Die Bonder Equipment Market Report

Published Date: 22 January 2026 | Report Code: die-bonder-equipment

Die Bonder Equipment Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Die Bonder Equipment market from 2023 to 2033, presenting key insights including market size, growth rates, industry trends, and regional dynamics. It aims to guide stakeholders in making informed decisions based on future market forecasts.

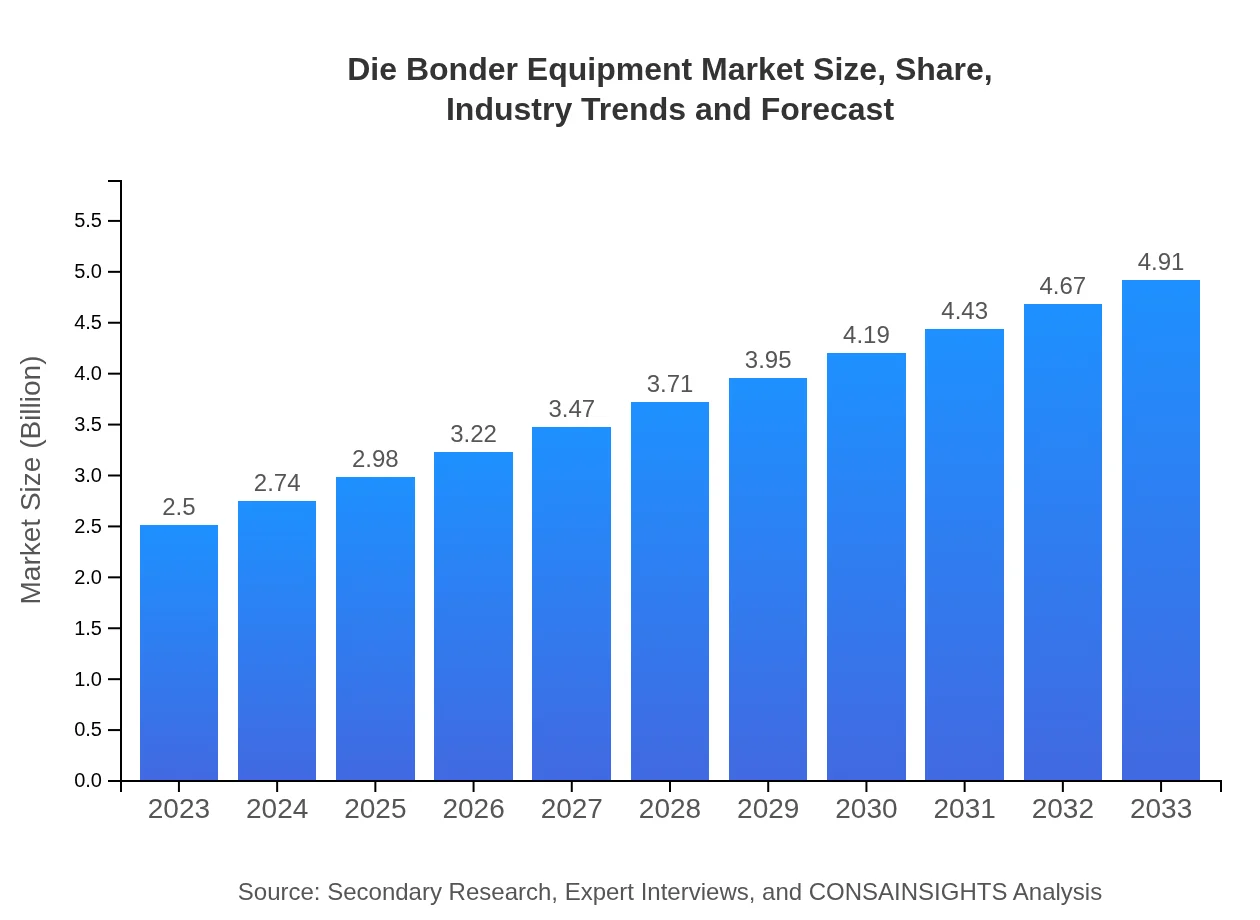

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $2.50 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $4.91 Billion |

| Top Companies | K&S Engineering, ASM Pacific Technology, Henkel AG, SET Corporation |

| Last Modified Date | 22 January 2026 |

Die Bonder Equipment Market Overview

Customize Die Bonder Equipment Market Report market research report

- ✔ Get in-depth analysis of Die Bonder Equipment market size, growth, and forecasts.

- ✔ Understand Die Bonder Equipment's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Die Bonder Equipment

What is the Market Size & CAGR of Die Bonder Equipment market in 2023?

Die Bonder Equipment Industry Analysis

Die Bonder Equipment Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Die Bonder Equipment Market Analysis Report by Region

Europe Die Bonder Equipment Market Report:

Europe’s die bonder equipment market size is approximately $0.87 billion in 2023 and is set to nearly double to $1.72 billion by 2033. The region is bolstered by high demand in the medical device and industrial automation sectors.Asia Pacific Die Bonder Equipment Market Report:

The Asia Pacific region, with a market size of $0.44 billion in 2023, is expected to grow to $0.87 billion by 2033, driven by countries like China and Japan leading in semiconductor manufacturing. Constant innovations and investments in electronics are fuelling demand.North America Die Bonder Equipment Market Report:

North America shows a strong market performance with current valuation at $0.86 billion in 2023, expected to rise to $1.69 billion by 2033. The drive is primarily due to advancements in technology and the strong presence of automotive and aerospace industries.South America Die Bonder Equipment Market Report:

In South America, the market is projected to increase from $0.16 billion in 2023 to $0.31 billion in 2033. Growth is being spurred by rising investments in electronic manufacturing and improving infrastructure.Middle East & Africa Die Bonder Equipment Market Report:

The Middle East and Africa region is showing gradual growth, with a market size of $0.17 billion in 2023, projected to reach $0.33 billion by 2033. Growth is attributed to increasing electronics manufacturing and investments in automation.Tell us your focus area and get a customized research report.

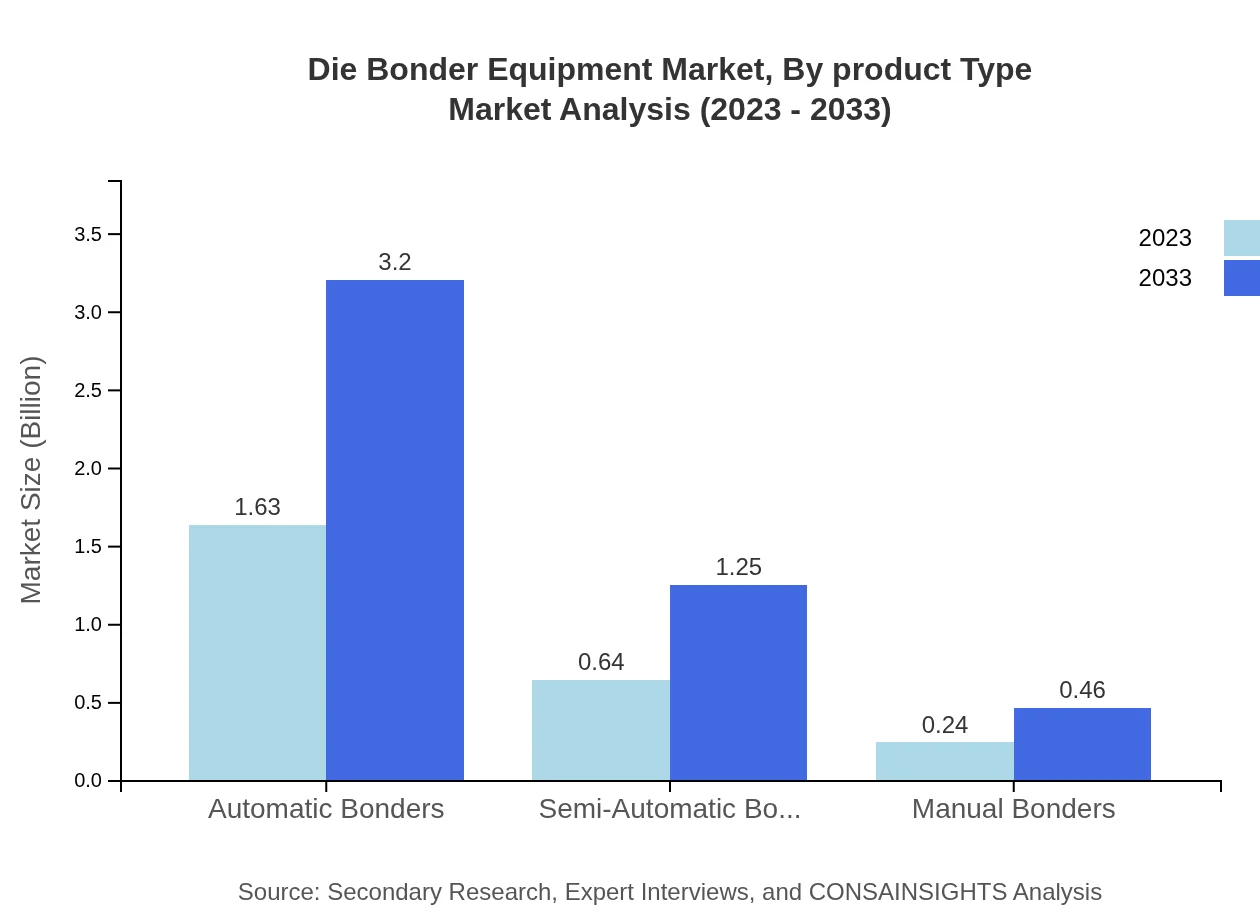

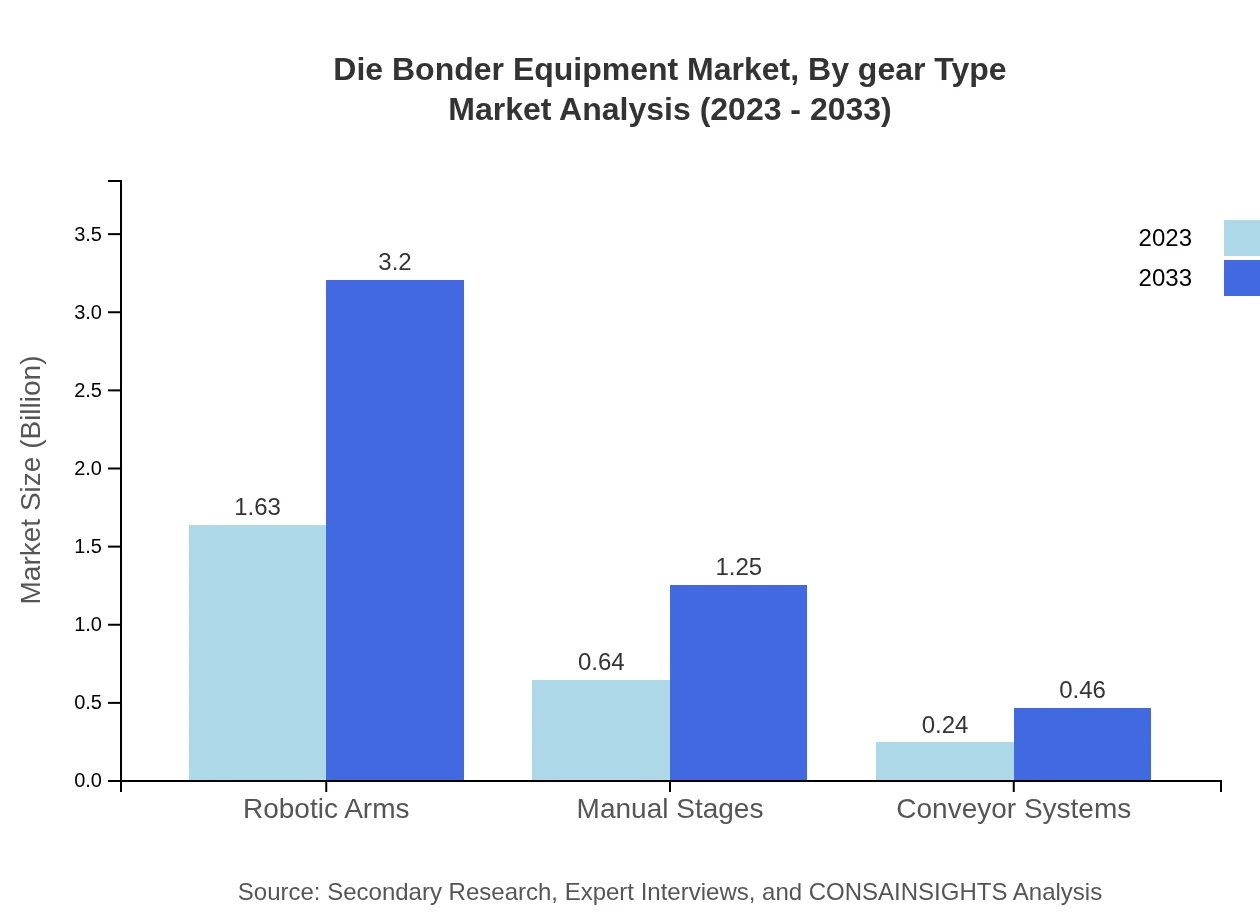

Die Bonder Equipment Market Analysis By Product Type

Robotic Arms dominate the market with a valuation of $1.63 billion in 2023 projected to grow to $3.20 billion by 2033. This is followed by Manual Stages which are valued at $0.64 billion and are expected to reach $1.25 billion by 2033. Conveyor Systems hold a smaller yet vital position in the market with a current size of $0.24 billion.

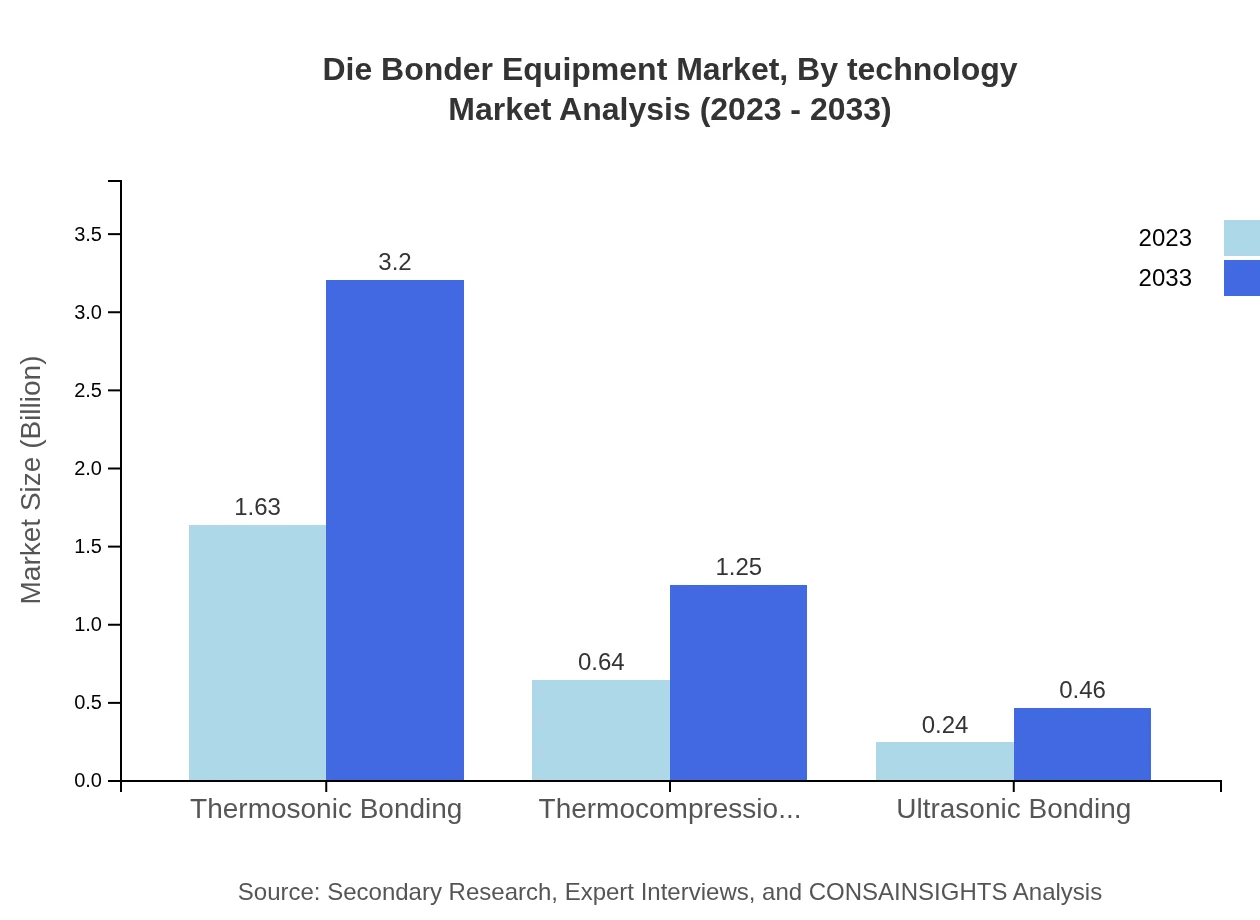

Die Bonder Equipment Market Analysis By Technology

The market is primarily divided into Thermosonic Bonding, Thermocompression Bonding, and Ultrasonic Bonding technologies. Thermosonic Bonding holds a major share at 65.08% consistently across the forecast period, indicating its crucial role in applications like semiconductor manufacturing.

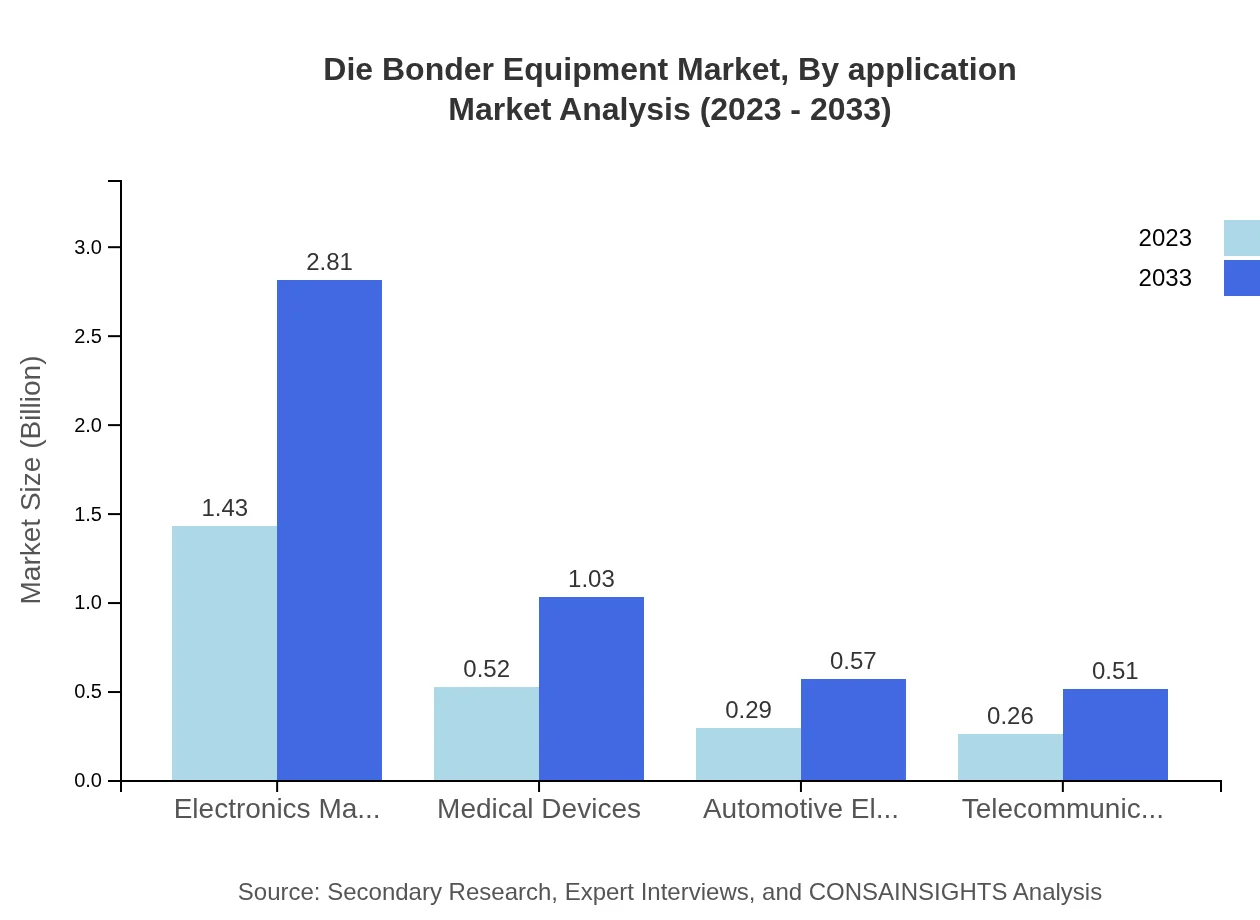

Die Bonder Equipment Market Analysis By Application

Electronics Manufacturing is leading with a market size of $1.43 billion in 2023 projected to reach $2.81 billion by 2033. This is followed by Medical Devices at $0.52 billion expected to nearly double by 2033, showcasing the growing importance of precise manufacturing in healthcare.

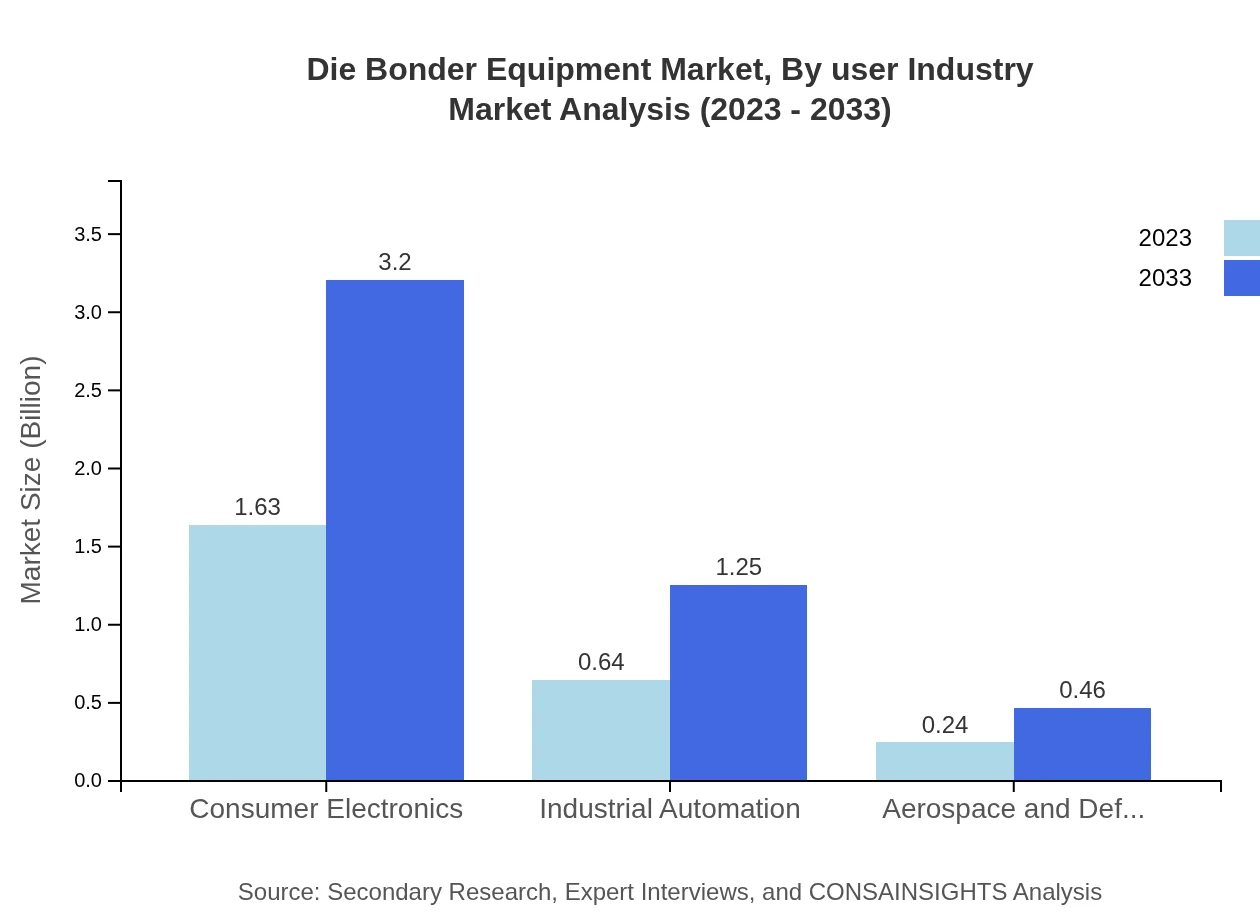

Die Bonder Equipment Market Analysis By User Industry

Key user industries include Consumer Electronics, Automotive Electronics, and Telecommunications. Consumer Electronics dominate the market with a significant share of 65.08% in 2023, expected to sustain this trend for the forecast period.

Die Bonder Equipment Market Analysis By Gear Type

The die bonders are segmented into three main categories - Automatic Bonders, Semi-Automatic Bonders, and Manual Bonders. Automatic Bonders lead in the market, indicating a trend towards automation and increased production efficiency in manufacturing processes.

Die Bonder Equipment Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Die Bonder Equipment Industry

K&S Engineering:

A leading provider of advanced equipment for semiconductor packaging and assembly, focusing on precision and automation systems that enhance production efficiency.ASM Pacific Technology:

Specializes in die bonding technologies, offering innovative solutions that cater to a wide range of industries including consumer electronics and automotive.Henkel AG:

Recognized for its adhesive technologies, Henkel also provides crucial die bonder systems that support the assembly of various electronic devices.SET Corporation:

A specialist in providing advanced die bonders, SET Corporation focuses on high precision and speed, significantly improving assembly processes in semiconductor manufacturing.We're grateful to work with incredible clients.

FAQs

What is the market size of die Bonder Equipment?

The global market size for die-bonder equipment is projected to reach approximately $2.5 billion by 2033, growing at a CAGR of 6.8%. This growth is driven by increasing demand in various electronic sectors, enhancing production efficiency.

What are the key market players or companies in this die Bonder Equipment industry?

Key players in the die-bonder equipment industry include prominent manufacturers and technology firms specializing in semiconductor equipment. Their innovations and production capabilities significantly shape market dynamics, driving advancements and establishing competitive advantages.

What are the primary factors driving the growth in the die Bonder Equipment industry?

Growth in the die-bonder equipment industry is driven by rising demand in electronics manufacturing, advancements in semiconductor technology, and increasing automation in production processes, necessitating more efficient bonding solutions.

Which region is the fastest Growing in the die Bonder Equipment?

Asia Pacific is the fastest-growing region for die-bonder equipment, with a market size forecast to double from $0.44 billion in 2023 to $0.87 billion by 2033, reflecting strong growth in electronics manufacturing and automotive sectors.

Does ConsaInsights provide customized market report data for the die Bonder Equipment industry?

Yes, ConsaInsights offers tailored market report data for the die-bonder equipment industry. Customized reports can be created to address specific user needs, encompassing detailed insights and projections relevant to market trends.

What deliverables can I expect from this die Bonder Equipment market research project?

Deliverables from the die-bonder equipment market research project include detailed reports, market forecasts, segmented analysis, competitive landscape insights, and trend identification, providing comprehensive views on market dynamics.

What are the market trends of die Bonder Equipment?

Key trends in the die-bonder equipment market include increasing automation in manufacturing processes, advancements in bonding technologies like thermosonic and thermocompression bonding, along with a shift toward energy-efficient equipment and sustainable practices.