Cutting Equipment Accessories Consumables Market Report

Published Date: 22 January 2026 | Report Code: cutting-equipment-accessories-consumables

Cutting Equipment Accessories Consumables Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Cutting Equipment Accessories Consumables market, including insights on market size, growth trends, segmentation, and future forecasts from 2023 to 2033.

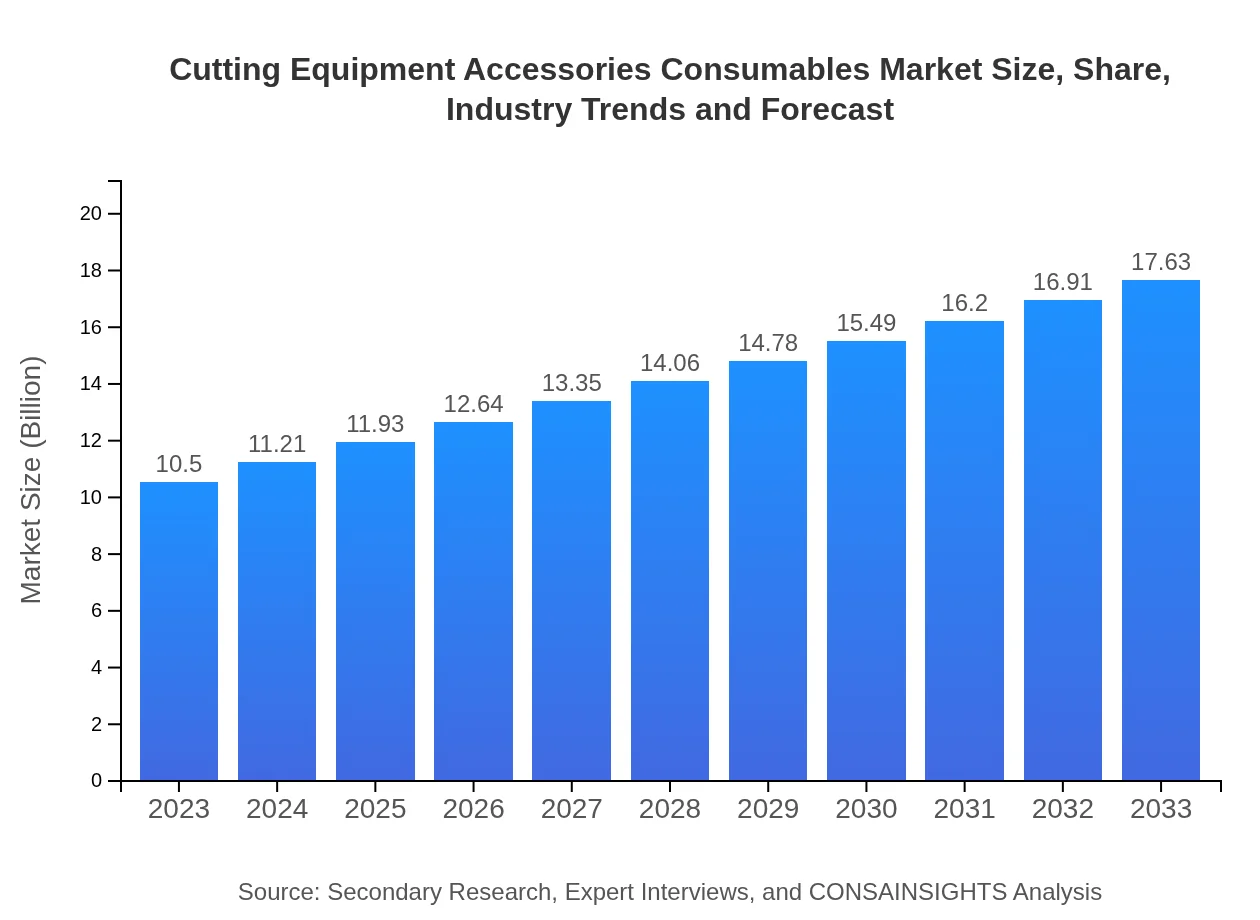

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $10.50 Billion |

| CAGR (2023-2033) | 5.2% |

| 2033 Market Size | $17.63 Billion |

| Top Companies | Husqvarna Group, Bosch, Makita, DeWalt |

| Last Modified Date | 22 January 2026 |

Cutting Equipment Accessories Consumables Market Overview

Customize Cutting Equipment Accessories Consumables Market Report market research report

- ✔ Get in-depth analysis of Cutting Equipment Accessories Consumables market size, growth, and forecasts.

- ✔ Understand Cutting Equipment Accessories Consumables's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Cutting Equipment Accessories Consumables

What is the Market Size & CAGR of Cutting Equipment Accessories Consumables market in 2023?

Cutting Equipment Accessories Consumables Industry Analysis

Cutting Equipment Accessories Consumables Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Cutting Equipment Accessories Consumables Market Analysis Report by Region

Europe Cutting Equipment Accessories Consumables Market Report:

Europe's market is set to increase from USD 3.71 billion in 2023 to USD 6.23 billion by 2033, with strong demand for high-quality cutting tools in the automotive and manufacturing sectors.Asia Pacific Cutting Equipment Accessories Consumables Market Report:

In the Asia Pacific region, the market is poised to grow from USD 1.78 billion in 2023 to USD 2.99 billion by 2033, driven by rapid industrialization and increasing manufacturing activities in countries like China and India.North America Cutting Equipment Accessories Consumables Market Report:

North America shows a strong market presence, growing from USD 3.58 billion in 2023 to USD 6.01 billion by 2033, fueled by technological advancements and a robust manufacturing base.South America Cutting Equipment Accessories Consumables Market Report:

The South American market is expected to expand from USD 0.27 billion in 2023 to USD 0.45 billion by 2033 as economic growth stimulates demand for cutting equipment in construction and manufacturing sectors.Middle East & Africa Cutting Equipment Accessories Consumables Market Report:

The Middle East and Africa are witnessing growth from USD 1.16 billion in 2023 to USD 1.95 billion by 2033, largely due to increased infrastructure development and mining activities.Tell us your focus area and get a customized research report.

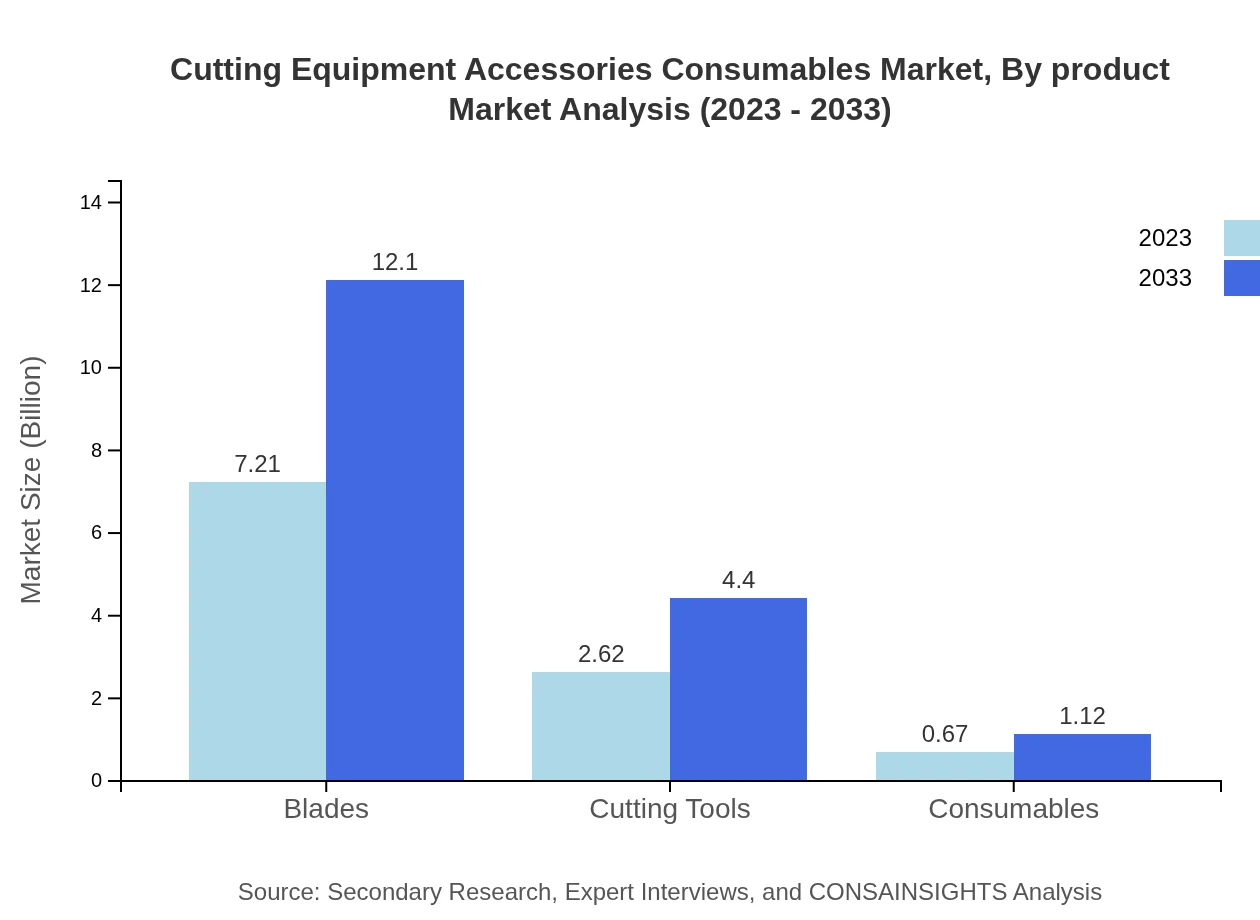

Cutting Equipment Accessories Consumables Market Analysis By Product

The market by product type includes segments such as Blades, Cutting Tools, and Consumables. Blades dominate the market, growing from USD 7.21 billion in 2023 to USD 12.10 billion by 2033, holding a market share of 68.66%. Cutting Tools and Consumables are also significant, with projected growths to USD 4.40 billion and USD 1.12 billion, respectively.

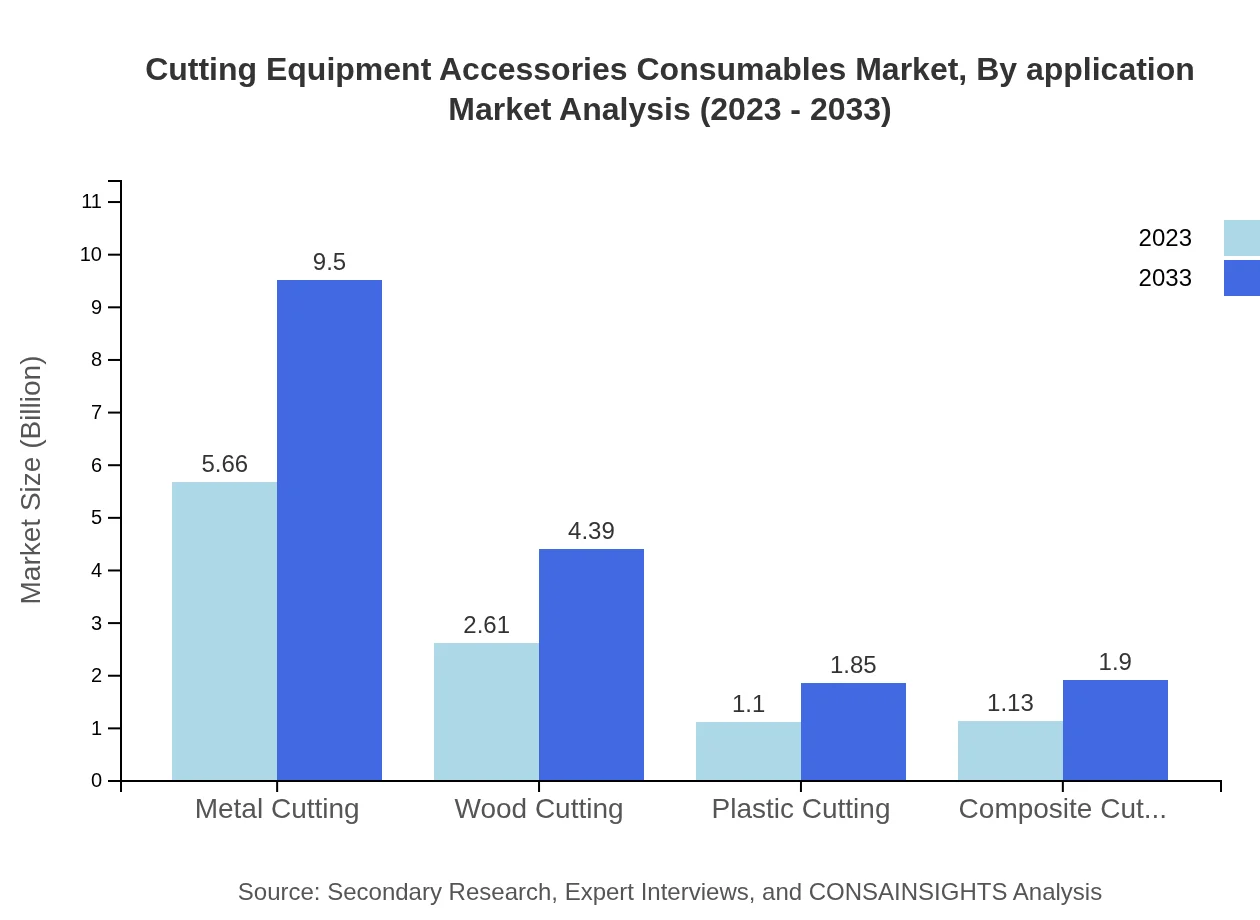

Cutting Equipment Accessories Consumables Market Analysis By Application

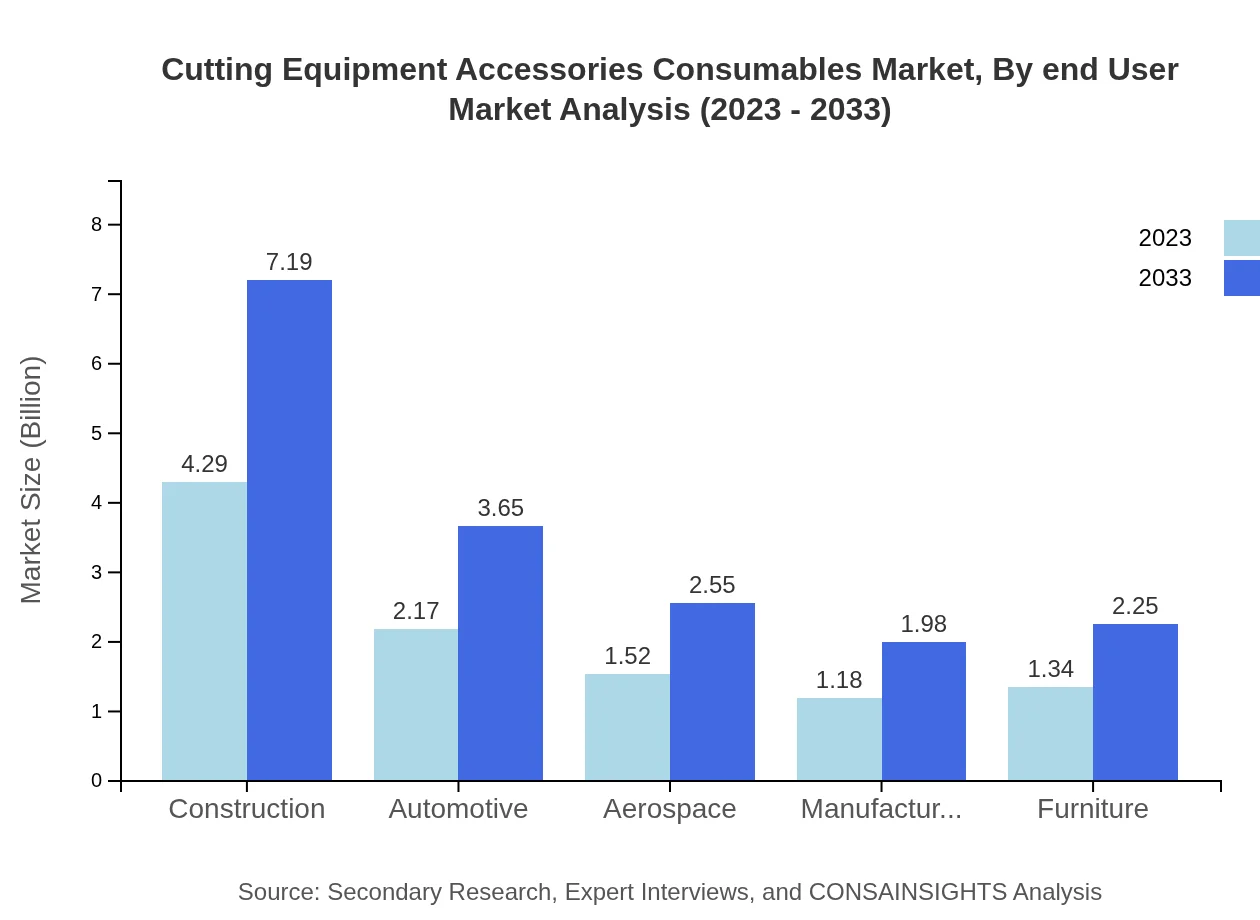

Key application areas include Construction, Automotive, Aerospace, and Manufacturing. Construction leads with revenues rising from USD 4.29 billion to USD 7.19 billion, representing a steady demand for cutting tools in growing urban environments. Automotive applications show similar growth trends.

Cutting Equipment Accessories Consumables Market Analysis By End User

End-users encompass industries such as Manufacturing and Aerospace. Manufacturing accounts for a significant share and demonstrates robust growth, from USD 1.18 billion to USD 1.98 billion by 2033.

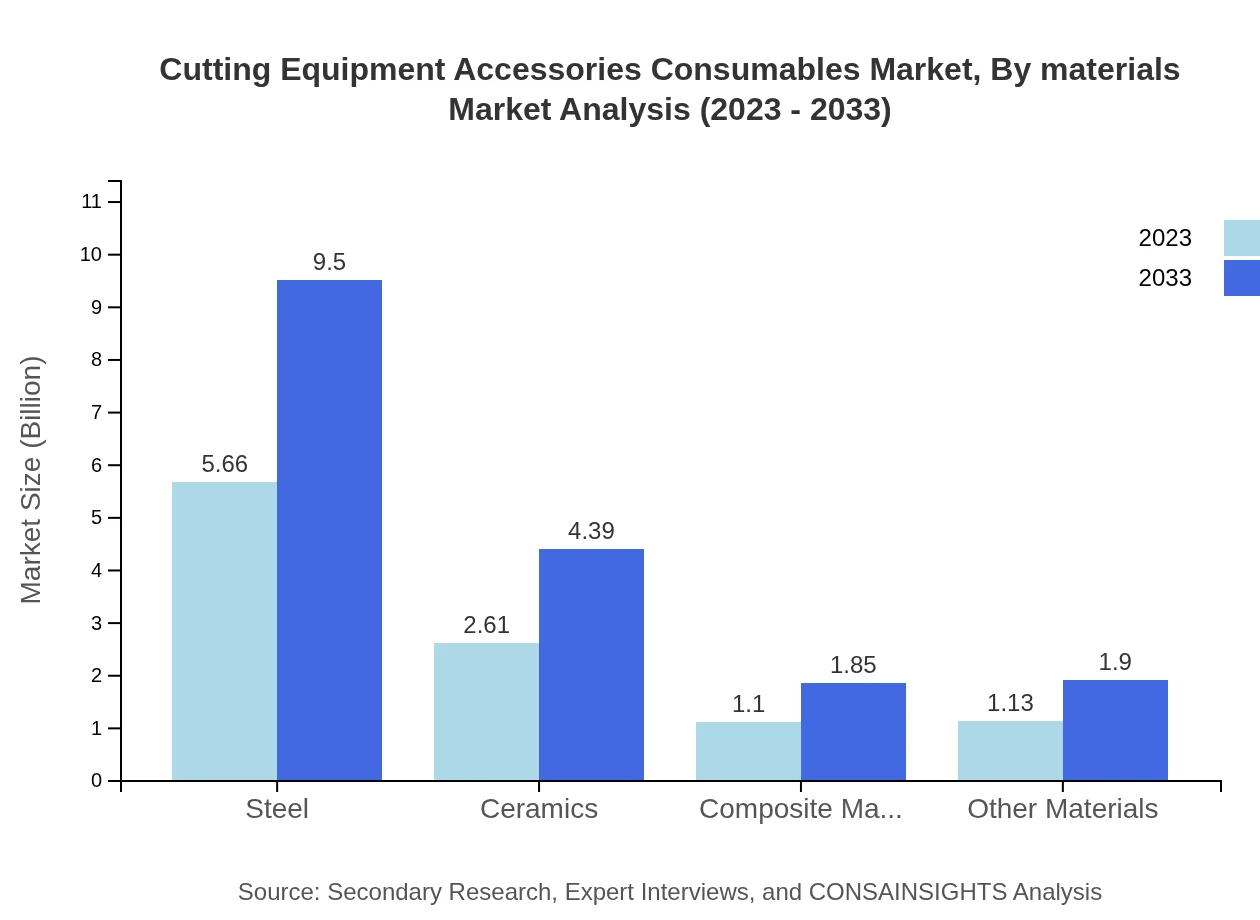

Cutting Equipment Accessories Consumables Market Analysis By Materials

Materials such as Steel, Ceramics, and Composites are crucial to the market. Steel remains dominant, growing from USD 5.66 billion to USD 9.50 billion by 2033, driven by ongoing industrial applications.

Cutting Equipment Accessories Consumables Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Cutting Equipment Accessories Consumables Industry

Husqvarna Group:

A leader in outdoor power products, Husqvarna is known for its high-quality cutting equipment and innovative accessories that cater to various industries.Bosch:

Bosch offers a wide range of cutting tools and accessories, leveraging advanced technology for high performance and durability across multiple applications.Makita:

Makita is recognized for its cutting-edge power tools and accessories, especially in the construction and woodworking sectors.DeWalt:

DeWalt is a prominent brand in industrial tools and accessories, focusing on innovative designs that enhance cutting efficiency.We're grateful to work with incredible clients.

FAQs

What is the market size of cutting equipment accessories consumables?

The global market size for cutting equipment accessories consumables is estimated at $10.5 billion in 2023, with a projected CAGR of 5.2% from 2023 to 2033, indicating steady growth driven by technological advancements and increasing industrial demands.

What are the key market players or companies in the cutting equipment accessories consumables industry?

Key players in the cutting equipment accessories consumables industry include major manufacturers and suppliers who dominate various segments, focusing on product innovation and regional expansions. Leading companies are known for advanced technology, diverse product offerings, and significant market share representation.

What are the primary factors driving the growth in the cutting equipment accessories consumables industry?

The growth in the cutting equipment accessories consumables industry is driven by several factors such as the increased demand from manufacturing and construction sectors, advancements in cutting technologies, a growing emphasis on precision engineering, and the need for cost-effective solutions across various applications.

Which region is the fastest Growing in the cutting equipment accessories consumables?

The fastest-growing region in the cutting equipment accessories consumables market is Europe, projected to grow from $3.71 billion in 2023 to $6.23 billion by 2033. Other regions like North America and Asia-Pacific also show significant growth potential as industrial activities expand.

Does ConsaInsights provide customized market report data for the cutting equipment accessories consumables industry?

Yes, ConsaInsights offers customized market report data for the cutting equipment accessories consumables industry, tailored to meet specific client needs. These custom reports include detailed analysis, regional insights, and segment data to aid strategic decision-making.

What deliverables can I expect from this cutting equipment accessories consumables market research project?

From this market research project, clients can expect comprehensive reports featuring market size, growth forecasts, analysis of key trends, competitive landscape, regional studies, and detailed segmentation insights to better understand market dynamics and facilitate informed strategies.

What are the market trends of cutting equipment accessories consumables?

Current market trends in cutting equipment accessories consumables include the rise of smart and automated cutting technologies, a shift towards sustainable and eco-friendly materials, increasing demand for high-precision tools, and an emphasis on customization in products for specialized applications.