Crane And Hoist Market Report

Published Date: 22 January 2026 | Report Code: crane-and-hoist

Crane And Hoist Market Size, Share, Industry Trends and Forecast to 2033

This report offers comprehensive insights into the global Crane and Hoist market, detailing the current market conditions and projections from 2023 to 2033. It examines market size, industry dynamics, regional analysis, and trends shaping the future of this critical industry.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $3.80 Billion |

| CAGR (2023-2033) | 6.3% |

| 2033 Market Size | $7.11 Billion |

| Top Companies | Konecranes, Mitsubishi Electric, Terex Corporation, Liebherr Group, JLG Industries |

| Last Modified Date | 22 January 2026 |

Crane And Hoist Market Overview

Customize Crane And Hoist Market Report market research report

- ✔ Get in-depth analysis of Crane And Hoist market size, growth, and forecasts.

- ✔ Understand Crane And Hoist's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Crane And Hoist

What is the Market Size & CAGR of Crane And Hoist market in 2023?

Crane And Hoist Industry Analysis

Crane And Hoist Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Crane And Hoist Market Analysis Report by Region

Europe Crane And Hoist Market Report:

Europe boasts a mature market for Crane and Hoist products, expected to escalate from $1.21 billion in 2023 to $2.26 billion by 2033. The push towards automation and safety, coupled with traditional industries in Germany and France, significantly strengthens market prospects.Asia Pacific Crane And Hoist Market Report:

The Asia Pacific region is a significant market for Crane and Hoist, projected to grow from $0.68 billion in 2023 to $1.28 billion by 2033. Rapid industrialization, increasing construction projects, and a growing logistics market contribute to the rise. Major countries like China and India are focusing on infrastructure development, further driving the demand for cranes and hoists.North America Crane And Hoist Market Report:

North America is witnessing substantial growth, with the market projected to rise from $1.40 billion in 2023 to $2.62 billion by 2033. The region benefits from a strong industrial base, advanced technology deployment, and a robust logistics network, particularly in the United States and Canada.South America Crane And Hoist Market Report:

In South America, the market size is expected to expand from $0.07 billion in 2023 to $0.13 billion by 2033. Investment in mining and construction sectors in countries like Brazil and Chile is anticipated to catalyze growth, despite economic fluctuations within the region.Middle East & Africa Crane And Hoist Market Report:

The Middle East and Africa market is set to grow from $0.44 billion in 2023 to $0.82 billion by 2033. The increase will be driven by ongoing large-scale projects, particularly in the UAE and Saudi Arabia, coupled with substantial investments in infrastructure.Tell us your focus area and get a customized research report.

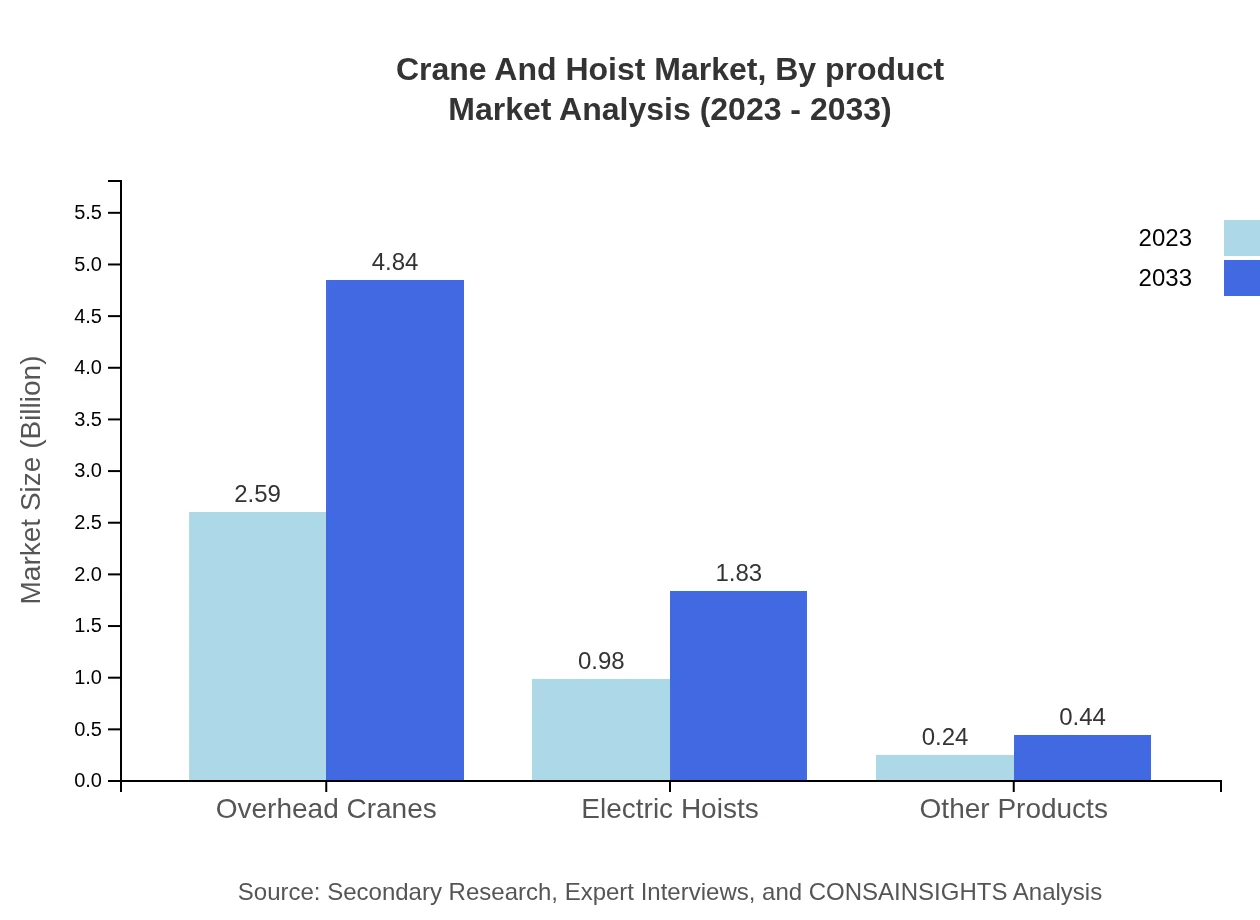

Crane And Hoist Market Analysis By Product

The market for Crane and Hoist products is diverse, featuring segments like Overhead Cranes, Electric Hoists, and Manual Cranes. Overhead cranes dominate the market, accounting for significant shares in 2023 and beyond. Likewise, Electric Hoists and Manual Cranes serve their respective applications across various industries, focusing on efficiency and versatility.

Crane And Hoist Market Analysis By Application

Key applications of cranes and hoists are evident in sectors such as construction, manufacturing, and logistics. The construction industry leads with major market shares, reflecting ongoing expansions in infrastructure and real estate development. Additionally, manufacturing and logistics sectors are gaining traction to enhance operational efficiency.

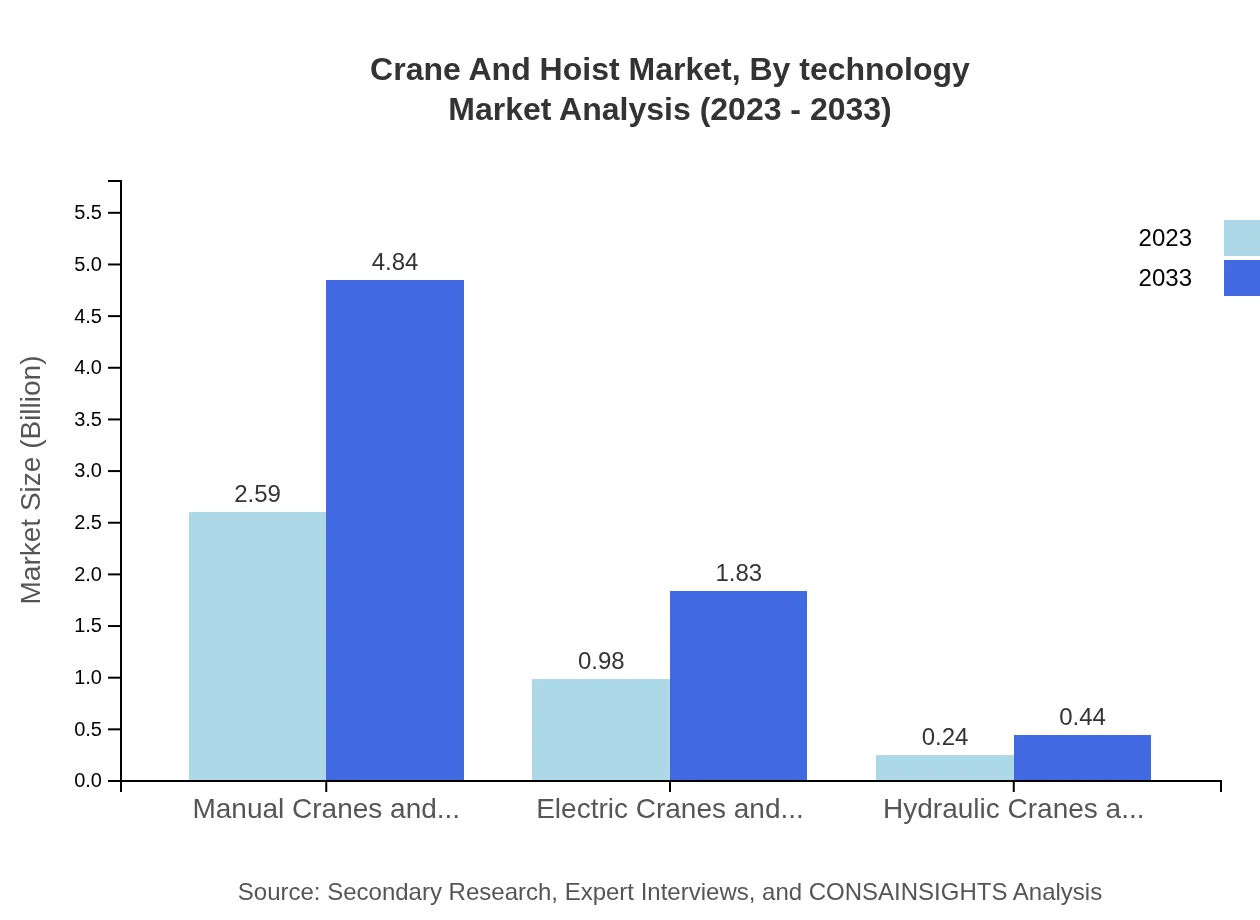

Crane And Hoist Market Analysis By Technology

Technological advancements are essential to the Crane and Hoist sector. The incorporation of electric and hydraulic technologies simplifies operations, enhances performance, and ensures workplace safety. Innovations like IoT-integrated smart cranes are paving the way for safer, more efficient lifting operations.

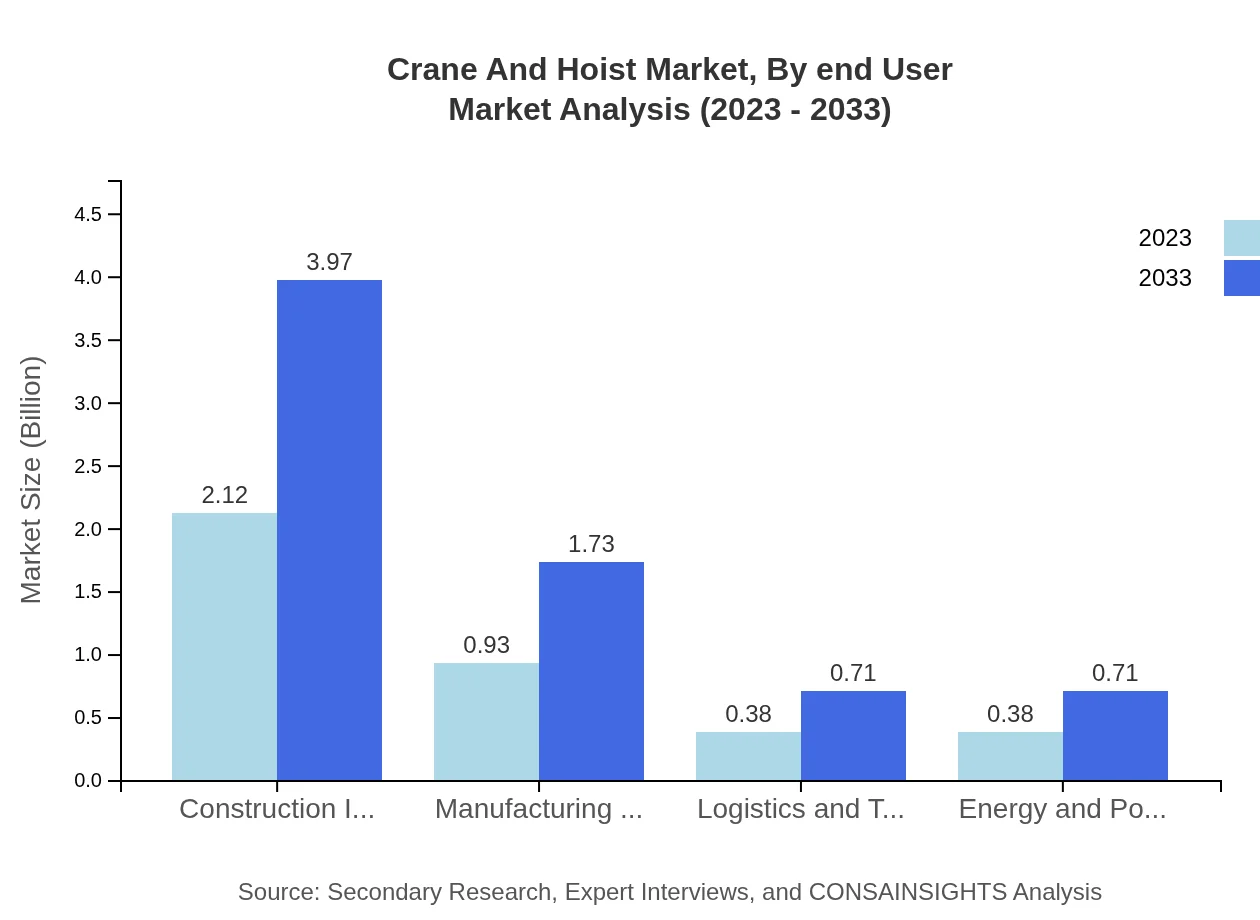

Crane And Hoist Market Analysis By End User

The end-user analysis shows major segments including construction, manufacturing, logistics, and aerospace industries. Logistics and construction sectors bear the most significant market shares, focusing on demand for lifting technologies that support high-efficiency workflows and safety protocols.

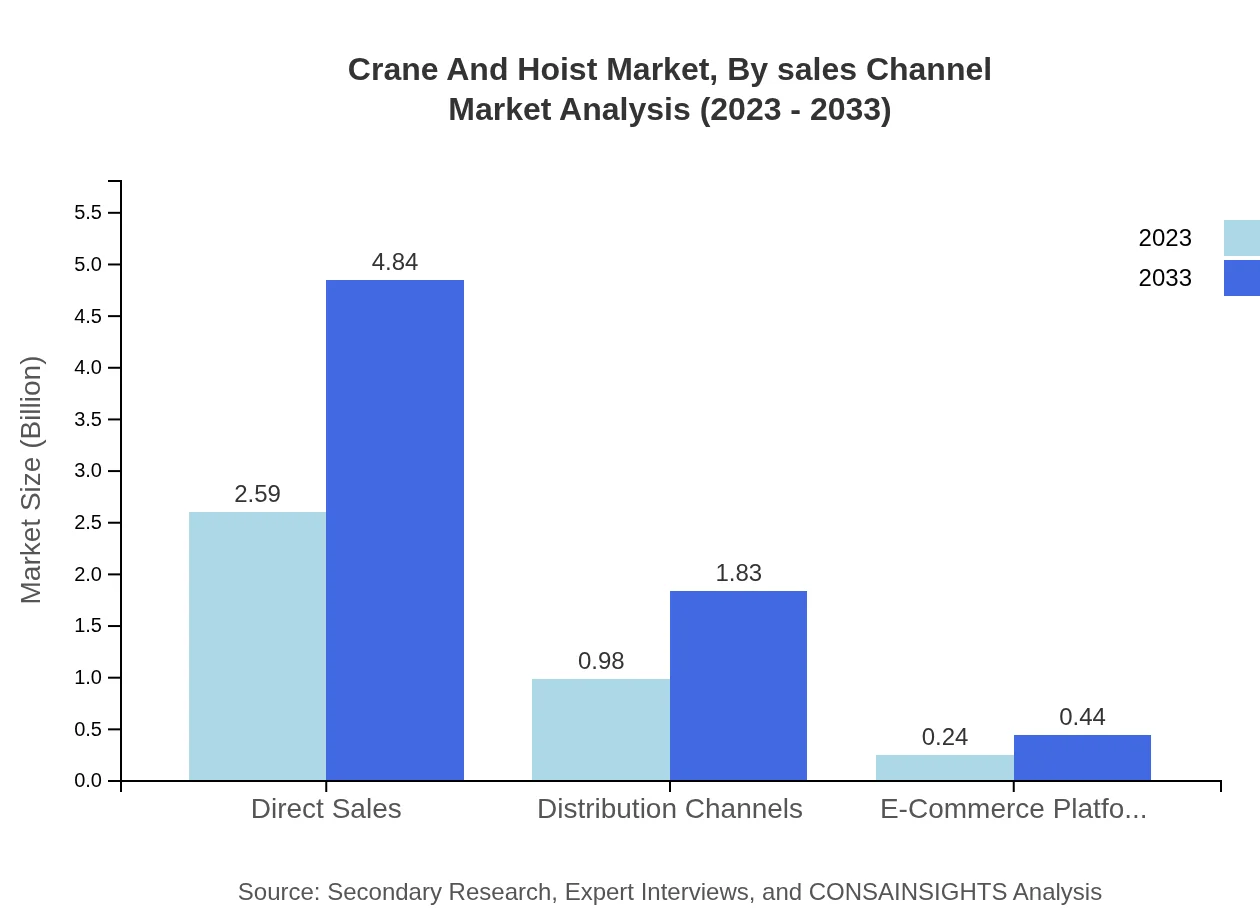

Crane And Hoist Market Analysis By Sales Channel

Sales channels for crane and hoist systems include direct sales, distribution channels, and e-commerce platforms. Direct sales remain prevalent in industrial sectors, whereas e-commerce is providing growing access to a wide range of products leveraging technological developments.

Crane And Hoist Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Crane And Hoist Industry

Konecranes:

A leader in lifting equipment, Konecranes offers a wide array of cranes and hoists providing innovative solutions tailored to various industry requirements.Mitsubishi Electric:

Recognized for its technological advancements, Mitsubishi Electric is pivotal in providing electric hoists and cranes that prioritize performance and reliability.Terex Corporation:

Terex is known for its robust line of cranes and material handling products aimed at construction and industrial sectors, promoting efficiency and safety.Liebherr Group:

Liebherr Group is a reputable manufacturer with a comprehensive portfolio of cranes and hoists renowned for their durability and innovative engineering.JLG Industries:

JLG Industries specializes in aerial work platforms and telehandlers, significantly contributing to the lifting sector through innovative products.We're grateful to work with incredible clients.

FAQs

What is the market size of crane And Hoist?

The global crane and hoist market is currently valued at $3.8 billion, with a projected CAGR of 6.3% over the next decade. This growth reflects the increasing demand for automated material handling solutions in various industries.

What are the key market players or companies in the crane And Hoist industry?

Key players in the crane and hoist market include companies like Konecranes, Terex Corporation, and Manitowoc. These firms are known for their innovative technologies and extensive product offerings, contributing heavily to market expansion and customer base diversification.

What are the primary factors driving the growth in the crane And Hoist industry?

Driving factors for market growth include rising industrial automation, increased construction activities, and advancements in crane technology. Additionally, the demand for efficient material handling solutions boosts production capabilities across numerous sectors.

Which region is the fastest Growing in the crane And Hoist market?

The Asia Pacific region is expected to exhibit the fastest growth in the crane and hoist market from 2023 to 2033, with market size projected to rise from $0.68 billion to $1.28 billion, driven by rapid industrialization and urban development.

Does ConsInsights provide customized market report data for the crane And Hoist industry?

Yes, ConsInsights offers customized market report data tailored to specific needs within the crane and hoist industry. This service ensures that clients receive relevant insights and detailed analytics to support strategic decisions in their operations.

What deliverables can I expect from this crane And Hoist market research project?

Deliverables from the crane and hoist market research project include comprehensive market analysis, competitive landscape review, segment-wise insights, regional market evaluations, and forecasts to assist in informed decision-making for stakeholders.

What are the market trends of crane And Hoist?

Current trends in the crane and hoist market include the adoption of smart technologies, increased focus on safety and efficiency, and the rise of electric and automated models. Sustainability is also shaping future product innovations and consumer preferences.