Die Attach Equipment Market Report

Published Date: 31 January 2026 | Report Code: die-attach-equipment

Die Attach Equipment Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Die Attach Equipment market, offering insights into its current condition, market size, growth potential, and trends from 2023 to 2033.

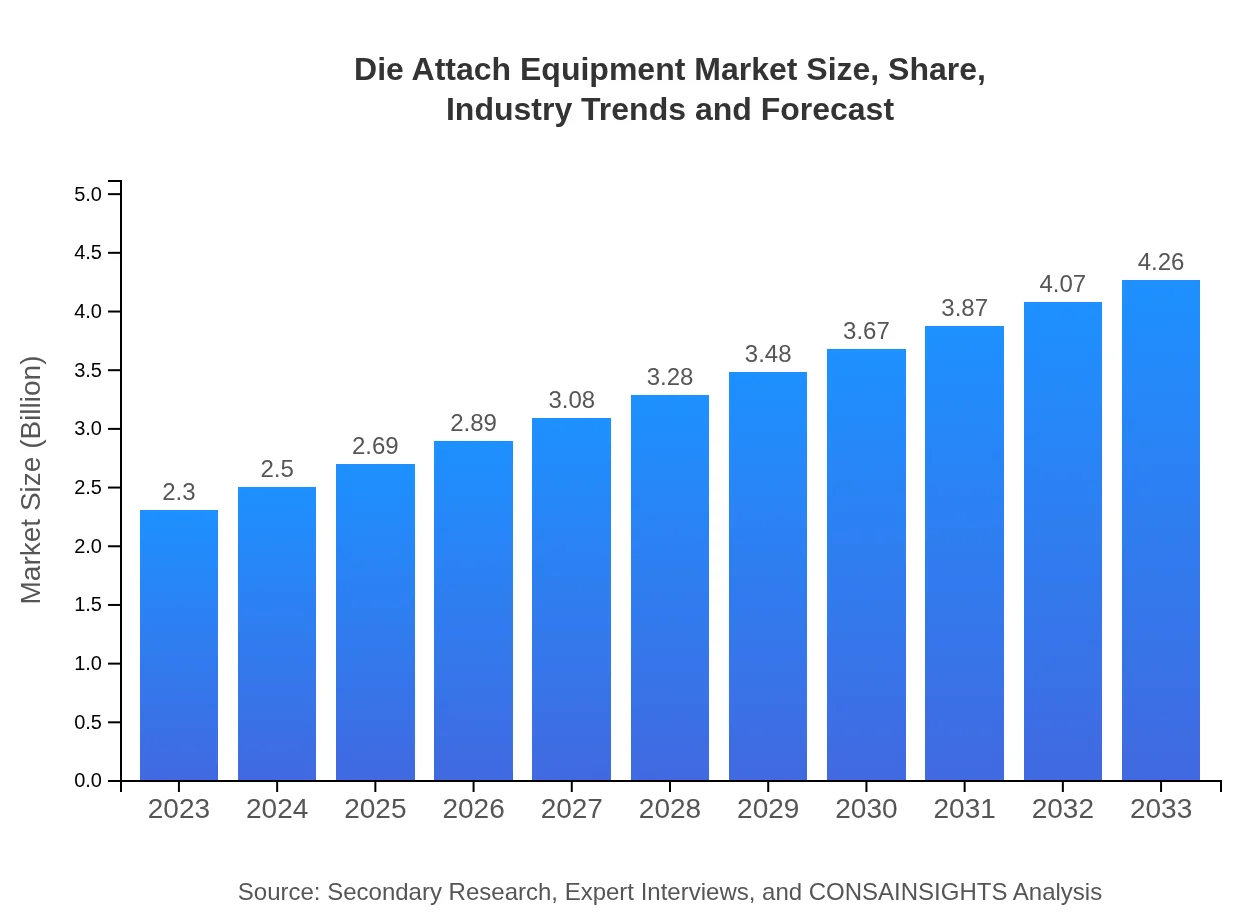

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $2.30 Billion |

| CAGR (2023-2033) | 6.2% |

| 2033 Market Size | $4.26 Billion |

| Top Companies | ASM Pacific Technology, K&S Microelectronics, SUSS MicroTec, Shinkawa |

| Last Modified Date | 31 January 2026 |

Die Attach Equipment Market Overview

Customize Die Attach Equipment Market Report market research report

- ✔ Get in-depth analysis of Die Attach Equipment market size, growth, and forecasts.

- ✔ Understand Die Attach Equipment's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Die Attach Equipment

What is the Market Size & CAGR of Die Attach Equipment market in 2023?

Die Attach Equipment Industry Analysis

Die Attach Equipment Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Die Attach Equipment Market Analysis Report by Region

Europe Die Attach Equipment Market Report:

Europe's Die Attach Equipment market is forecasted to increase from USD 0.57 billion in 2023 to USD 1.05 billion in 2033, underpinned by regulatory support for electronics manufacturing and a focus on innovation in consumer electronics, automotive, and medical devices.Asia Pacific Die Attach Equipment Market Report:

In the Asia Pacific region, the Die Attach Equipment market is projected to grow from USD 0.44 billion in 2023 to USD 0.82 billion by 2033, driven primarily by the semiconductor industry boom in countries like China, Japan, and South Korea. The growing demand for consumer electronics continues to stimulate investment in high-quality die attach equipment.North America Die Attach Equipment Market Report:

North America is anticipated to exhibit a robust market growth from USD 0.88 billion in 2023 to USD 1.63 billion by 2033. The presence of major semiconductor manufacturers and steady investments in automotive electronics and IoT devices contribute to this growth.South America Die Attach Equipment Market Report:

The South American market is expected to expand from USD 0.16 billion in 2023 to USD 0.30 billion in 2033. While the growth is slower compared to other regions, increasing investments in telecommunications and automotive sectors are anticipated to drive demand for die attach technologies.Middle East & Africa Die Attach Equipment Market Report:

In the Middle East and Africa, the market is projected to grow from USD 0.25 billion in 2023 to USD 0.46 billion in 2033, as countries in the region continue to diversify their economies and invest in technology sectors, including telecommunications and automotive.Tell us your focus area and get a customized research report.

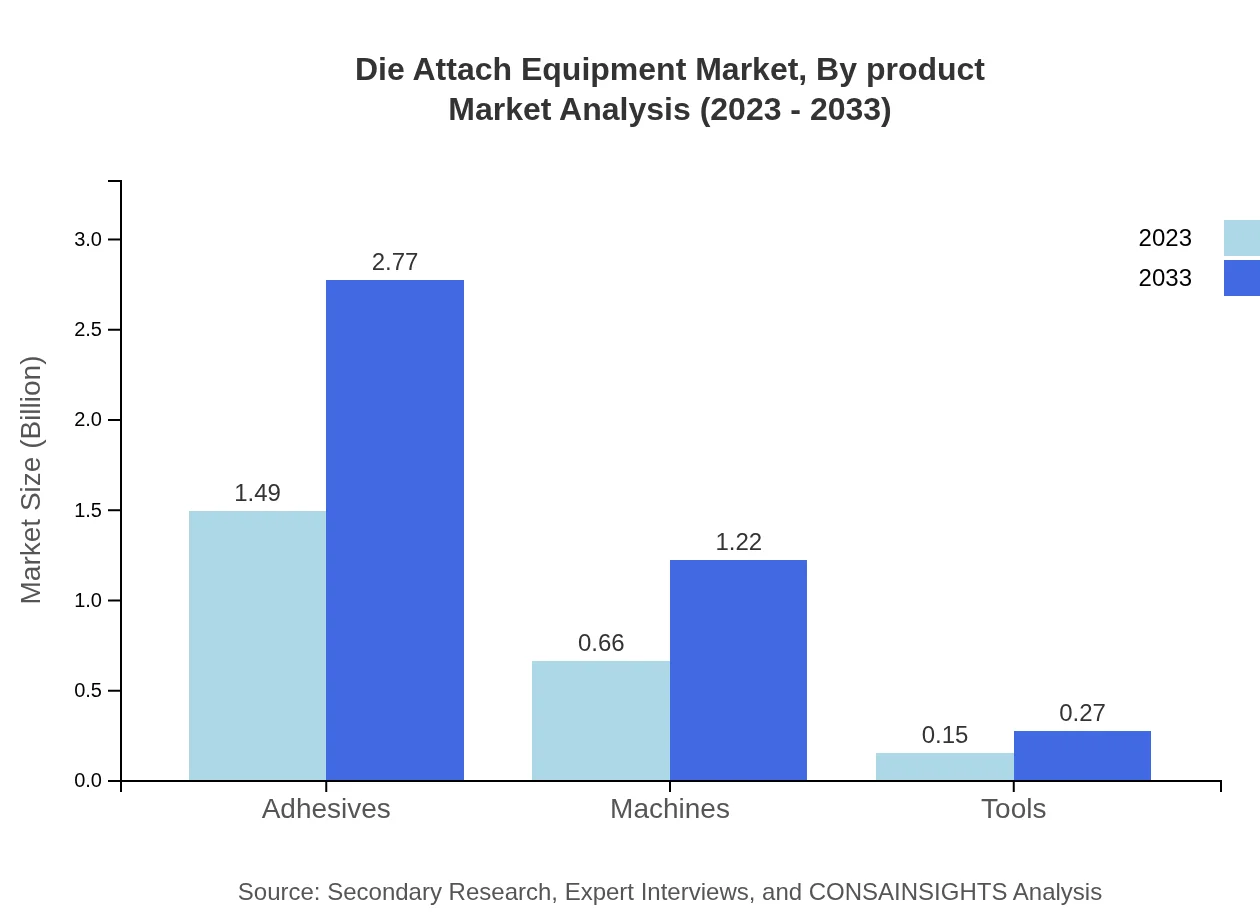

Die Attach Equipment Market Analysis By Product

The Die-Attach Equipment market by product includes segments such as adhesives, machines, and tools. Adhesives hold the largest market share, valued at USD 1.49 billion in 2023 and projected to grow to USD 2.77 billion by 2033, accounting for 64.97% of the total market share in both years. Machines are also significant, growing from USD 0.66 billion in 2023 to USD 1.22 billion by 2033, making up 28.67% of the market. Tools, while currently a smaller segment, are expected to grow from USD 0.15 billion to USD 0.27 billion during the same period.

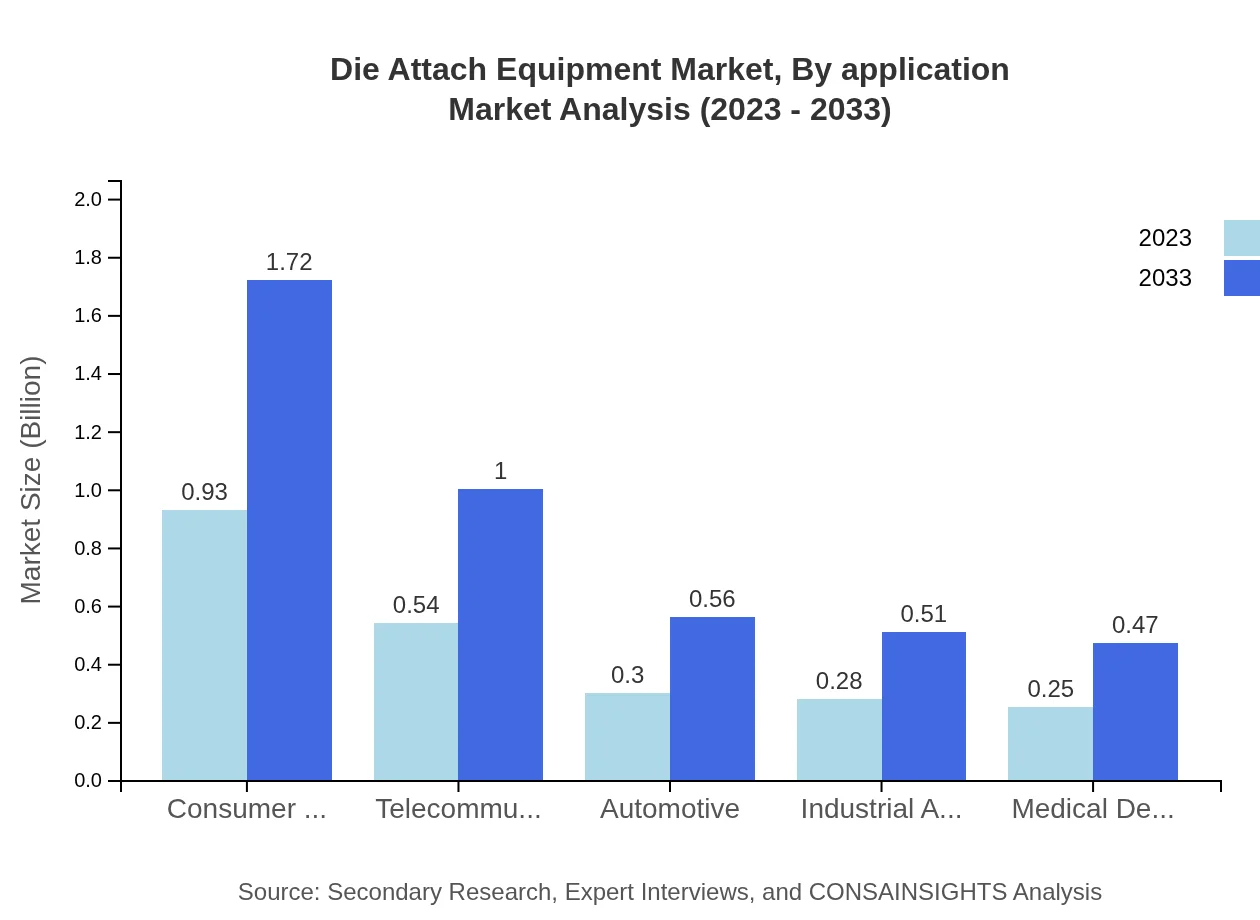

Die Attach Equipment Market Analysis By Application

The applications of Die Attach Equipment span several industries such as consumer electronics, telecommunications, automotive, and medical devices. In 2023, the consumer electronics sector is expected to account for a market size of USD 0.93 billion, growing to USD 1.72 billion by 2033, representing 40.28% of market share throughout the period. Telecommunication applications will also experience growth, expanding from USD 0.54 billion to USD 1.00 billion, with a share of 23.51%. The automotive sector is poised to grow from USD 0.30 billion to USD 0.56 billion, commanding a share of 13.16%.

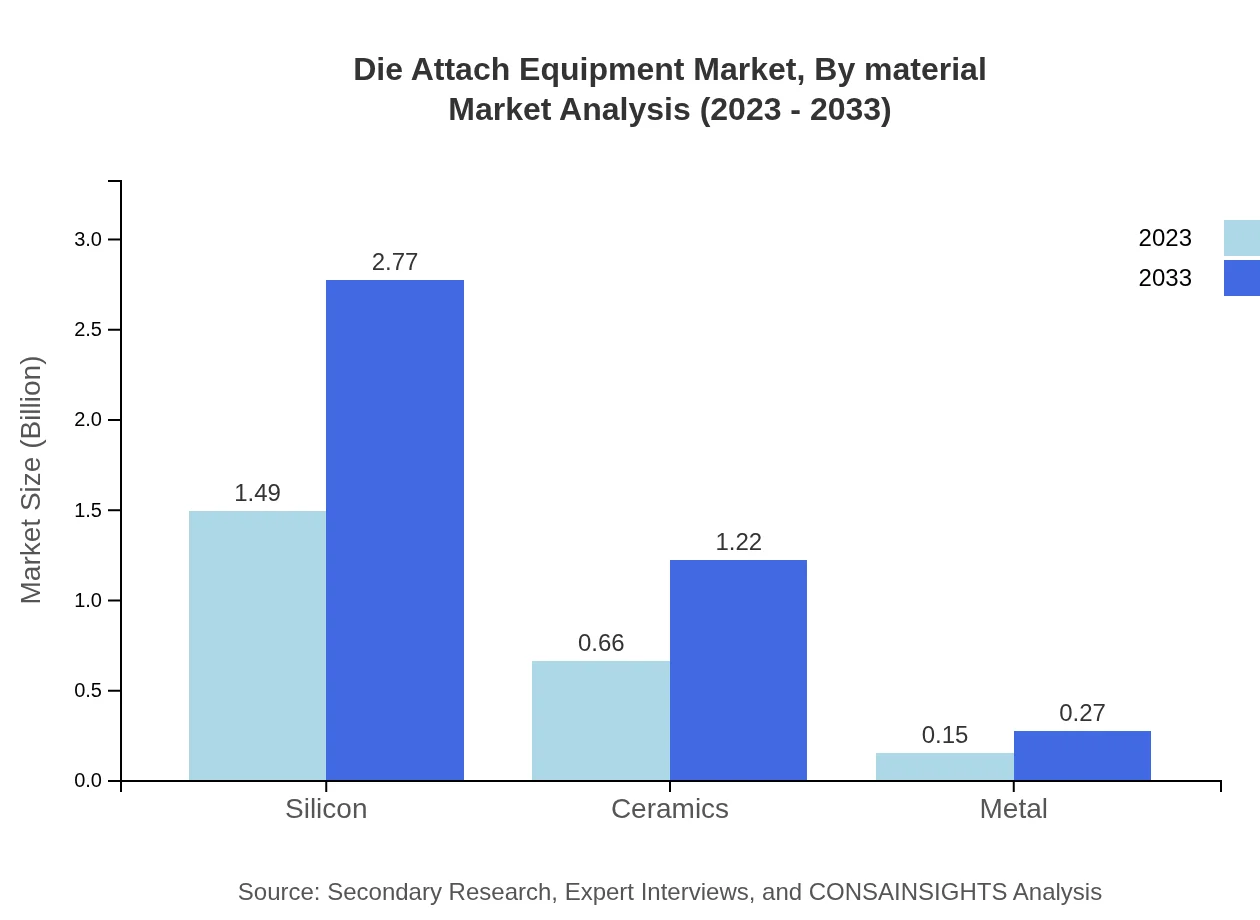

Die Attach Equipment Market Analysis By Material

Material segmentation includes silicon, ceramics, metals, and others. Silicon dominates, with market values of USD 1.49 billion in 2023 and USD 2.77 billion in 2033, retaining a share of 64.97%. Ceramics are also noteworthy, growing from USD 0.66 billion to USD 1.22 billion, representing 28.67% of the market, while metals will increase from USD 0.15 billion to USD 0.27 billion, maintaining a 6.36% share.

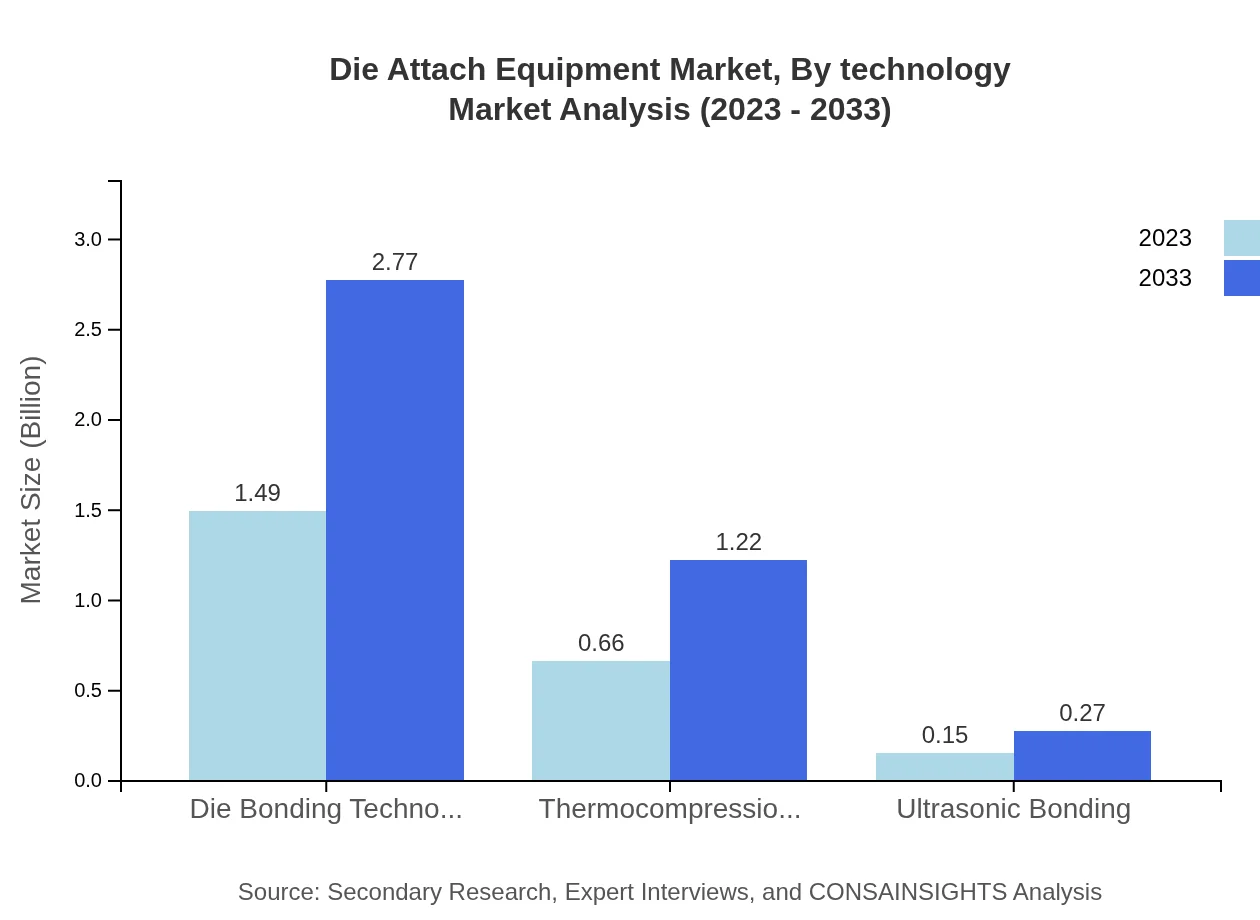

Die Attach Equipment Market Analysis By Technology

The technological segmentation includes die bonding technology, thermocompression bonding, and ultrasonic bonding. Die bonding technology commands the largest share at USD 1.49 billion in 2023, growing to USD 2.77 billion by 2033, with a constant share of 64.97%. Thermocompression bonding is expected to grow from USD 0.66 billion to USD 1.22 billion, while ultrasonic bonding remains steady with a value of USD 0.15 billion in 2023, reaching USD 0.27 billion by 2033.

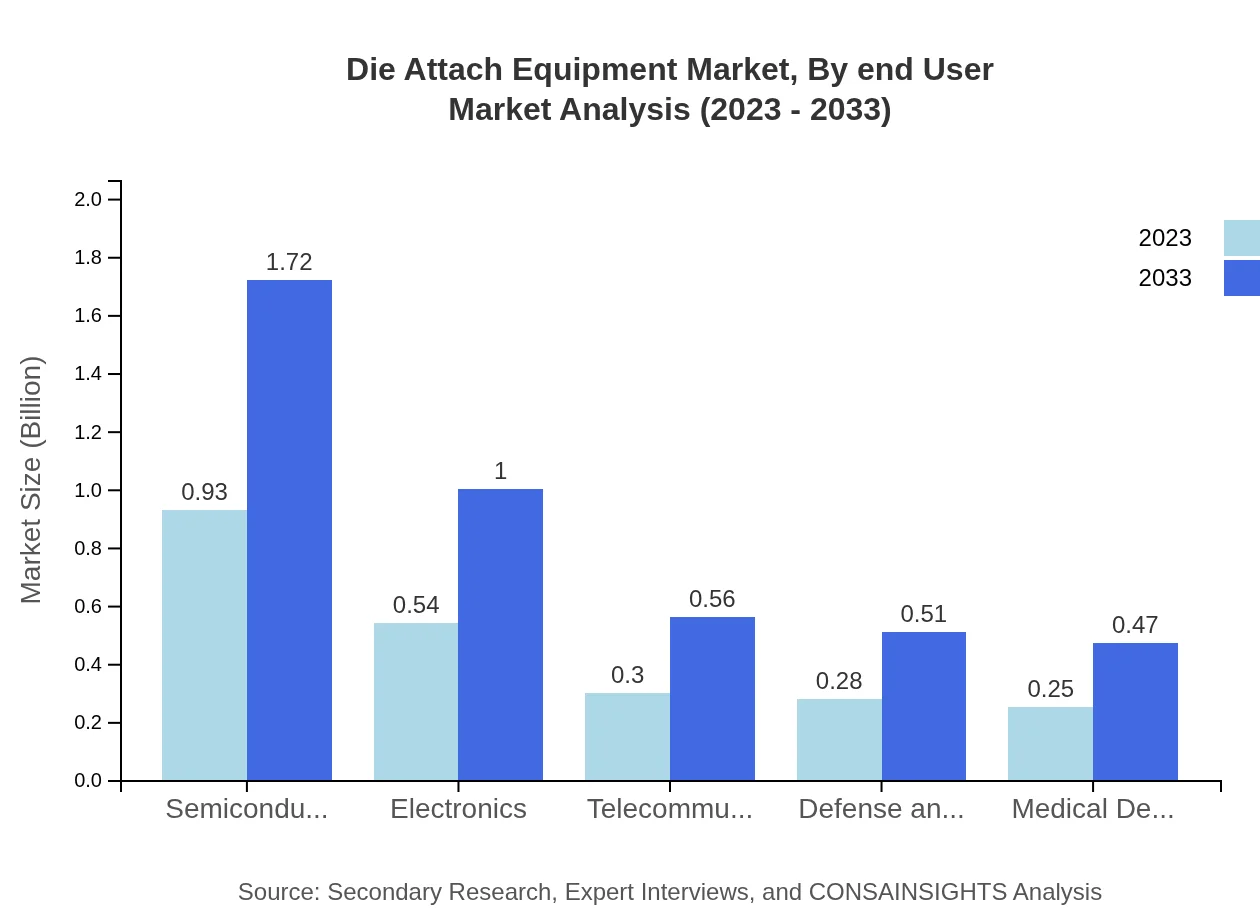

Die Attach Equipment Market Analysis By End User

End-user segmentation includes industries such as aerospace, automotive, telecommunications, and medical devices. Medical devices represent a significant segment, expected to grow from USD 0.25 billion in 2023 to USD 0.47 billion by 2033, maintaining a share of 11.07%. The automotive sector will expand from USD 0.30 billion to USD 0.56 billion, holding a share of 13.16%, while aerospace will represent similar growth patterns reflecting technological advancements in manufacturing.

Die Attach Equipment Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Die Attach Equipment Industry

ASM Pacific Technology:

A leading supplier of semiconductor assembly and packaging equipment, known for its innovative die attach solutions and significant contribution to enhancing production efficiency.K&S Microelectronics:

A key player specializing in advanced packaging technologies, K&S Microelectronics focuses on robust die attach equipment that meets the demands of high-performance applications.SUSS MicroTec:

Renowned for its innovative microfabrication solutions, SUSS MicroTec provides high-precision die attach technologies catering to various industries, including automotive and telecommunications.Shinkawa:

Shinkawa is recognized for its high-performance bonding equipment pivotal in enhancing productivity across semiconductor manufacturing sectors.We're grateful to work with incredible clients.

FAQs

What is the market size of die Attach equipment?

The die-attach equipment market is valued at $2.3 billion in 2023, with an impressive CAGR of 6.2% projected until 2033. This growth is driven by increasing demand across various sectors, particularly semiconductors and electronics.

What are the key market players or companies in this die Attach equipment industry?

Key players in the die-attach equipment industry include global leaders such as ASM International, Bonder Technology, and Palomar Technologies. Their innovative solutions and technology advancements contribute significantly to the market's growth and efficiency.

What are the primary factors driving the growth in the die Attach equipment industry?

Growth in the die-attach equipment sector is driven by increasing adoption in consumer electronics, automotive, and medical devices. Enhanced demand for compact, high-performance electronic devices fuels the need for advanced die-attach solutions.

Which region is the fastest Growing in the die Attach equipment?

The fastest-growing region for die-attach equipment from 2023 to 2033 is North America, projected to rise from $0.88 billion to $1.63 billion. Europe also shows substantial growth, increasing from $0.57 billion to $1.05 billion.

Does ConsaInsights provide customized market report data for the die Attach equipment industry?

Yes, ConsaInsights offers customized market report data tailored to specific requirements within the die-attach equipment industry. This ensures businesses access relevant insights for strategic decisions and market positioning.

What deliverables can I expect from this die Attach equipment market research project?

The deliverables from the die-attach equipment market research project include detailed market analysis reports, competitive landscape assessments, growth projections, and segmentation data, ensuring comprehensive insights to drive informed decisions.

What are the market trends of die Attach equipment?

Current market trends in die-attach equipment involve a shift towards automation and precision bonding technologies, alongside growth in semiconductor applications. Innovations in materials and increased miniaturization of electronic components are also key focal points.