Coordinate Measuring Machine Market Report

Published Date: 22 January 2026 | Report Code: coordinate-measuring-machine

Coordinate Measuring Machine Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Coordinate Measuring Machine market from 2023 to 2033, focusing on market size, segmentation, regional insights, technological advancements, and forecasts, offering valuable insights for stakeholders in the industry.

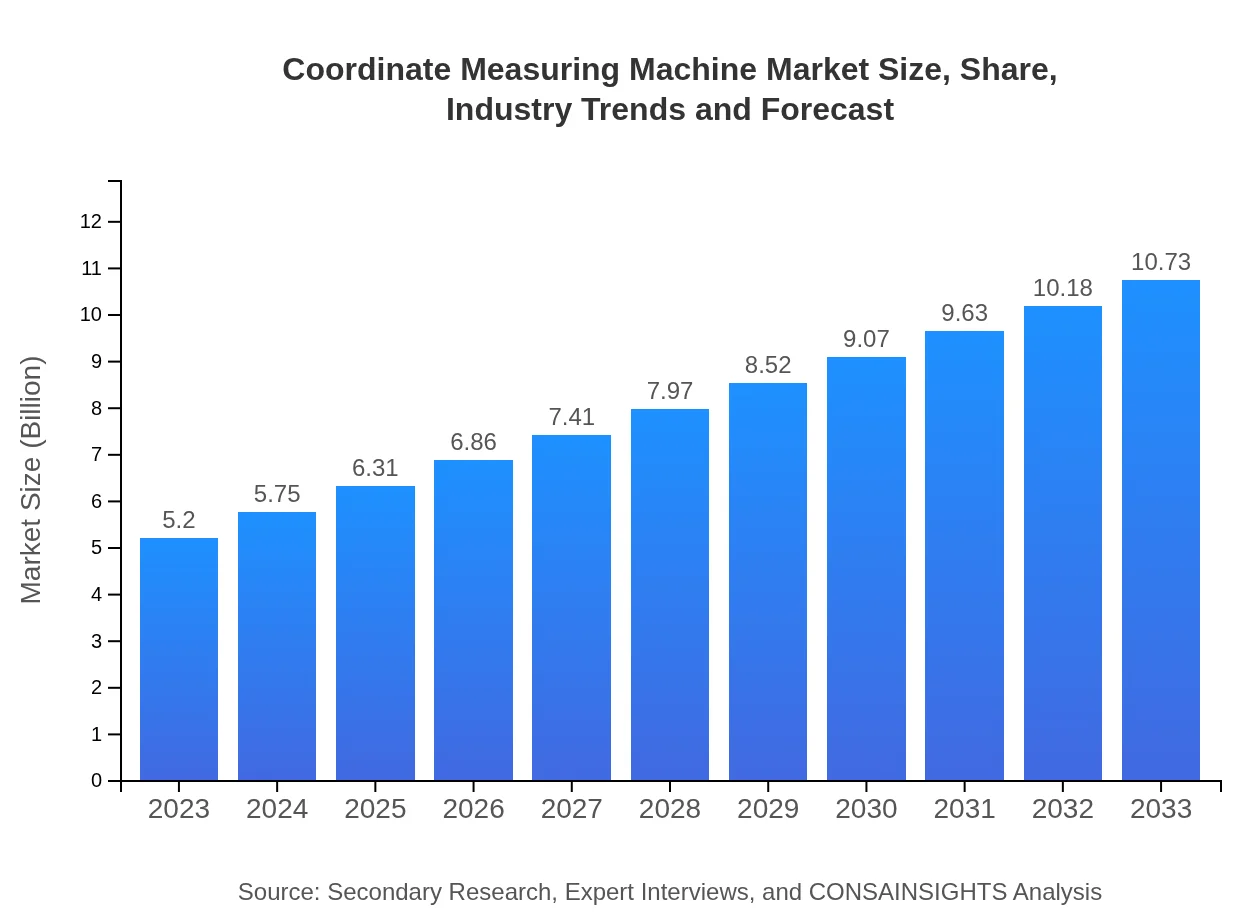

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.20 Billion |

| CAGR (2023-2033) | 7.3% |

| 2033 Market Size | $10.73 Billion |

| Top Companies | Hexagon AB, Faro Technologies, Inc., WENZEL Group, Zeiss Group, Mitutoyo Corporation |

| Last Modified Date | 22 January 2026 |

Coordinate Measuring Machine Market Overview

Customize Coordinate Measuring Machine Market Report market research report

- ✔ Get in-depth analysis of Coordinate Measuring Machine market size, growth, and forecasts.

- ✔ Understand Coordinate Measuring Machine's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Coordinate Measuring Machine

What is the Market Size & CAGR of Coordinate Measuring Machine market in 2023?

Coordinate Measuring Machine Industry Analysis

Coordinate Measuring Machine Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Coordinate Measuring Machine Market Analysis Report by Region

Europe Coordinate Measuring Machine Market Report:

Europe remains a significant player in the CMM market, expected to experience growth from $1.46 billion in 2023 to $3.02 billion in 2033. The ongoing investments in advanced manufacturing technologies and stringent quality control measures in industries like aerospace and automotive further drive market demand.Asia Pacific Coordinate Measuring Machine Market Report:

The Asia Pacific region is poised for substantial growth in the Coordinate Measuring Machine market, estimated at $2.03 billion by 2033, up from $0.98 billion in 2023. This growth is driven by increasing manufacturing activities in countries like China and Japan, where precision engineering is paramount. The rise of the electronics and automotive industries in this region further accelerates the demand for CMMs.North America Coordinate Measuring Machine Market Report:

North America leads the market with a projected growth from $1.98 billion in 2023 to $4.09 billion in 2033. The presence of major manufacturing hubs and increasing automation in industries such as automotive, aerospace, and healthcare solidify its status as a vital market for CMMs.South America Coordinate Measuring Machine Market Report:

In South America, the market is expected to grow moderately, from $0.32 billion in 2023 to $0.65 billion in 2033. The growth is influenced by the expanding automotive and aerospace industries, where efficient measurement technologies are crucial for maintaining quality standards.Middle East & Africa Coordinate Measuring Machine Market Report:

The Middle East and Africa CMM market is anticipated to increase from $0.45 billion in 2023 to $0.94 billion in 2033. Growth in construction, oil and gas industries, and a push towards improved manufacturing efficiency in various sectors are key drivers in this region.Tell us your focus area and get a customized research report.

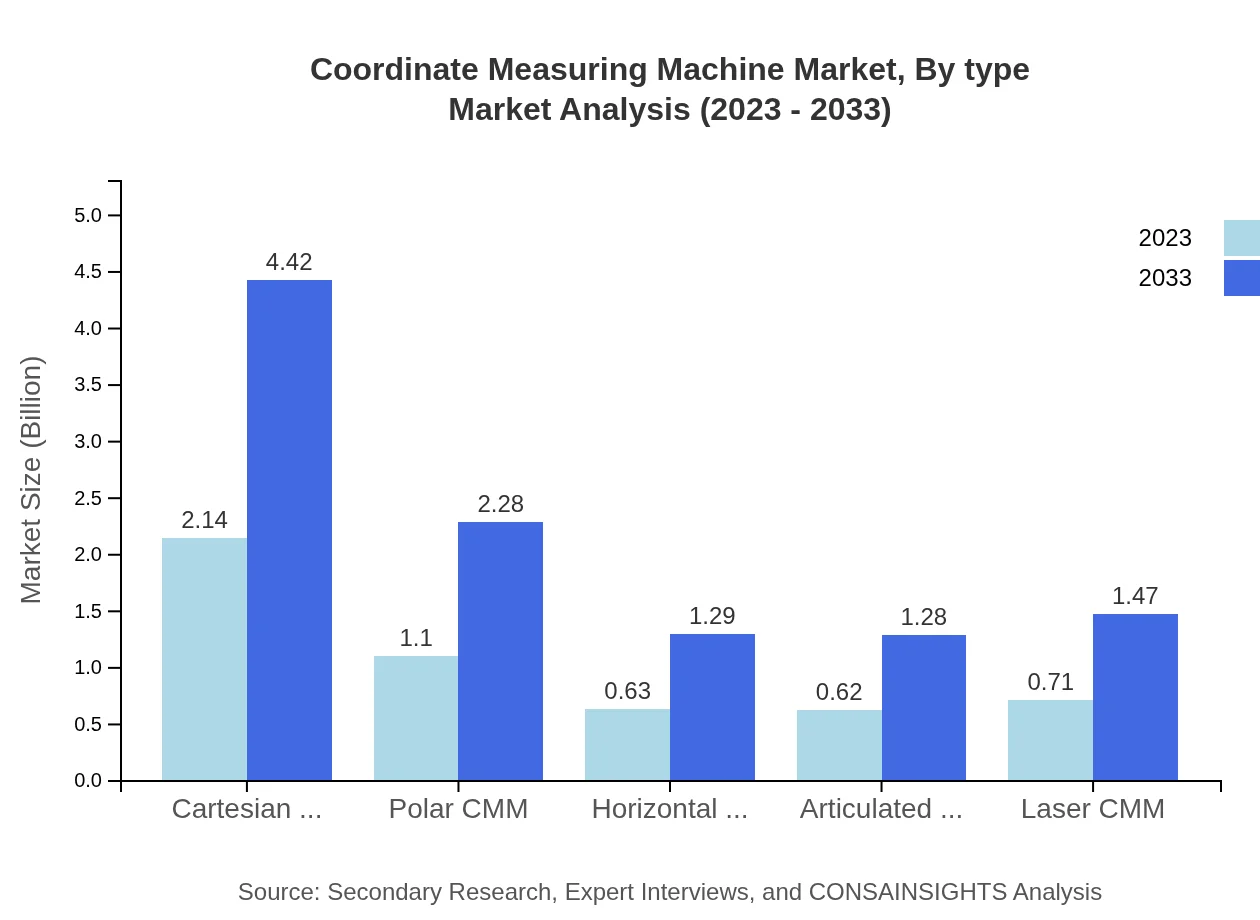

Coordinate Measuring Machine Market Analysis By Type

The market for Coordinate Measuring Machines is classified into different types: Cartesian CMM, Polar CMM, Horizontal Arm CMM, Articulated Arm CMM, and Laser CMM. In 2023, the Cartesian CMM leads with a market size of $2.14 billion, projected to reach $4.42 billion by 2033, maintaining a market share of 41.16%. The Polar and Horizontal Arm CMMs also show promising growth, expected to reach $2.28 billion from $1.10 billion and $1.29 billion from $0.63 billion, respectively, by 2033.

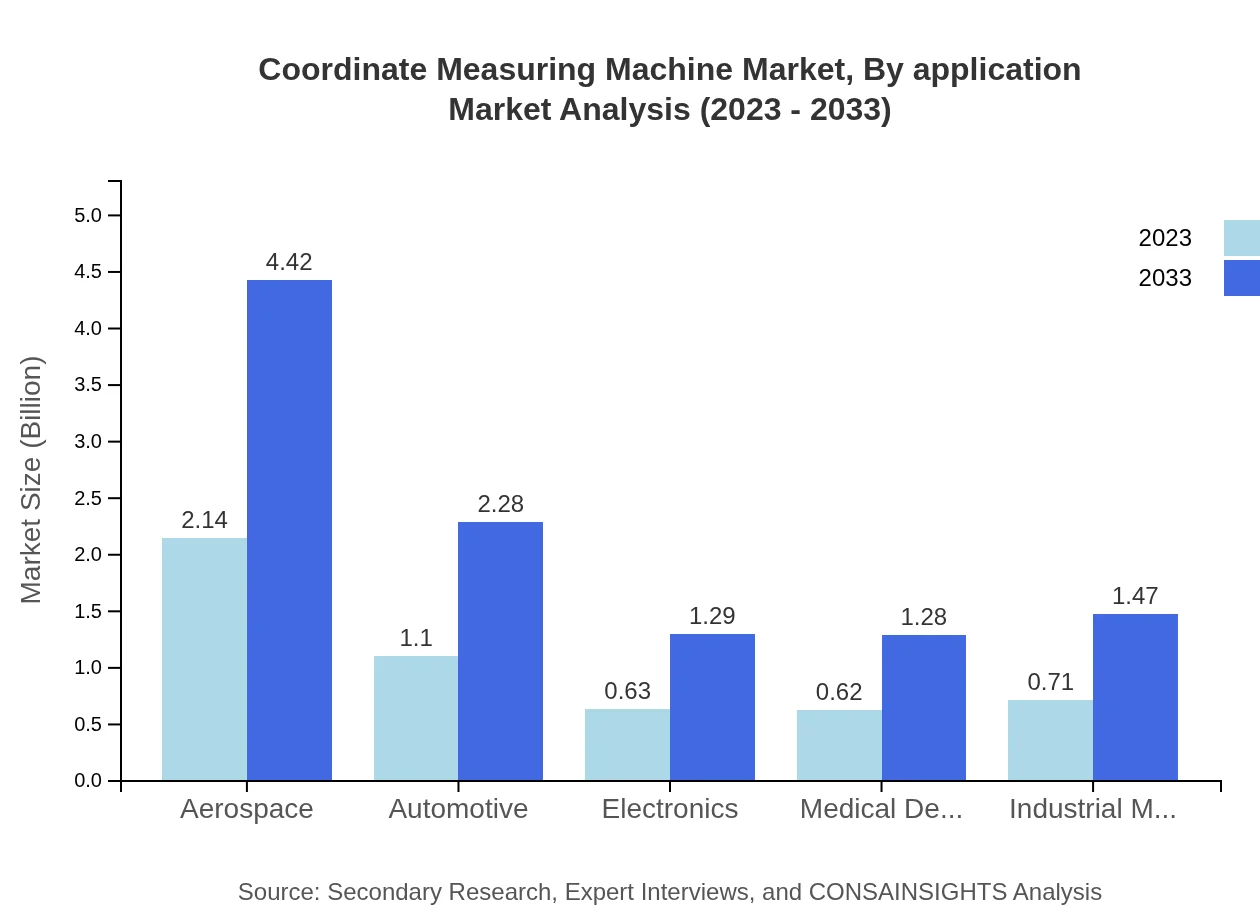

Coordinate Measuring Machine Market Analysis By Application

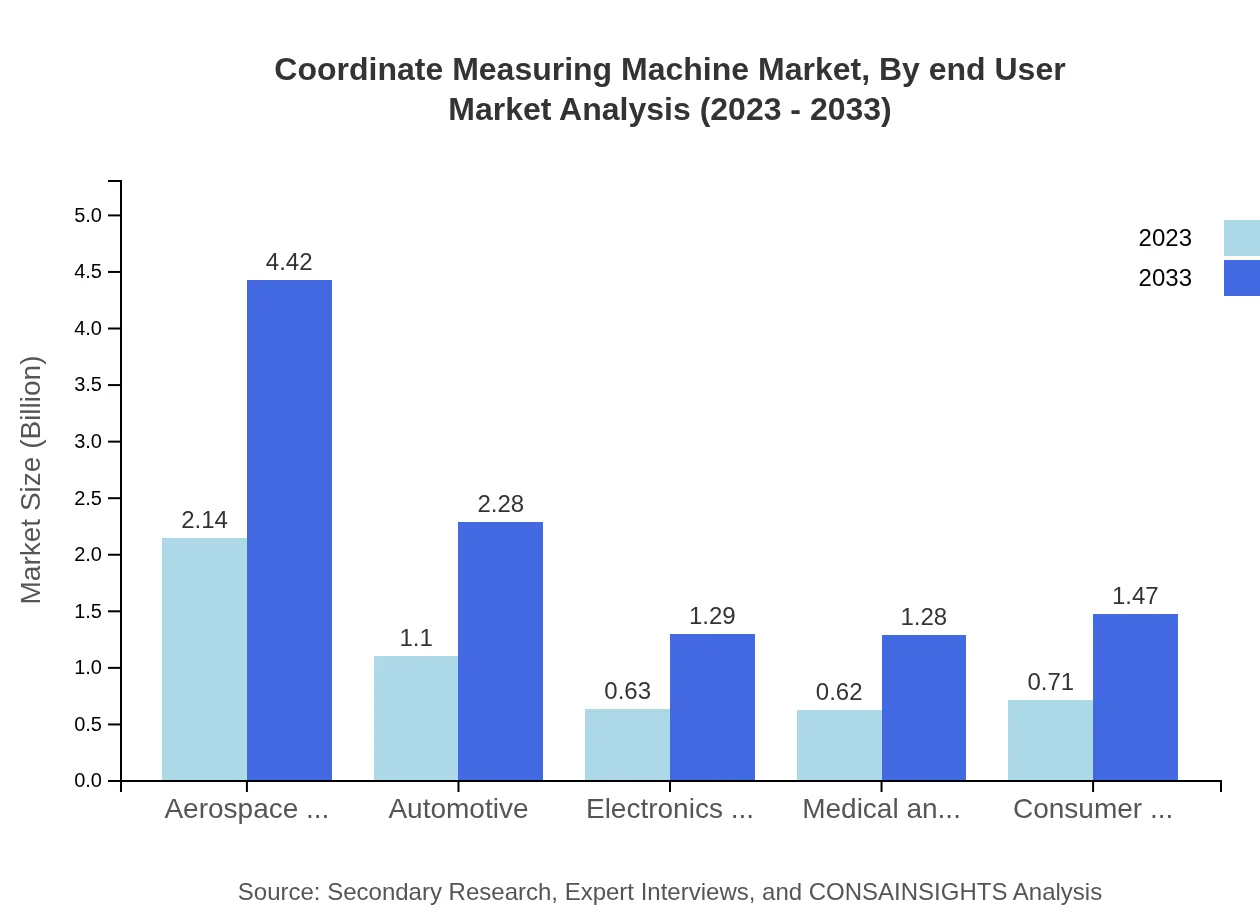

Key applications ofCoordinate Measuring Machines include Aerospace and Defense, Automotive, Electronics Manufacturing, Medical and Healthcare, and Consumer Goods. The aerospace sector demonstrates significant demand for CMM devices, expanding from $2.14 billion in 2023 to $4.42 billion in 2033, with a steady market share of 41.16%. The automotive sector follows closely, expected to show growth from $1.10 billion to $2.28 billion during the same period.

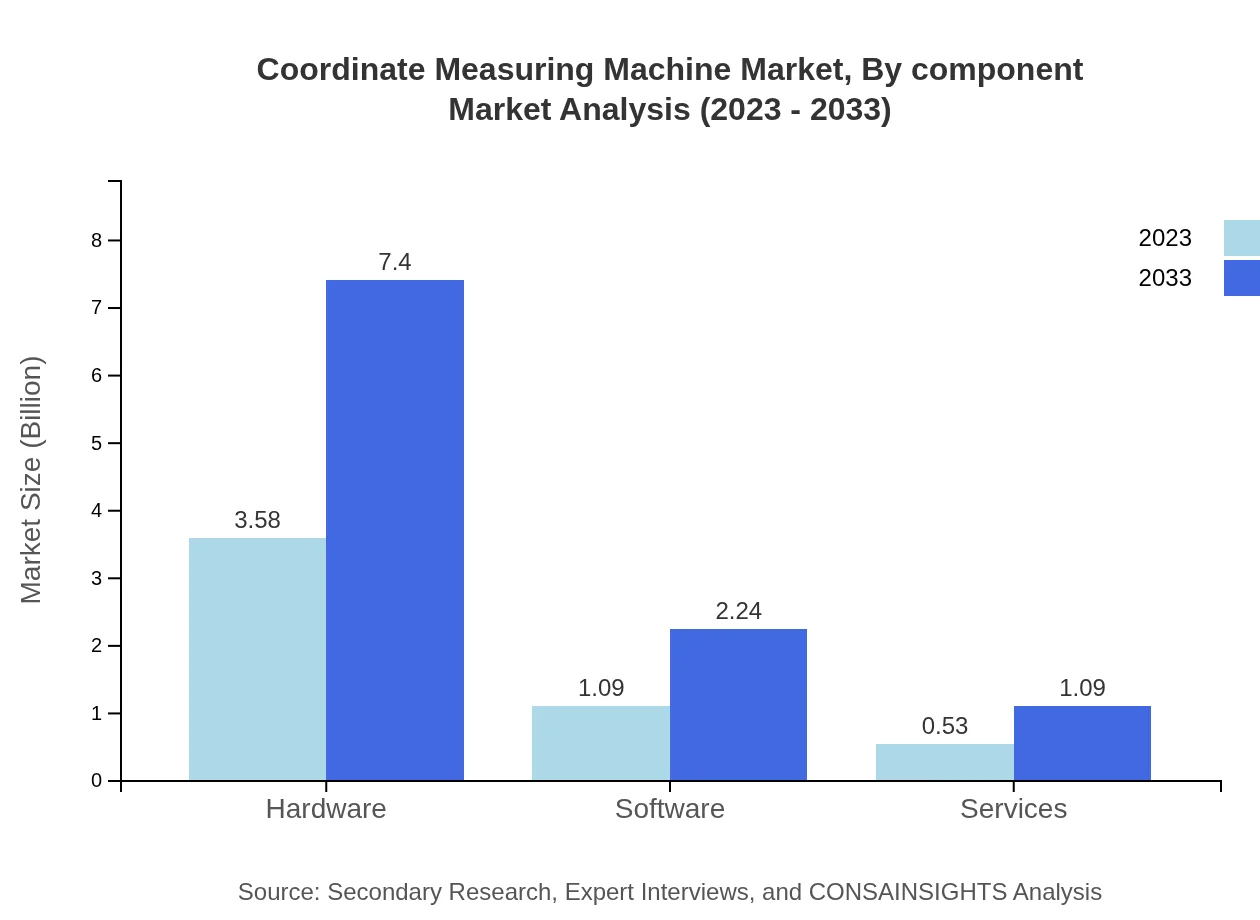

Coordinate Measuring Machine Market Analysis By Component

Segments by component within the CMM market include Hardware, Software, and Services. Hardware constitutes the largest segment, indicating growth from $3.58 billion in 2023 to $7.40 billion by 2033, holding a market share of 68.9%. Software and services also experience growth, with projections of $1.09 billion to $2.24 billion and $0.53 billion to $1.09 billion, respectively.

Coordinate Measuring Machine Market Analysis By End User

The end-user analysis highlights industries utilizing CMMs, including Aerospace, Automotive, Electronics, Medical Devices, and Industrial Machinery. The aerospace industry leads with a market size expansion from $2.14 billion to $4.42 billion, followed by automotive with an increase from $1.10 billion to $2.28 billion, showcasing the critical role of CMMs in high-stakes manufacturing environments.

Coordinate Measuring Machine Market Analysis By Technology

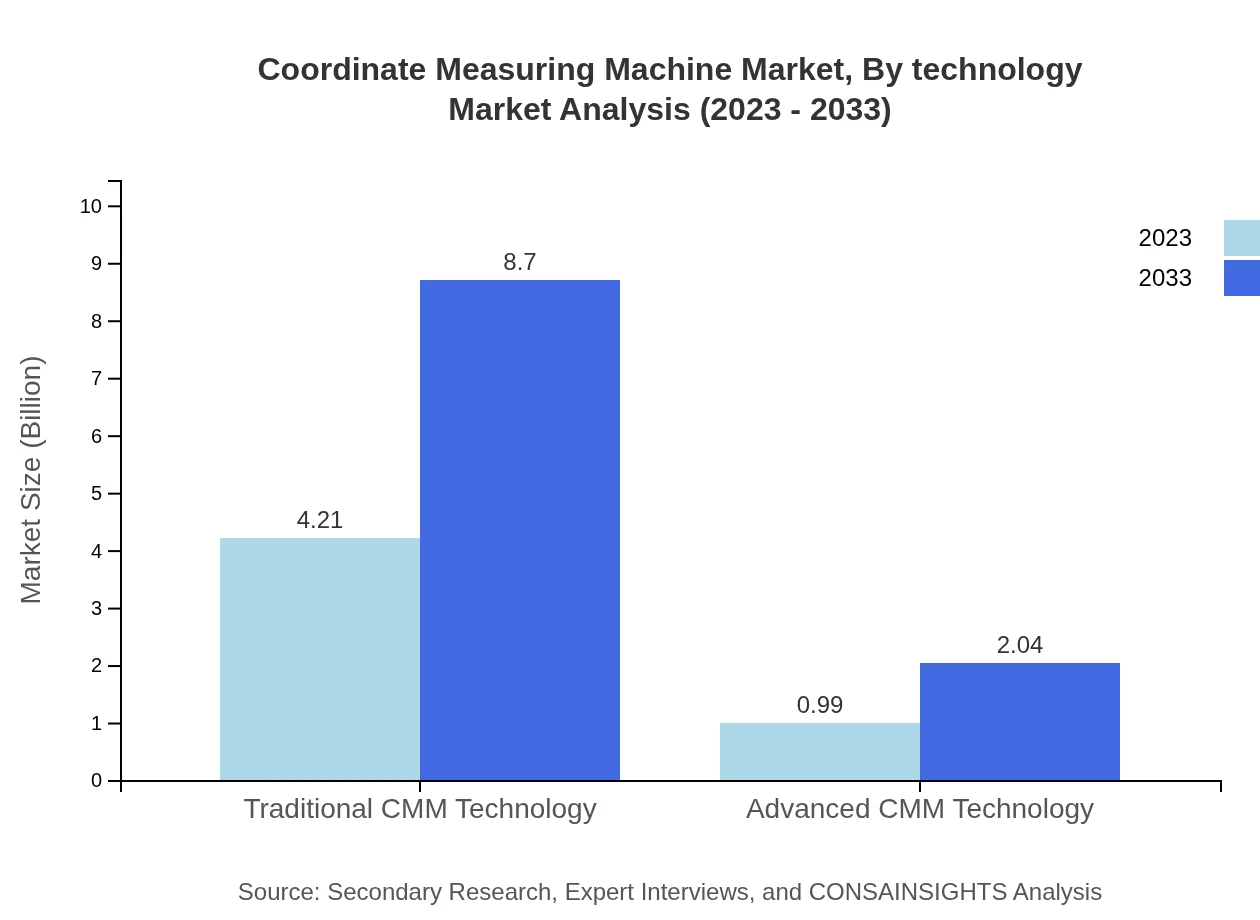

The technology segment divides into Traditional and Advanced CMM systems. Traditional CMM technology remains dominant, expected to grow from $4.21 billion to $8.70 billion by 2033, constituting 81.03% of the market. Advanced CMM technology is on the rise, expected to increase from $0.99 billion to $2.04 billion, indicating innovation in measurement solutions.

Coordinate Measuring Machine Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Coordinate Measuring Machine Industry

Hexagon AB:

A leading provider of design, measurement, and visualization technology, Hexagon is known for its innovative CMM solutions, emphasizing precision and efficiency in manufacturing processes.Faro Technologies, Inc.:

Faro manufactures portable coordinate measuring machines that advance metrology capabilities across various sectors, promoting greater accuracy and flexibility in measurements.WENZEL Group:

Known for its high-performance CMMs, WENZEL focuses on providing quality assurance solutions tailored for the automotive and aerospace industries.Zeiss Group:

Zeiss is recognized for its cutting-edge optical and industrial metrology products. Their commitment to quality and precision makes them leaders in the CMM market.Mitutoyo Corporation:

Mitutoyo offers a wide range of measuring instruments including CMMs, consistently focusing on innovation and precision engineering.We're grateful to work with incredible clients.

FAQs

What is the market size of the Coordinate Measuring Machine?

The Coordinate Measuring Machine (CMM) market is projected to grow from $5.2 billion in 2023 to a substantially larger figure in 2033, achieving a CAGR of 7.3% over the forecast period.

What are the key market players or companies in this industry?

Key players in the Coordinate Measuring Machine market include renowned companies such as Hexagon, Zeiss, and Mitutoyo, which dominate through innovative solutions and extensive market reach.

What are the primary factors driving the growth in the CMM industry?

The growth of the CMM market is being propelled by advancements in manufacturing technologies, increased automation, and the rising demand for precision measurement across various industries.

Which region is the fastest Growing in the CMM market?

The Asia Pacific region is forecasted to witness significant growth in the Coordinate Measuring Machine market, expanding from $0.98 billion in 2023 to $2.03 billion by 2033.

Does ConsaInsights provide customized market report data for the CMM industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs within the Coordinate Measuring Machine industry, catering to diverse client requirements.

What deliverables can I expect from this CMM market research project?

Deliverables from the CMM market research project may include comprehensive reports, market insights, regional analyses, and segment breakdowns, among other detailed analytics.

What are the market trends of the CMM?

Current market trends in the Coordinate Measuring Machine sector highlight the shift towards advanced measurement technologies and the integration of IoT solutions for enhanced accuracy.