Cotton Processing Market Report

Published Date: 22 January 2026 | Report Code: cotton-processing

Cotton Processing Market Size, Share, Industry Trends and Forecast to 2033

This market report provides insights into the Cotton Processing sector, covering market trends, size forecasts, and analytical data for the period between 2023 and 2033. Key growth drivers and regional analyses are highlighted, alongside an overview of market segmentation and leading players.

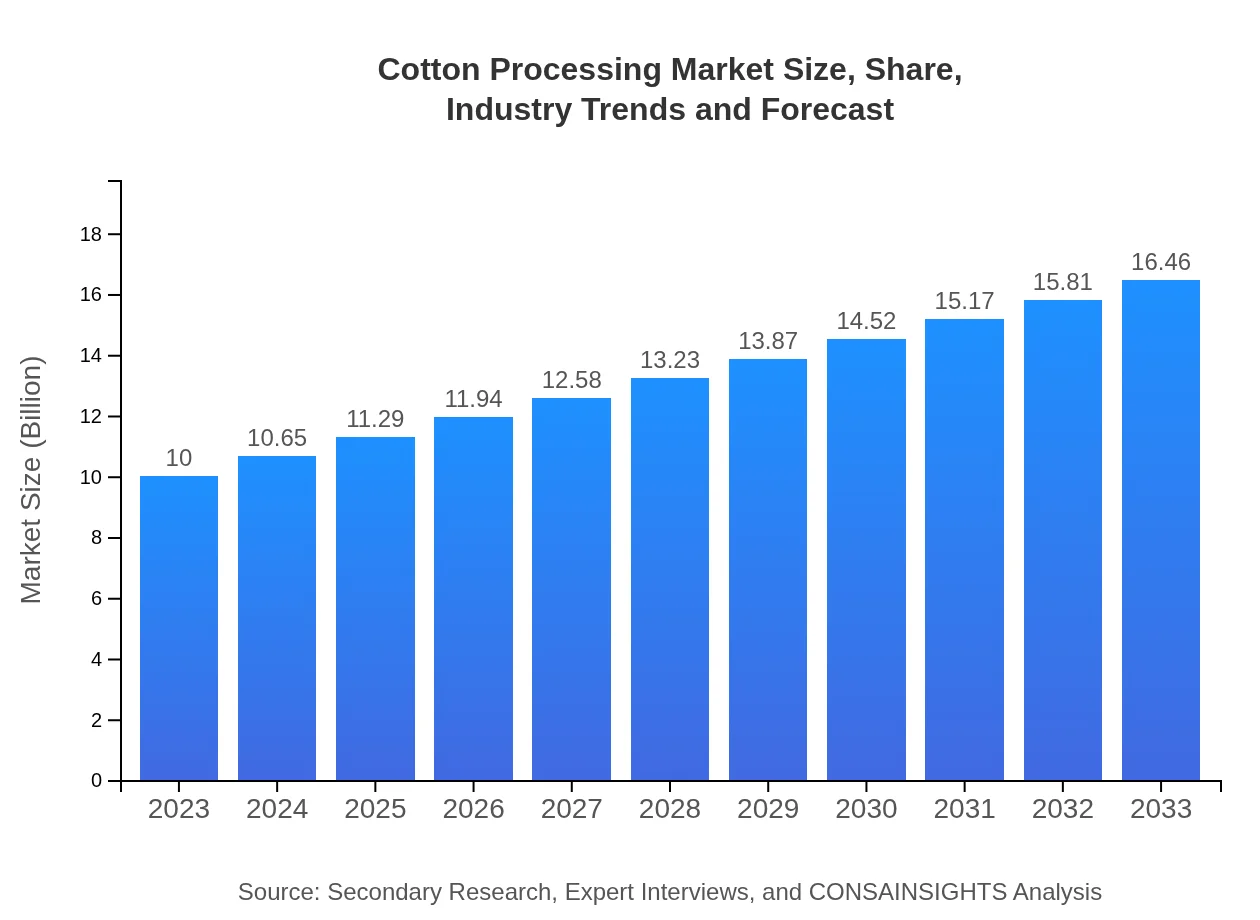

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $10.00 Billion |

| CAGR (2023-2033) | 5% |

| 2033 Market Size | $16.46 Billion |

| Top Companies | Cargill, Inc., Cotton Incorporated, Lenzing AG |

| Last Modified Date | 22 January 2026 |

Cotton Processing Market Overview

Customize Cotton Processing Market Report market research report

- ✔ Get in-depth analysis of Cotton Processing market size, growth, and forecasts.

- ✔ Understand Cotton Processing's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Cotton Processing

What is the Market Size & CAGR of Cotton Processing market in 2023?

Cotton Processing Industry Analysis

Cotton Processing Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Cotton Processing Market Analysis Report by Region

Europe Cotton Processing Market Report:

Europe's market is set to expand from USD 2.93 billion in 2023 to USD 4.82 billion by 2033, with a significant emphasis on eco-friendly production practices driving growth in the region's textile and clothing industry.Asia Pacific Cotton Processing Market Report:

In 2023, the Cotton Processing market in the Asia Pacific region is valued at USD 2.01 billion, projected to reach USD 3.31 billion by 2033. Growth in this region is driven by high cotton production, particularly in countries like India and China, which are leading exporters of cotton textiles and garments.North America Cotton Processing Market Report:

In North America, the market is projected to grow from USD 3.34 billion in 2023 to USD 5.50 billion by 2033, fueled by advancements in textile manufacturing technologies and a shift toward sustainable materials in apparel.South America Cotton Processing Market Report:

The South America market is valued at USD 0.33 billion in 2023 and expected to grow to USD 0.54 billion by 2033. Increasing consumer demand for cotton products and improved agricultural practices are contributing factors to this growth.Middle East & Africa Cotton Processing Market Report:

The Middle East and Africa market, valued at USD 1.39 billion in 2023, is anticipated to grow to USD 2.28 billion by 2033. Increasing investment in cotton production and processing technologies is key to this region's market development.Tell us your focus area and get a customized research report.

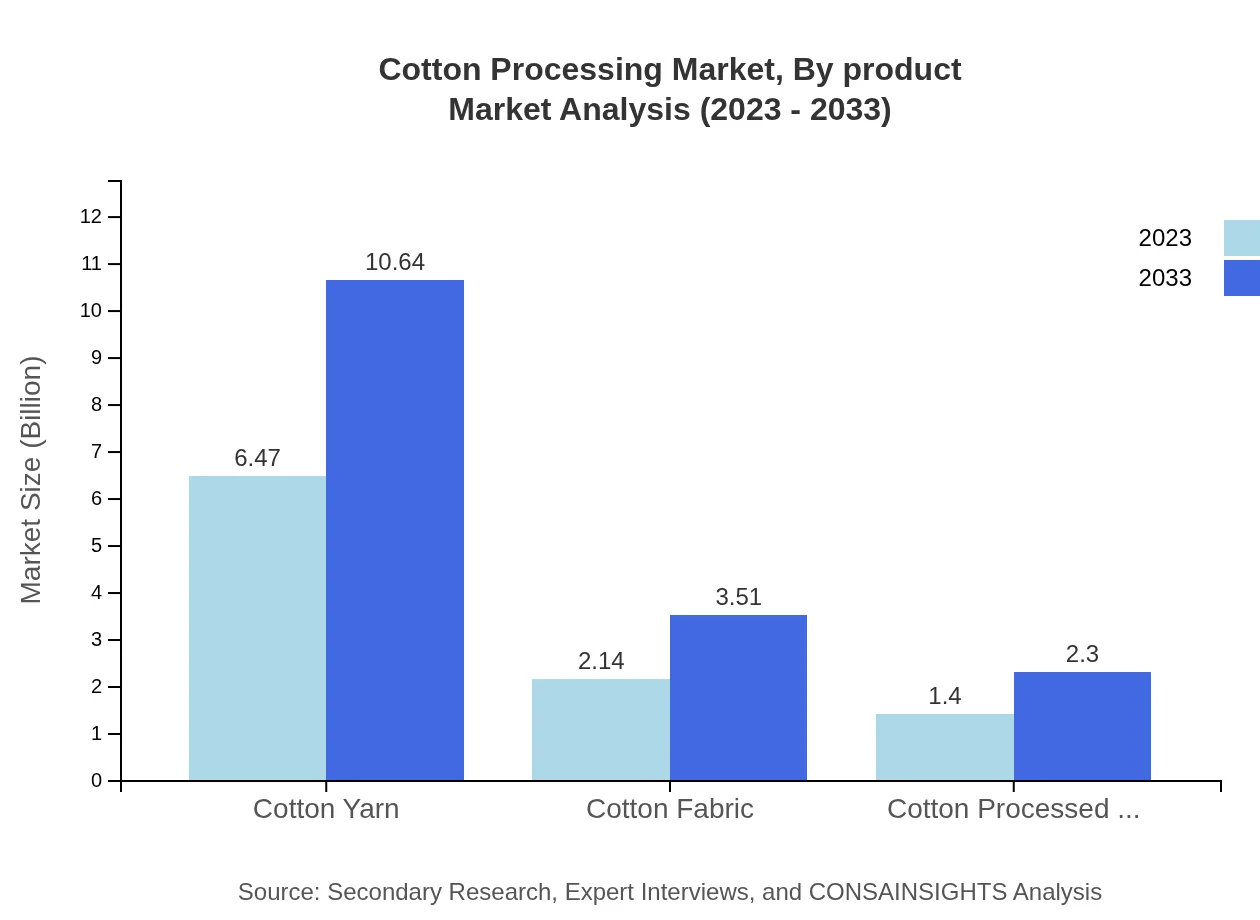

Cotton Processing Market Analysis By Product

The Cotton Processing market comprises several product types, with Cotton Yarn dominating at a market size of USD 6.47 billion in 2023, projected to reach USD 10.64 billion by 2033. Ginning and Spinning are also significant contributors, with market sizes of USD 4.57 billion and USD 2.19 billion respectively in 2023, highlighting their critical role in raw cotton processing.

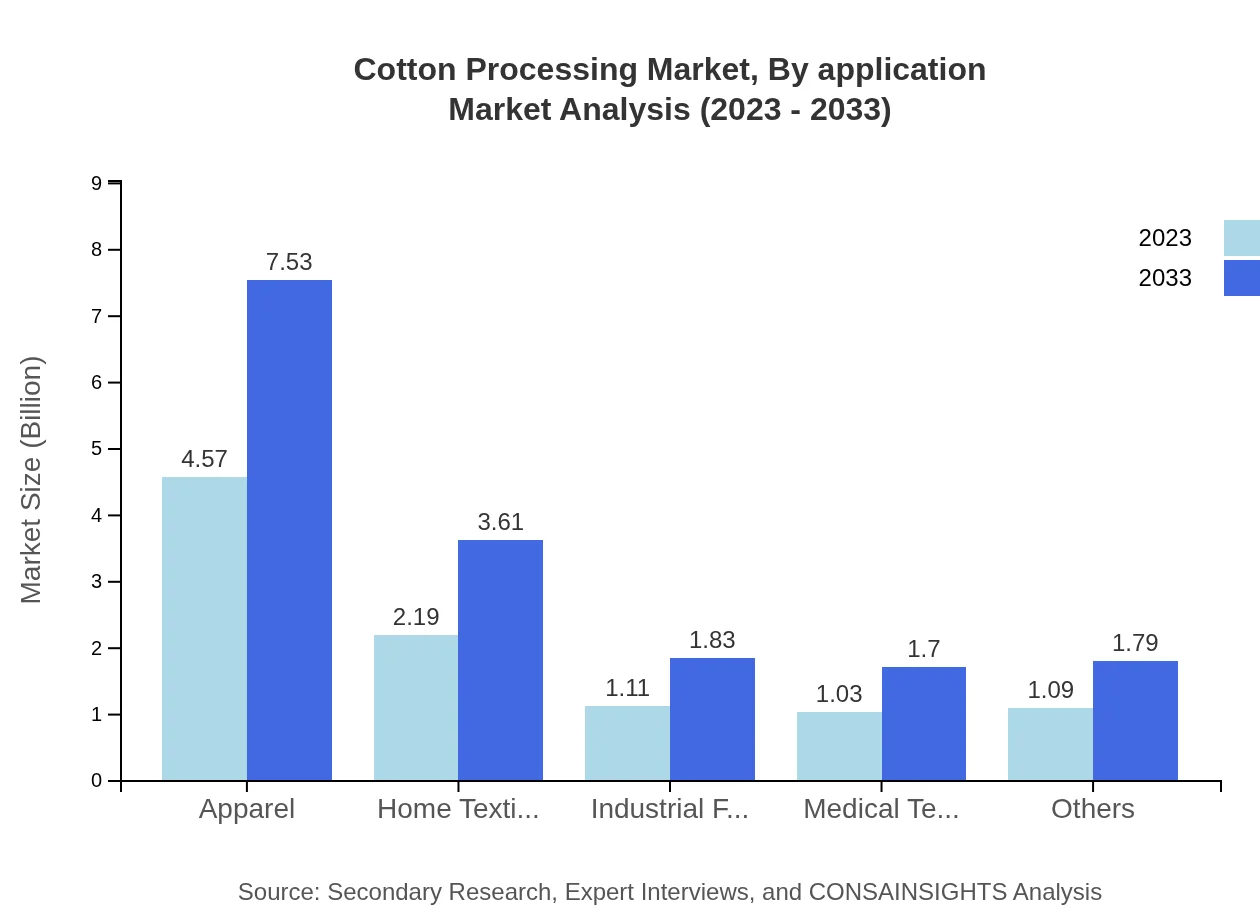

Cotton Processing Market Analysis By Application

Key applications of cotton include apparel, home goods, and medical textiles. The apparel segment constitutes the largest share of the market, valued at USD 4.57 billion in 2023. Home textiles and medical textiles are also gaining significant traction as consumer trends lean towards increased sustainability in their choices.

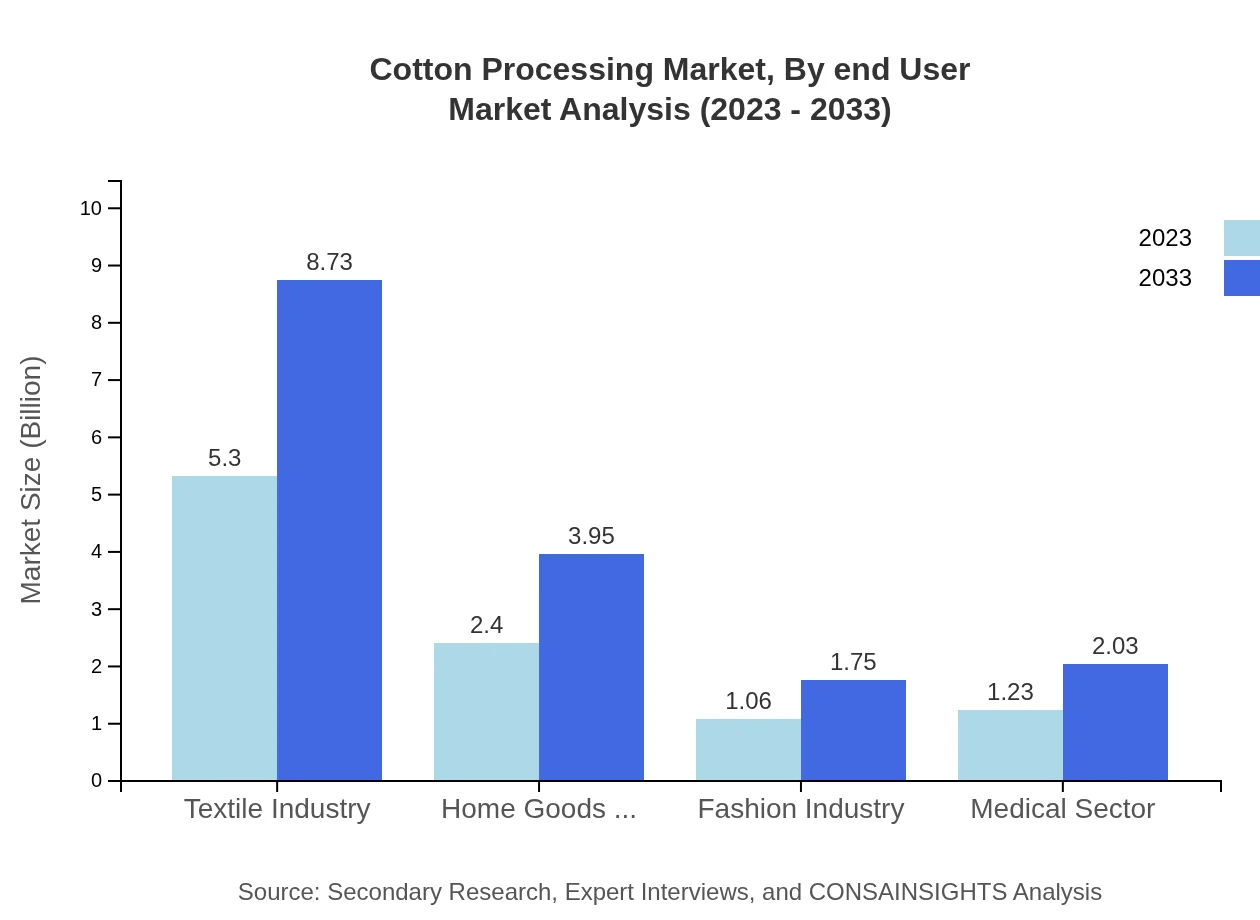

Cotton Processing Market Analysis By End User

End-user industries for cotton processed products include the fashion industry, healthcare sector, and home goods manufacturers. The fashion industry is a major market player, with substantial growth expected driven by the transition towards sustainable materials.

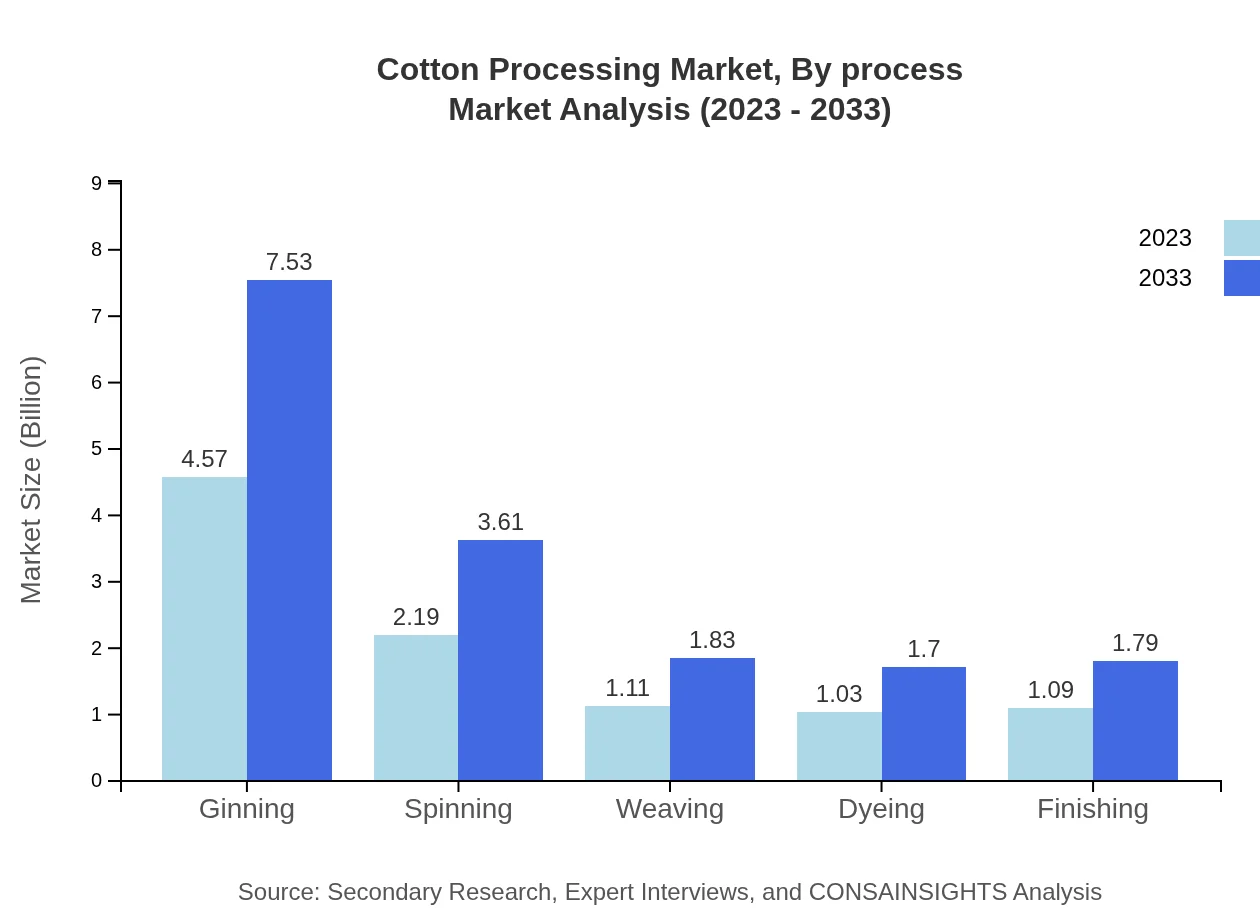

Cotton Processing Market Analysis By Process

The primary processing methods include Ginning, Spinning, Weaving, Dyeing, and Finishing. Ginning remains the largest processing segment with a market value of USD 4.57 billion in 2023, as efficient ginning is crucial for obtaining quality fiber from raw cotton.

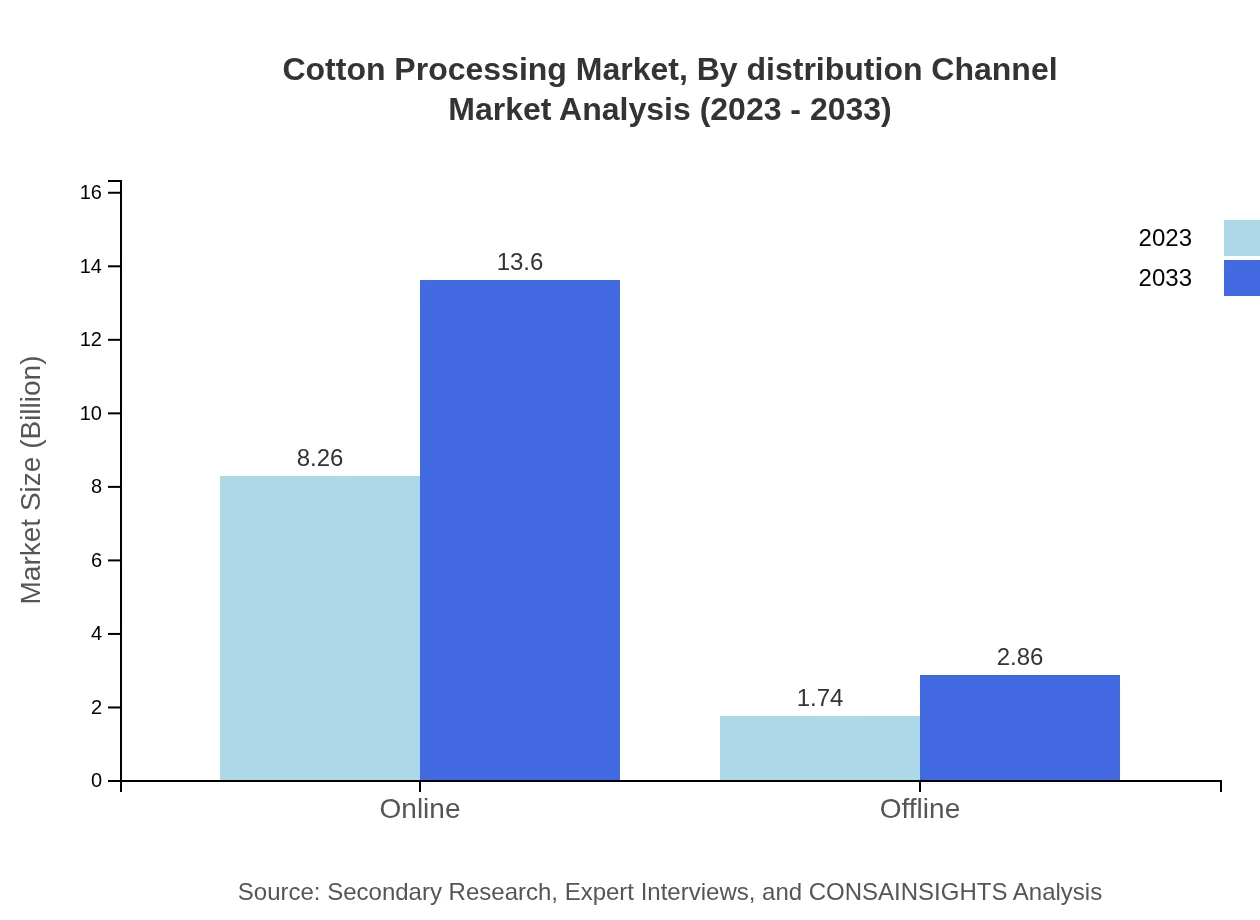

Cotton Processing Market Analysis By Distribution Channel

Distribution channels for cotton products are predominantly online, reflecting a market size of USD 8.26 billion in 2023. Offline channels comprise a smaller segment, but are crucial for traditional retail and direct sales.

Cotton Processing Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Cotton Processing Industry

Cargill, Inc.:

A major global player in agricultural commodities, Cargill also focuses on cotton sourcing and marketing, contributing significantly to setting market trends.Cotton Incorporated:

Cotton Incorporated leads in cotton promotion and research, providing support to growers and manufacturers to enhance cotton processing standards and sustainability.Lenzing AG:

Known for eco-friendly textile production, Lenzing incorporates sustainable cotton in its innovative fabrics, driving market demand for responsible sourcing.We're grateful to work with incredible clients.

FAQs

What is the market size of cotton Processing?

The global cotton-processing market is valued at approximately $10 billion in 2023, with a projected CAGR of around 5%, indicating resilience and growth potential through to 2033.

What are the key market players or companies in this cotton Processing industry?

Key players in the cotton-processing industry include major manufacturers and suppliers engaged in ginning, spinning, weaving, and dyeing, ensuring the continuous supply chain of raw and processed cotton products.

What are the primary factors driving the growth in the cotton Processing industry?

Growth in the cotton-processing industry is driven by rising demand for cotton fabrics in apparel, advancements in processing technologies, and increasing awareness of sustainable practices in textile manufacturing.

Which region is the fastest Growing in the cotton Processing?

The fastest-growing region in the cotton-processing market is North America, projected to grow from $3.34 billion in 2023 to $5.50 billion by 2033, showcasing robust market dynamics and demand.

Does ConsaInsights provide customized market report data for the cotton Processing industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs in the cotton-processing industry, providing insights that align with unique business requirements.

What deliverables can I expect from this cotton Processing market research project?

Deliverables from the cotton-processing market research project include comprehensive reports, market segment analyses, competitive landscape insights, and forecasts, valuable for strategic planning.

What are the market trends of cotton Processing?

Current trends in the cotton-processing market include sustainability initiatives, the rise of organic cotton, innovative processing techniques, and an increasing shift towards online distribution channels.