Cryogenic Insulation Market Report

Published Date: 22 January 2026 | Report Code: cryogenic-insulation

Cryogenic Insulation Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Cryogenic Insulation market, highlighting insights and data from 2023 to 2033. It covers market size, CAGR, regional dynamics, product performance, and the impact of technological advancements on the industry.

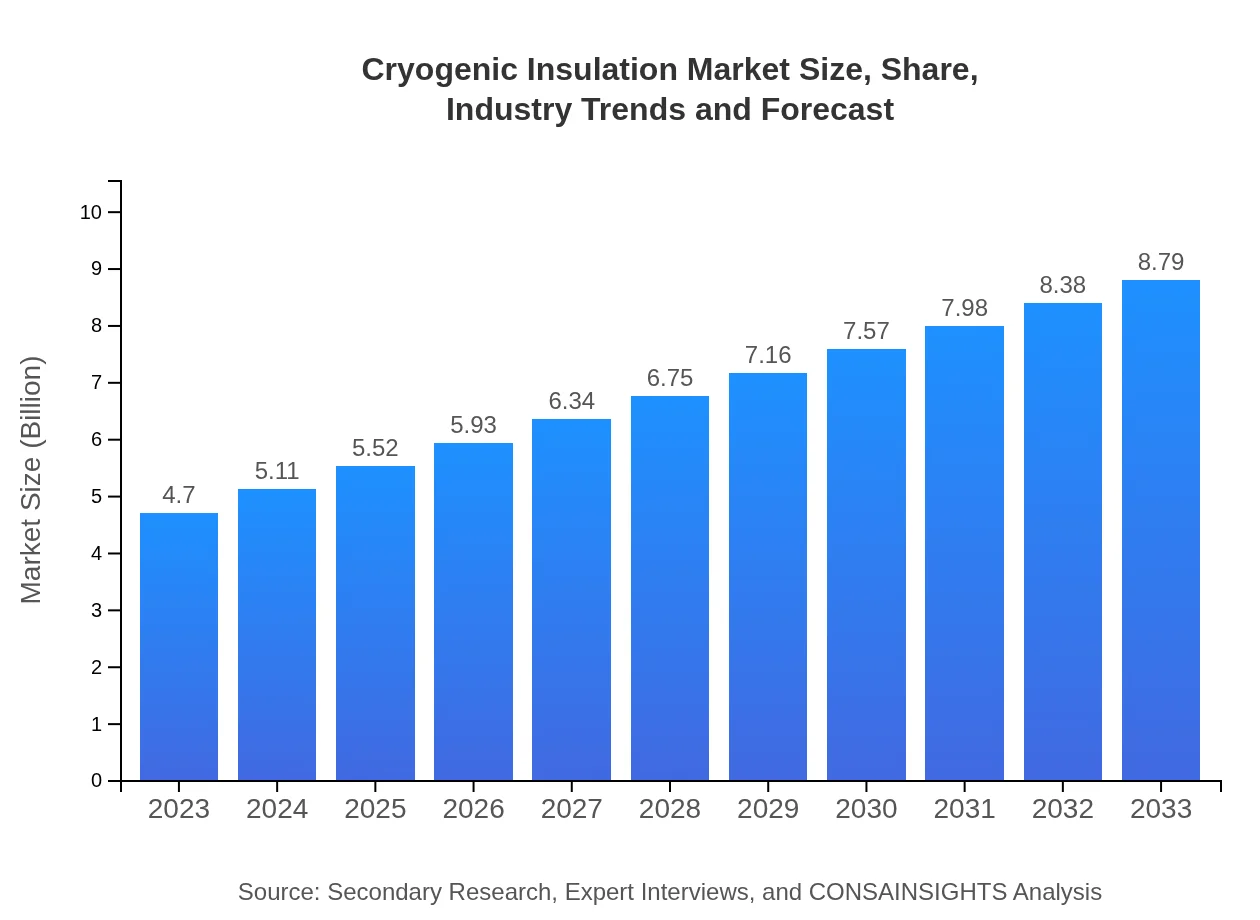

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $4.70 Billion |

| CAGR (2023-2033) | 6.3% |

| 2033 Market Size | $8.79 Billion |

| Top Companies | Owens Corning, Armacell International, The Dow Chemical Company, BASF |

| Last Modified Date | 22 January 2026 |

Cryogenic Insulation Market Overview

Customize Cryogenic Insulation Market Report market research report

- ✔ Get in-depth analysis of Cryogenic Insulation market size, growth, and forecasts.

- ✔ Understand Cryogenic Insulation's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Cryogenic Insulation

What is the Market Size & CAGR of Cryogenic Insulation market in 2033?

Cryogenic Insulation Industry Analysis

Cryogenic Insulation Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Cryogenic Insulation Market Analysis Report by Region

Europe Cryogenic Insulation Market Report:

The European market is forecasted to expand from 1.49 billion USD in 2023 to 2.79 billion USD by 2033, driven by stringent energy regulations and rising adoption of LNG technologies.Asia Pacific Cryogenic Insulation Market Report:

In the Asia Pacific region, the market is expected to grow from 0.85 billion USD in 2023 to 1.59 billion USD in 2033. The increasing demand for LNG and technological innovations in the chemical industry are key drivers of this growth.North America Cryogenic Insulation Market Report:

North America experiences substantial market growth, with projections increasing from 1.71 billion USD in 2023 to 3.19 billion USD in 2033. The surge in shale gas production and need for energy-efficient storage systems contribute significantly.South America Cryogenic Insulation Market Report:

The South America market is set to increase from 0.34 billion USD in 2023 to 0.63 billion USD in 2033. Rising investments in gas exploration and renewable energy mark significant prospects for cryogenic insulation growth in this region.Middle East & Africa Cryogenic Insulation Market Report:

This region is expected to see growth from 0.32 billion USD in 2023 to 0.60 billion USD by 2033, facilitated by increased investments in energy and industrial projects.Tell us your focus area and get a customized research report.

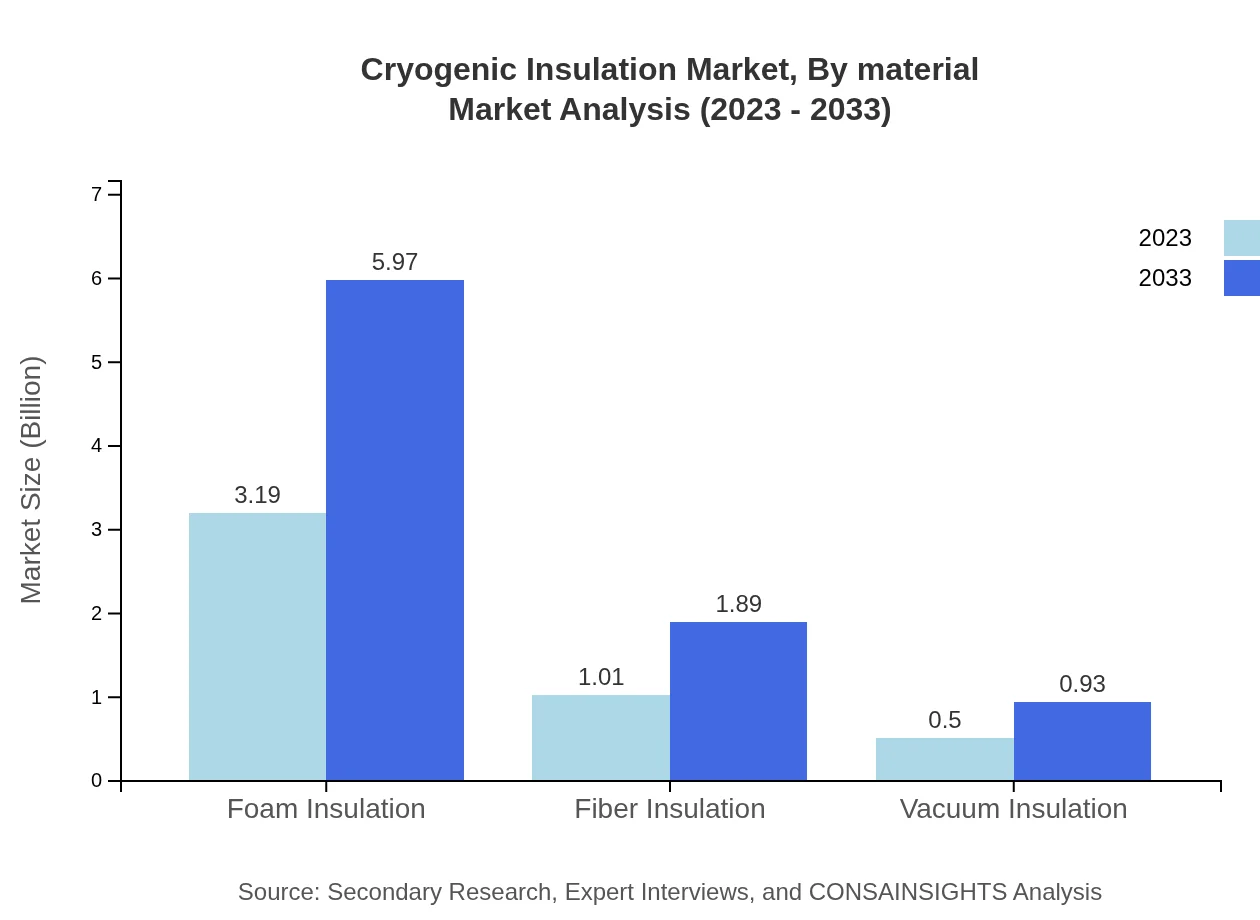

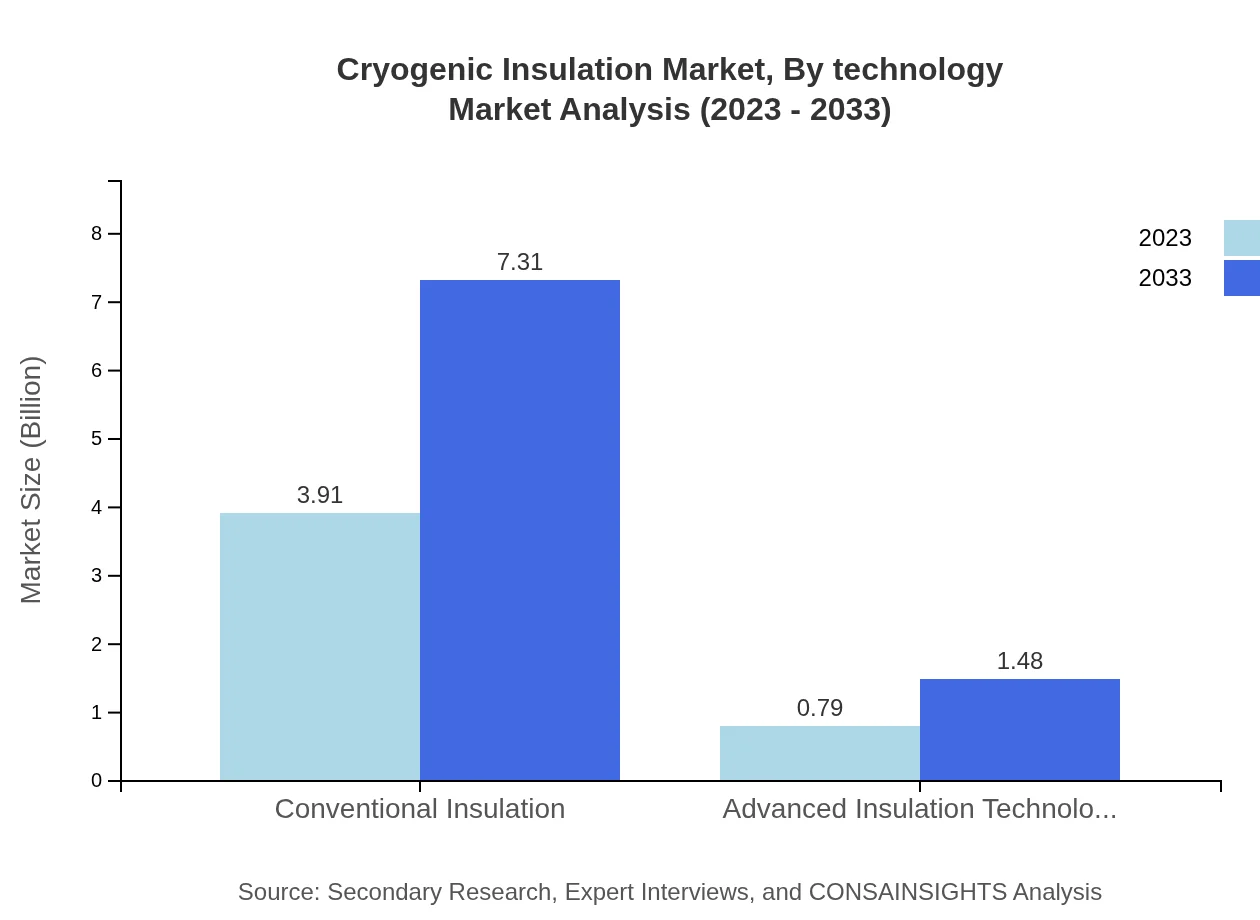

Cryogenic Insulation Market Analysis By Material

The material segment reveals key insights into the use of various types of insulation, with conventional insulation holding a significant market share of 83.12% in 2023, projected to rise to 83.12% by 2033. Foam insulation, with 67.89% in 2023, demonstrates consistent demand in the oil and gas sector, while fiber and vacuum insulation maintain a solid presence.

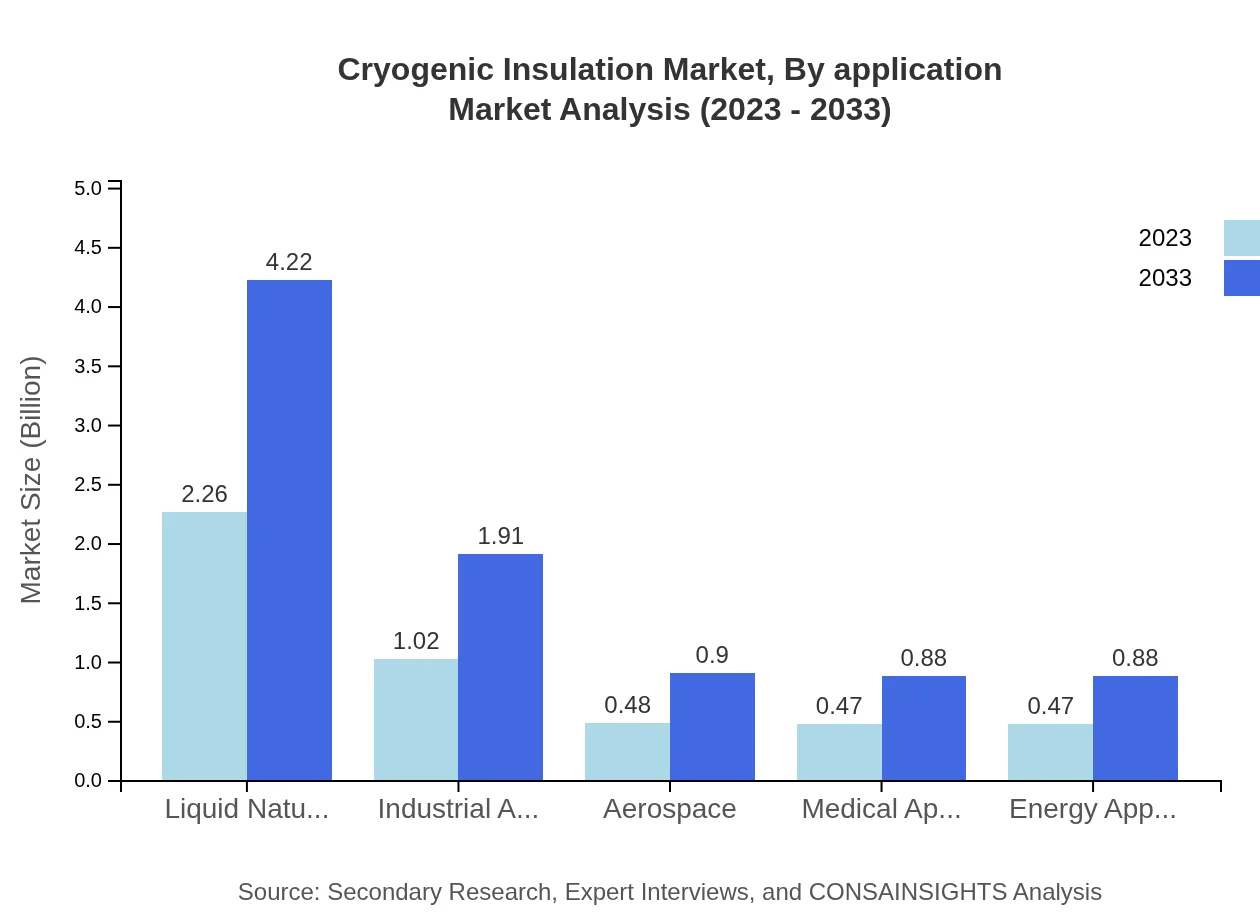

Cryogenic Insulation Market Analysis By Application

Applications in the oil and gas industry dominate, accounting for 47.98% of market share in 2023, with significant growth expected over the next decade. The chemicals and energy sectors follow, each representing about 21.77% and 10.22% respectively in 2023, with projections of growth due to increasing energy demands.

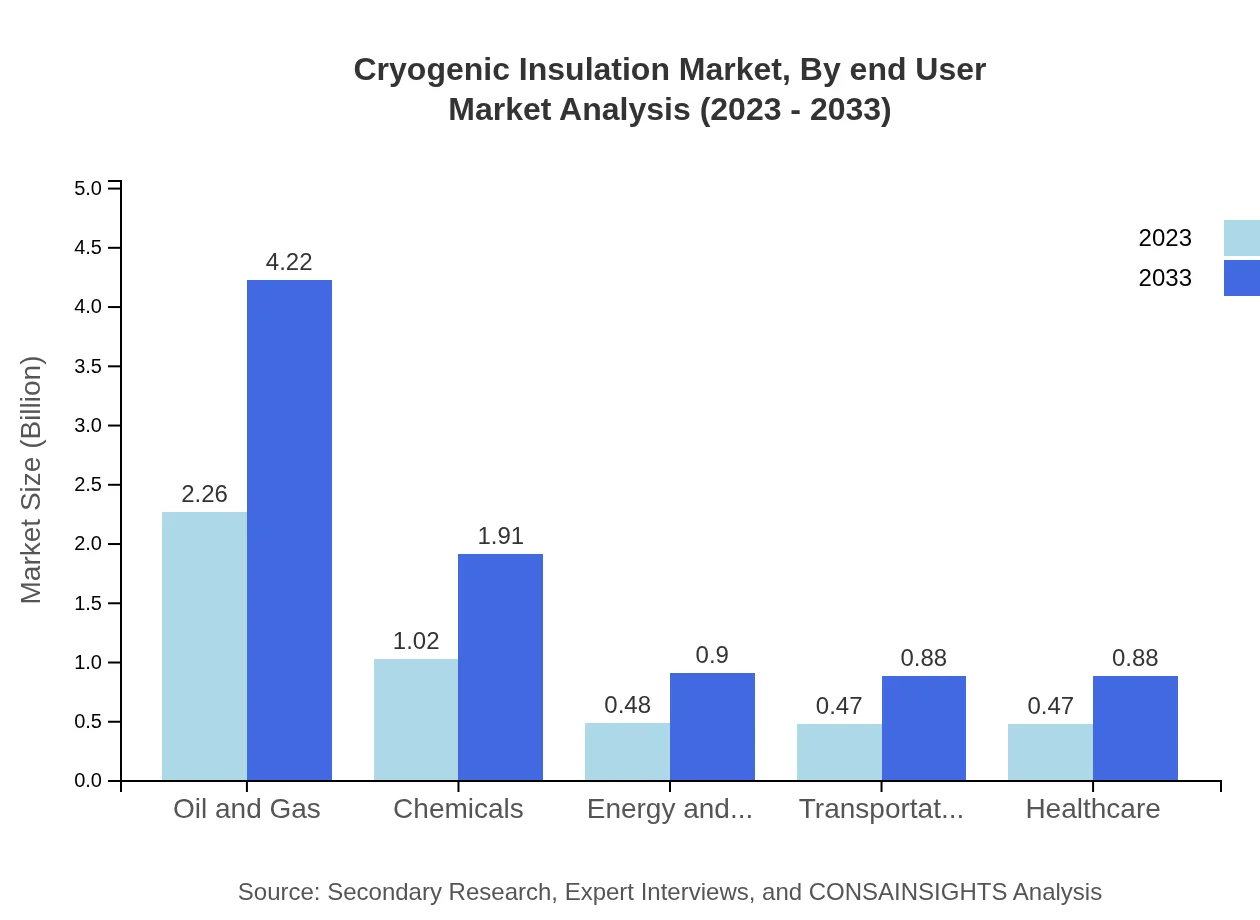

Cryogenic Insulation Market Analysis By End User

End-user analysis indicates industrial applications, especially in LNG, are the frontrunners. Aerospace and healthcare also contribute significantly, embodying around 10% each in 2023, with expected stable growth in innovation and demand.

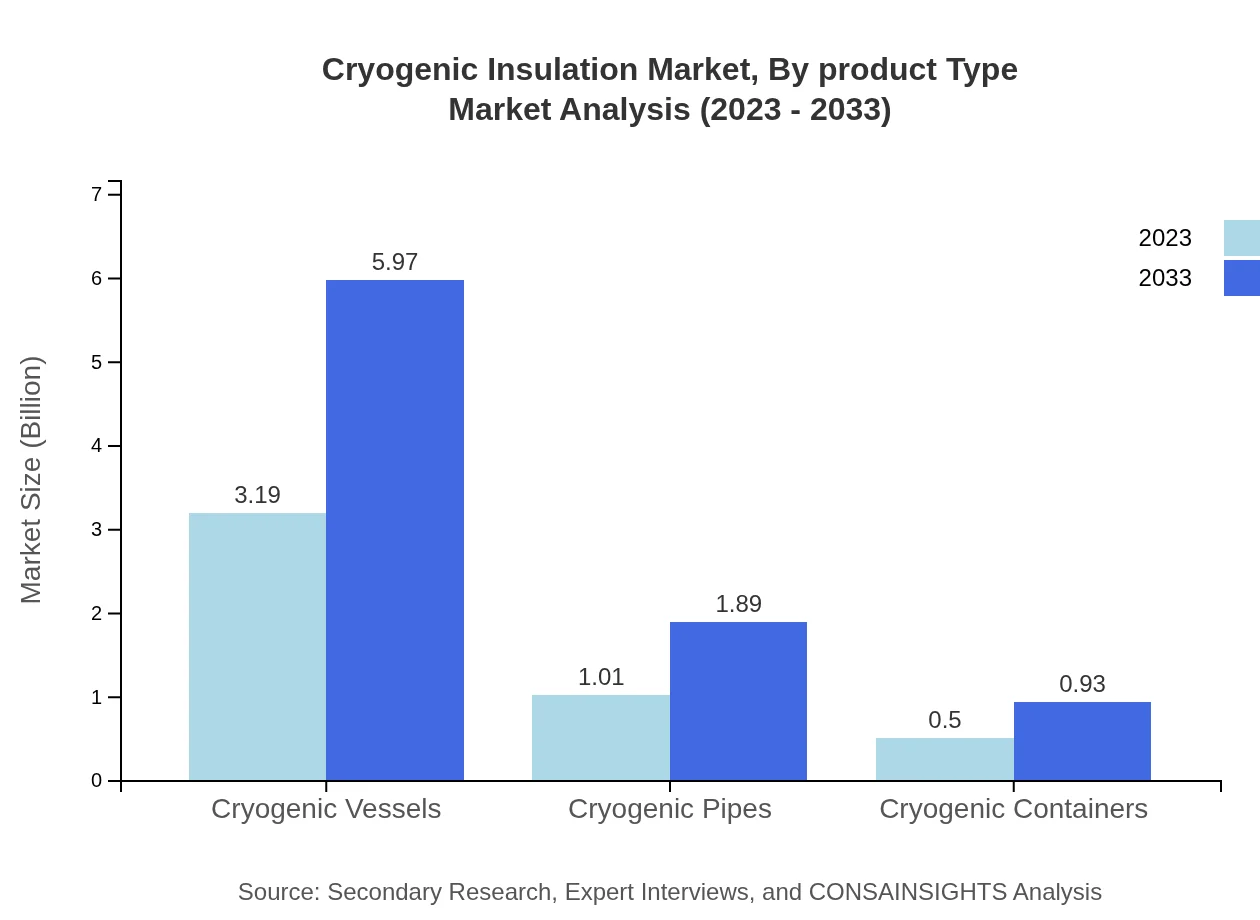

Cryogenic Insulation Market Analysis By Product Type

Product type analysis shows traditional cryogenic vessels and pipes maintain robust performance with over 67.89% and 21.51% shares respectively in 2023. Advanced technology products are gaining traction as industries shift towards enhanced performance solutions.

Cryogenic Insulation Market Analysis By Technology

Emerging technologies in cryogenic insulation, particularly advanced insulation materials, are forecasted to capture a growing market share. With innovations enhancing durability and efficiency, it's expected that this segment will grow significantly, paving the way for more sustainable applications.

Cryogenic Insulation Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Cryogenic Insulation Industry

Owens Corning:

A leading innovator in insulation products, Owens Corning offers advanced cryogenic insulation solutions that cater to the oil and gas industry with a commitment to sustainability.Armacell International:

Specializing in flexible insulation materials, Armacell provides a range of cryogenic insulation products that meet the highest safety standards for industrial applications.The Dow Chemical Company:

Dow is at the forefront of developing advanced insulation technologies, contributing innovative solutions that enhance energy efficiency across various sectors.BASF:

With a strong focus on performance materials, BASF offers cryogenic insulation solutions that are widely used in both industrial and residential applications.We're grateful to work with incredible clients.

FAQs

What is the market size of cryogenic insulation?

The cryogenic insulation market is valued at approximately $4.7 billion in 2023, with a projected CAGR of 6.3% from 2023 to 2033. This growth reflects the increased demand for effective insulation solutions in various applications across industries.

What are the key market players or companies in the cryogenic insulation industry?

Key players in the cryogenic insulation market include leading companies specializing in advanced insulation technologies. They contribute significantly to the market's growth through innovations and strategic partnerships, focusing on sectors like oil and gas, energy, and aerospace.

What are the primary factors driving the growth in the cryogenic insulation industry?

Growth in the cryogenic insulation industry is driven by rising demand in sectors like LNG, healthcare, and aerospace, alongside advancements in insulation technologies and practices aimed at improving energy efficiency and reducing operational costs.

Which region is the fastest Growing in cryogenic insulation?

The fastest-growing region for cryogenic insulation is North America, with market growth projected from $1.71 billion in 2023 to $3.19 billion by 2033. This growth is attributable to increased investments in oil and gas sectors and LNG infrastructure.

Does ConsaInsights provide customized market report data for the cryogenic insulation industry?

Yes, ConsaInsights offers customized market report data tailored to client specifications in the cryogenic insulation industry, allowing businesses to gain specific insights and analytics suited to their unique needs and market strategies.

What deliverables can I expect from this cryogenic insulation market research project?

Deliverables from the cryogenic insulation market research project include comprehensive market analysis reports, segmented data insights, competitive landscape analysis, and forecasts that help stakeholders understand market trends and opportunities.

What are the market trends of cryogenic insulation?

Key market trends in cryogenic insulation include the growing adoption of insulation technologies in LNG applications, increasing focus on energy efficiency, and the introduction of advanced materials that enhance thermal performance and sustainability across various industries.