Cutting Discs Market Report

Published Date: 22 January 2026 | Report Code: cutting-discs

Cutting Discs Market Size, Share, Industry Trends and Forecast to 2033

This detailed market report provides insights into the Cutting Discs industry, including market sizes, growth trends, regional analysis, and forecasts from 2023 to 2033. Key segments of the market are also evaluated to give a comprehensive understanding of the landscape.

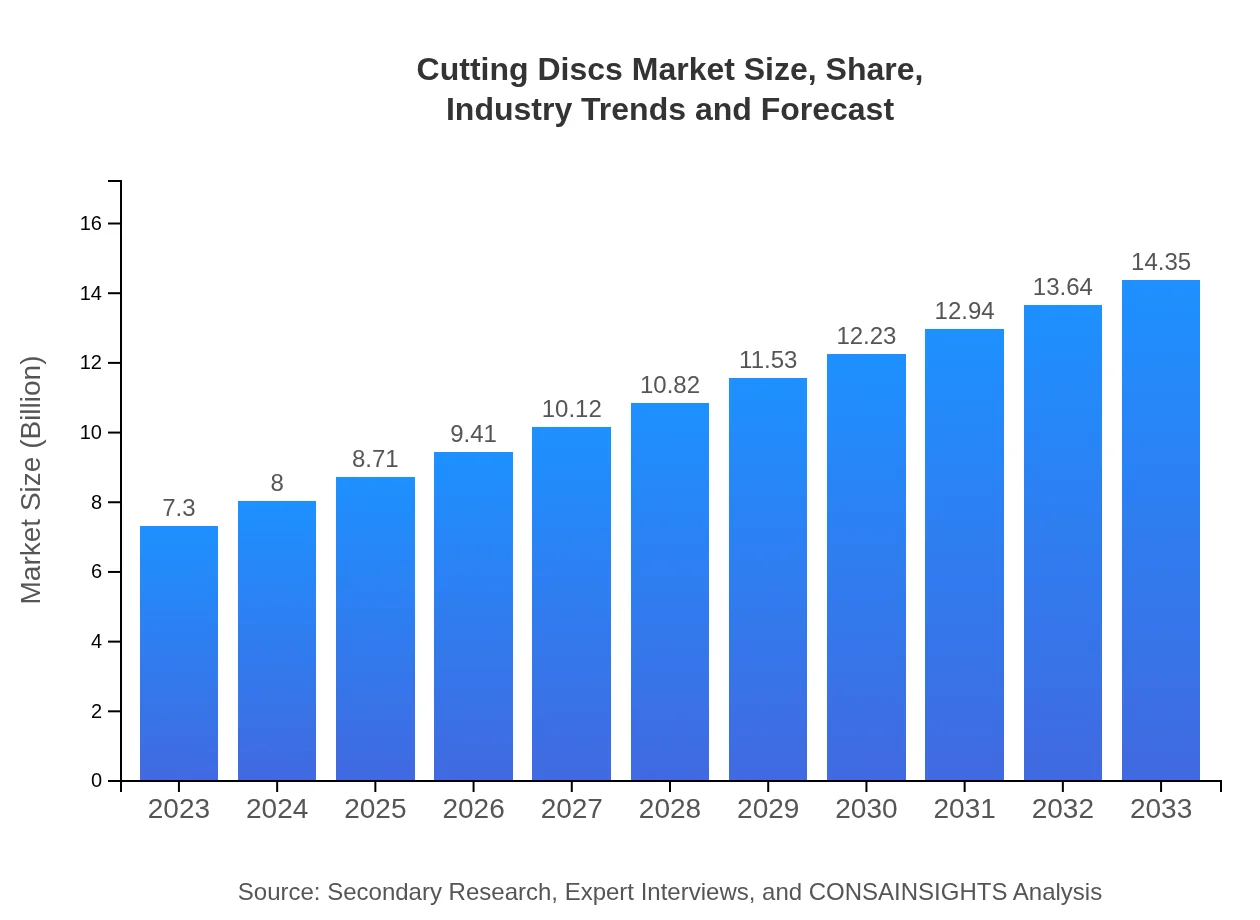

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $7.30 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $14.35 Billion |

| Top Companies | Saint-Gobain, 3M, Bosch, Norton Abrasives, Makita |

| Last Modified Date | 22 January 2026 |

Cutting Discs Market Overview

Customize Cutting Discs Market Report market research report

- ✔ Get in-depth analysis of Cutting Discs market size, growth, and forecasts.

- ✔ Understand Cutting Discs's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Cutting Discs

What is the Market Size & CAGR of Cutting Discs market in 2033?

Cutting Discs Industry Analysis

Cutting Discs Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Cutting Discs Market Analysis Report by Region

Europe Cutting Discs Market Report:

In 2023, the European market for Cutting Discs was valued at USD 2.27 billion, expected to almost double to USD 4.46 billion by 2033. The region is characterized by advanced manufacturing processes and stringent regulations leading to a push for high-quality products. Significant investments in sustainable technologies contribute to market growth and innovation.Asia Pacific Cutting Discs Market Report:

The Asia Pacific region held a significant share of the Cutting Discs market, valued at USD 1.37 billion in 2023, expected to grow to USD 2.70 billion by 2033. Rapid industrialization, urbanization, and the increasing demand for construction materials drive market growth in countries like China and India. The region's emerging economies present substantial opportunities due to rising disposable incomes and an expanding middle class.North America Cutting Discs Market Report:

North America saw a market size of USD 2.66 billion in 2023, projected to reach USD 5.23 billion by 2033. The region's growth is driven by technological advancements in manufacturing and a surge in demand from the automotive and aerospace industries. Strong regulatory frameworks also support the adoption of cutting-edge cutting technologies.South America Cutting Discs Market Report:

The South American Cutting Discs market was valued at USD 0.21 billion in 2023, anticipated to double to USD 0.42 billion by 2033. Countries like Brazil and Argentina are focusing on infrastructure development and increasing construction activities, contributing to the market growth. However, economic volatility presents challenges in investment and growth dynamics.Middle East & Africa Cutting Discs Market Report:

The Middle East and Africa market was valued at USD 0.78 billion in 2023, expected to reach USD 1.54 billion by 2033. As construction and infrastructure projects in countries like UAE and South Africa gain momentum, the demand for cutting discs is projected to surge, aided by government investment in development initiatives.Tell us your focus area and get a customized research report.

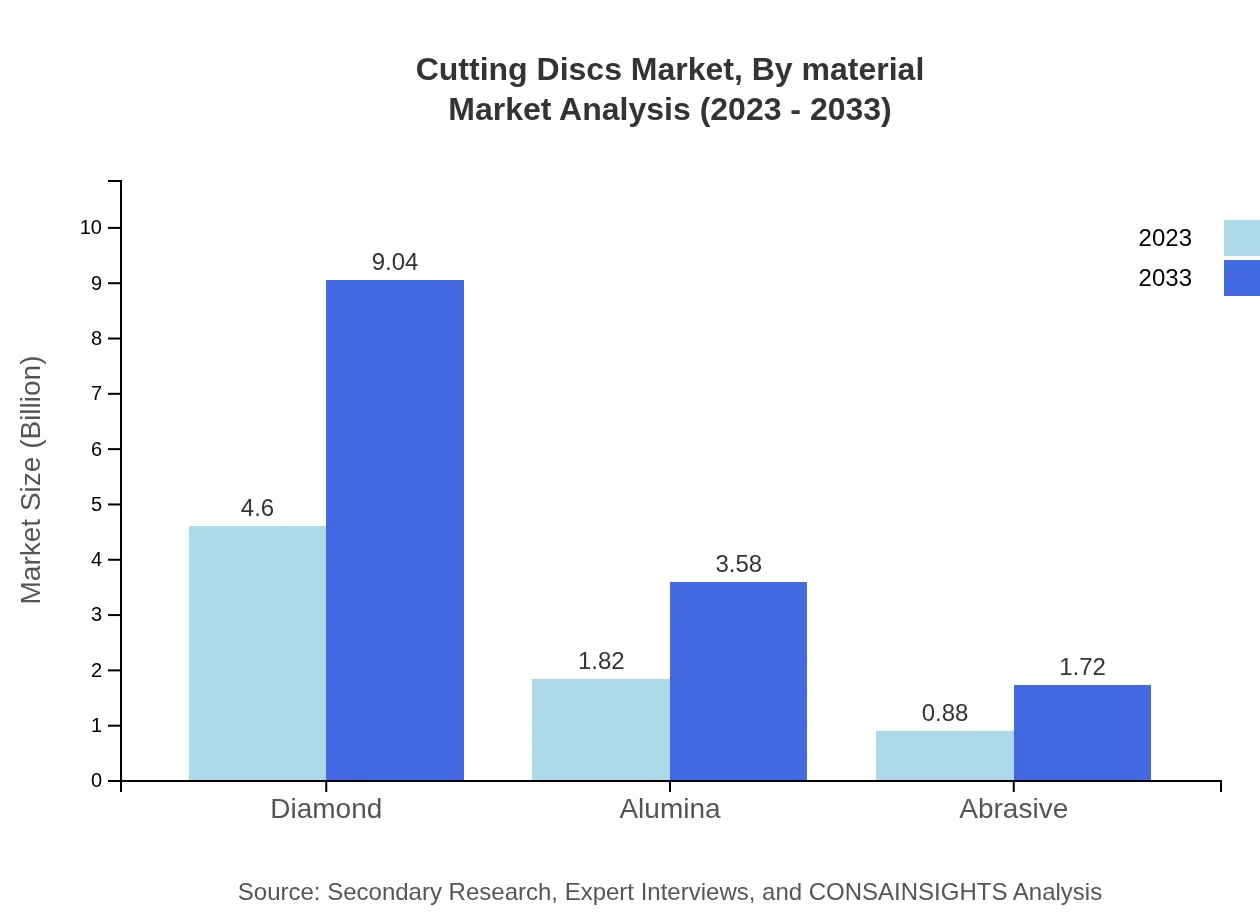

Cutting Discs Market Analysis By Material

The market by material is dominated by Diamond and Alumina cutting discs. As of 2023, Diamond discs accounted for a market size of USD 4.60 billion, anticipating to reach USD 9.04 billion by 2033. Their performance in cutting harder materials drives their high market share. Alumina discs follow, with a projected market size of USD 1.82 billion in 2023, expected to grow accordingly.

Cutting Discs Market Analysis By Application

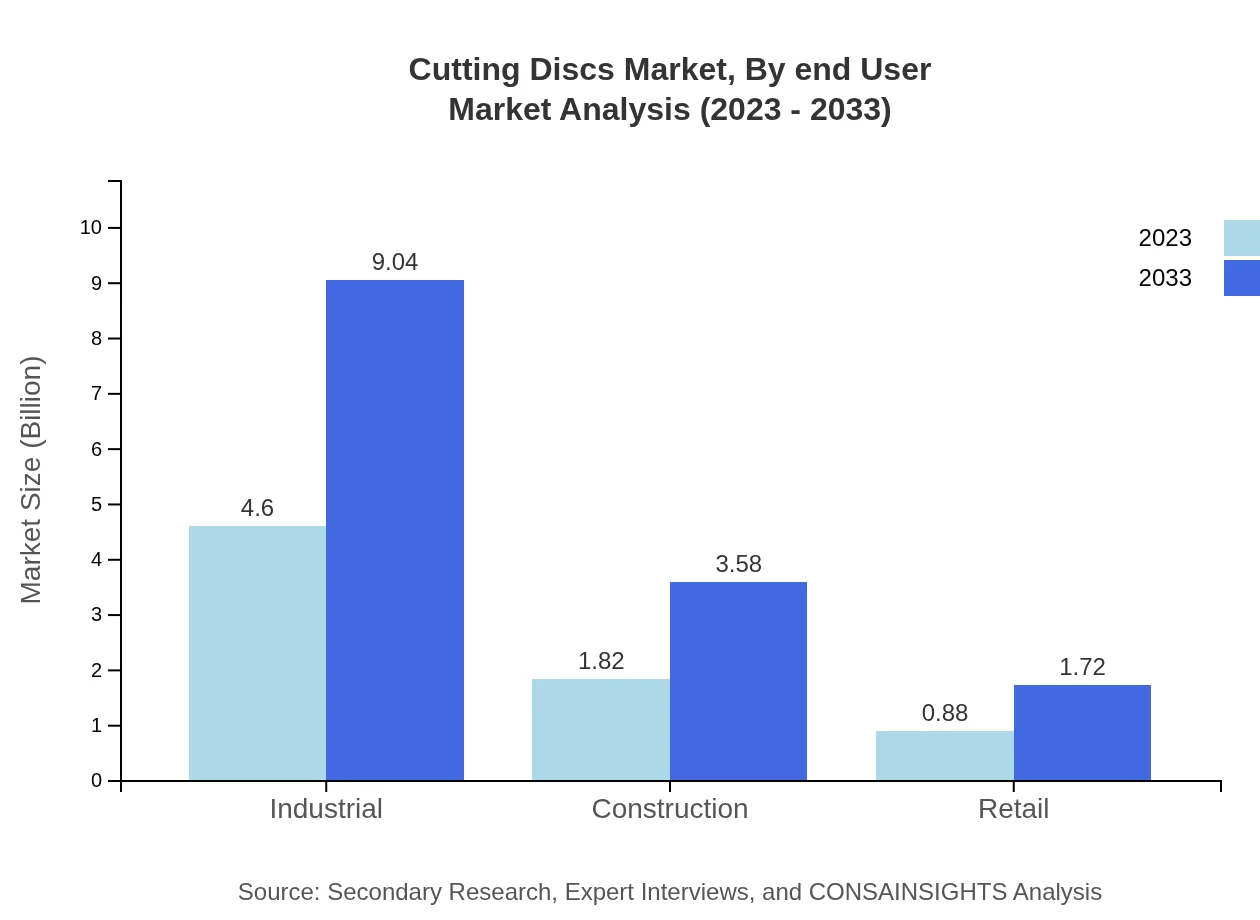

The industrial sector remains the leading application segment for Cutting Discs, projected to maintain a size of USD 4.60 billion in 2023, cultivating to USD 9.04 billion by 2033. Other notable segments include the construction industry, with expected growth from USD 1.82 billion to USD 3.58 billion during the forecast period due to rising construction activities.

Cutting Discs Market Analysis By End User

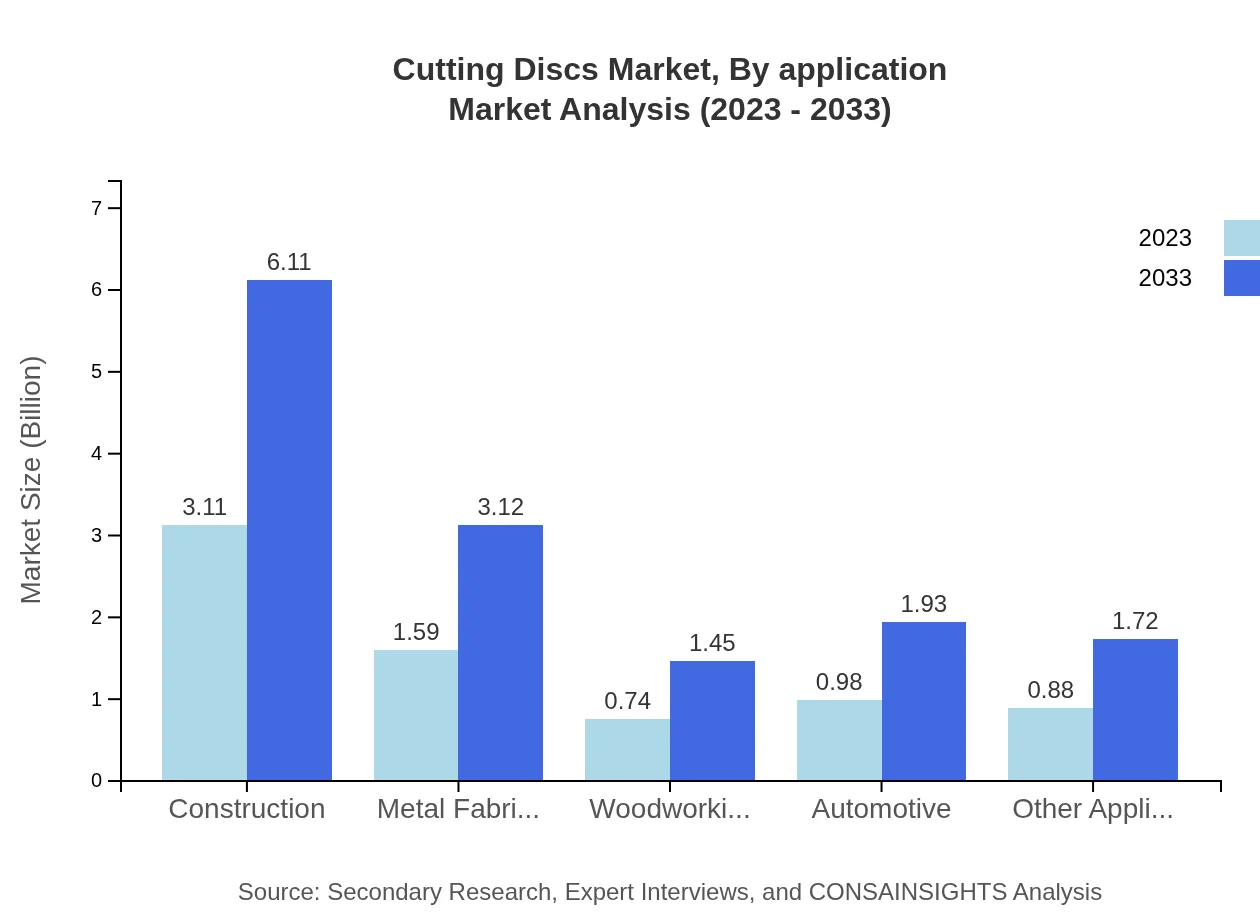

In terms of end-user industries, Metal Fabrication holds a significant share, with a market size of USD 1.59 billion documented in 2023, likely reaching USD 3.12 billion by 2033. The automotive end-user segment is also vital, with specifications driven by precision and performance requirements.

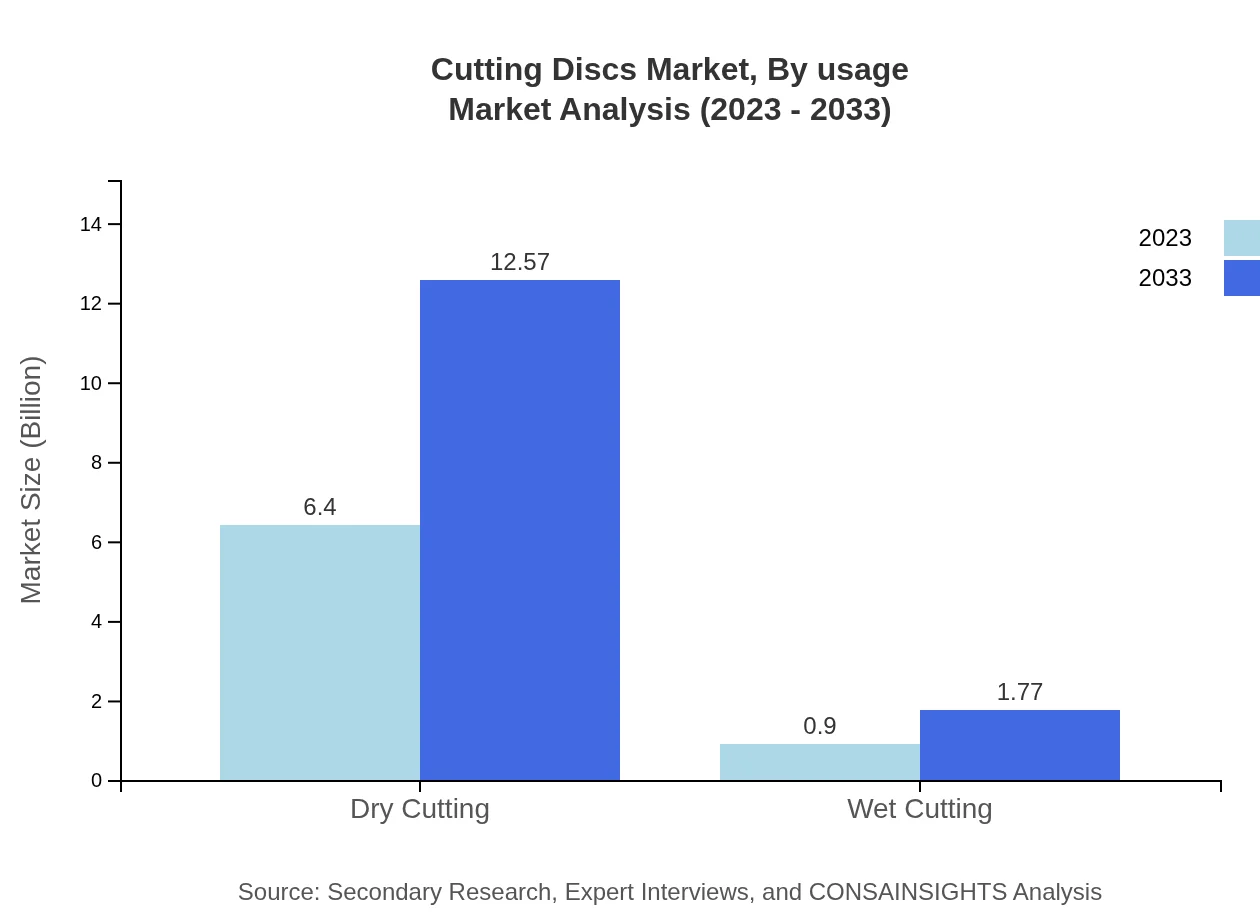

Cutting Discs Market Analysis By Usage

The Cutting Discs market is primarily divided into Dry Cutting and Wet Cutting segments. Dry Cutting constitutes the larger share, with a market size of USD 6.40 billion in 2023 as compared to USD 0.90 billion for Wet Cutting, yet both segments are expected to see substantial growth by 2033 reflecting advancements in various practices.

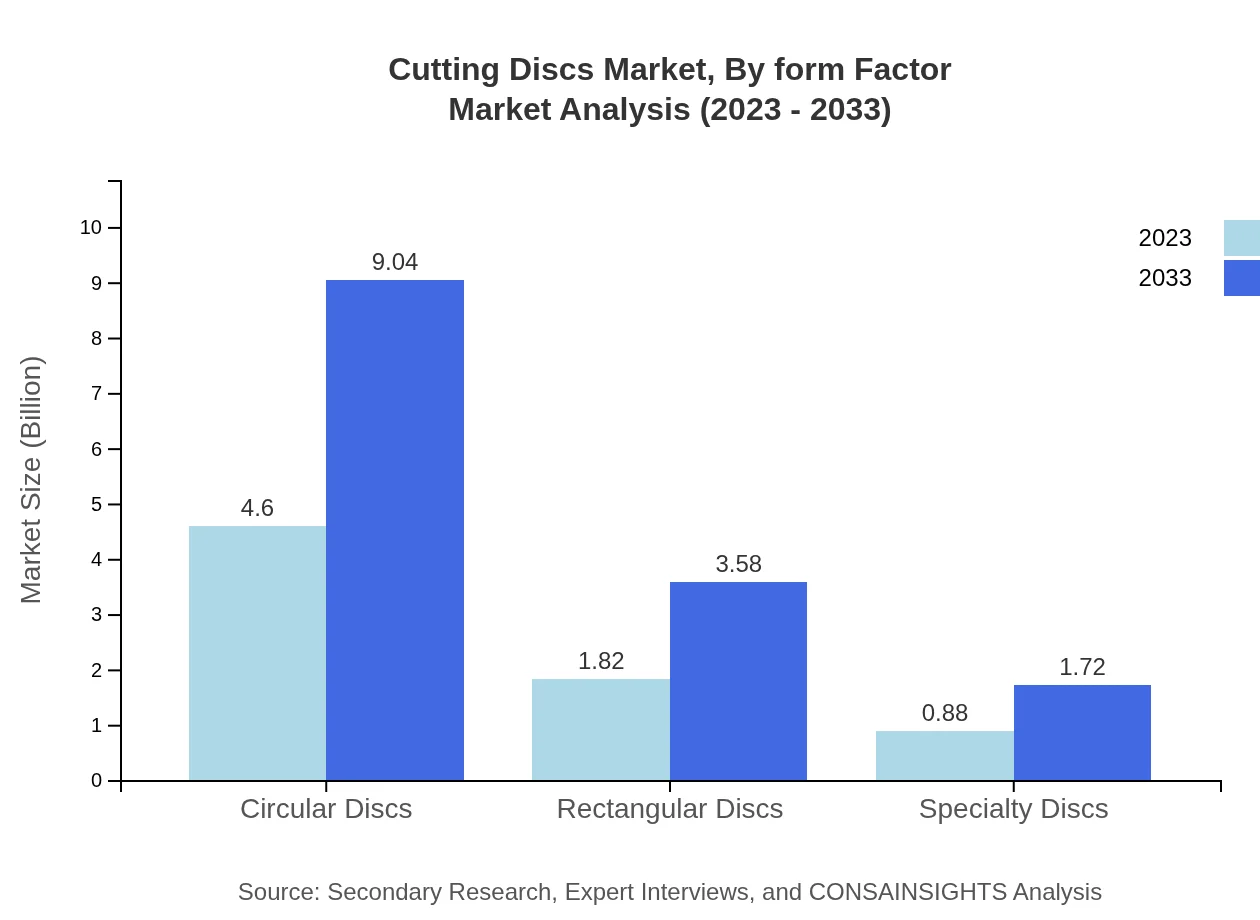

Cutting Discs Market Analysis By Form Factor

The form factor segment is characterized by Circular Discs capturing about 63.04% of the market share as of 2023, valued at USD 4.60 billion, rising to USD 9.04 billion by 2033, emphasizing their versatility across applications. Rectangular and Specialty Discs follow suit, reflecting specific applications in niche markets.

Cutting Discs Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Cutting Discs Industry

Saint-Gobain:

A global leader in building materials, Saint-Gobain has a robust portfolio in manufacturing high-quality cutting discs optimized for various applications, marked by continuous innovation and sustainable practices.3M:

3M is renowned for its advanced adhesive technologies and grinding solutions, providing an impressive range of cutting discs that cater to different markets including metal, construction, and automotive industries.Bosch:

Bosch offers a comprehensive range of cutting discs, focusing on high performance and quality, serving industries such as construction, automotive, and metal processing.Norton Abrasives:

A trusted name in the cutting tools industry, Norton Abrasives specializes in developing high-quality abrasive products, including cutting discs that adhere to stringent performance standards.Makita:

Makita is recognized for its innovative power tools and cutting discs designed for professional and personal use, emphasizing quality and durability across all product offerings.We're grateful to work with incredible clients.

FAQs

What is the market size of cutting Discs?

The global cutting-discs market is valued at approximately $7.3 billion in 2023, with a projected growth at a CAGR of 6.8%. By 2033, the market is expected to expand significantly, showcasing the demand across various sectors.

What are the key market players or companies in this cutting Discs industry?

Key players in the cutting-discs market include firms specializing in manufacturing and distribution, recognized for their innovation and product quality. These companies focus on expanding their portfolios and enhancing operational efficiencies to secure a competitive advantage.

What are the primary factors driving the growth in the cutting Discs industry?

Factors such as the increasing demand in construction and automotive industries, advancements in cutting technologies, and a growing inclination towards efficient manufacturing processes are primarily driving growth in the cutting-discs market worldwide.

Which region is the fastest Growing in the cutting Discs market?

The fastest-growing region in the cutting-discs market is North America, with anticipated growth from $2.66 billion in 2023 to $5.23 billion by 2033, reflecting significant demand in industrial applications and construction projects.

Does ConsaInsights provide customized market report data for the cutting Discs industry?

Yes, ConsaInsights offers customized market report data for the cutting-discs industry. Clients can request tailored reports that align with specific requirements or focus areas, providing targeted insights for strategic planning.

What deliverables can I expect from this cutting Discs market research project?

In a cutting-discs market research project, clients can expect detailed reports encompassing market analysis, trends, competitive landscape, and segment insights, along with actionable recommendations to inform decision-making and strategy.

What are the market trends of cutting Discs?

Current trends in the cutting-discs market include increasing demand for dry cutting techniques, the rise of diamond-based discs, and a focus on sustainable manufacturing practices, reflecting changing customer preferences and technological advancements.