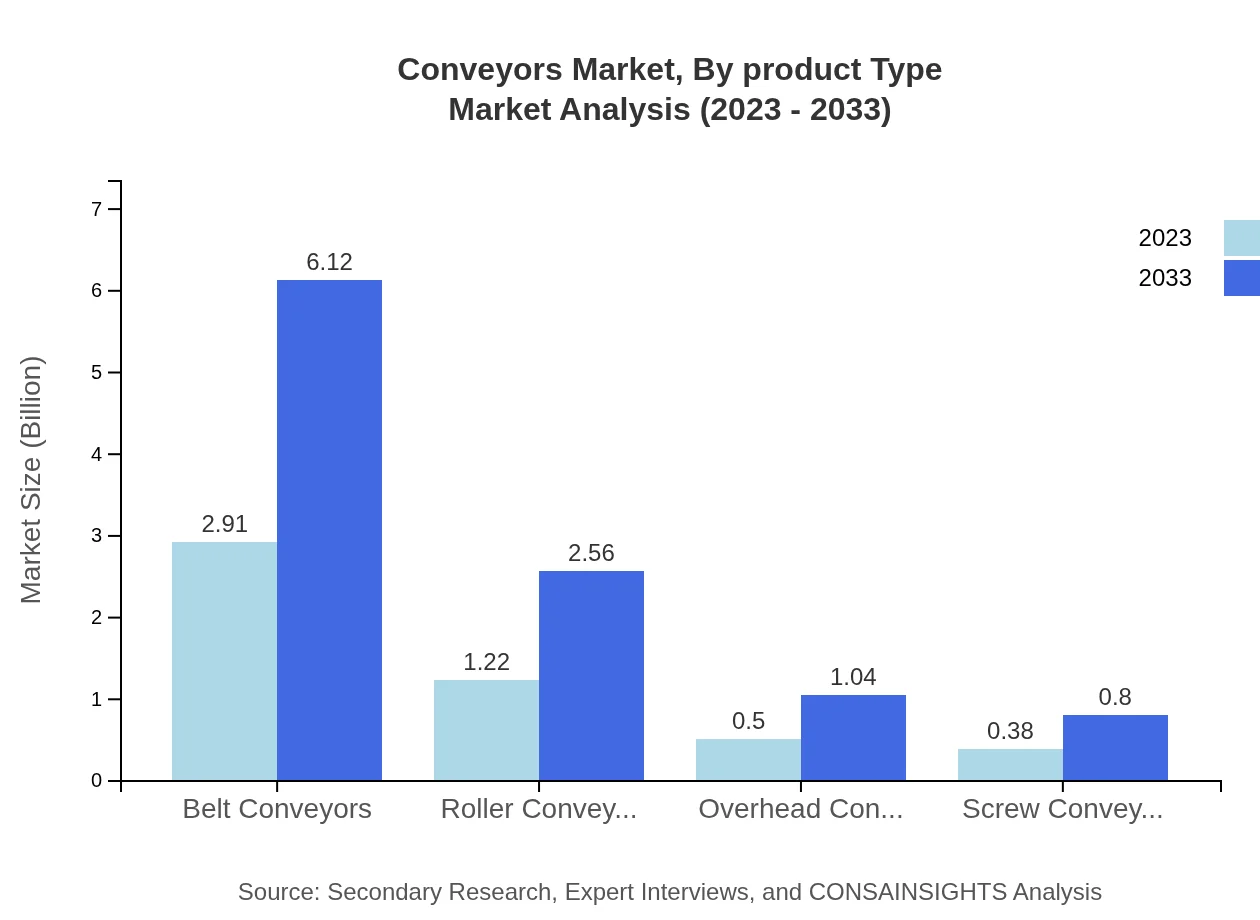

Conveyors Market Analysis By Product Type

Within the Conveyors market, belt conveyors account for the highest share, constituting approximately 58.18% in 2023, expected to rise to 58.18% by 2033. Roller conveyors follow with a market share of 24.34%, while overhead and screw conveyors contribute 9.91% and 7.57%, respectively, indicating diverse application across various sectors.

Conveyors Market Analysis By Application

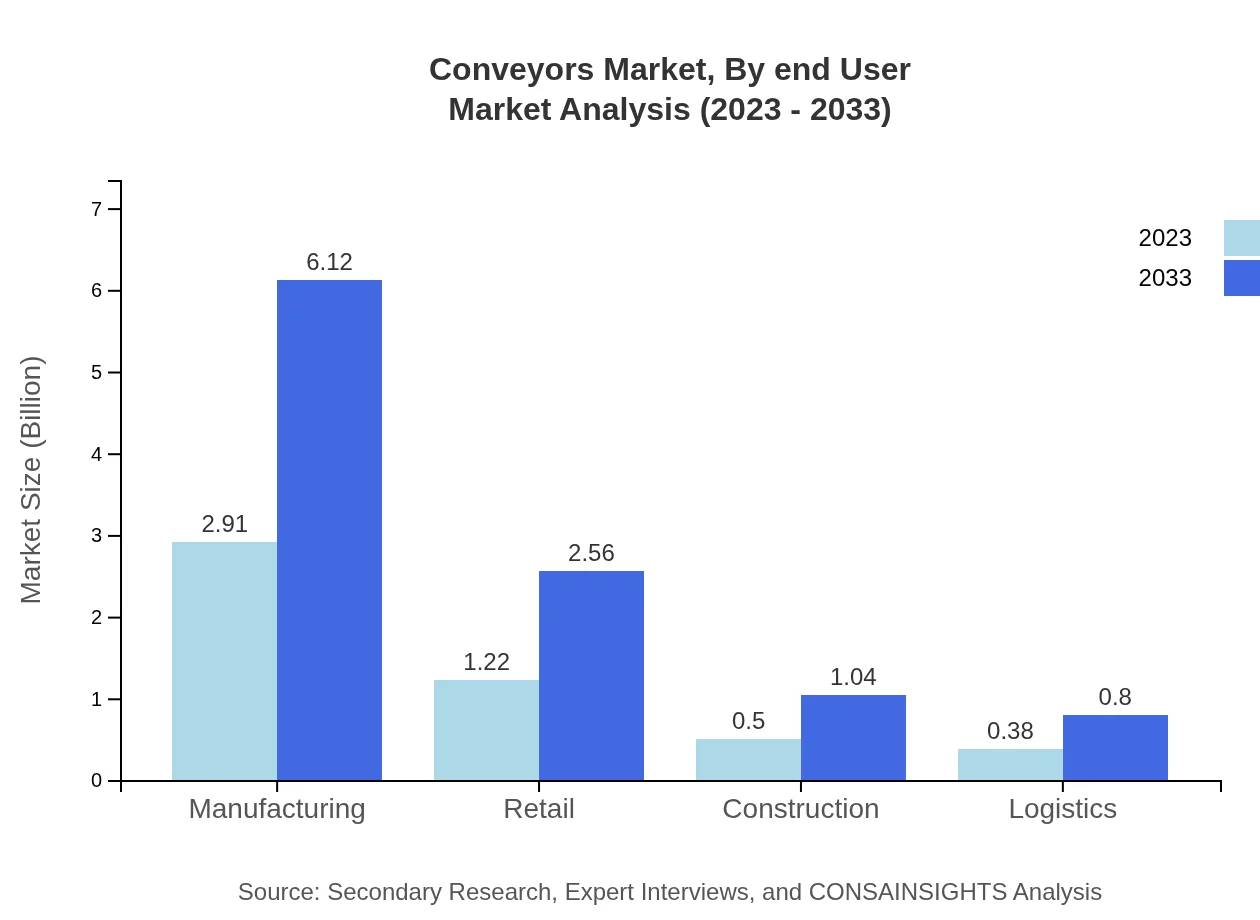

The application segmentation highlights manufacturing as the leading sector with a size of USD 2.91 billion in 2023 anticipated to reach USD 6.12 billion by 2033. Other significant applications include retail and logistics, reflecting the extensive use of conveyors in streamlining operations.

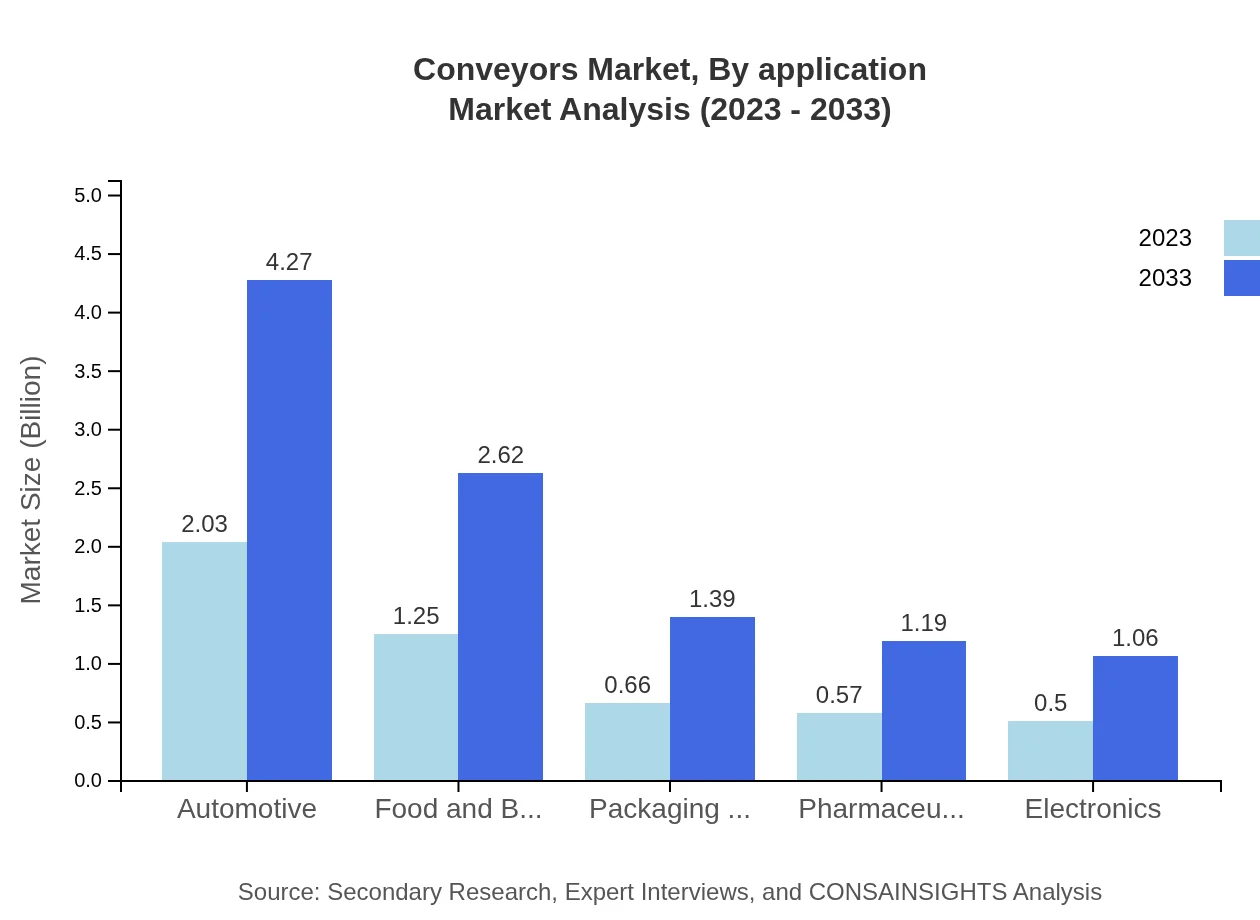

Conveyors Market Analysis By End User

Automotive and food & beverage industries are among the principal end-users of conveyor systems, with automotive's market size projected to grow from USD 2.03 billion to USD 4.27 billion by 2033. Retail and pharmaceutical industries also show robust growth, underlining the essential role of conveyors in various sectors.

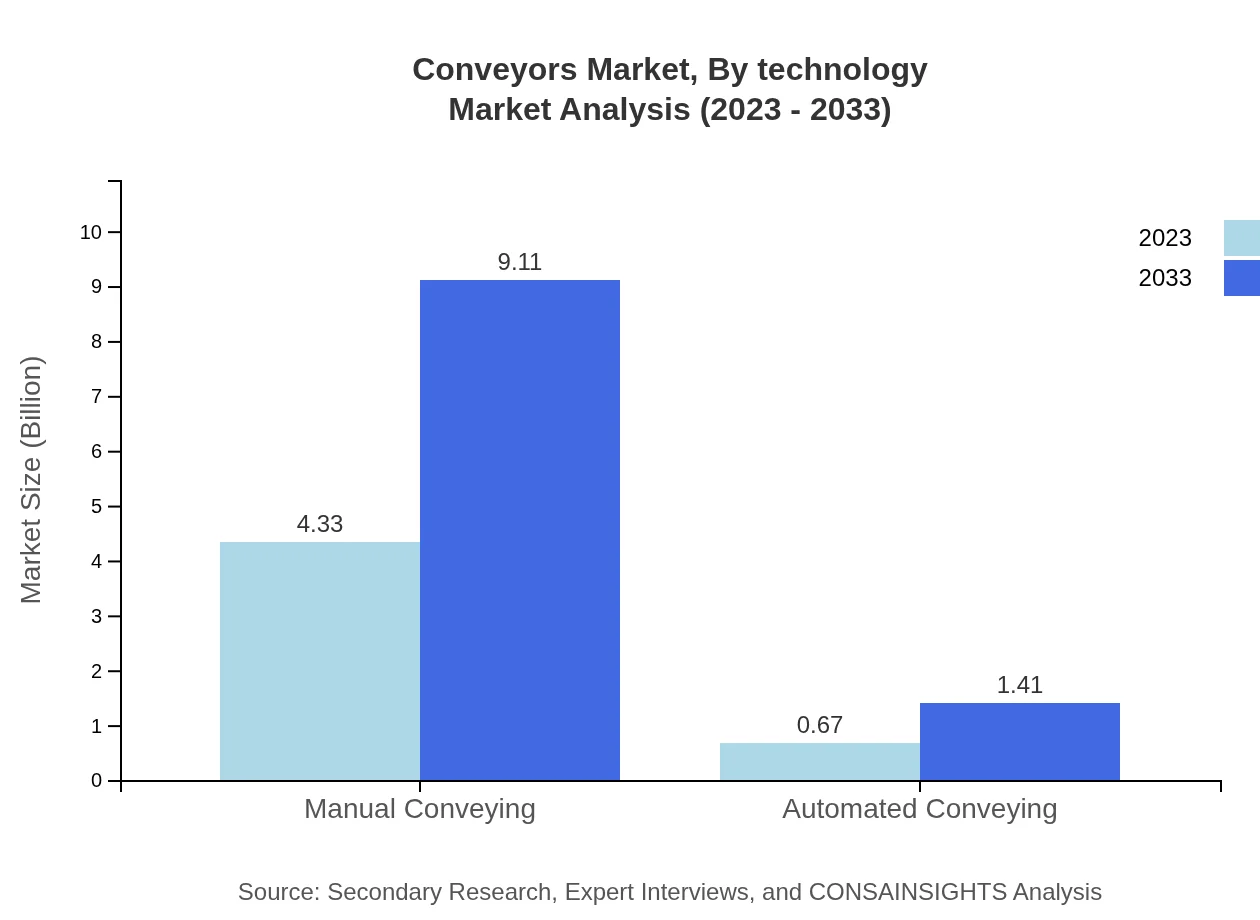

Conveyors Market Analysis By Technology

Technological advancements are reshaping the conveyors market. Manual conveying systems constitute a major portion, with a substantial market size surpassing automated systems. However, automated conveying solutions are gaining traction due to their efficiency and integration capabilities, indicating a shift towards more technologically-driven operations in the coming years.

Conveyors Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Conveyors Industry

Siemens AG:

A global leader in automation, Siemens offers a range of conveyor solutions optimized for efficiency and integration, driving advancements in the industry.Dorner Mfg. Corp.:

Dorner specializes in manufacturing versatile conveyor systems, known for their innovation and quality, serving various industries including food and packaging.Fives Group:

With a focus on advanced logistics solutions, Fives Group delivers high-quality conveyors tailored to specific industry needs, enhancing operational efficiency.Honeywell Intelligrated:

Honeywell's Intelligrated division designs and integrates automated material handling systems, leveraging cutting-edge technology to revolutionize the conveying industry.BEUMER Group:

A global provider of intralogistics, BEUMER Group is recognized for its innovative conveyor technologies used in various sectors, including cement and baggage handling.We're grateful to work with incredible clients.

FAQs

What is the market size of conveyors?

The global conveyors market is currently valued at approximately $5 billion and is projected to grow at a CAGR of 7.5%, reflecting increasing demand across sectors. This growth indicates its expanding role in manufacturing, logistics, and other industries.

What are the key market players or companies in this conveyors industry?

Key players in the conveyors market include global giants such as Honeywell, DEMATIC, Siemens, and Panasonic. These companies are known for their innovations in automation and material handling solutions, driving advancements in conveyor technology and systems.

What are the primary factors driving the growth in the conveyors industry?

The growth of the conveyors industry is primarily driven by increasing automation in manufacturing, rising demand for efficient material handling solutions, and the expansion of sectors like e-commerce and logistics that require robust conveyor systems for faster operations.

Which region is the fastest Growing in the conveyors market?

The Asia Pacific region is the fastest-growing market for conveyors, projected to expand from $0.96 billion in 2023 to $2.02 billion by 2033. This surge is fueled by rapid industrialization and a growing logistics infrastructure across countries in the region.

Does ConsaInsights provide customized market report data for the conveyors industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs within the conveyors industry. Clients can request detailed insights based on unique parameters or particular market segments they are interested in.

What deliverables can I expect from this conveyors market research project?

From the conveyors market research project, clients can expect comprehensive reports detailing market size, growth forecasts, regional analyses, competitive landscapes, and segment-specific insights, ensuring informed strategic decisions.

What are the market trends of conveyors?

Key market trends in the conveyors industry include increasing demand for automated systems, the adoption of smart conveyor technologies, and sustainable practices. Growth is notably prominent in segments such as manufacturing, retail, and logistics.