Cryogenic Valve Market Report

Published Date: 22 January 2026 | Report Code: cryogenic-valve

Cryogenic Valve Market Size, Share, Industry Trends and Forecast to 2033

This report provides comprehensive insights into the Cryogenic Valve market, detailing market trends, forecasts from 2023 to 2033, and various market dynamics, including regional analysis, segmentation, and technology trends impacting growth.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

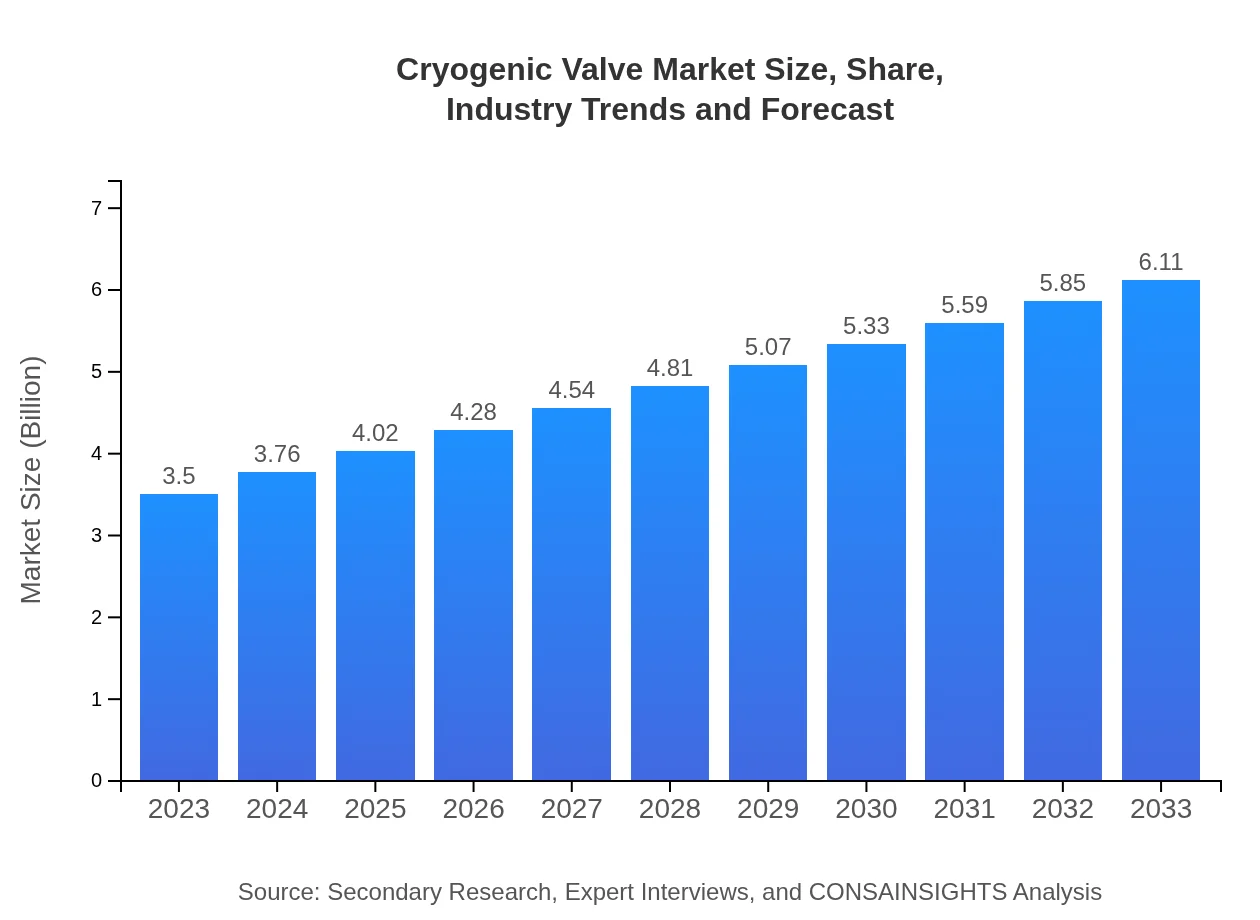

| 2023 Market Size | $3.50 Billion |

| CAGR (2023-2033) | 5.6% |

| 2033 Market Size | $6.11 Billion |

| Top Companies | Emerson Electric Co., Cameron International Corporation, Parker Hannifin Corporation, Flowserve Corporation, Worcester Controls Corporation |

| Last Modified Date | 22 January 2026 |

Cryogenic Valve Market Overview

Customize Cryogenic Valve Market Report market research report

- ✔ Get in-depth analysis of Cryogenic Valve market size, growth, and forecasts.

- ✔ Understand Cryogenic Valve's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Cryogenic Valve

What is the Market Size & CAGR of Cryogenic Valve market in 2023?

Cryogenic Valve Industry Analysis

Cryogenic Valve Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Cryogenic Valve Market Analysis Report by Region

Europe Cryogenic Valve Market Report:

In Europe, the Cryogenic Valve market is expected to grow from USD 1.02 billion in 2023 to USD 1.78 billion by 2033. The increasing focus on reducing carbon emissions and enhancing energy efficiency through cryogenic technologies in various industries is a significant factor influencing this growth.Asia Pacific Cryogenic Valve Market Report:

The Asia Pacific region is experiencing robust growth, projected to reach USD 1.18 billion by 2033, up from USD 0.68 billion in 2023. Factors such as rapid industrialization, increasing LNG projects, and heightened investments in infrastructure development are driving demand for cryogenic valves in countries like China and India.North America Cryogenic Valve Market Report:

The North American market is anticipated to experience noteworthy growth, with projections estimating a rise from USD 1.13 billion in 2023 to USD 1.97 billion by 2033, driven by a strong focus on LNG export expansion and strict safety regulations in gas transportation.South America Cryogenic Valve Market Report:

In South America, the Cryogenic Valve market is forecasted to grow from USD 0.33 billion in 2023 to USD 0.58 billion in 2033. This growth is largely attributed to advancements in oil and gas extraction technologies and the expansion of renewable energy projects.Middle East & Africa Cryogenic Valve Market Report:

The Middle East and Africa region is projected to witness steady growth, with the market expanding from USD 0.35 billion in 2023 to USD 0.61 billion by 2033. The rise in petrochemical manufacturing and gas transportation projects are key drivers behind this upward trend.Tell us your focus area and get a customized research report.

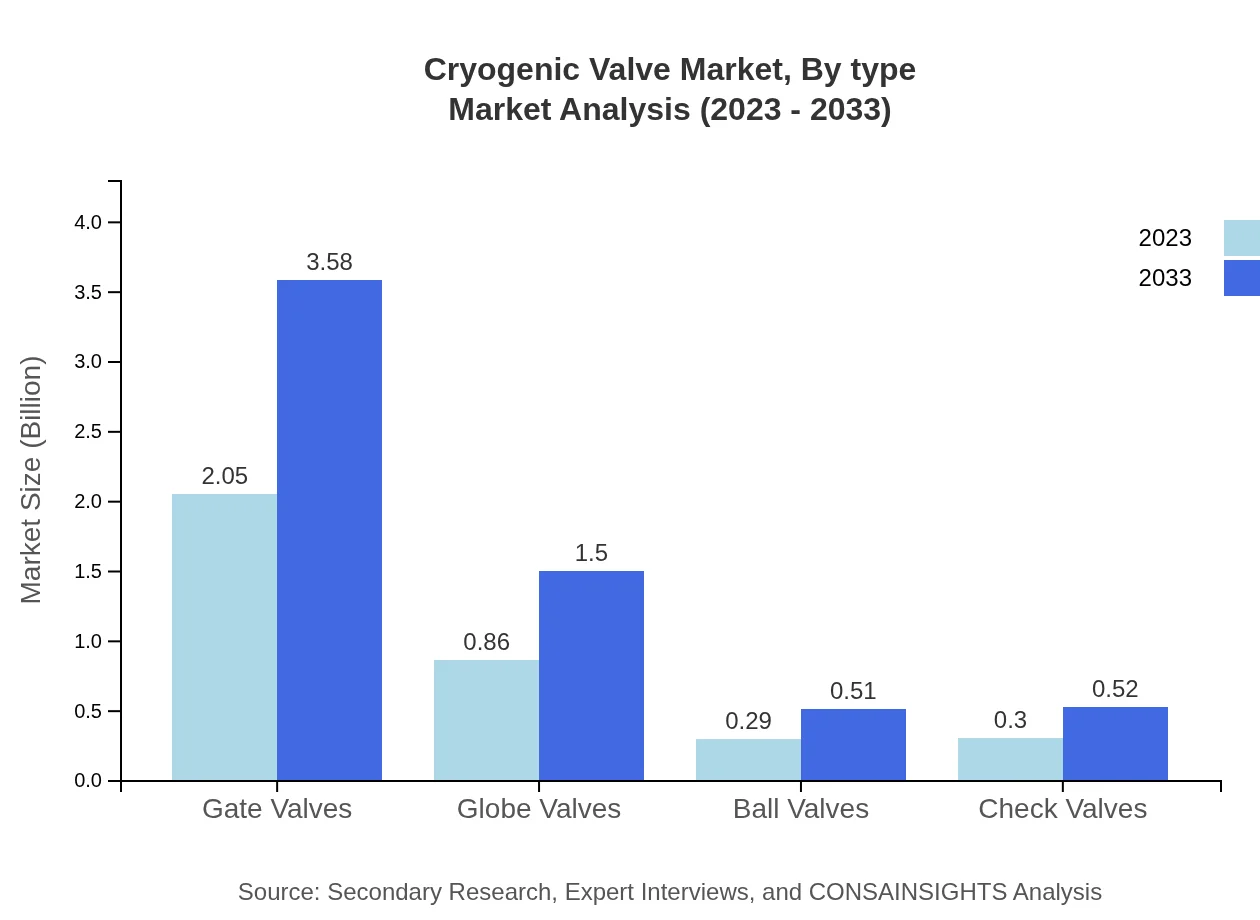

Cryogenic Valve Market Analysis By Type

The market shares of different cryogenic valve types reflect key industry trends. Gate Valves dominate the market size, projected to grow from USD 2.05 billion in 2023 to USD 3.58 billion by 2033, holding a stable market share of 58.52%. Globe Valves follow with market growth from USD 0.86 billion to USD 1.50 billion, accounting for 24.54%. Ball and Check Valves represent smaller segments but are critical for specific applications, maintaining respective market shares of 8.37% each.

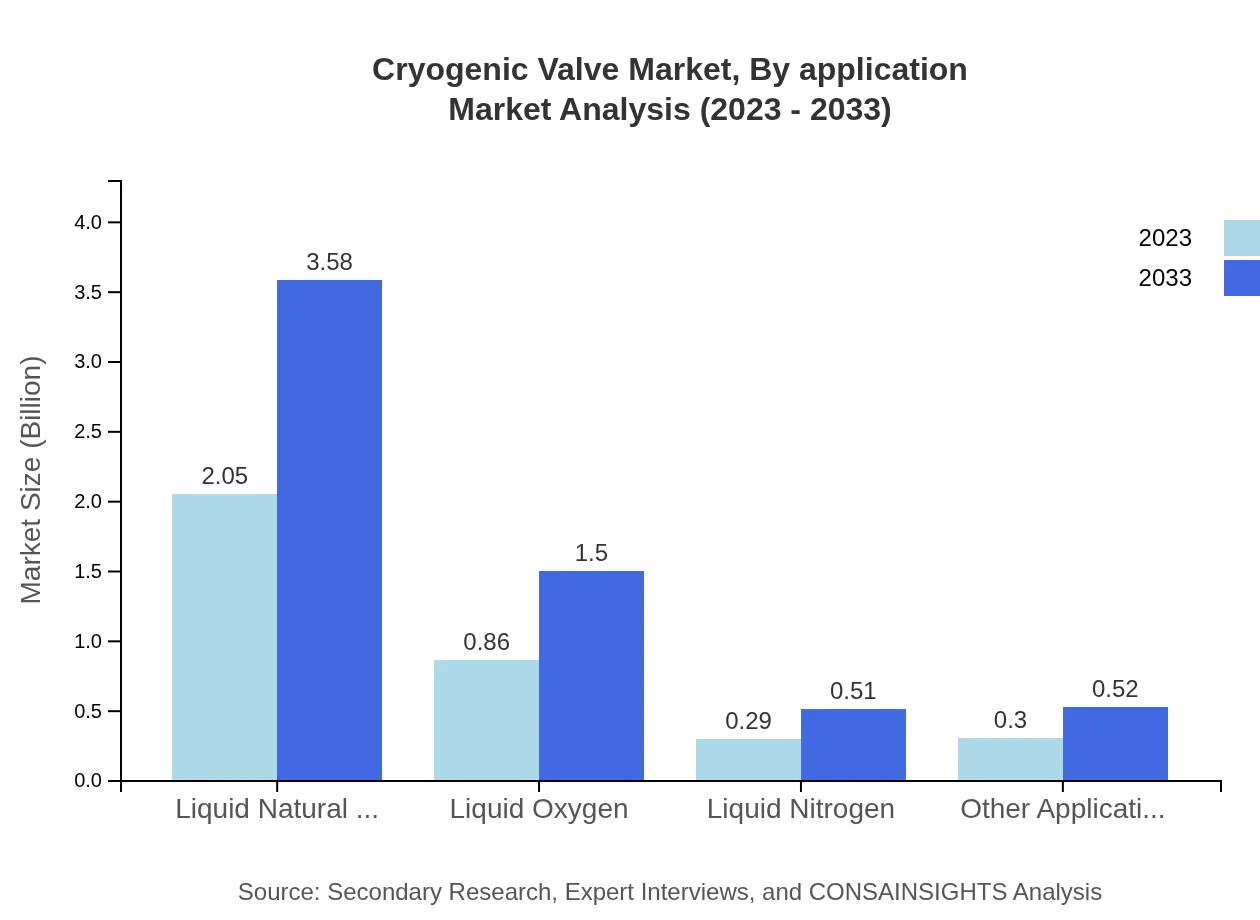

Cryogenic Valve Market Analysis By Application

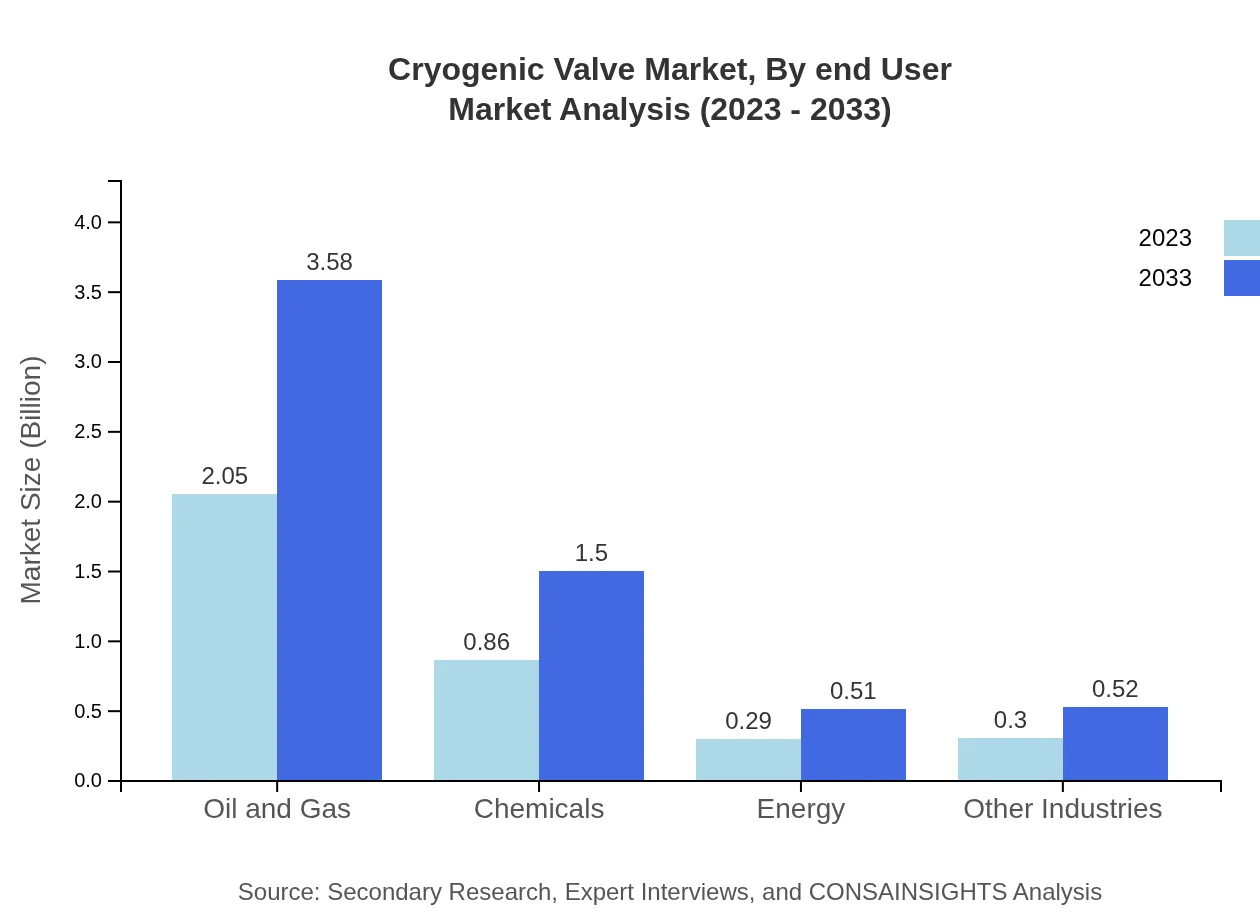

The applications of cryogenic valves are predominantly in the Oil and Gas sector, where the market is anticipated to grow from USD 2.05 billion in 2023 to USD 3.58 billion by 2033. Other applications include Chemicals and Energy sectors, which are also experiencing significant growth. Their market shares reflect the increasing importance of safety and efficiency in gas handling.

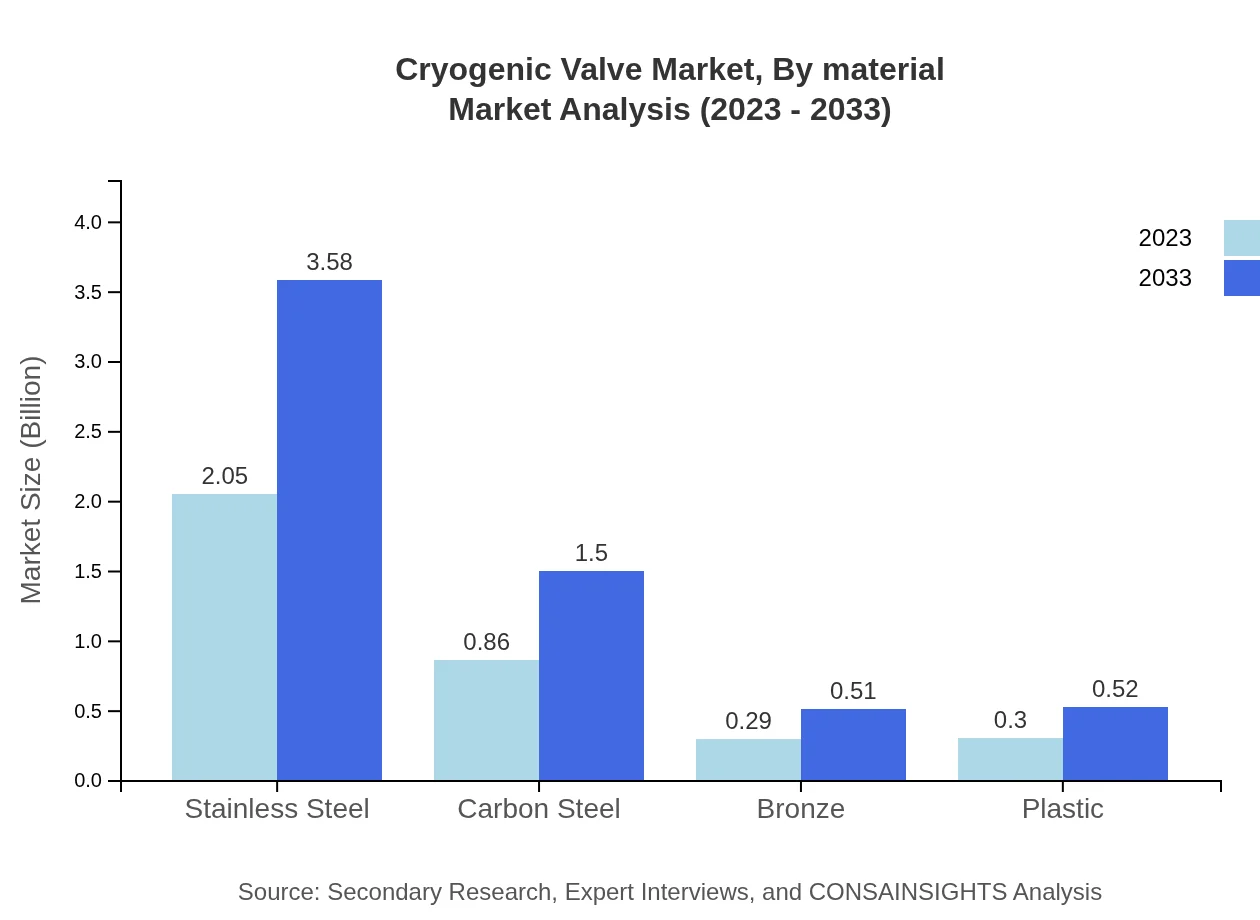

Cryogenic Valve Market Analysis By Material

Material-wise, Stainless Steel valves dominate the market, expected to expand from USD 2.05 billion to USD 3.58 billion, holding 58.52% of the market share. Carbon Steel and Bronze are crucial in specific applications, while Plastic materials represent growing interest for lightweight valve solutions in certain segments.

Cryogenic Valve Market Analysis By End User

The end-user market segmentation highlights Oil and Gas as a prominent sector, contributing significantly to the growth of cryogenic valves. Other critical sectors include Chemicals and Energy, which together represent robust market opportunities, given their demand for improved efficiencies in cryogenic processes.

Cryogenic Valve Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Cryogenic Valve Industry

Emerson Electric Co.:

A global leader in automation solutions, Emerson offers cutting-edge cryogenic valves that emphasize reliability and efficiency in gas handling systems.Cameron International Corporation:

Part of Schlumberger, Cameron specializes in valve solutions for the oil and gas industry, providing innovative cryogenic valve technology to enhance safety and operational efficiency.Parker Hannifin Corporation:

Parker manufactures a wide range of cryogenic products, including valves that cater specifically to various industrial applications, supporting advancements in energy efficiency and safety.Flowserve Corporation:

Flowserve provides a diverse portfolio of cryogenic valves, focusing on the demanding needs of the petrochemical and power generation industries.Worcester Controls Corporation:

Known for its innovations in valve technology, Worcester Controls manufactures high-performance cryogenic valves suitable for various industrial applications.We're grateful to work with incredible clients.

FAQs

What is the market size of cryogenic valves?

In 2023, the global cryogenic valve market is valued at approximately $3.5 billion. It is forecasted to grow at a CAGR of 5.6% and reach significantly higher values by 2033, underscoring robust demand for cryogenic technologies.

What are the key market players or companies in the cryogenic valve industry?

The cryogenic valve market is driven by key players including Emerson Electric Co., ValvTechnologies, Inc., and Parker Hannifin Corporation. These companies lead with innovative technologies, extensive product lines, and strong distribution networks, reinforcing their market positions.

What are the primary factors driving the growth in the cryogenic valve industry?

Key growth drivers in the cryogenic valve market include rising demand in the LNG sector, advancements in cryogenic applications, and increased investments in healthcare and aerospace technologies. Sustainable energy solutions are also creating new opportunities for market expansion.

Which region is the fastest Growing in the cryogenic valve market?

The Asia Pacific region is the fastest-growing market for cryogenic valves. Projected to grow from $0.68 billion in 2023 to $1.18 billion by 2033, it shows a significant increase fueled by industrial expansion and energy demands.

Does ConsaInsights provide customized market report data for the cryogenic valve industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs in the cryogenic valve industry, providing in-depth analysis, regional insights, and segmentation data adjusted to client requirements.

What deliverables can I expect from this cryogenic valve market research project?

Deliverables from the cryogenic valve market research project include comprehensive market analysis, competitor profiles, and regional forecasts. Clients will receive segmented data, trends analysis, and strategic recommendations tailored to their business needs.

What are the market trends of cryogenic valves?

Current trends in the cryogenic valve market include an increasing focus on sustainable energy solutions, technological advancements in valve materials, and the growing adoption of automation in manufacturing processes, enhancing performance and efficiency.