Covid19 Impact On Smart Manufacturing Market Report

Published Date: 22 January 2026 | Report Code: covid19-impact-on-smart-manufacturing

Covid19 Impact On Smart Manufacturing Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Covid19 impact on the smart manufacturing industry, including market size forecasts, regional analysis, industry trends, and key players from 2023 to 2033.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

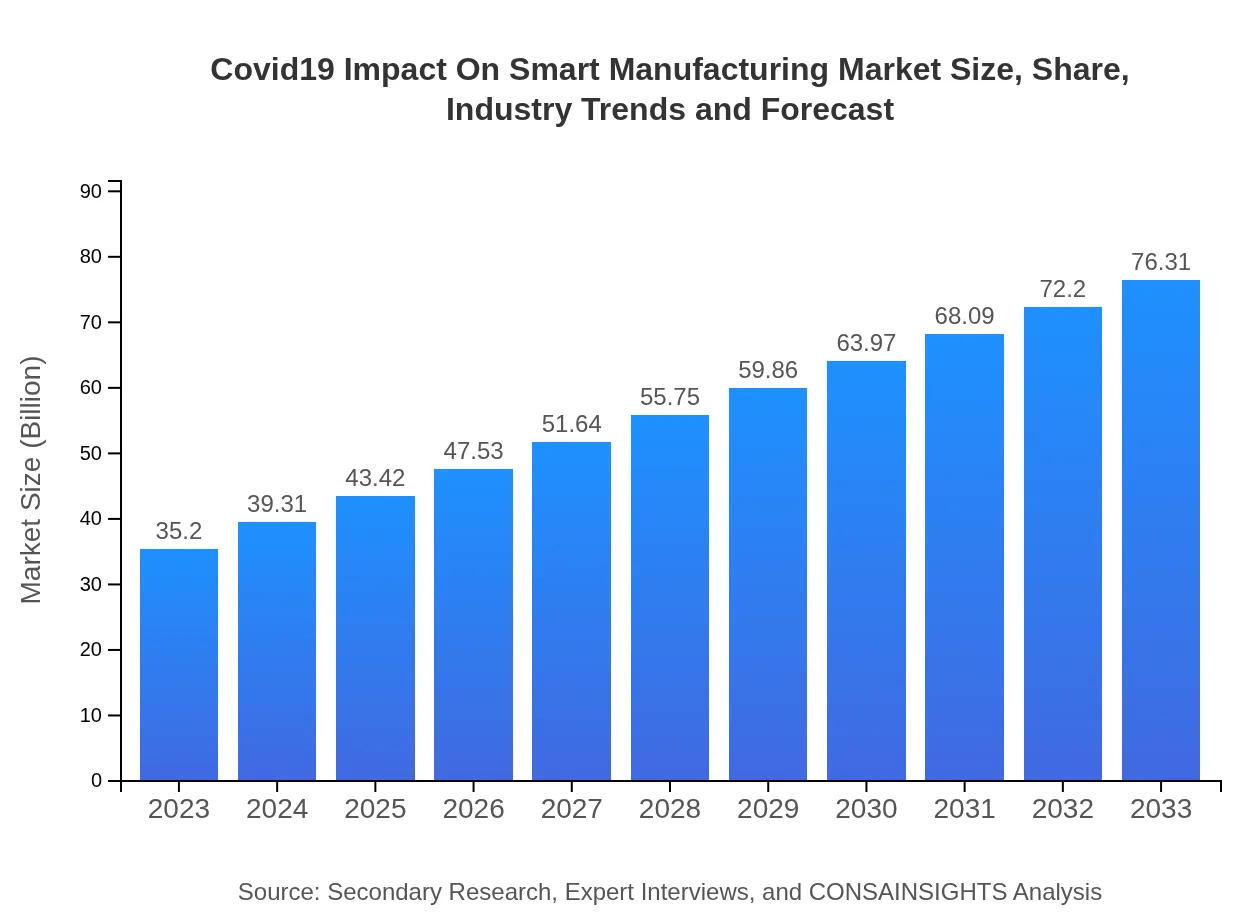

| 2023 Market Size | $35.20 Billion |

| CAGR (2023-2033) | 7.8% |

| 2033 Market Size | $76.31 Billion |

| Top Companies | Siemens AG, General Electric, Honeywell International Inc., Rockwell Automation, ABB Ltd. |

| Last Modified Date | 22 January 2026 |

Covid19 Impact On Smart Manufacturing Market Overview

Customize Covid19 Impact On Smart Manufacturing Market Report market research report

- ✔ Get in-depth analysis of Covid19 Impact On Smart Manufacturing market size, growth, and forecasts.

- ✔ Understand Covid19 Impact On Smart Manufacturing's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Covid19 Impact On Smart Manufacturing

What is the Market Size & CAGR of Covid19 Impact On Smart Manufacturing market in 2023?

Covid19 Impact On Smart Manufacturing Industry Analysis

Covid19 Impact On Smart Manufacturing Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Covid19 Impact On Smart Manufacturing Market Analysis Report by Region

Europe Covid19 Impact On Smart Manufacturing Market Report:

The European smart manufacturing market will grow from $9.37 billion in 2023 to $20.31 billion by 2033. EU initiatives on digital transformation and sustainability are propelling the adoption of smart manufacturing processes across various sectors.Asia Pacific Covid19 Impact On Smart Manufacturing Market Report:

In the Asia-Pacific region, the smart manufacturing market is expected to grow from $6.72 billion in 2023 to $14.57 billion by 2033, driven by strong manufacturing bases in countries like China and Japan. The focus on integrating IoT and AI in manufacturing is leading to increased productivity and efficiency.North America Covid19 Impact On Smart Manufacturing Market Report:

North America holds a significant share, with the market expected to grow from $12.97 billion in 2023 to $28.12 billion by 2033. The U.S. is a leader in adopting advanced manufacturing technologies, driven by the need for operational efficiency and innovation.South America Covid19 Impact On Smart Manufacturing Market Report:

The South American market is projected to expand from $1.28 billion in 2023 to $2.77 billion by 2033. While growth is slower than in other regions, there is a rising interest in automating processes and adopting smart technologies, particularly in industries like agriculture and mining.Middle East & Africa Covid19 Impact On Smart Manufacturing Market Report:

This region faces unique challenges but is expected to grow from $4.86 billion in 2023 to $10.54 billion by 2033. Countries are exploring digital solutions to improve industrial efficiency, particularly in oil and gas, and construction sectors.Tell us your focus area and get a customized research report.

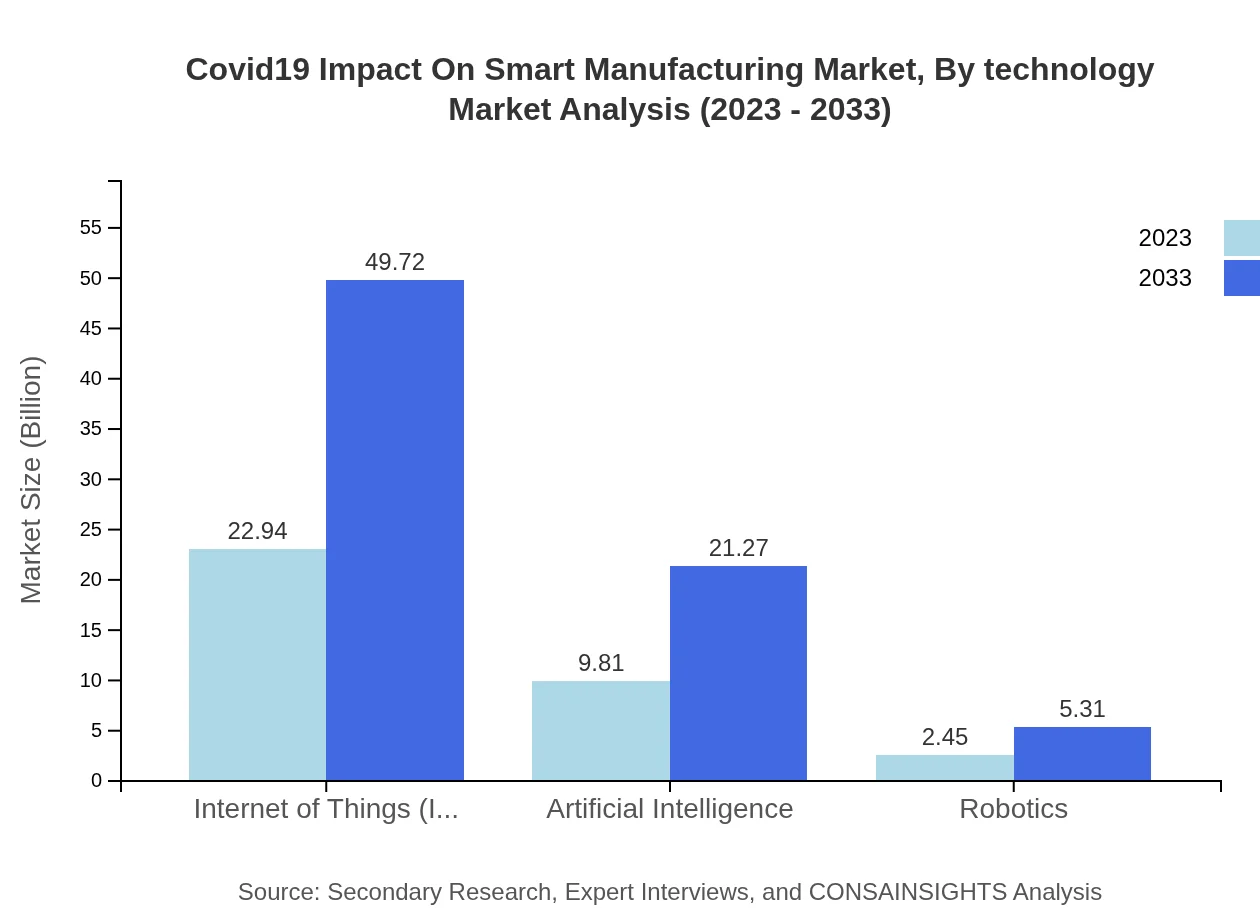

Covid19 Impact On Smart Manufacturing Market Analysis By Technology

The key technologies reshaping smart manufacturing include IoT, robotics, AI, and process automation. IoT systems are forecasted to grow from $22.94 billion in 2023 to $49.72 billion by 2033, significantly enhancing connectivity and real-time data analytics. Other technologies like AI will also see substantial growth, with projections from $9.81 billion to $21.27 billion in the same period.

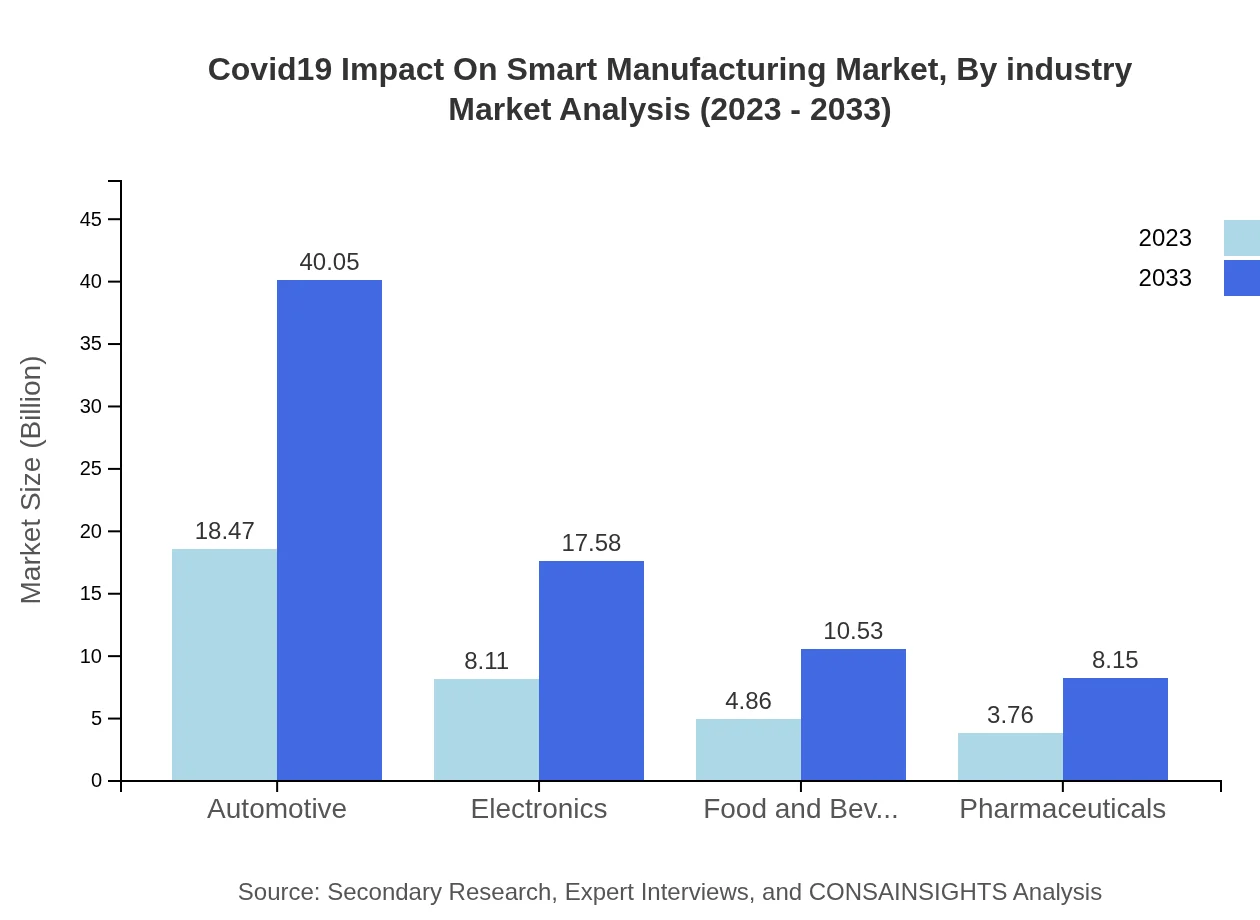

Covid19 Impact On Smart Manufacturing Market Analysis By Industry

The automotive industry is the largest segment, growing from $18.47 billion in 2023 to $40.05 billion by 2033, accounting for over 52% market share. Electronics and pharmaceuticals are also essential sectors with respective significant growth, driven by needs for automation and data integration.

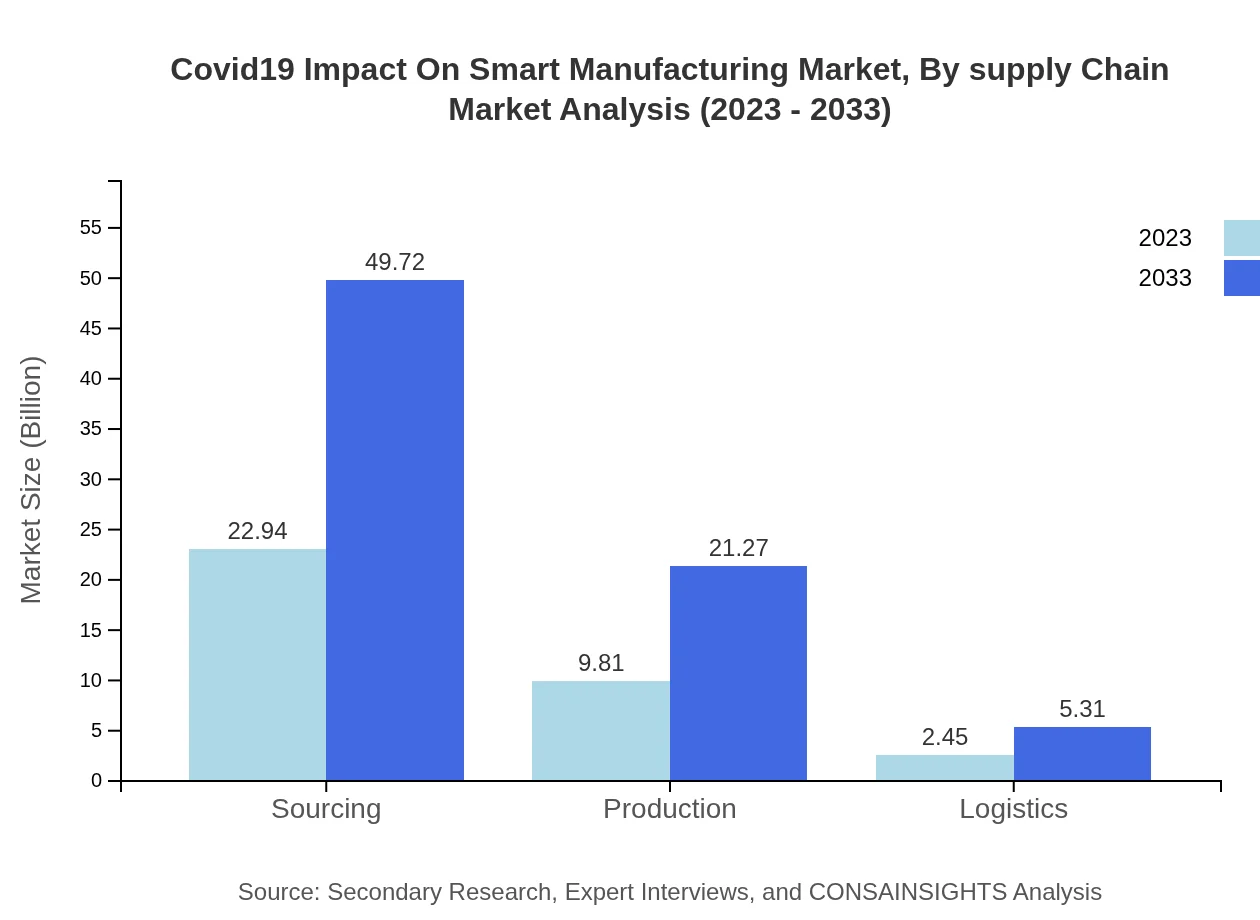

Covid19 Impact On Smart Manufacturing Market Analysis By Supply Chain

Smart manufacturing optimizes every aspect of the supply chain, from sourcing to logistics. Sourcing technologies will rise from $22.94 billion to $49.72 billion, enhancing procurement processes. Logistics will evolve from $2.45 billion to $5.31 billion, improving distribution efficiency.

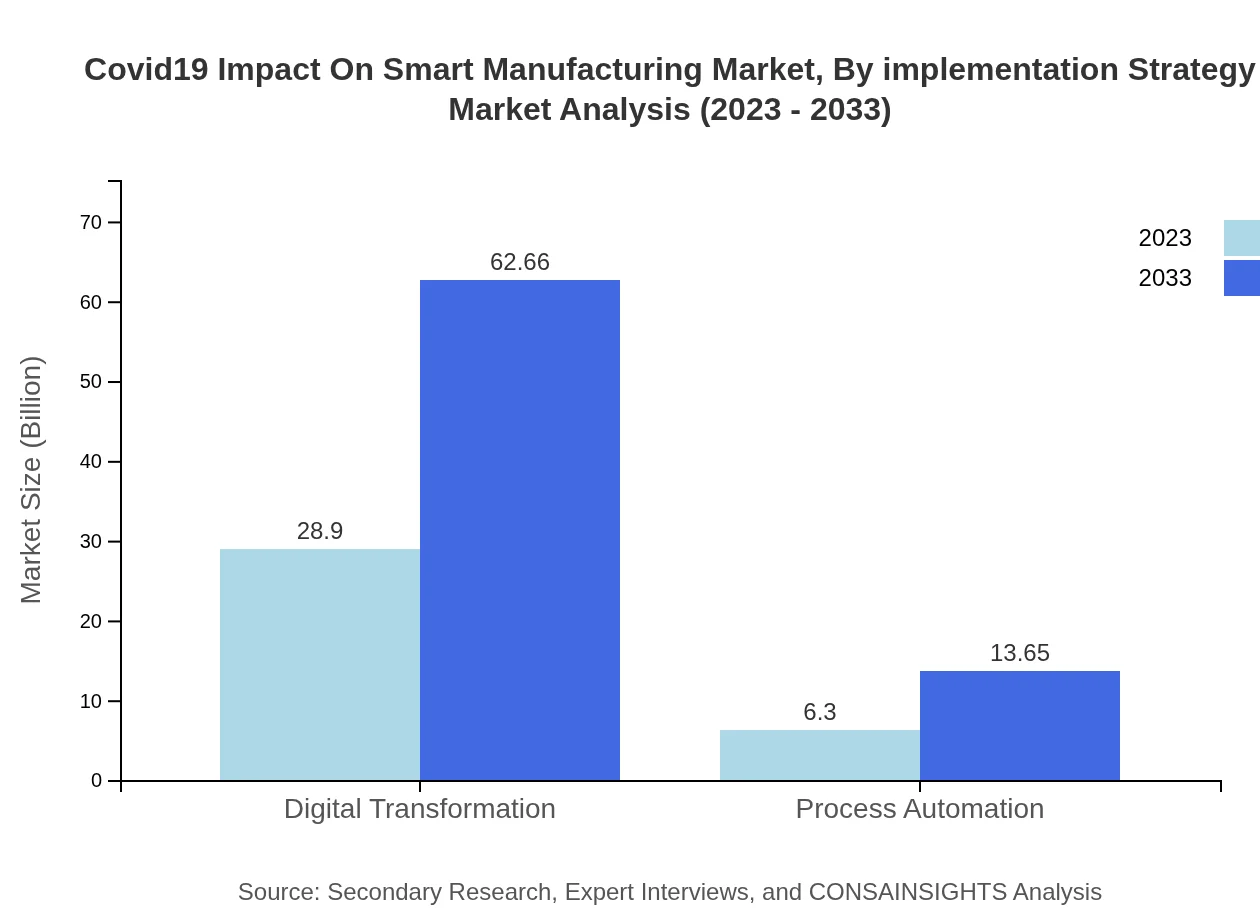

Covid19 Impact On Smart Manufacturing Market Analysis By Implementation Strategy

Implementation strategies focusing on digital transformation and process automation are key. Digital transformation market share will grow from $28.90 billion to $62.66 billion, emphasizing the shift towards comprehensive technology integration across manufacturing processes.

Covid19 Impact On Smart Manufacturing Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Covid19 Impact On Smart Manufacturing Industry

Siemens AG:

A leader in automation and digitalization, Siemens provides innovative solutions and technologies to enhance manufacturing efficiency and sustainability.General Electric:

Pioneering industry solutions like Predix, GE focuses on IoT and digital twins to optimize manufacturing and operational efficiencies.Honeywell International Inc.:

Honeywell offers integrated solutions leveraging IoT, AI, and analytics, driving transformation in industrial operations.Rockwell Automation:

Specializing in industrial automation, Rockwell provides state-of-the-art technology designed to improve productivity and innovation in manufacturing.ABB Ltd.:

ABB combines software and hardware in robotics and automation to create intelligent manufacturing solutions that enhance operational efficiency.We're grateful to work with incredible clients.

FAQs

What is the market size of covid19 Impact On Smart Manufacturing?

The covid19 impact on smart manufacturing market is projected to grow from $35.2 billion in 2023 to significant heights by 2033, with a compound annual growth rate (CAGR) of 7.8%, highlighting its robust expansion in the coming decade.

What are the key market players or companies in this covid19 Impact On Smart Manufacturing industry?

Key players in the covid19 impact on smart manufacturing market include industry giants known for their innovations and technological advancements, such as Siemens, General Electric, and Honeywell. Their contributions are pivotal in shaping industry standards and practices.

What are the primary factors driving the growth in the covid19 Impact On Smart Manufacturing industry?

The growth in the covid19 impact on smart manufacturing industry is primarily driven by the increasing need for automation, the growing demand for IoT solutions, and advancements in AI technologies. These factors enhance operational efficiency and productivity in manufacturing.

Which region is the fastest Growing in the covid19 Impact On Smart Manufacturing?

North America is the fastest-growing region in the covid19 impact on smart manufacturing sector, with a market expected to expand from $12.97 billion in 2023 to $28.12 billion by 2033. This growth is fueled by technological advancements and increased industrial automation.

Does ConsaInsights provide customized market report data for the covid19 Impact On Smart Manufacturing industry?

Yes, ConsaInsights offers customized market report data tailored to the needs of clients within the covid19 impact on smart manufacturing sector, providing detailed insights and analytics for informed business decisions.

What deliverables can I expect from this covid19 Impact On Smart Manufacturing market research project?

From the covid19 impact on smart manufacturing market research project, expect comprehensive reports, actionable insights, market segmentation analysis, and future trend forecasts, aiding in strategic planning and decision-making.

What are the market trends of covid19 Impact On Smart Manufacturing?

Current market trends in the covid19 impact on smart manufacturing include the rise of digital transformation, skyrocketing investment in IoT applications, and increasing adoption of AI and automation technologies, positioning manufacturers for future challenges.