Dielectric Etchers Market Report

Published Date: 31 January 2026 | Report Code: dielectric-etchers

Dielectric Etchers Market Size, Share, Industry Trends and Forecast to 2033

This market report provides an in-depth analysis of the Dielectric Etchers market, covering market trends, size, segmentation, and forecasts from 2023 to 2033. It includes valuable insights into regional markets and leading players in the industry, helping stakeholders make informed decisions.

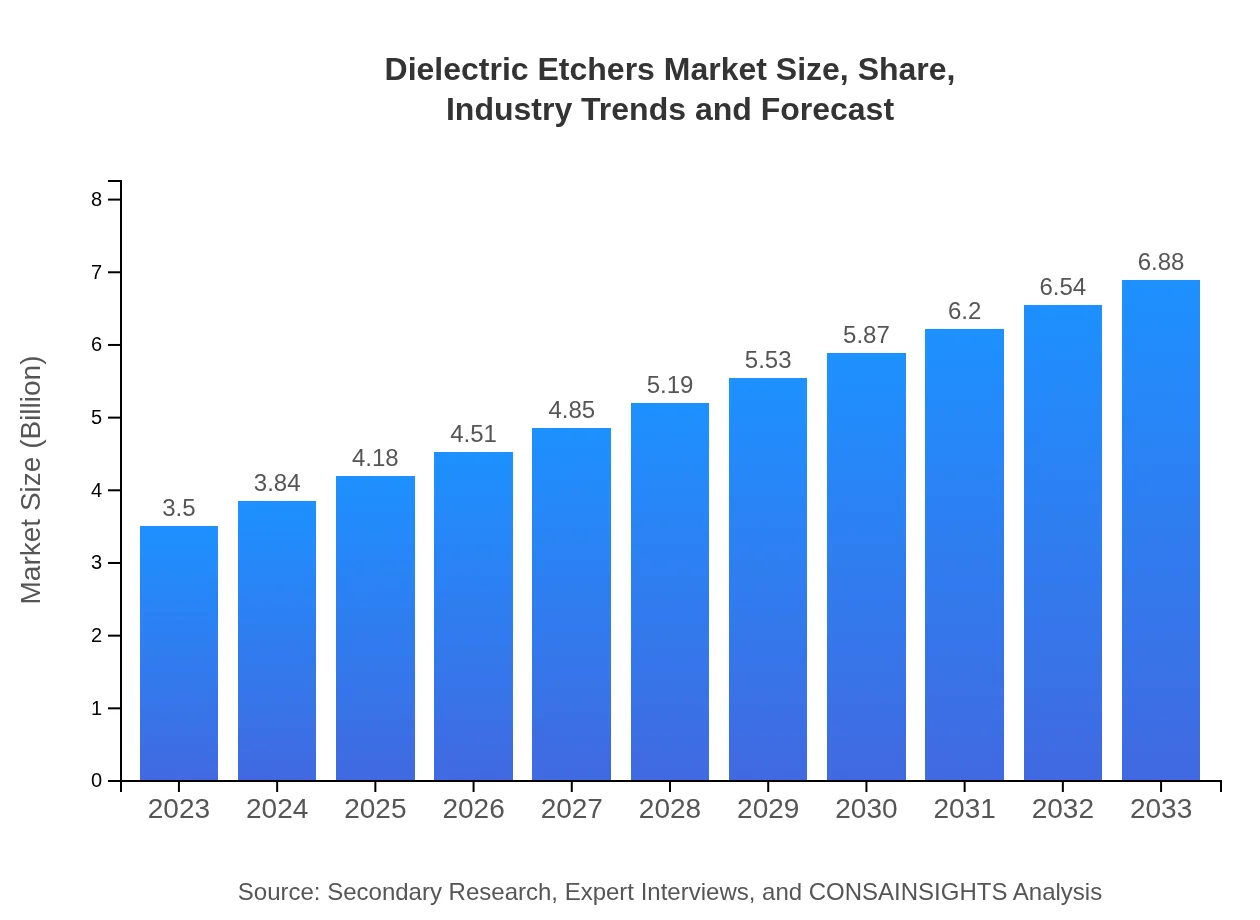

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $3.50 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $6.88 Billion |

| Top Companies | Applied Materials, Inc., Lam Research Corporation, Tokyo Electron Limited, ASML Holding N.V. |

| Last Modified Date | 31 January 2026 |

Dielectric Etchers Market Overview

Customize Dielectric Etchers Market Report market research report

- ✔ Get in-depth analysis of Dielectric Etchers market size, growth, and forecasts.

- ✔ Understand Dielectric Etchers's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Dielectric Etchers

What is the Market Size & CAGR of Dielectric Etchers market in 2023?

Dielectric Etchers Industry Analysis

Dielectric Etchers Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Dielectric Etchers Market Analysis Report by Region

Europe Dielectric Etchers Market Report:

Europe's dielectric etchers market is set to rise from $1.06 billion in 2023 to $2.07 billion by 2033, driven by stringent environmental regulations that push for advanced manufacturing technologies and sustainability in electronics production. Significant growth is expected in countries like Germany and France, where manufacturing is heavily emphasized.Asia Pacific Dielectric Etchers Market Report:

In the Asia-Pacific region, the market is projected to grow from $0.72 billion in 2023 to $1.42 billion by 2033, fueled by high demand from key semiconductor manufacturing hubs like China, Taiwan, and South Korea. The region's robust electronics manufacturing sector is a significant contributor to this growth, alongside government initiatives to support semiconductor technology advancements.North America Dielectric Etchers Market Report:

North America, particularly the United States, leads the market with a projected increase from $1.15 billion in 2023 to $2.25 billion by 2033. Technological innovations, a strong semiconductor industry, and the rise in electric vehicles contribute to the region's growth, alongside investments in smart devices and IoT technologies.South America Dielectric Etchers Market Report:

The South American market for dielectric etchers is expected to grow from $0.13 billion in 2023 to $0.26 billion by 2033. The gradual development of the electronics sector and increased investment in telecommunications infrastructure are anticipated to boost demand for etching technologies in the region.Middle East & Africa Dielectric Etchers Market Report:

The market in the Middle East and Africa is projected to grow from $0.44 billion in 2023 to $0.87 billion by 2033. The growth is supported by increasing investment in digital infrastructure, coupled with rising demand for advanced manufacturing capabilities in electronics.Tell us your focus area and get a customized research report.

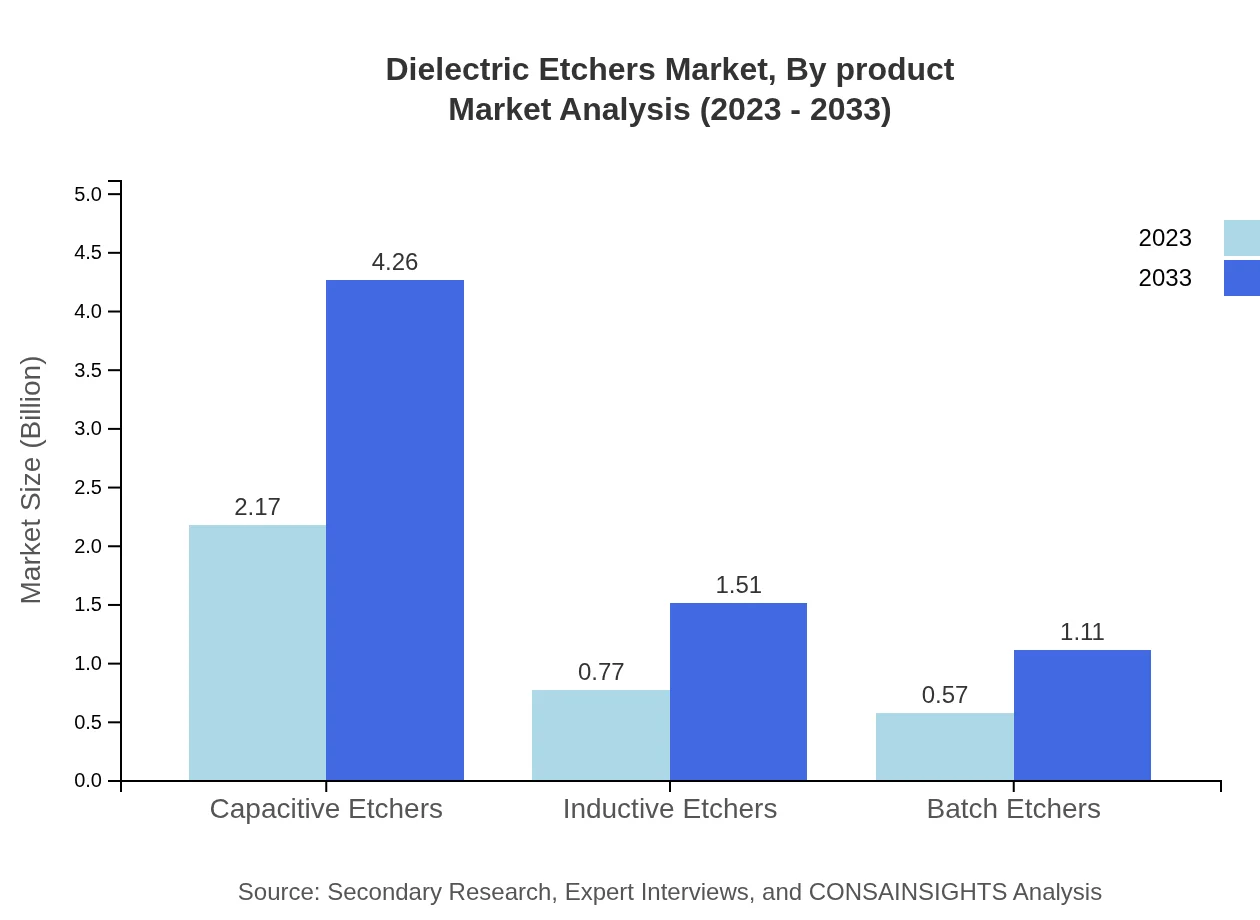

Dielectric Etchers Market Analysis By Product

The dielectric etchers market is divided into capacitance, inductance, and batch etchers. Capacitive etchers dominate the market, accounting for $2.17 billion in 2023, with a projected growth to $4.26 billion by 2033, representing 61.96% market share throughout the forecast period. Inductive etchers and batch etchers follow, growing steadily to support various applications in the semiconductor and electronics industries.

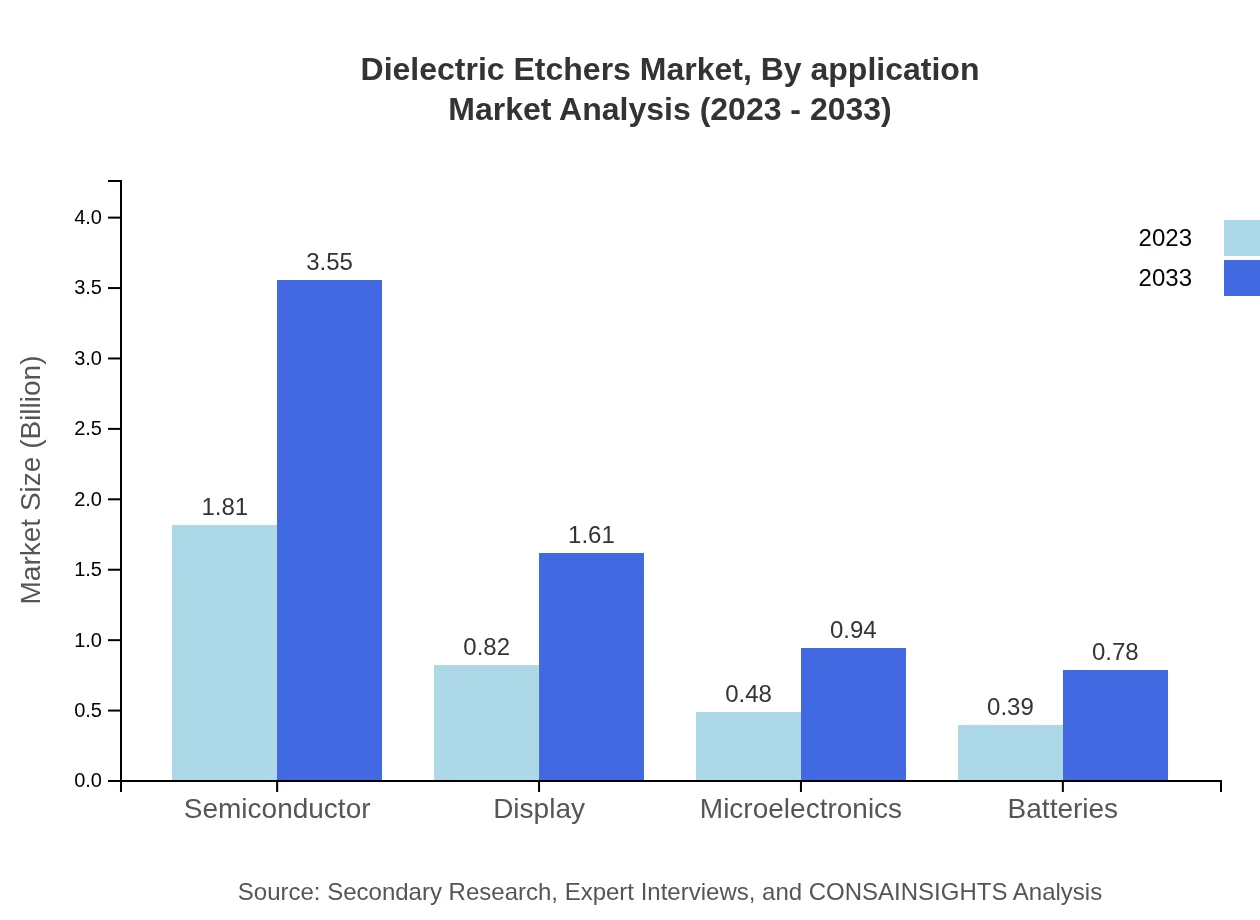

Dielectric Etchers Market Analysis By Application

Key applications of dielectric etchers include semiconductors, displays, automotive electronics, and telecommunications. The semiconductor segment leads with a market size of $1.81 billion in 2023 and is expected to reach $3.55 billion by 2033, holding a significant market share of 51.59%. Displays and automotive electronic applications are also noteworthy contributors to market growth.

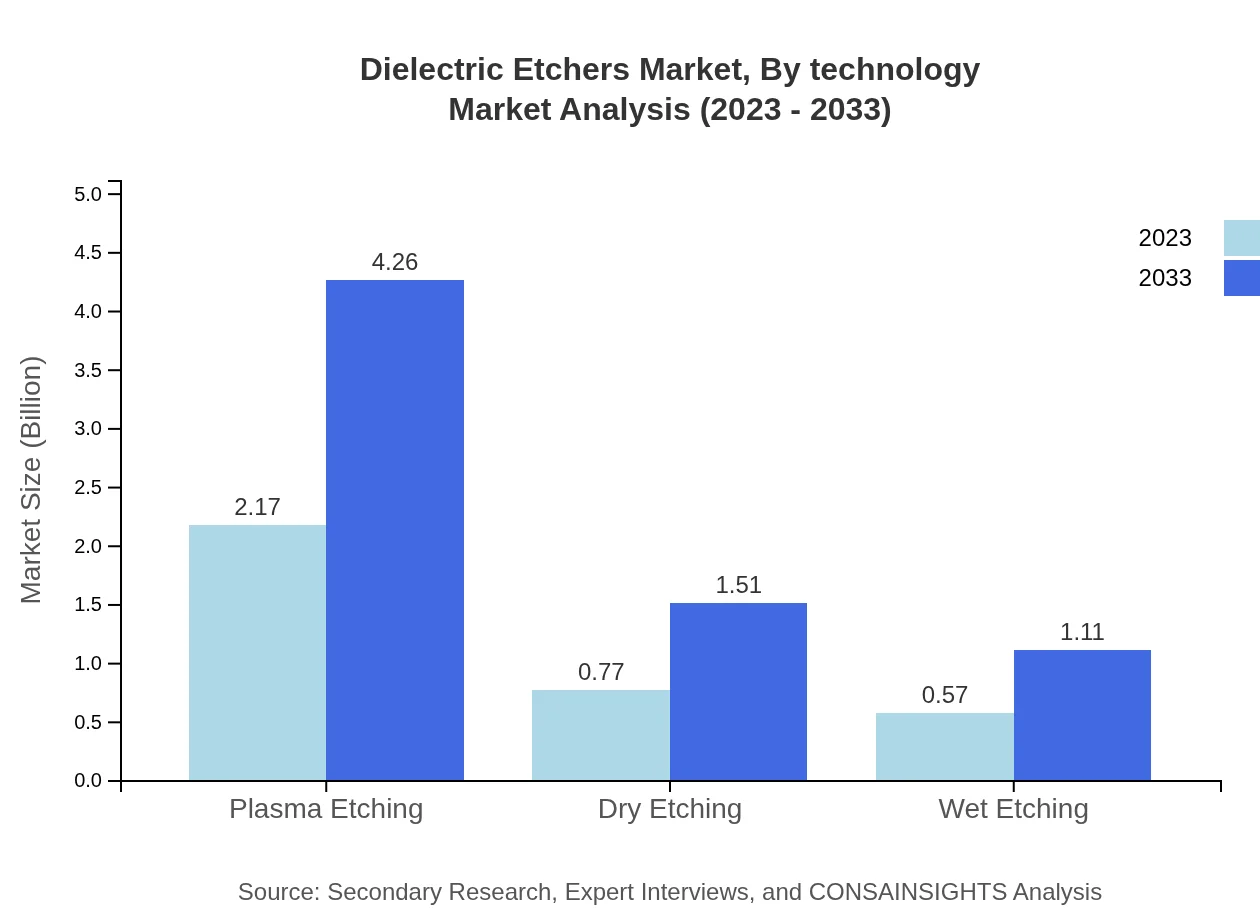

Dielectric Etchers Market Analysis By Technology

The dielectric etchers market utilizes various technologies including plasma etching, dry etching, and wet etching. Plasma etching commands a sizable market with $2.17 billion in 2023, reflecting a share of 61.96%. The dry etching and wet etching technologies are expected to experience gradual growth, underscoring their importance in specific applications.

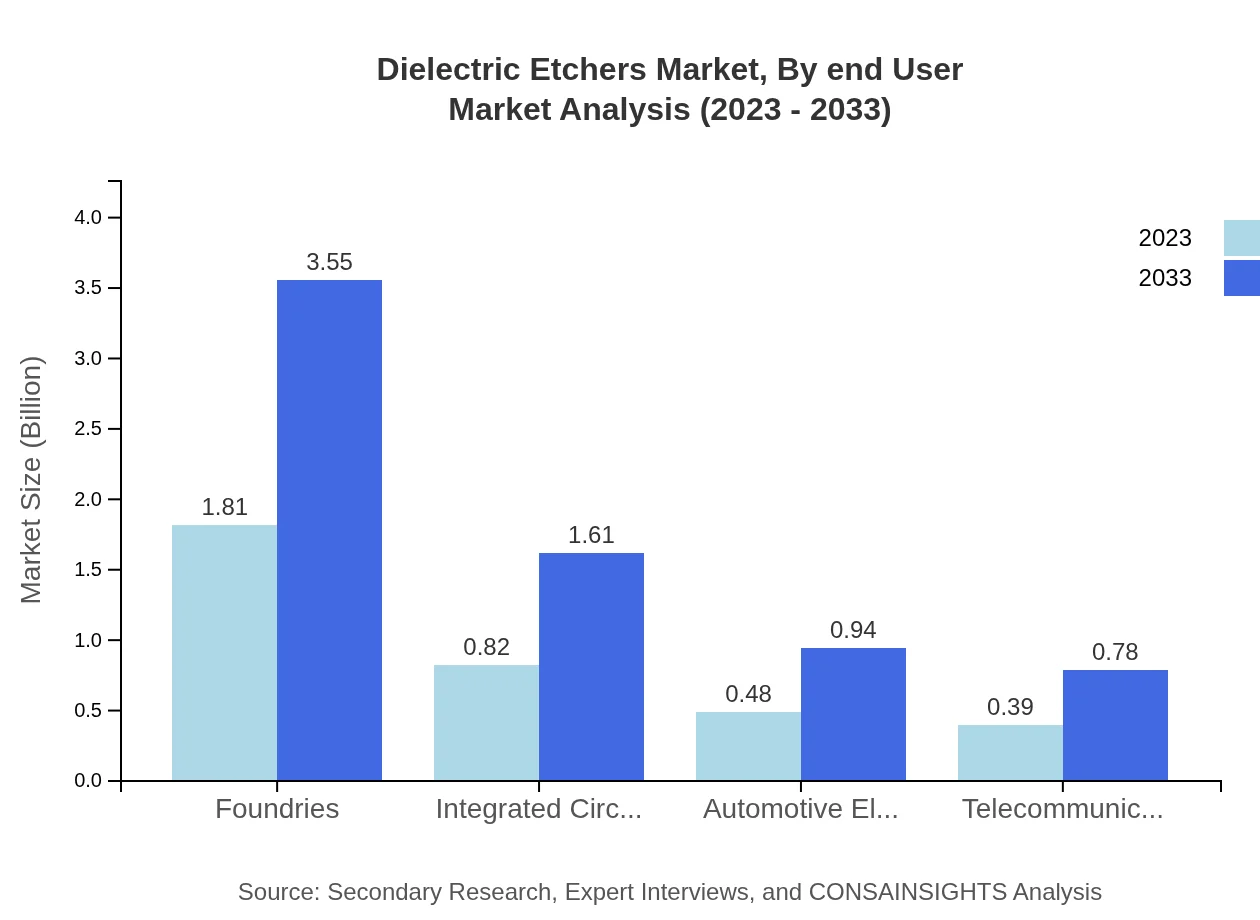

Dielectric Etchers Market Analysis By End User

End-users in the dielectric etchers market primarily consist of semiconductor manufacturers, consumer electronics producers, and telecom companies. The extensive reliance on high-quality semiconductor devices in smartphones and automation systems continues to drive demand. In 2023, the semiconductor segment alone is valued at $1.81 billion, forecasted to grow to $3.55 billion by 2033.

Dielectric Etchers Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Dielectric Etchers Industry

Applied Materials, Inc.:

A leader in materials engineering solutions, Applied Materials provides innovative equipment, services, and software for the semiconductor industry.Lam Research Corporation:

Specializing in wafer fabrication equipment and services, Lam Research helps customers achieve higher yields and lower costs through advanced etching technologies.Tokyo Electron Limited:

Tokyo Electron is one of the largest manufacturers of semiconductor production equipment, including dielectric etching systems, known for their high quality and reliability.ASML Holding N.V.:

ASML, the world’s leading supplier of photolithography equipment for the semiconductor industry, also holds a significant role in dielectric etching and related technologies.We're grateful to work with incredible clients.

FAQs

What is the market size of dielectric etchers?

The dielectric etchers market is projected to grow from $3.5 billion in 2023 to approximately $5.33 billion in 2033, exhibiting a CAGR of 6.8% during the forecast period, driven by advancements in semiconductor manufacturing.

What are the key market players or companies in this dielectric etchers industry?

Key players in the dielectric etchers market include prominent companies like Applied Materials, Tokyo Electron Limited, LAM Research, ASML, and KLA Corporation, contributing significantly to technological advancements and market growth.

What are the primary factors driving the growth in the dielectric etchers industry?

Factors driving market growth include increasing demand for smaller and more efficient electronic devices, advancements in semiconductor manufacturing technologies, and growing applications of dielectrics in various industries.

Which region is the fastest Growing in the dielectric etchers market?

The Asia Pacific region is witnessing significant growth, with the market projected to increase from $0.72 billion in 2023 to $1.42 billion by 2033, making it the fastest growing region in the dielectric etchers market.

Does ConsaInsights provide customized market report data for the dielectric etchers industry?

Yes, ConsaInsights offers customized market report data to meet specific client needs in the dielectric etchers industry, allowing for tailored insights and detailed analysis to support strategic decisions.

What deliverables can I expect from this dielectric etchers market research project?

Expect comprehensive deliverables including market size and growth forecasts, competitive landscape analysis, regional insights, segment breakdown, and actionable recommendations for strategic initiatives.

What are the market trends of dielectric etchers?

Current trends include the shift towards advanced semiconductor technology, rising demand for miniaturized electronics, and increasing investments in R&D, which are all pushing the dielectric etchers market toward innovation and growth.