Die Cutting Machine Market Report

Published Date: 22 January 2026 | Report Code: die-cutting-machine

Die Cutting Machine Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the die cutting machine market from 2023 to 2033, including market dynamics, size, trends, regional performance, and key players shaping the industry.

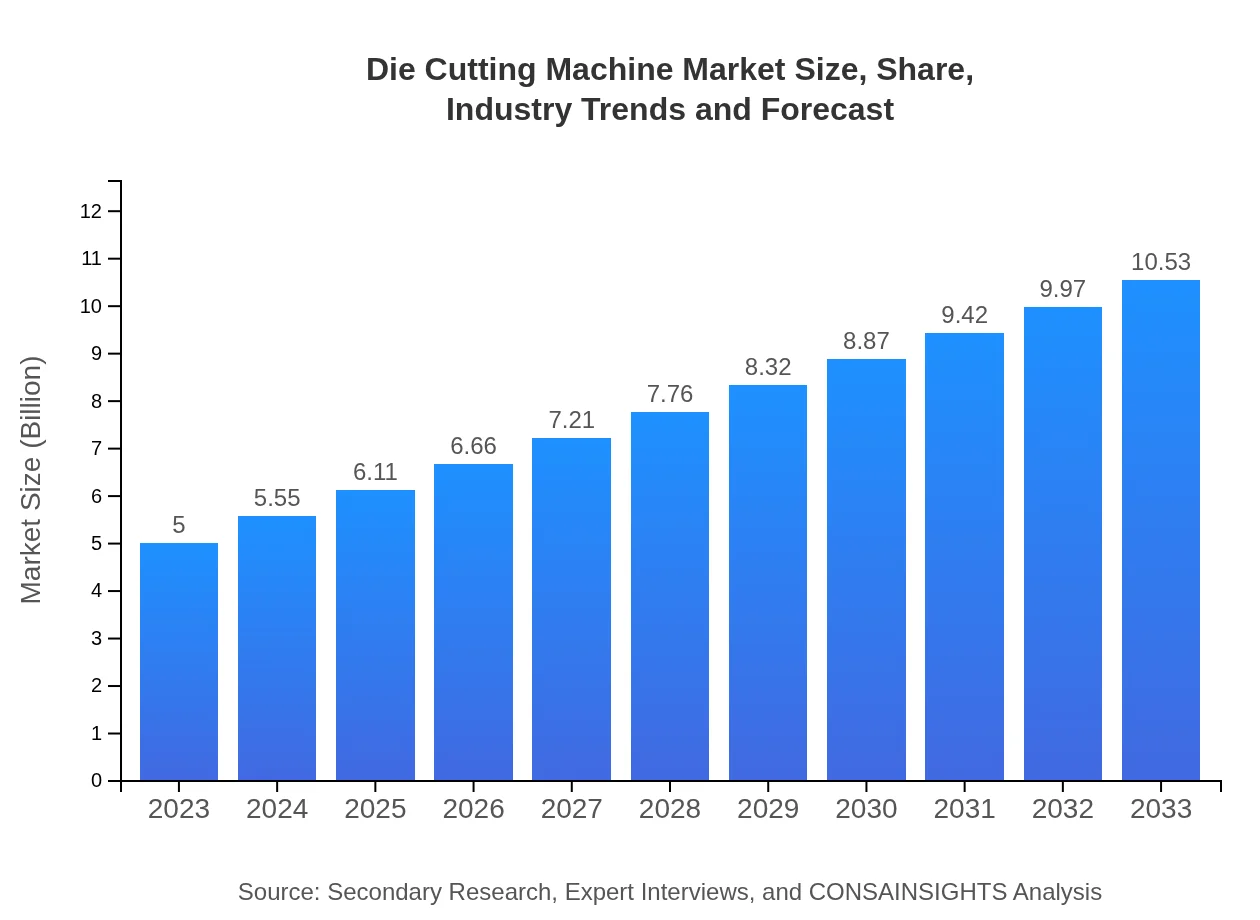

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.00 Billion |

| CAGR (2023-2033) | 7.5% |

| 2033 Market Size | $10.53 Billion |

| Top Companies | Bobst Group SA, Heidelberg Druckmaschinen AG, Koenig & Bauer AG, Sakurai Graphic Systems Corporation, Mitsubishi Heavy Industries Printing & Packaging Machinery |

| Last Modified Date | 22 January 2026 |

Die Cutting Machine Market Overview

Customize Die Cutting Machine Market Report market research report

- ✔ Get in-depth analysis of Die Cutting Machine market size, growth, and forecasts.

- ✔ Understand Die Cutting Machine's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Die Cutting Machine

What is the Market Size & CAGR of Die Cutting Machine market in 2023?

Die Cutting Machine Industry Analysis

Die Cutting Machine Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Die Cutting Machine Market Analysis Report by Region

Europe Die Cutting Machine Market Report:

In Europe, the die cutting machine market was valued at $1.61 billion in 2023, with expectations to reach $3.39 billion by 2033. Strong regulatory policies favoring sustainability in packaging and production are propelling the growth of advanced die cutting technologies.Asia Pacific Die Cutting Machine Market Report:

In the Asia Pacific region, the die cutting machine market was valued at $0.95 billion in 2023, projected to reach approximately $2.00 billion by 2033. Growing manufacturing capacities in countries like China and India, coupled with rapid urbanization, are driving demand for efficient packaging solutions that utilize die cutting technologies.North America Die Cutting Machine Market Report:

North America boasts a robust die cutting machine market, valued at $1.81 billion in 2023 and projected to grow to $3.80 billion by 2033. The region is characterized by significant technological advancements and a focus on automation within manufacturing processes, leading to enhanced product offerings.South America Die Cutting Machine Market Report:

The South American market remains modest, with a size of $0.18 billion in 2023, expected to rise to $0.39 billion by 2033. Factors such as rising consumer spending and investment in industrial growth contribute to this upturn, albeit slowly compared to other regions.Middle East & Africa Die Cutting Machine Market Report:

The market in the Middle East and Africa is emerging, with a current valuation of $0.45 billion in 2023, expected to grow to $0.95 billion by 2033. Investments in construction and manufacturing are paving the way for broader adoption of die cutting machines in various applications across the region.Tell us your focus area and get a customized research report.

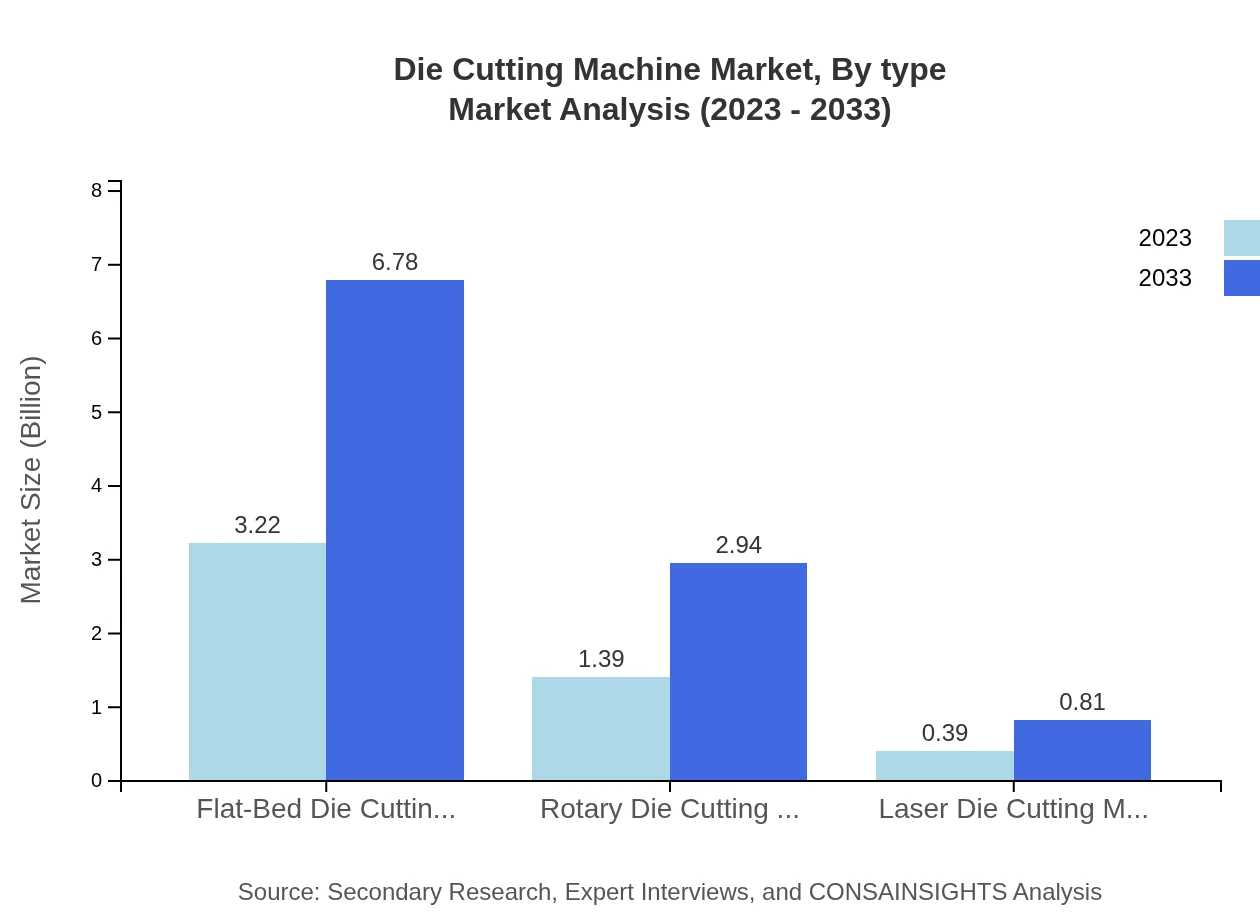

Die Cutting Machine Market Analysis By Type

In terms of types, flat-bed die cutting machines dominate the market with a size of $3.22 billion in 2023, expected to rise to $6.78 billion by 2033, representing a steady market share of 64.38% throughout the forecast period. Rotary die cutting machines follow with $1.39 billion, projected at $2.94 billion by 2033, holding a 27.9% share. Laser machines, while smaller at $0.39 billion and growing to $0.81 billion, account for a 7.72% market share, indicating a niche but increasing interest in precision cutting technologies.

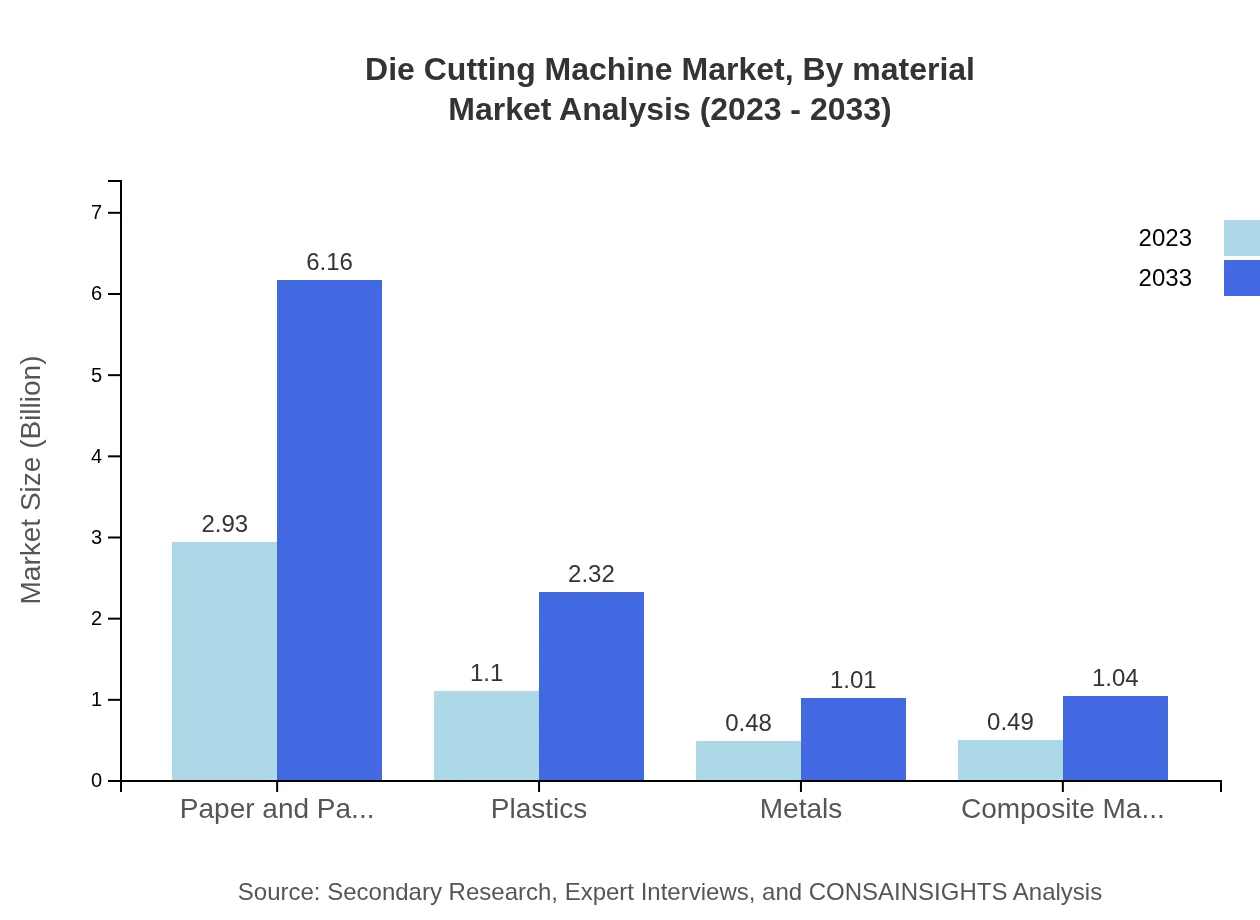

Die Cutting Machine Market Analysis By Material

Major materials processed using die cutting machines include paper and paperboard, which will continue to lead the industry with $2.93 billion in 2023 and are expected to reach $6.16 billion by 2033, capturing 58.52% of the market share. Plastics follow with a size of $1.10 billion, anticipated to grow to $2.32 billion, holding a 22.04% share. Metals and composite materials represent smaller segments but are gaining traction, evidencing the versatility of die cutting applications across various materials.

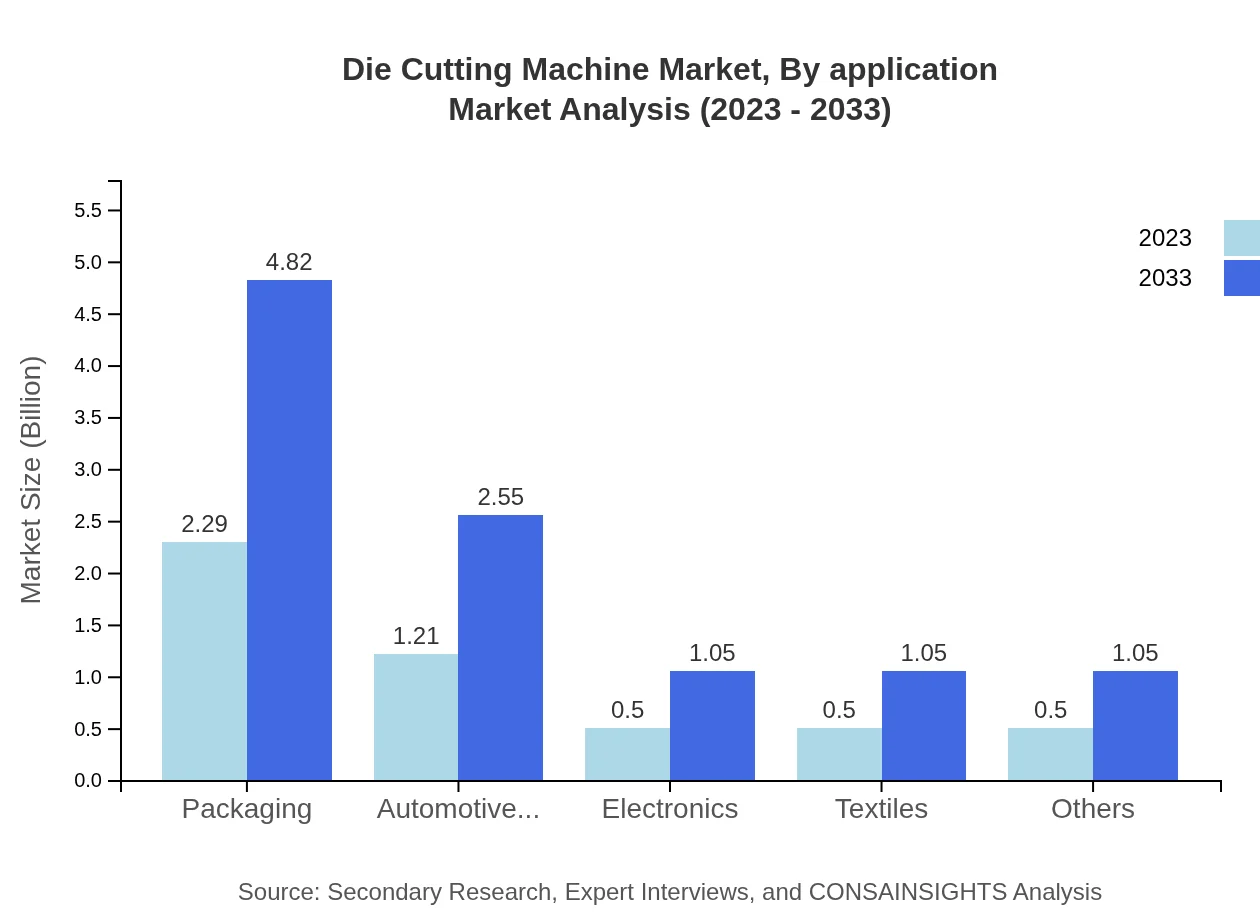

Die Cutting Machine Market Analysis By Application

The application segments showcase packaging as a primary focus area, valued at $2.29 billion in 2023 and projected to reach $4.82 billion by 2033, holding 45.8% of the market. The automotive parts segment, generating $1.21 billion, is expected to see continued growth, driven by the automotive industry's technological advancements. Electronics and textiles are also notable application segments, with consistent demand for precision die cutting.

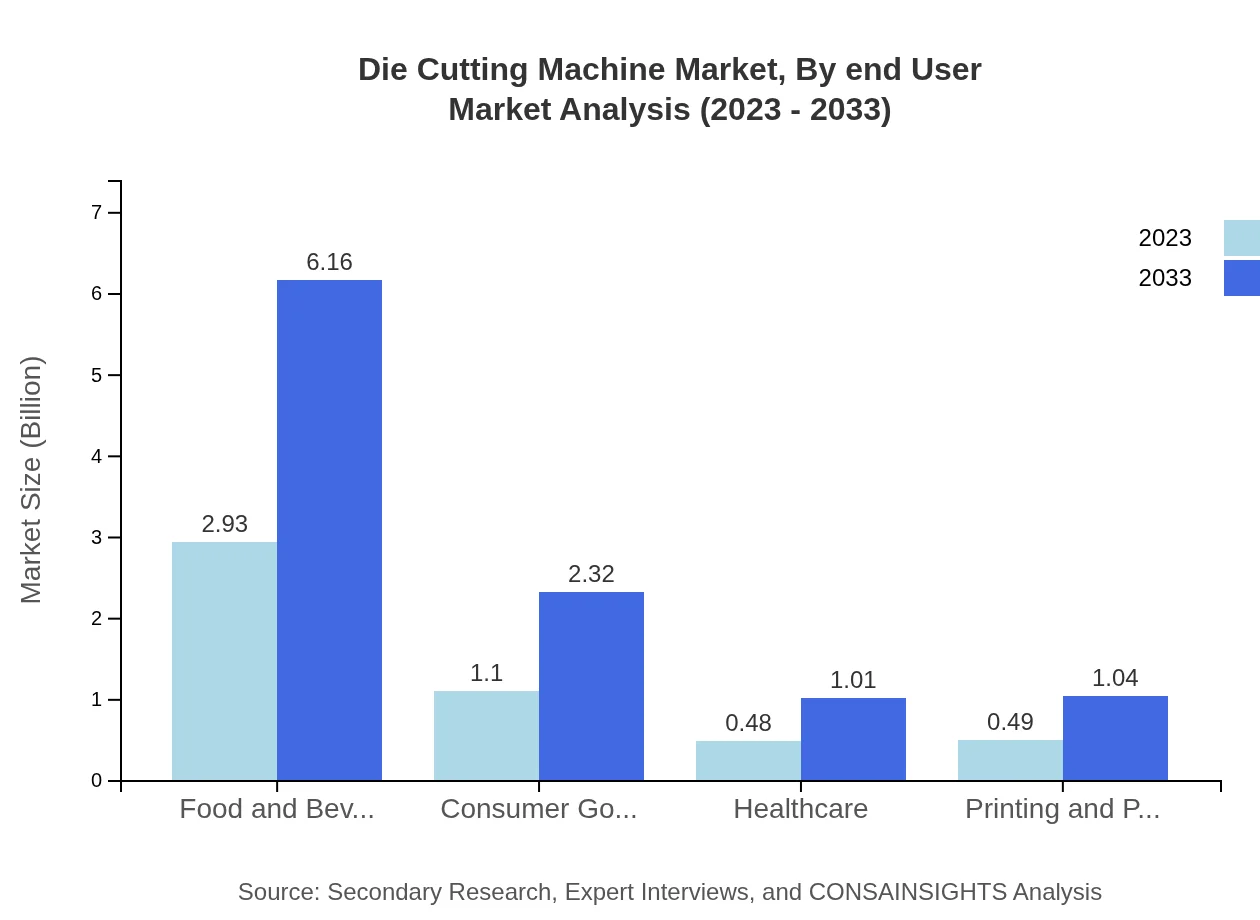

Die Cutting Machine Market Analysis By End User

The primary end-users of die cutting machines include the food and beverage industry, which constituted a market size of $2.93 billion in 2023 and will reach $6.16 billion by 2033, comprising 58.52% market share. Consumer goods and healthcare sectors are also significant, reflecting the importance of die cutting technology in meeting strict industry standards and customization needs.

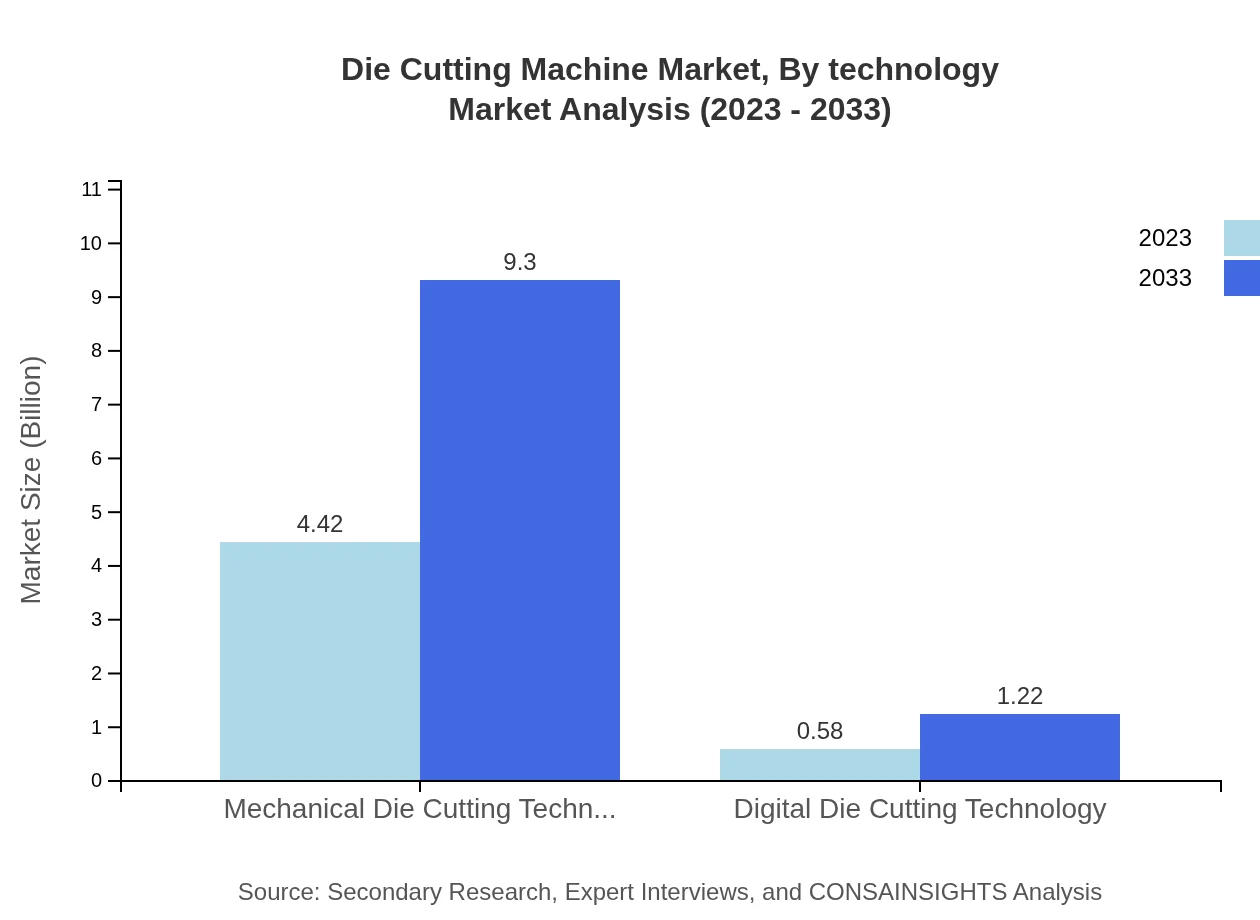

Die Cutting Machine Market Analysis By Technology

Mechanical die cutting technology is the most widely used, with a size of $4.42 billion and an 88.37% market share, expected to grow to $9.30 billion. In contrast, digital die cutting technology remains a smaller yet fast-growing segment, with a size of $0.58 billion in 2023 and a projected growth to $1.22 billion, indicating growing preferences for precision and flexibility in production environments.

Die Cutting Machine Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Die Cutting Machine Industry

Bobst Group SA:

A leading supplier of machinery and services to packaging manufacturers, Bobst specializes in die cutting solutions that enhance productivity and efficiency.Heidelberg Druckmaschinen AG:

Known for its innovative technologies in printing and packaging, Heidelberg offers advanced die cutting machines that cater to diverse market needs.Koenig & Bauer AG:

Koenig & Bauer produces high-quality die cutting solutions recognized for precision and reliability across various applications.Sakurai Graphic Systems Corporation:

Specializing in press technology, Sakurai provides die cutting machines that integrate cutting-edge features tailored for modern production demands.Mitsubishi Heavy Industries Printing & Packaging Machinery:

This company focuses on supplying advanced packaging solutions, including die cutting systems that optimize performance in various sectors.We're grateful to work with incredible clients.

FAQs

What is the market size of die Cutting Machine?

The global die-cutting machine market is anticipated to reach a size of approximately $5 billion by 2033, growing at a CAGR of 7.5% from 2023 to 2033. This reflects the increasing demand across various applications.

What are the key market players or companies in this die Cutting Machine industry?

Key players in the die-cutting machine market include leading manufacturers and suppliers that specialize in producing flat-bed, rotary, and laser die cutting machines. These companies are vital for technological advancements and expanding market reach.

What are the primary factors driving the growth in the die Cutting machine industry?

Key growth drivers for the die-cutting machine industry include the rising demand in packaging sectors, technological advancements in automation, and the increasing use of custom designs in manufacturing processes. These factors collectively propel market expansion.

Which region is the fastest Growing in the die Cutting machine market?

The Asia Pacific region is expected to exhibit the fastest growth in the die-cutting machine market, with projections showing a market increase from $0.95 billion in 2023 to $2.00 billion by 2033, highlighting significant market opportunities.

Does ConsaInsights provide customized market report data for the die Cutting machine industry?

Yes, ConsaInsights offers tailored market reports that provide specific insights into the die-cutting machine industry, addressing unique client needs and ensuring comprehensive analyses that facilitate informed decision-making.

What deliverables can I expect from this die Cutting machine market research project?

From the die-cutting machine market research project, expect detailed reports with market size, growth forecasts, regional analyses, competitive insights, and segment data to support strategic planning and investment decisions.

What are the market trends of die Cutting machine?

Current market trends in the die-cutting machine industry include a shift towards automation, the integration of digital technologies, and an emphasis on sustainable practices, which enhance production efficiency and reduce environmental impact.