Corrosion Monitoring Market Report

Published Date: 22 January 2026 | Report Code: corrosion-monitoring

Corrosion Monitoring Market Size, Share, Industry Trends and Forecast to 2033

This report presents a comprehensive analysis of the Corrosion Monitoring market, detailing insights into market size, segmentation, regional dynamics, technology advancements, and forecasts from 2023 to 2033.

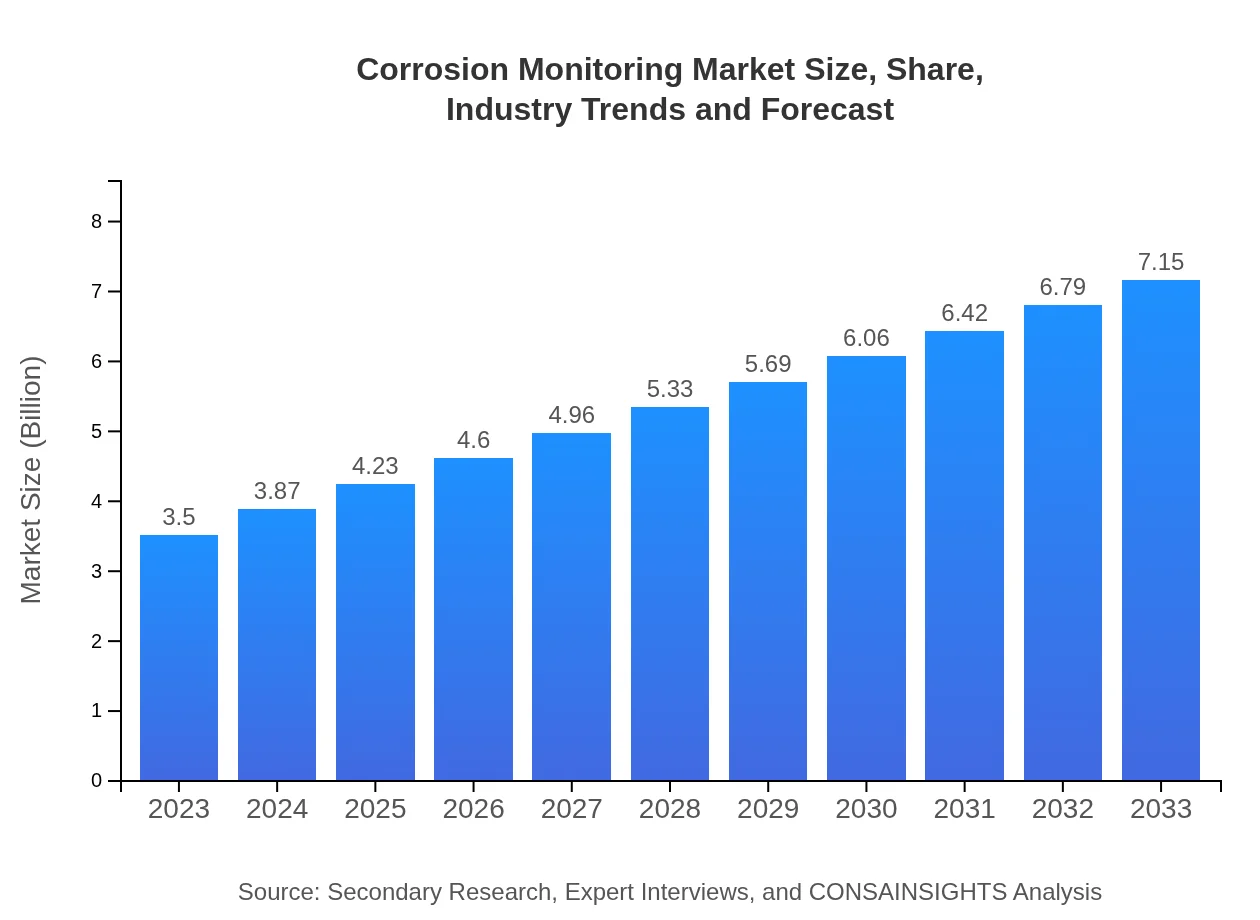

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $3.50 Billion |

| CAGR (2023-2033) | 7.2% |

| 2033 Market Size | $7.15 Billion |

| Top Companies | CorrOcean, Bacharach, Honeywell , Emerson |

| Last Modified Date | 22 January 2026 |

Corrosion Monitoring Market Overview

Customize Corrosion Monitoring Market Report market research report

- ✔ Get in-depth analysis of Corrosion Monitoring market size, growth, and forecasts.

- ✔ Understand Corrosion Monitoring's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Corrosion Monitoring

What is the Market Size & CAGR of Corrosion Monitoring market in 2023?

Corrosion Monitoring Industry Analysis

Corrosion Monitoring Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Corrosion Monitoring Market Analysis Report by Region

Europe Corrosion Monitoring Market Report:

The European corrosion monitoring market is expected to grow from USD 1.05 billion in 2023 to USD 2.16 billion by 2033. European manufacturers are increasingly investing in R&D to innovate monitoring solutions, influenced by rigorous environmental standards and safety regulations.Asia Pacific Corrosion Monitoring Market Report:

In the Asia-Pacific region, the corrosion monitoring market is set to grow from USD 0.65 billion in 2023 to USD 1.34 billion by 2033. The rapid industrialization, coupled with a rising awareness of infrastructure integrity, is driving this growth. Countries like China and India are significant contributors, expanding their asset management strategies across various sectors.North America Corrosion Monitoring Market Report:

North America leads the corrosion monitoring market, with projections suggesting growth from USD 1.28 billion in 2023 to USD 2.61 billion by 2033. This growth is fueled by stringent regulatory compliance in industries such as oil and gas and infrastructure, driving the adoption of advanced monitoring technologies.South America Corrosion Monitoring Market Report:

The South American market, while smaller, is expected to witness growth from USD 0.06 billion in 2023 to USD 0.12 billion in 2033. Increasing investments in the oil and gas sector and evolving regulations regarding safety protocols are influencing the corrosion monitoring trends in this region.Middle East & Africa Corrosion Monitoring Market Report:

The Middle East and Africa are predicted to grow from USD 0.46 billion in 2023 to USD 0.93 billion by 2033, primarily driven by the oil and gas sector's operational demands. With infrastructure advancements in various countries, the demand for effective corrosion monitoring solutions continues to rise.Tell us your focus area and get a customized research report.

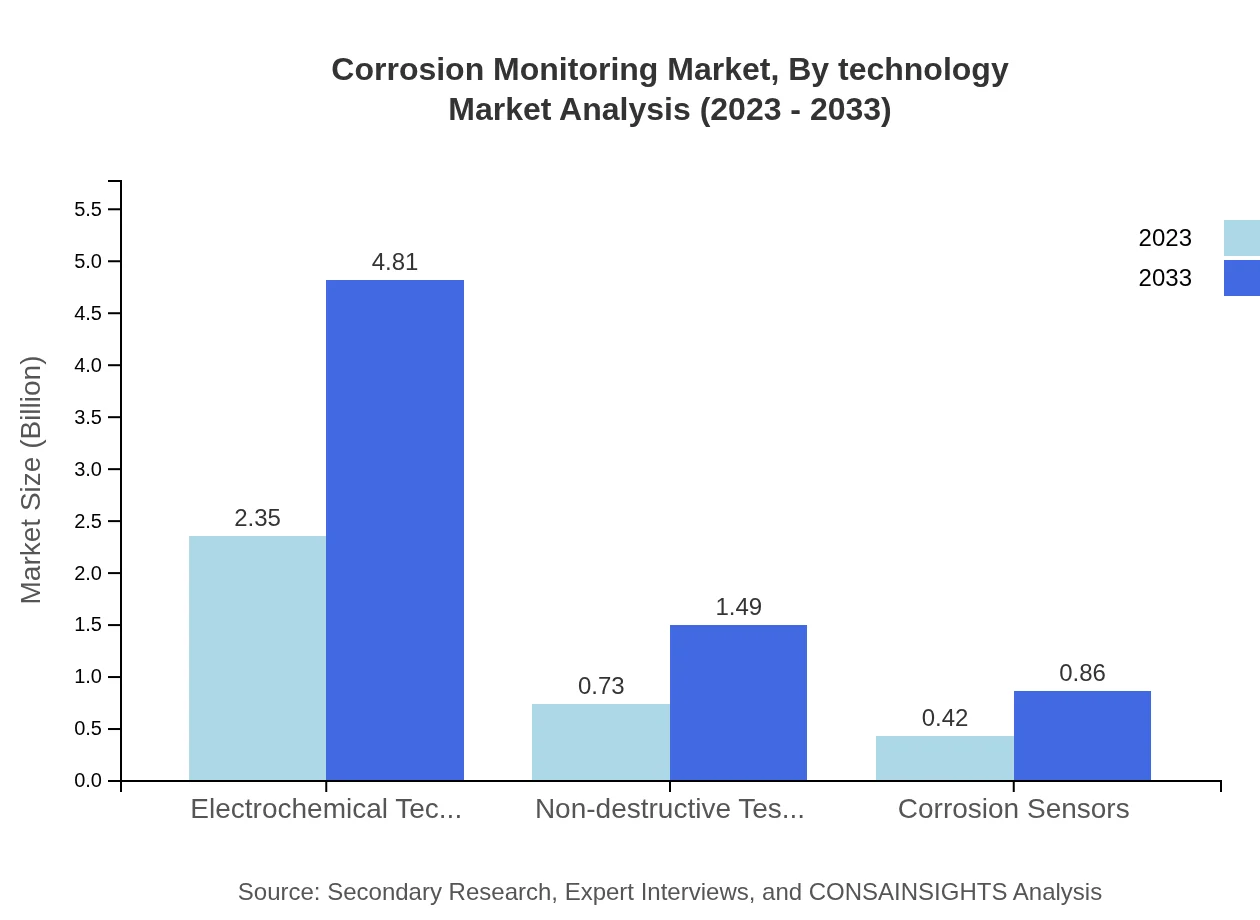

Corrosion Monitoring Market Analysis By Technology

The corrosion monitoring market by technology is dominated by electrochemical techniques, contributing significantly to the overall market size, with a growth from USD 2.35 billion in 2023 to USD 4.81 billion by 2033. Non-destructive testing also plays a vital role, characterizing different segments with advancements in sensor technologies and deployment methods.

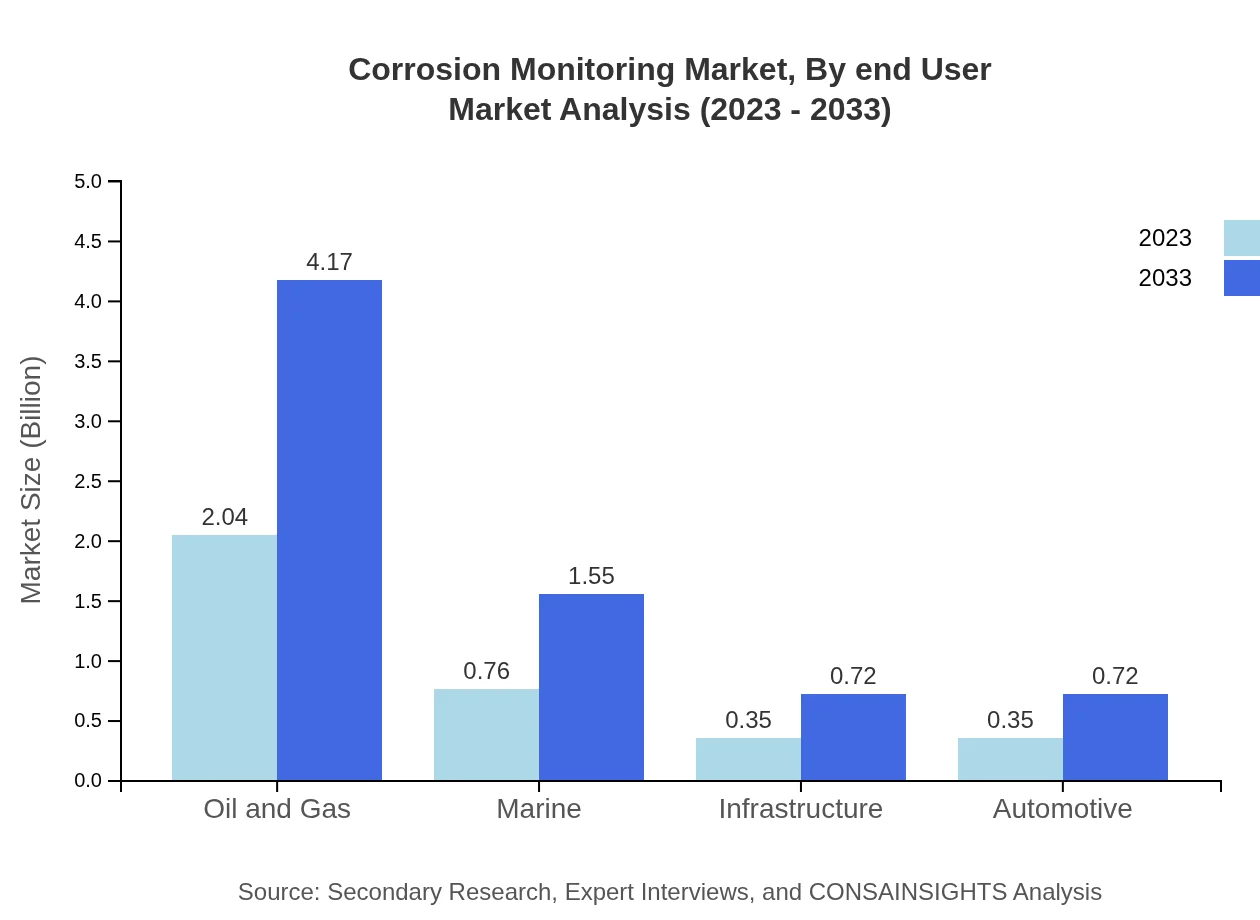

Corrosion Monitoring Market Analysis By End User

Analysis by end-user industry showcases the oil and gas sector as the dominant segment, accounting for USD 2.04 billion in 2023, expected to grow to USD 4.17 billion by 2033. Other industries, like marine and automotive, also significantly contribute, diversifying the growth landscape in corrosion monitoring.

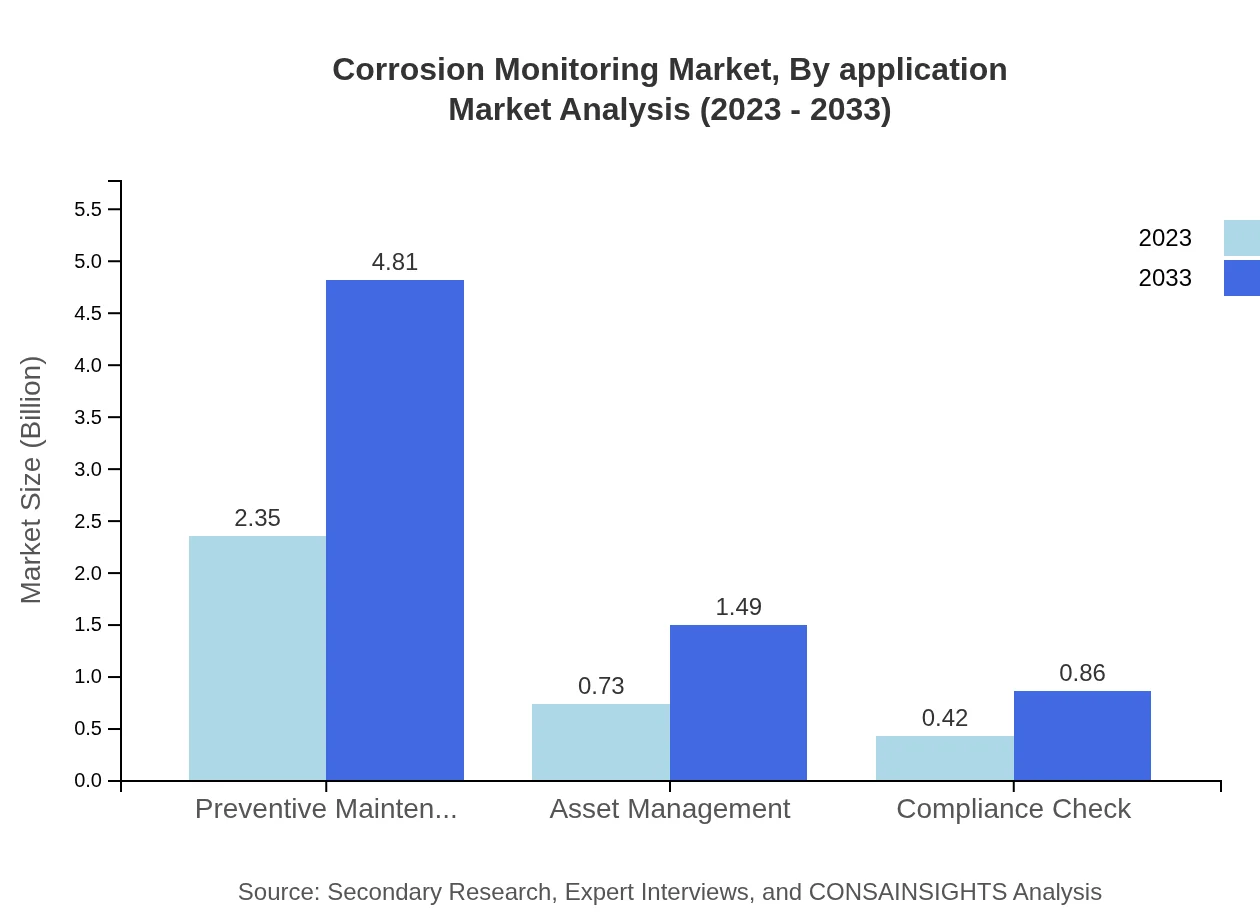

Corrosion Monitoring Market Analysis By Application

Preventive maintenance applications represent a major segment of the corrosion monitoring market, growing from USD 2.35 billion in 2023 to USD 4.81 billion by 2033. Compliance checks and asset management applications also show considerable growth and relevance in ensuring regulatory adherence and asset lifecycle management.

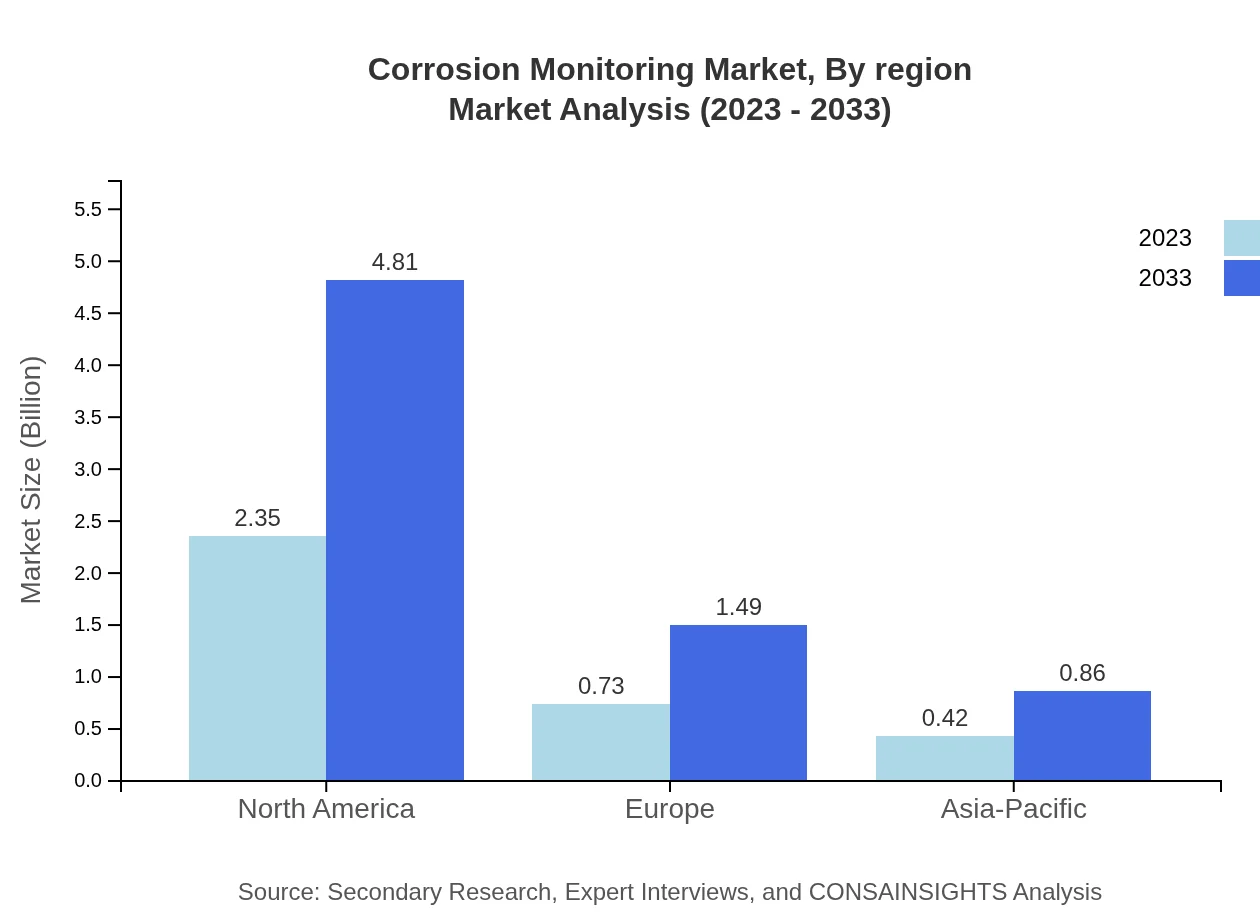

Corrosion Monitoring Market Analysis By Region

Regional analysis confirms North America as a major player, with Europe and Asia-Pacific showing strong growth potential. Regions are diversifying their approaches to incorporate more advanced technologies tailored to local regulatory frameworks and industry demands.

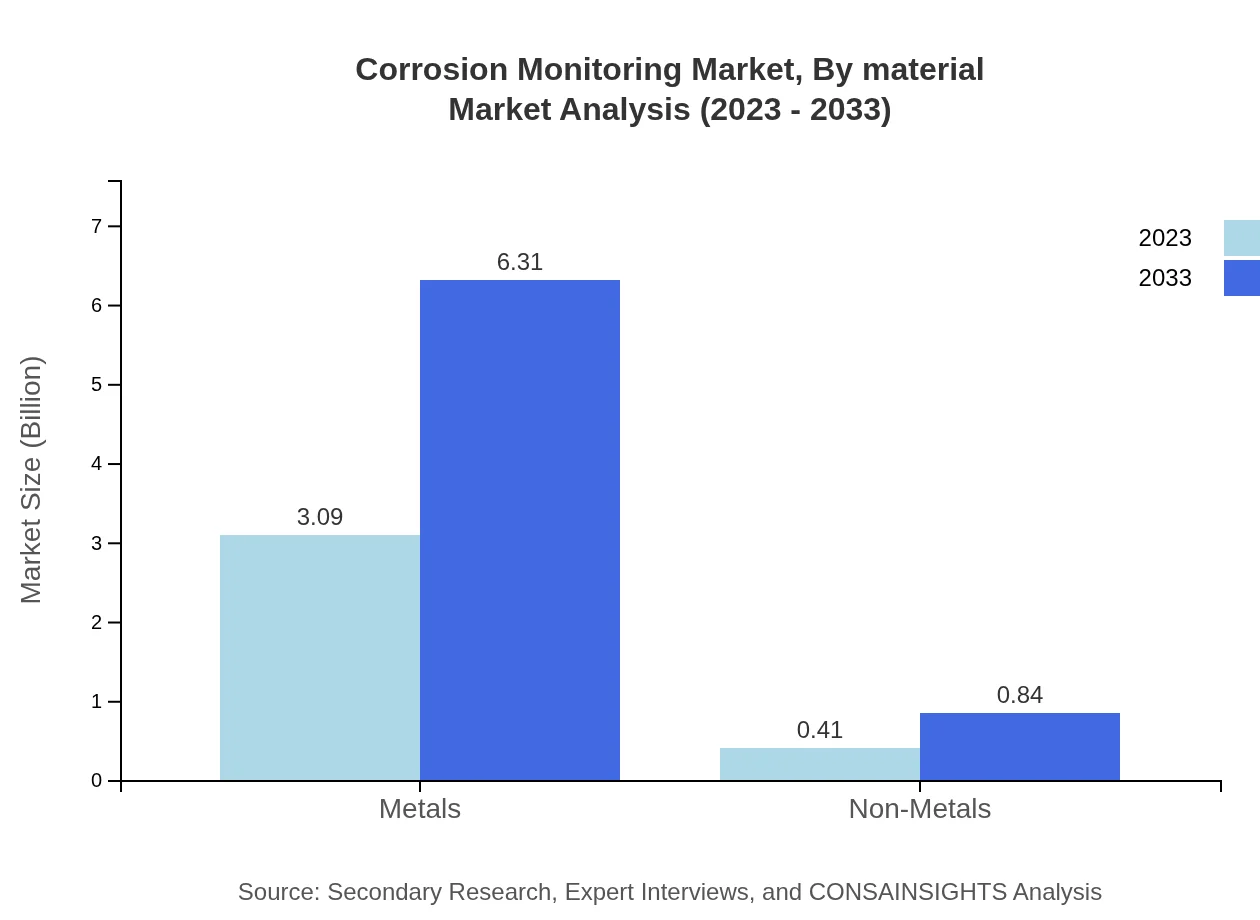

Corrosion Monitoring Market Analysis By Material

The corrosion monitoring market by material type indicates metals being the dominant segment, growing from USD 3.09 billion in 2023 to USD 6.31 billion by 2033. Non-metals, although smaller in value and volume, still represent key applications in sectors where metal fatigue and corrosion can heavily impact operational reliability.

Corrosion Monitoring Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Corrosion Monitoring Industry

CorrOcean:

A leading provider of corrosion monitoring technologies and predictive maintenance solutions, CorrOcean specializes in advanced monitoring equipment and remote data management tools used across industries.Bacharach:

Bacharach offers innovative solutions for monitoring corrosion in critical environments, known for their range of sensors and management systems, catering primarily to the oil and gas sectors.Honeywell :

Honeywell is a major player in the technology landscape of corrosion monitoring, developing comprehensive solutions that integrate with enterprise asset management systems.Emerson:

Emerson focuses on advanced digital monitoring solutions to facilitate predictive maintenance and enhance operational efficiency across various industries.We're grateful to work with incredible clients.

FAQs

What is the market size of corrosion Monitoring?

The corrosion-monitoring market is currently valued at approximately $3.5 billion, with a projected compound annual growth rate (CAGR) of 7.2% from 2023 to 2033, reflecting strong demand and growth potential.

What are the key market players or companies in this corrosion Monitoring industry?

Key players in the corrosion-monitoring market include major corporations that specialize in industrial solution technologies, sensor manufacturers, and providers of non-destructive testing services. These companies are pivotal in advancing corrosion detection and management techniques.

What are the primary factors driving the growth in the corrosion Monitoring industry?

Growth in the corrosion-monitoring industry is driven by increasing awareness of corrosion impacts, stringent compliance regulations, expansion in infrastructure, and advancements in sensor technology aimed at enhancing asset longevity and reducing maintenance costs.

Which region is the fastest Growing in the corrosion Monitoring?

Among various regions, North America exhibits significant growth potential, projected to rise from $1.28 billion in 2023 to $2.61 billion by 2033, making it the fastest-growing area in the corrosion-monitoring market.

Does ConsaInsights provide customized market report data for the corrosion Monitoring industry?

Yes, ConsaInsights offers tailored market report data for the corrosion-monitoring industry, enabling clients to obtain insights specific to their needs, including sector performance, competitor analysis, and regional developments.

What deliverables can I expect from this corrosion Monitoring market research project?

Deliverables for corrosion-monitoring market research typically include a comprehensive report featuring market size estimations, growth forecasts, key player profiles, market trends, and sector-specific analysis, ensuring informed decision-making.

What are the market trends of corrosion Monitoring?

Current trends in the corrosion-monitoring market include the increasing adoption of smart corrosion sensors, integration of IoT technologies, and the growing emphasis on preventive maintenance strategies to optimize asset performance and safety.