Copy Milling Machine Market Report

Published Date: 22 January 2026 | Report Code: copy-milling-machine

Copy Milling Machine Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Copy Milling Machine market, detailing market trends, segmentation, size, and growth forecasts from 2023 to 2033.

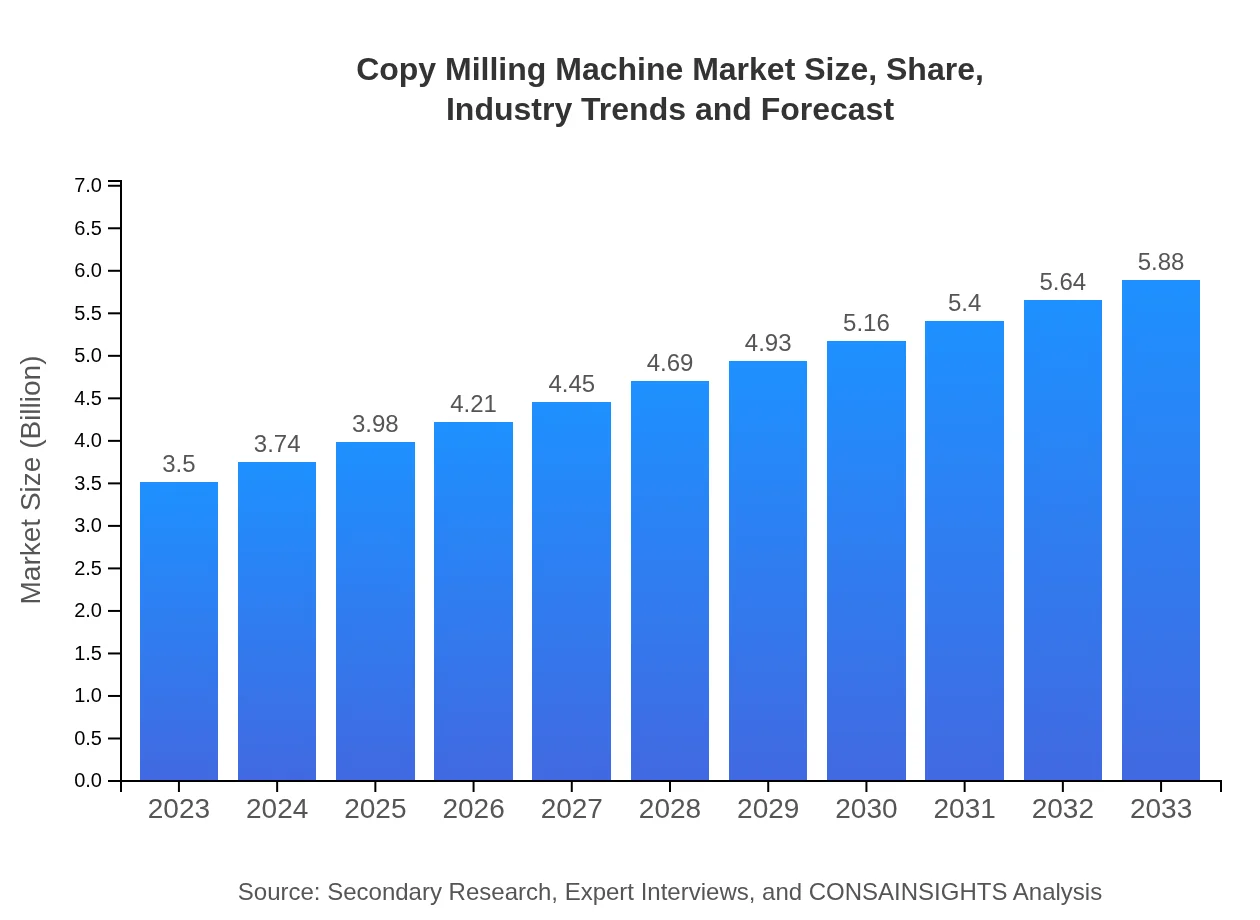

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $3.50 Billion |

| CAGR (2023-2033) | 5.2% |

| 2033 Market Size | $5.88 Billion |

| Top Companies | DMG Mori, Mazak Corporation, Haas Automation, Okuma Corporation |

| Last Modified Date | 22 January 2026 |

Copy Milling Machine Market Overview

Customize Copy Milling Machine Market Report market research report

- ✔ Get in-depth analysis of Copy Milling Machine market size, growth, and forecasts.

- ✔ Understand Copy Milling Machine's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Copy Milling Machine

What is the Market Size & CAGR of Copy Milling Machine market in 2023?

Copy Milling Machine Industry Analysis

Copy Milling Machine Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Copy Milling Machine Market Analysis Report by Region

Europe Copy Milling Machine Market Report:

The European market is valued at $0.94 billion in 2023 and is anticipated to reach $1.58 billion by 2033. The demand for high-precision milling machines is growing due to stringent regulations in manufacturing processes across the automotive and aerospace sectors. Countries such as Germany and the UK are leading this demand.Asia Pacific Copy Milling Machine Market Report:

In 2023, the Asia Pacific region accounted for a market size of $0.68 billion with projections to reach $1.14 billion by 2033. This growth is driven by increasing manufacturing activity and investments in automation in countries like China and India. The region is rapidly expanding its aerospace and automotive sectors, which rely heavily on precision machining technologies.North America Copy Milling Machine Market Report:

North America has a market size of $1.30 billion in 2023, with expectations to grow to $2.19 billion by 2033. The United States dominates this region due to its robust aerospace and automotive industries, with significant investments in technological advancements and high-performance equipment.South America Copy Milling Machine Market Report:

The South American copy milling machine market is estimated at $0.19 billion in 2023, growing to $0.32 billion by 2033. The market is supported by a gradual recovery in the region's manufacturing activities, especially in Brazil and Argentina, which are investing in modernizing their machining capabilities.Middle East & Africa Copy Milling Machine Market Report:

The Middle East and Africa market for copy milling machines is projected at $0.39 billion for 2023, increasing to $0.65 billion by 2033. Economic diversification efforts in Gulf countries are boosting investments in manufacturing and infrastructure, thereby driving the need for advanced machining technologies.Tell us your focus area and get a customized research report.

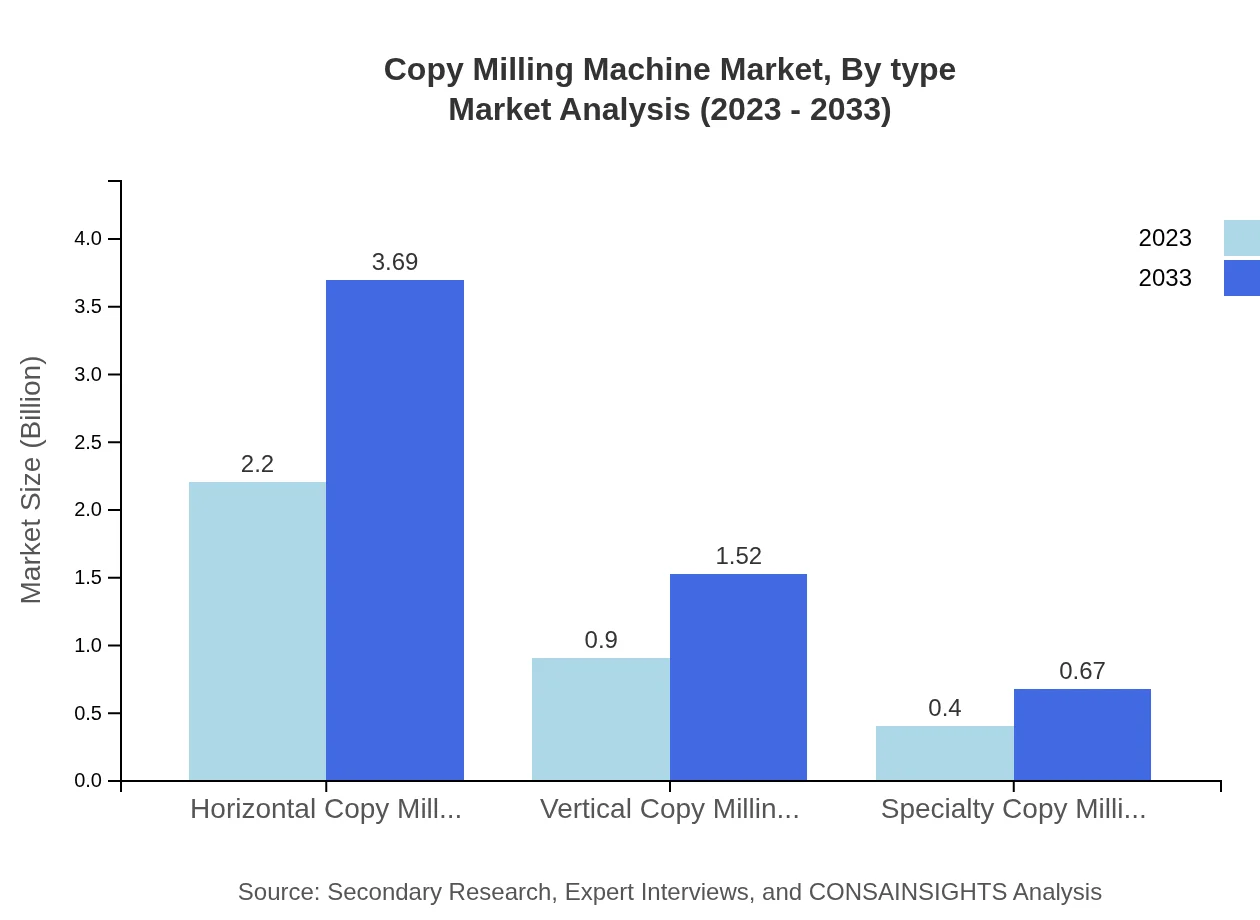

Copy Milling Machine Market Analysis By Type

The Copy Milling Machine Market segment reveals that Horizontal Copy Milling Machines are the most prominent, contributing $2.20 billion in 2023 and expected to rise to $3.69 billion by 2033, holding a 62.76% market share. CNC Copy Milling Machines also play a crucial role with the same market size and share as horizontal types. Vertical Copy Milling Machines account for $0.90 billion, projected to reach $1.52 billion, making up 25.85%. Specialty Copy Milling Machines round out the market with $0.40 billion in 2023, growing to $0.67 billion and holding 11.39%.

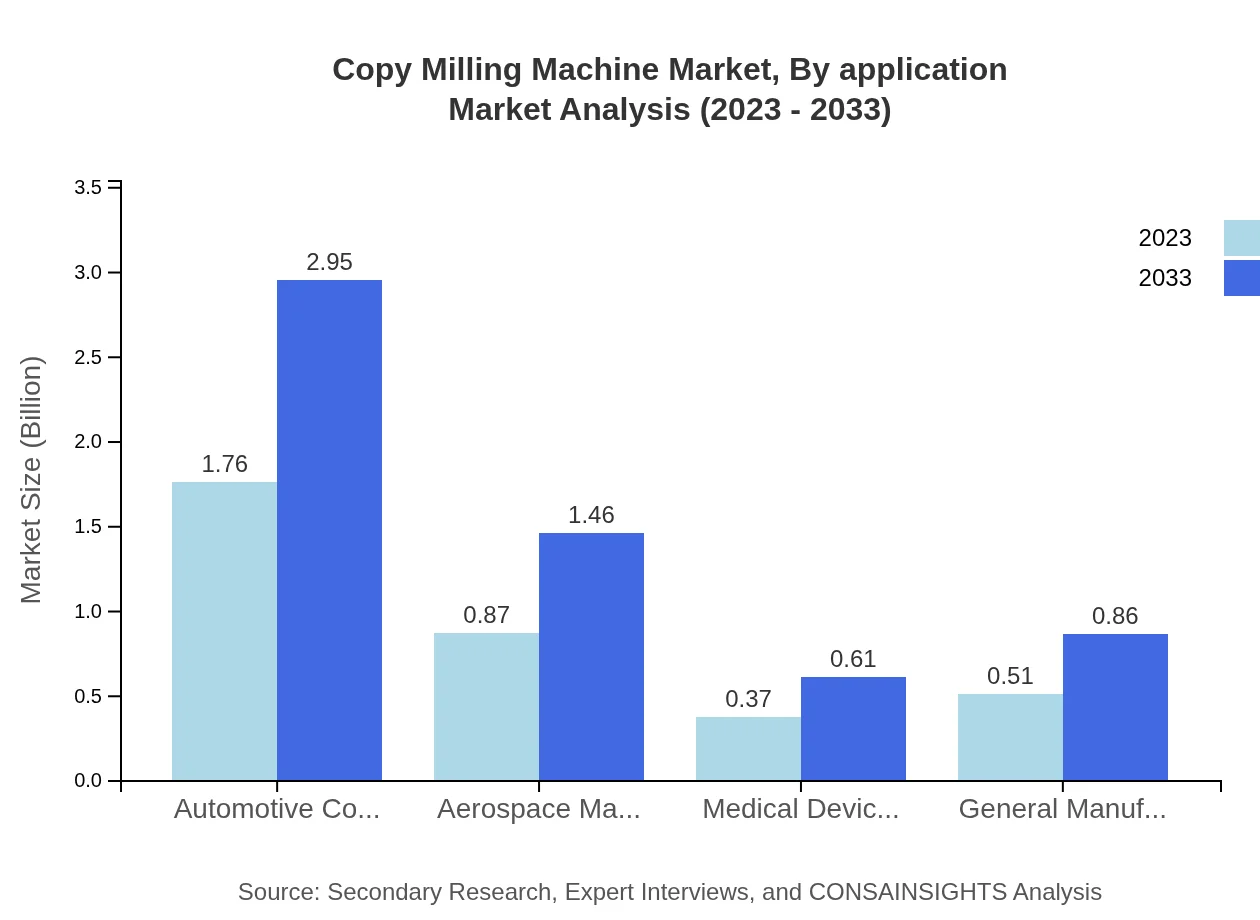

Copy Milling Machine Market Analysis By Application

By application, the automotive industry dominates with a market size of $1.76 billion in 2023, anticipated to grow to $2.95 billion by 2033, capturing 50.15% of the market. Aerospace Manufacturing follows with $0.87 billion, projected to climb to $1.46 billion, representing a 24.85% share. Medical Device Manufacturing contributes a market size of $0.37 billion, expected to reach $0.61 billion, holding 10.44% of the market, while general manufacturing accounts for $0.51 billion in 2023 and is expected to grow to $0.86 billion, holding 14.56%.

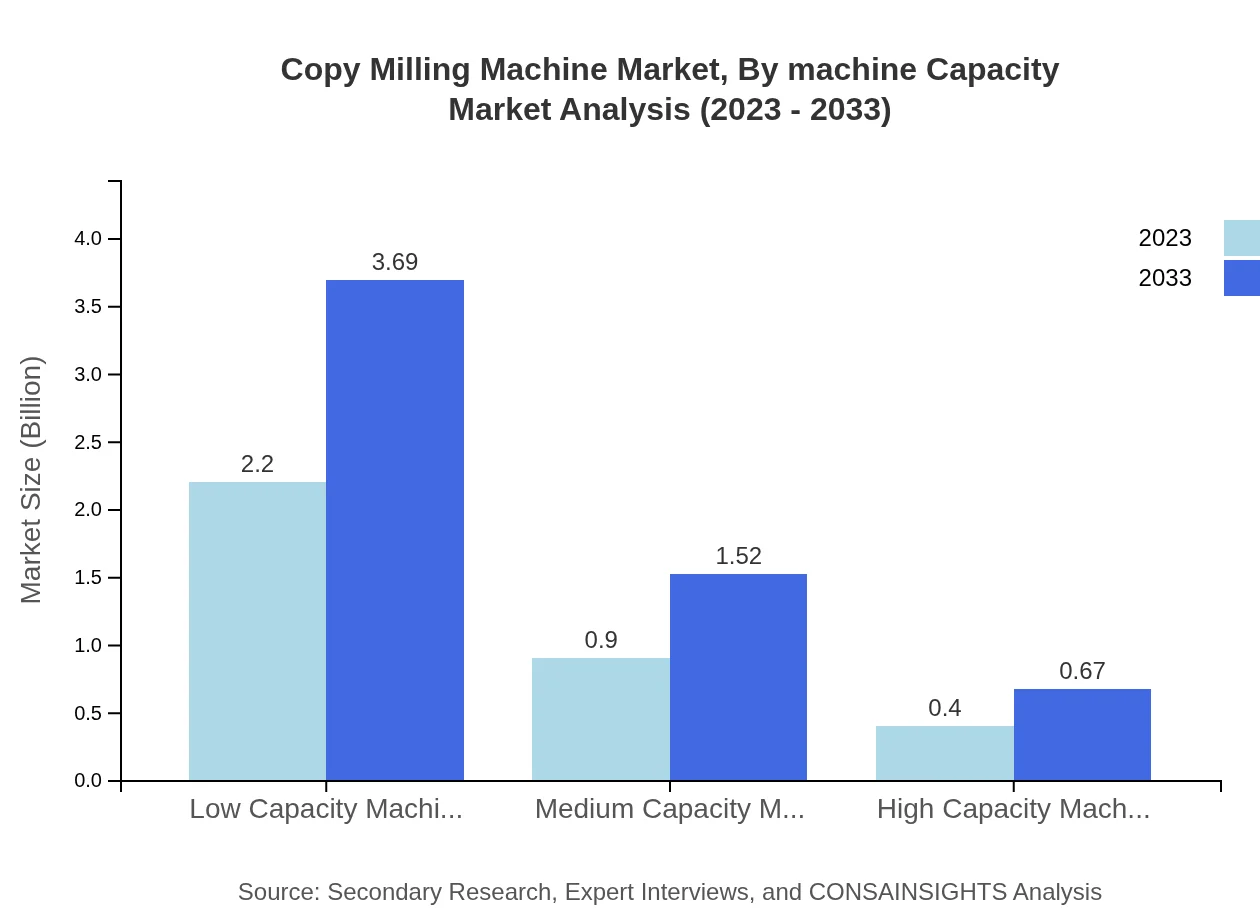

Copy Milling Machine Market Analysis By Machine Capacity

In terms of machine capacity, Low Capacity Machines are leading with a market size of $2.20 billion in 2023, expected to grow to $3.69 billion by 2033, maintaining a 62.76% market share. Medium Capacity Machines represent $0.90 billion, forecasted to reach $1.52 billion with a 25.85% share. High Capacity Machines make up the rest with $0.40 billion in 2023, projected to rise to $0.67 billion, holding 11.39% market share.

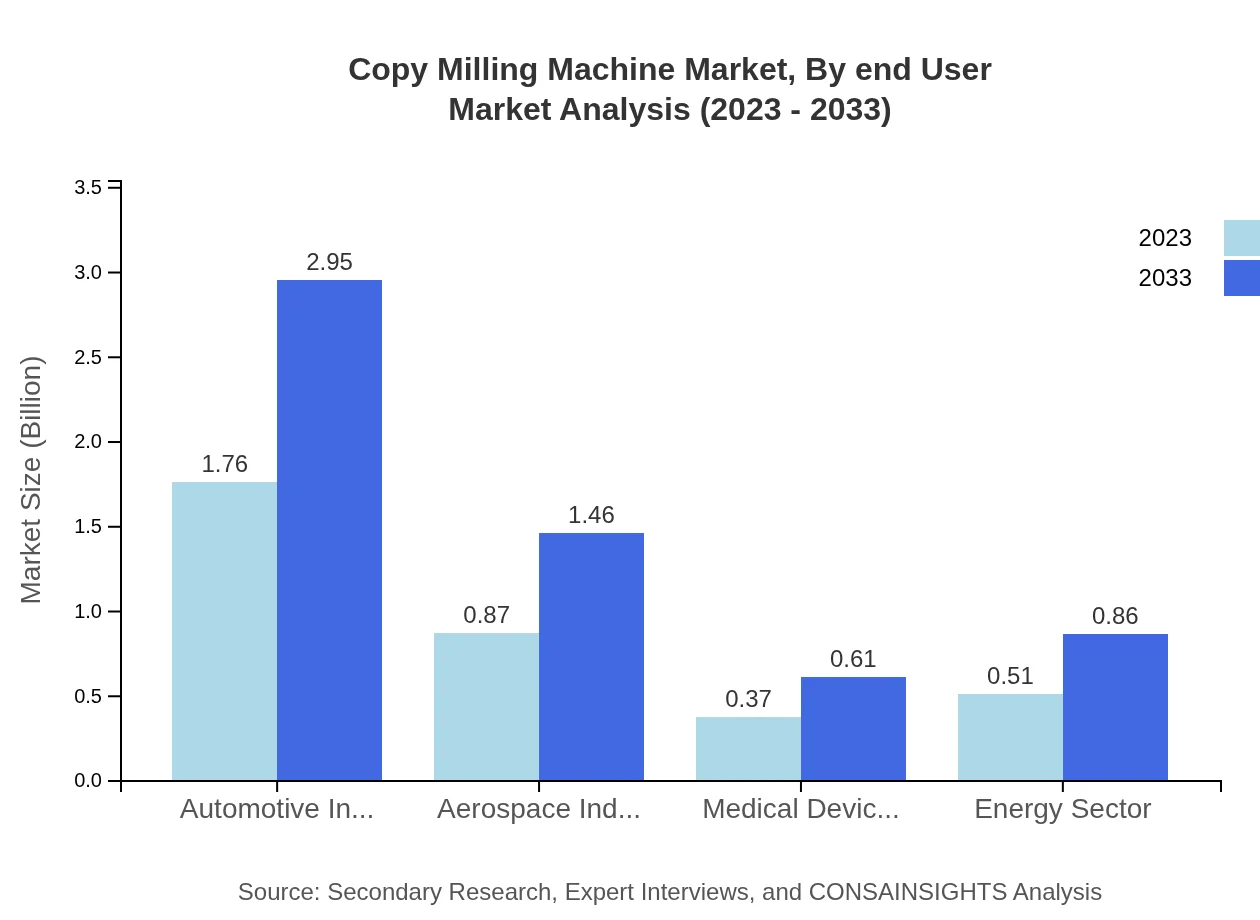

Copy Milling Machine Market Analysis By End User

The end-user industry of copy milling machines showcases significant usage in automotive components manufacturing, holding $1.76 billion in 2023 and rising to $2.95 billion by 2033, taking share of 50.15%. Aerospace manufacturing utilizes $0.87 billion, forecasted to increase to $1.46 billion, and medical device manufacturing consists of $0.37 billion, increasing to $0.61 billion.

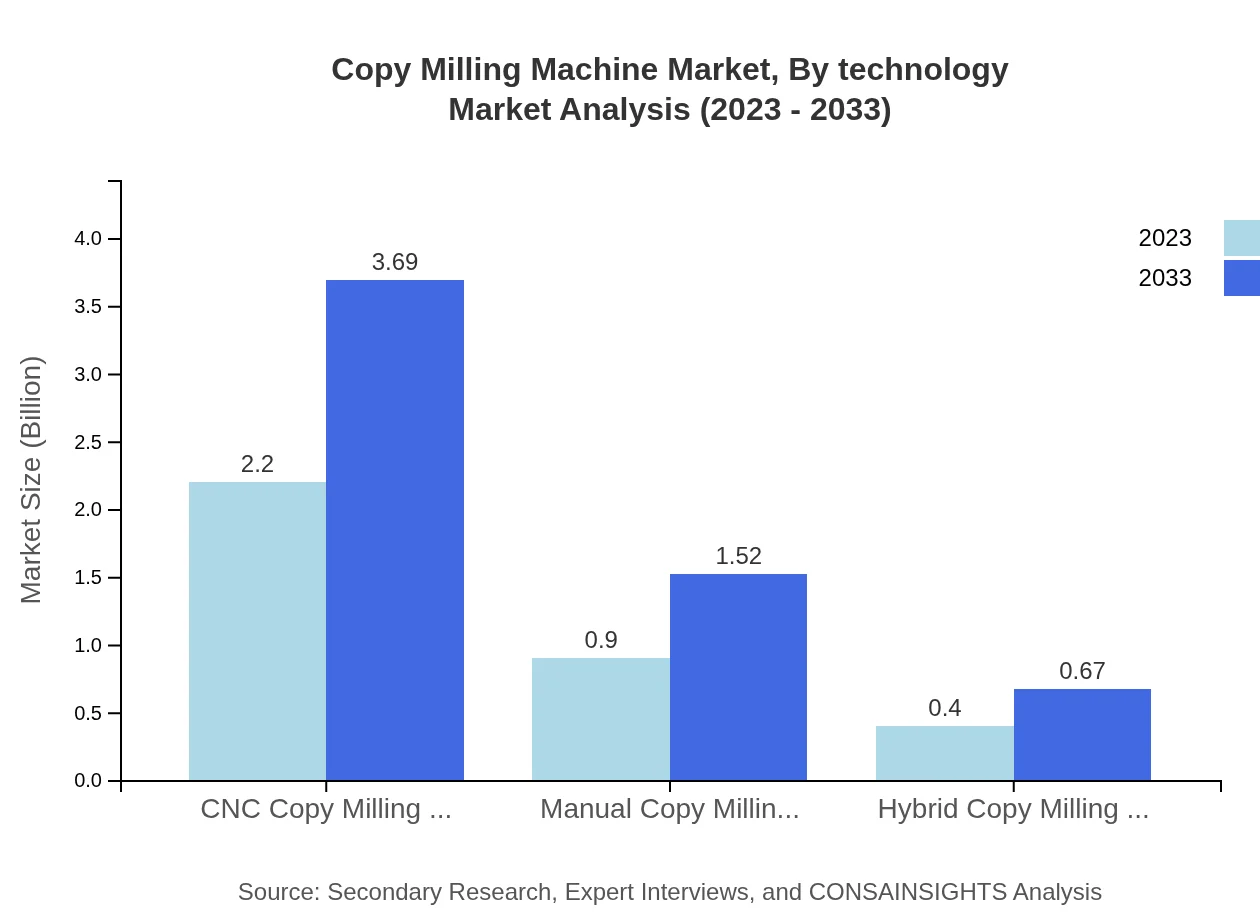

Copy Milling Machine Market Analysis By Technology

In the technology segment, CNC Copy Milling Machines dominate with $2.20 billion in 2023, expected to reach $3.69 billion by 2033, holding a steady 62.76% share. Manual Copy Milling Machines make up $0.90 billion, projected to expand to $1.52 billion, capturing 25.85% of the market. Hybrid Copy Milling Machines provide a substantial yet smaller portion of the market, valued at $0.40 billion in 2023 and anticipated to grow to $0.67 billion with an 11.39% market share.

Copy Milling Machine Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Copy Milling Machine Industry

DMG Mori:

A leading provider of CNC machines and milling technology known for integrating advanced software solutions into their systems, improving precision and efficiency.Mazak Corporation:

Specializes in the development of innovative machining solutions with a robust portfolio of CNC milling and turning machines, contributing to various industries.Haas Automation:

Renowned for its affordable CNC machines that deliver high performance and been widely adopted in small to medium-sized enterprises globally.Okuma Corporation:

Pioneering the integration of IoT in manufacturing processes, offering advanced milling machines with exceptional capabilities for various material types.We're grateful to work with incredible clients.

FAQs

What is the market size of copy Milling Machine?

The global copy milling machine market is valued at approximately $3.5 billion in 2023, with an expected compound annual growth rate (CAGR) of 5.2%. It is projected to grow significantly over the next decade.

What are the key market players or companies in the copy Milling Machine industry?

Key players in the copy milling machine market include DMG MORI, HAAS Automation, and Mazak. They are recognized for their advanced technology and extensive product lines that dominate the industry landscape.

What are the primary factors driving the growth in the copy milling machine industry?

Growth in the copy milling machine industry is driven by increasing demand in automotive and aerospace sectors, technological advancements in CNC machines, and the rising trend of automation in manufacturing to enhance efficiency.

Which region is the fastest Growing in the copy Milling Machine?

Asia Pacific is the fastest-growing region in the copy milling machine market, projected to expand from $0.68 billion in 2023 to $1.14 billion by 2033, fueled by rapid industrialization and increasing manufacturing activities.

Does Consainsights provide customized market report data for the copy Milling Machine industry?

Yes, Consainsights offers tailored market report data for the copy milling machine industry, enabling clients to access specific insights pertinent to their business needs and strategic goals.

What deliverables can I expect from this copy Milling Machine market research project?

Deliverables from the copy milling machine market research project include detailed market analysis, growth forecasts, competitive landscape assessments, and segment-wise data, enhancing decision-making capabilities for stakeholders.

What are the market trends of copy Milling Machine?

Key trends in the copy milling machine market include the increasing adoption of CNC technology, the shift towards automation, and growing demand in precision manufacturing across various sectors.