Dc Torque Tool Market Report

Published Date: 22 January 2026 | Report Code: dc-torque-tool

Dc Torque Tool Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Dc Torque Tool market, encompassing market trends, size, segmentation, and regional insights from 2023 to 2033. It aims to equip stakeholders with credible data to make informed decisions in this dynamic industry.

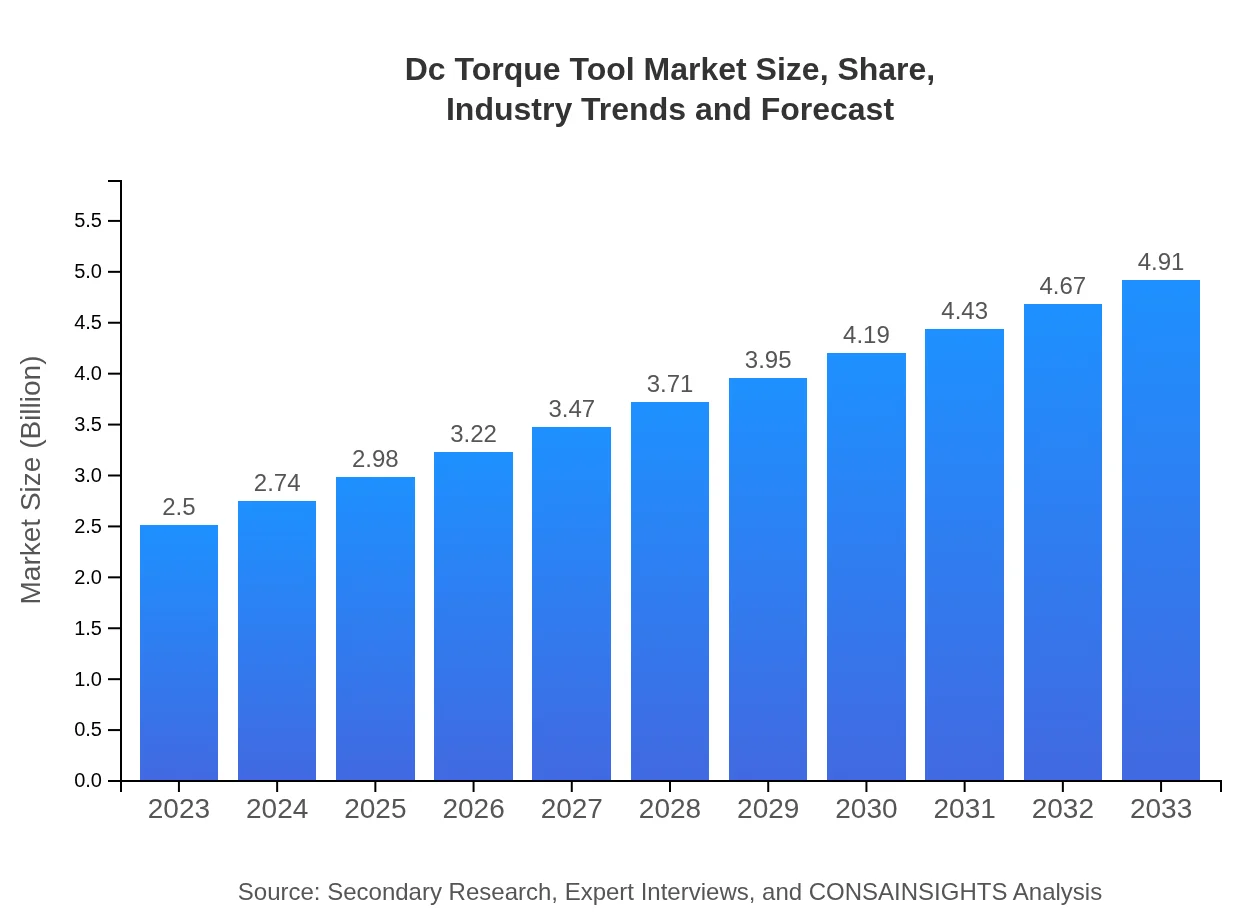

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $2.50 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $4.91 Billion |

| Top Companies | Stanley Black & Decker, Inc., Milwaukee Tools, Bosch Power Tools, Snap-On Inc. |

| Last Modified Date | 22 January 2026 |

Dc Torque Tool Market Overview

Customize Dc Torque Tool Market Report market research report

- ✔ Get in-depth analysis of Dc Torque Tool market size, growth, and forecasts.

- ✔ Understand Dc Torque Tool's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Dc Torque Tool

What is the Market Size & CAGR of Dc Torque Tool market in 2023?

Dc Torque Tool Industry Analysis

Dc Torque Tool Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Dc Torque Tool Market Analysis Report by Region

Europe Dc Torque Tool Market Report:

The European Dc Torque Tool market, valued at $0.78 billion in 2023, is expected to grow to $1.53 billion by 2033. Factors such as stringent quality regulations and the adoption of advanced manufacturing technologies contribute to this growth.Asia Pacific Dc Torque Tool Market Report:

In the Asia Pacific region, the market for Dc Torque Tools is expanding with a valuation of $0.45 billion in 2023 and is expected to reach $0.89 billion by 2033. The growth is driven by rapid industrialization, expanding automotive industries, and increasing investments in infrastructure.North America Dc Torque Tool Market Report:

North America is a significant player in the Dc Torque Tool market, currently valued at $0.94 billion in 2023, anticipated to grow to $1.84 billion by 2033. The region benefits from a robust automotive industry and advanced manufacturing processes emphasizing precision tooling.South America Dc Torque Tool Market Report:

In South America, the market is smaller but growing steadily, projected to rise from $0.09 billion in 2023 to $0.17 billion by 2033. This growth is bolstered by the ongoing development of the region's manufacturing sector.Middle East & Africa Dc Torque Tool Market Report:

The Middle East and Africa market for Dc Torque Tools is projected to grow from $0.24 billion in 2023 to $0.48 billion by 2033, driven by construction and infrastructural development in the region.Tell us your focus area and get a customized research report.

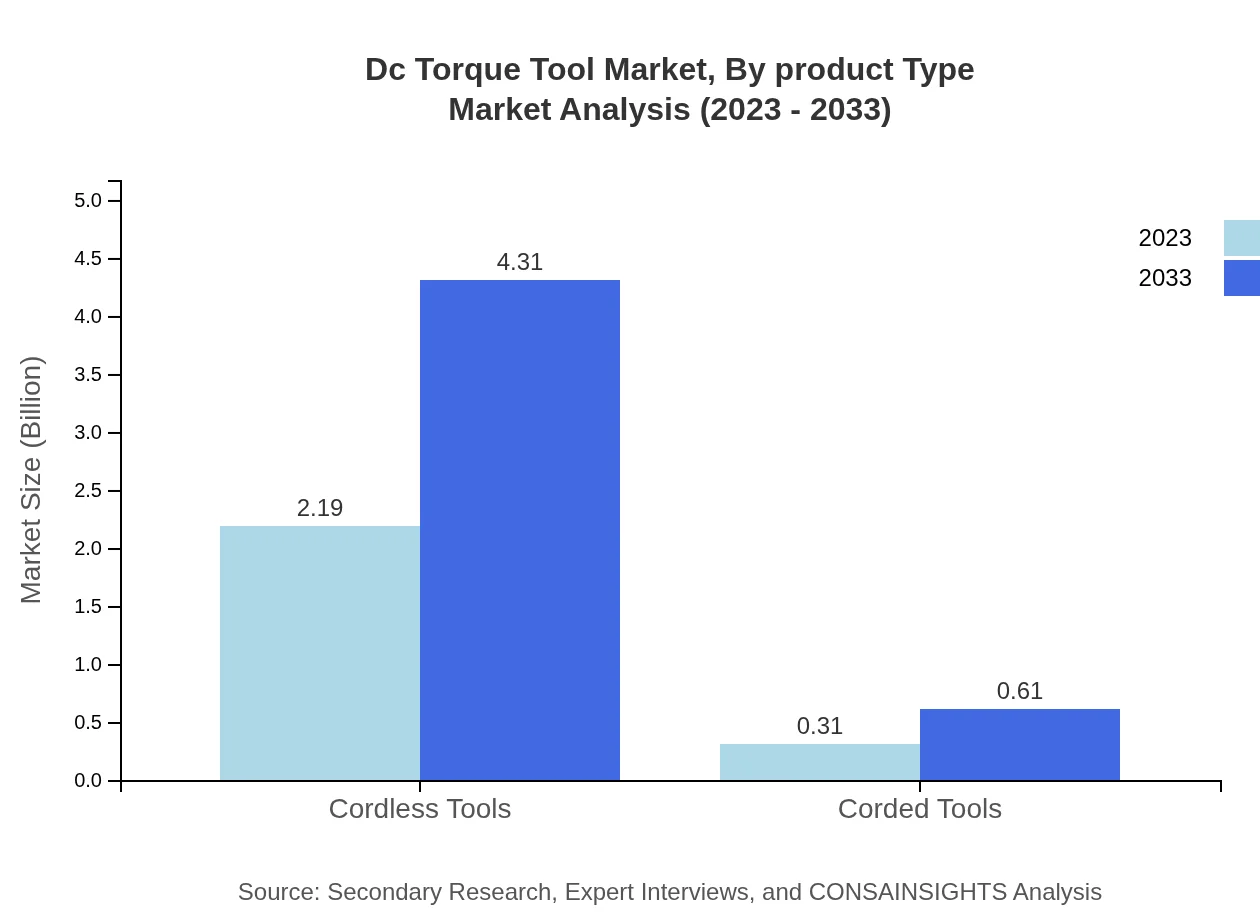

Dc Torque Tool Market Analysis By Product Type

In 2023, Cordless Tools dominate the market with a size of $2.19 billion, expected to grow to $4.31 billion by 2033, holding an 87.64% market share. Corded Tools follow, with a market size of $0.31 billion in 2023, projected to reach $0.61 billion by 2033, maintaining a 12.36% share of the market.

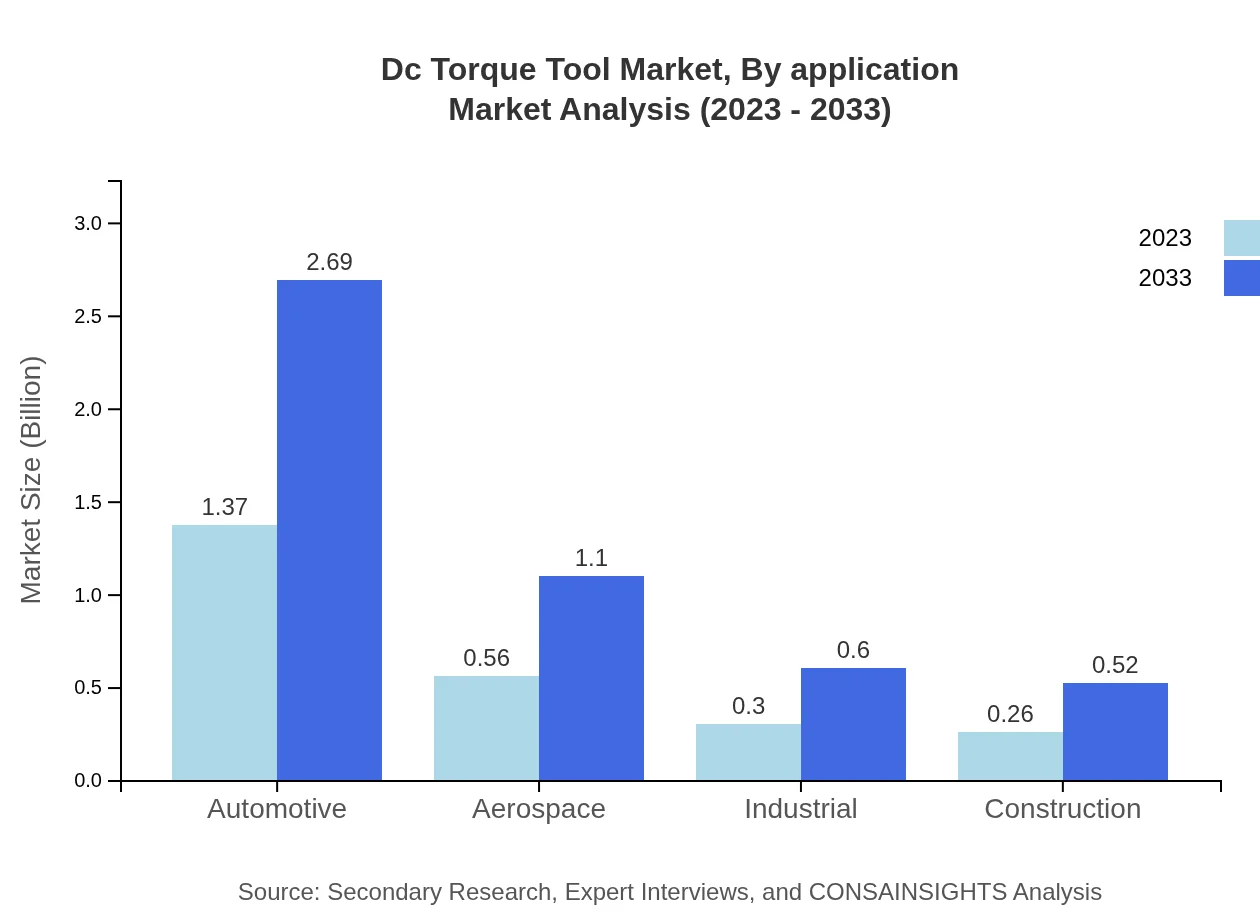

Dc Torque Tool Market Analysis By Application

The Automotive sector leads with a significant market size of $1.37 billion in 2023, rising to $2.69 billion by 2033, capturing 54.8% of the share. Aerospace comes second, with a market of $0.56 billion in 2023, expected to reach $1.10 billion by 2033 (22.47% market share). Industrial and Construction applications also showcase steady growth.

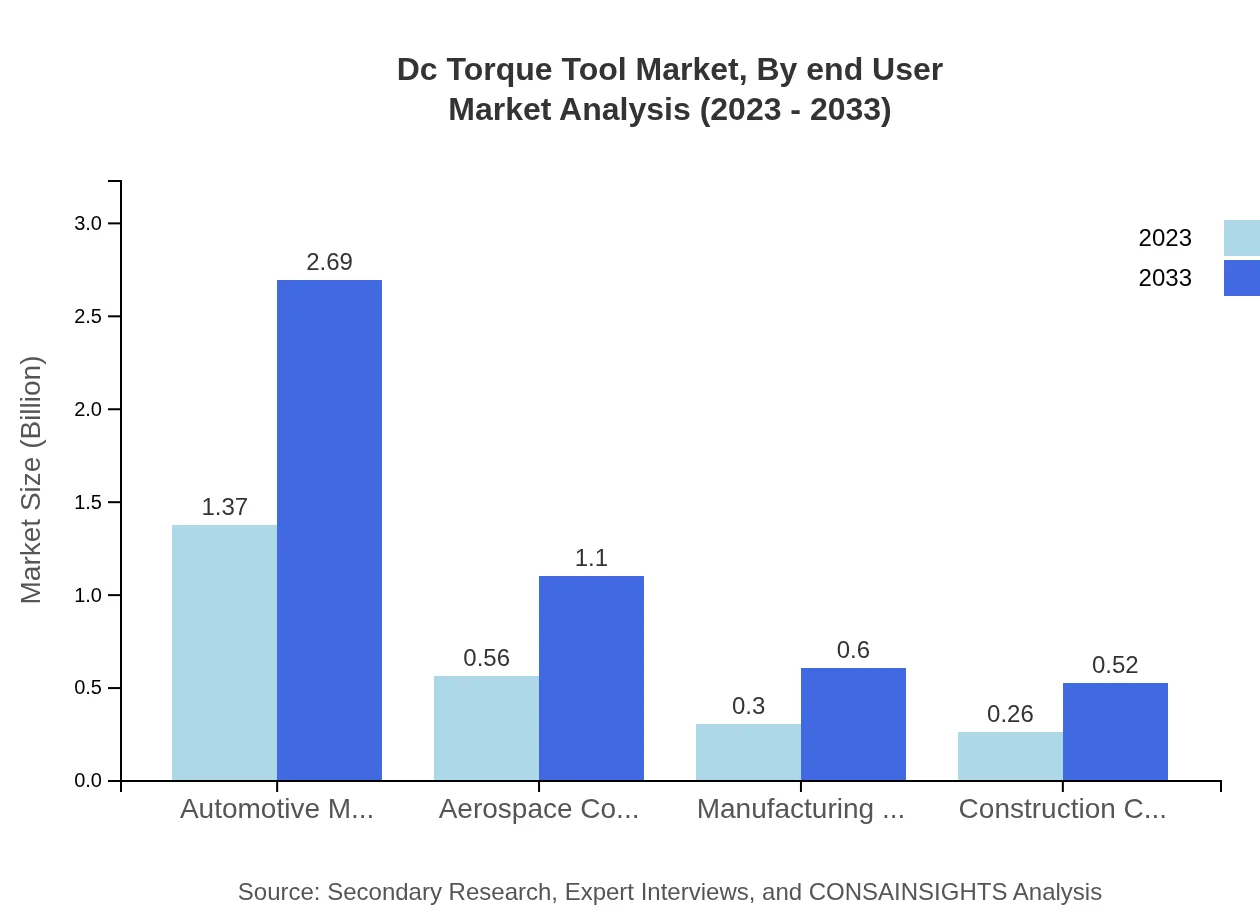

Dc Torque Tool Market Analysis By End User

Automotive Manufacturers hold the largest share at 54.8% in 2023, with their market size increasing from $1.37 billion to $2.69 billion by 2033. Aerospace companies represent 22.47% of the market, poised to grow from $0.56 billion to $1.10 billion. Other segments include Manufacturing Firms (12.19%) and Construction Contractors (10.54%).

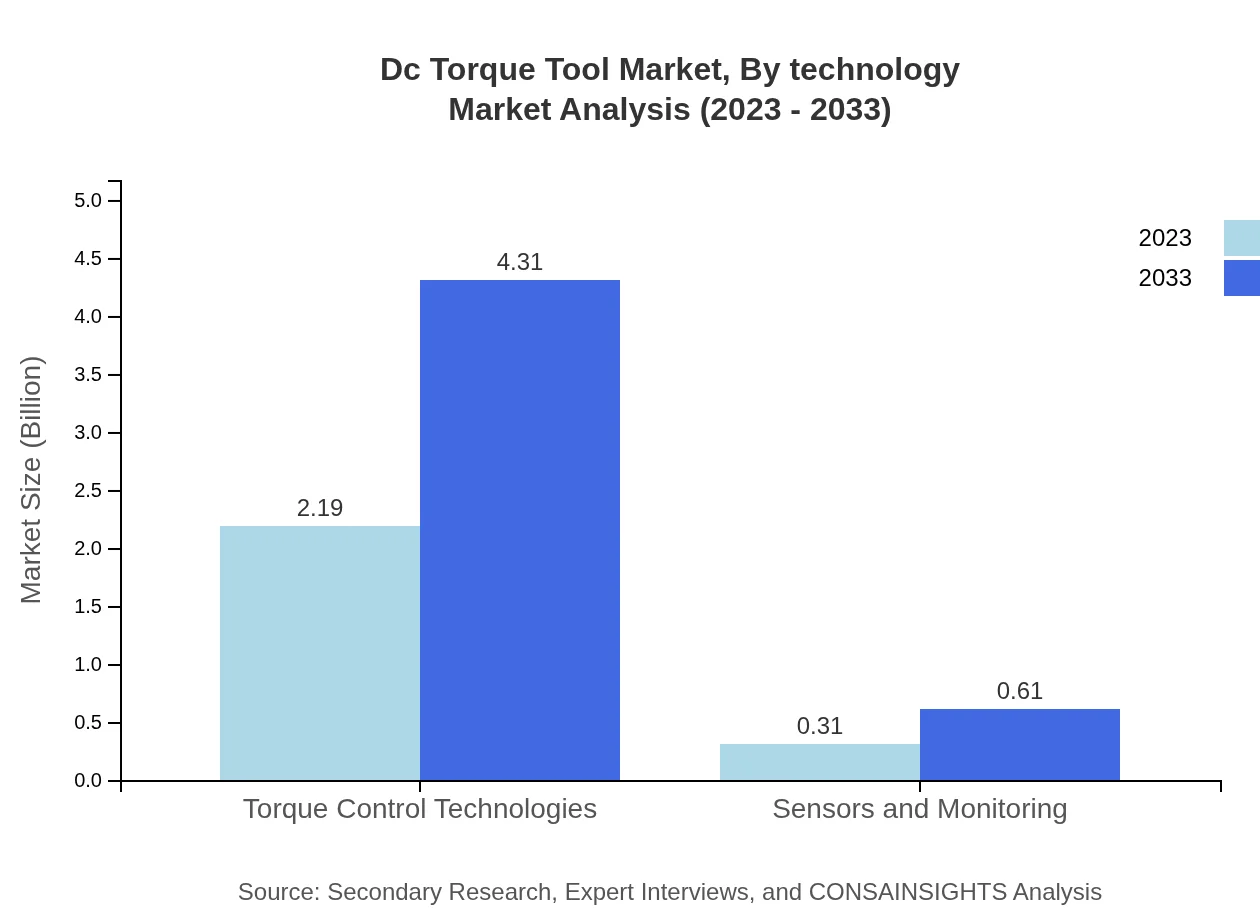

Dc Torque Tool Market Analysis By Technology

Torque Control Technologies, leading the technology segment, show a market size of $2.19 billion in 2023, expected to reach $4.31 billion by 2033, with an 87.64% market share. Sensors and Monitoring account for $0.31 billion in 2023, projected to grow to $0.61 billion by 2033, capturing 12.36% of the market.

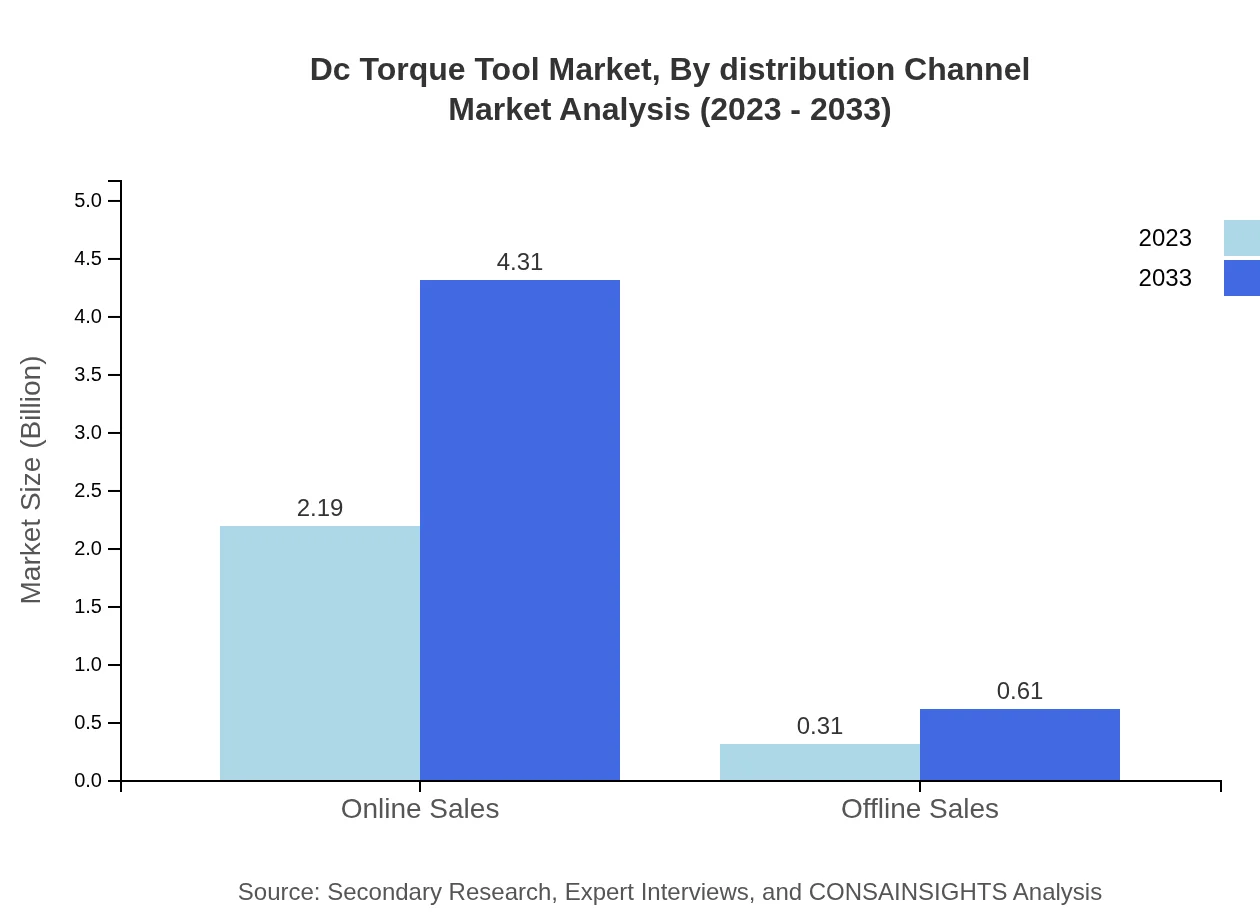

Dc Torque Tool Market Analysis By Distribution Channel

Online sales are a major contributor to the market, with a size of $2.19 billion in 2023, anticipated to grow to $4.31 billion by 2033, retaining an 87.64% share. Offline sales generate $0.31 billion in 2023, expected to reach $0.61 billion by 2033, maintaining a 12.36% share.

Dc Torque Tool Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Dc Torque Tool Industry

Stanley Black & Decker, Inc.:

A major player in the industrial tools market, Stanley Black & Decker offers a wide range of Dc Torque Tools known for their precision and durability, widely used in the automotive and construction industries.Milwaukee Tools:

Recognized for innovation and performance, Milwaukee Tools specializes in electric tools, including Dc Torque Tools, with a strong presence in North America and Europe.Bosch Power Tools:

A well-established brand, Bosch provides advanced power tools and accessories, including high-quality Dc Torque Tools, catering to multiple industries around the globe.Snap-On Inc.:

Snap-On is acclaimed for its automotive repair tools, offering professional-grade Dc Torque Tools valued for their reliability and performance in demanding environments.We're grateful to work with incredible clients.

FAQs

What is the market size of dc Torque Tool?

The global dc torque tool market is expected to reach approximately $2.5 billion by 2033, growing at a CAGR of 6.8% from its current market value. This growth reflects increasing demand across various industries, particularly automotive and manufacturing.

What are the key market players or companies in this dc Torque Tool industry?

Key players in the dc torque tool market include renowned manufacturers and technology companies that provide innovative torque solutions. These companies focus on research, development, and collaboration to enhance product features and expand their market reach.

What are the primary factors driving the growth in the dc Torque Tool industry?

Growth in the dc torque tool industry is driven by the evolving demands for precision engineering, advancements in battery technology, and increased automation in manufacturing processes. Additionally, rising investments in R&D enhance tool efficiency and functionality.

Which region is the fastest Growing in the dc Torque Tool?

The North America region is projected to be the fastest-growing market for dc torque tools, with market size increasing from $0.94 billion in 2023 to $1.84 billion by 2033. Factors include robust automotive manufacturing and technology innovations.

Does ConsaInsights provide customized market report data for the dc Torque Tool industry?

Yes, ConsaInsights offers tailored market report data specific to the dc torque tool industry. Customization allows clients to seek insights pertinent to their business needs and market opportunities that exceed general market reports.

What deliverables can I expect from this dc Torque Tool market research project?

Deliverables from the dc torque tool market research project typically include comprehensive reports featuring market size analysis, competitive landscape, regional insights, and trend forecasts, ensuring stakeholders receive actionable business intelligence.

What are the market trends of dc Torque Tool?

Key trends in the dc torque tool market range from increasing reliance on cordless technology, advancements in smart tools, and a shift towards digital monitoring solutions, reflecting the overall automation trends in manufacturing and construction sectors.