Digital Servo Press Market Report

Published Date: 22 January 2026 | Report Code: digital-servo-press

Digital Servo Press Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Digital Servo Press market, detailing current trends, market size, and growth forecasts through 2033. Insights such as regional performance and competitive landscape are also included to inform strategic decisions.

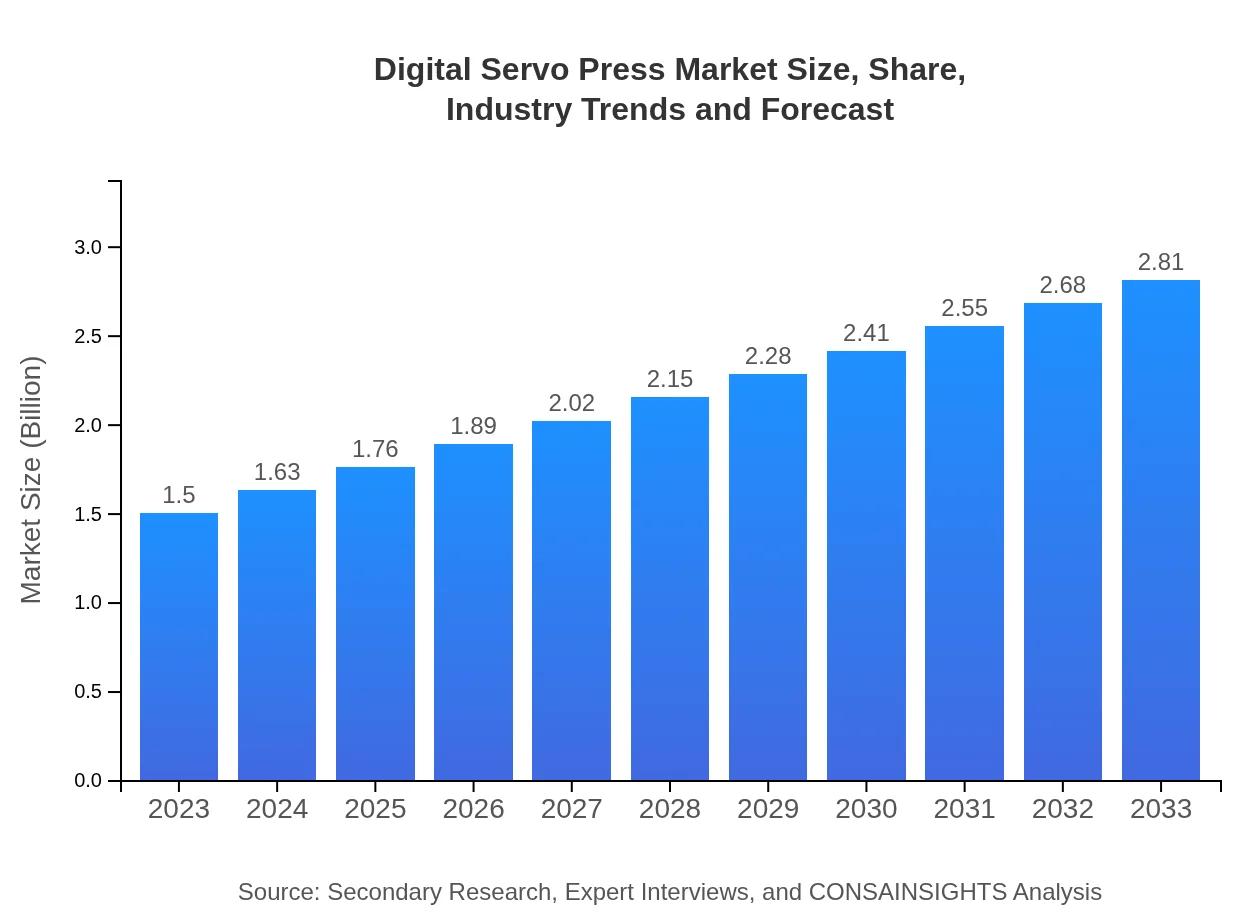

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $1.50 Billion |

| CAGR (2023-2033) | 6.3% |

| 2033 Market Size | $2.81 Billion |

| Top Companies | Schuler Group, AIDA Engineering, Setco, GKN Powder Metallurgy |

| Last Modified Date | 22 January 2026 |

Digital Servo Press Market Overview

Customize Digital Servo Press Market Report market research report

- ✔ Get in-depth analysis of Digital Servo Press market size, growth, and forecasts.

- ✔ Understand Digital Servo Press's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Digital Servo Press

What is the Market Size & CAGR of Digital Servo Press market in 2023?

Digital Servo Press Industry Analysis

Digital Servo Press Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Digital Servo Press Market Analysis Report by Region

Europe Digital Servo Press Market Report:

The European Digital Servo Press market is set to increase from $0.56 billion in 2023 to $1.04 billion by 2033. The region focuses on sustainability and environmental regulations, which are pushing manufacturers to adopt advanced, energy-efficient solutions that digital servo presses provide.Asia Pacific Digital Servo Press Market Report:

In the Asia Pacific region, the Digital Servo Press market is projected to grow from $0.28 billion in 2023 to $0.52 billion by 2033, driven by rapid industrialization and growing automotive production in countries like China, Japan, and South Korea. The region is witnessing significant technological advancements and increased adoption of automation across various sectors.North America Digital Servo Press Market Report:

In North America, the market is anticipated to grow from $0.48 billion in 2023 to $0.90 billion by 2033. The United States leads in the implementation of advanced manufacturing technologies, driven by the need for product innovation and operational efficiency across industries such as aerospace and automotive.South America Digital Servo Press Market Report:

The South American market is expected to expand from $0.08 billion in 2023 to $0.16 billion by 2033, primarily due to growing manufacturing sectors focused on automotive and consumer electronics. Efforts to modernize production systems and enhance efficiency are contributing to market growth.Middle East & Africa Digital Servo Press Market Report:

For the Middle East and Africa, the market is expected to grow from $0.10 billion in 2023 to $0.19 billion by 2033. Initiatives to enhance industrial production capabilities and diversification of economies are supporting the adoption of digital servo press technologies.Tell us your focus area and get a customized research report.

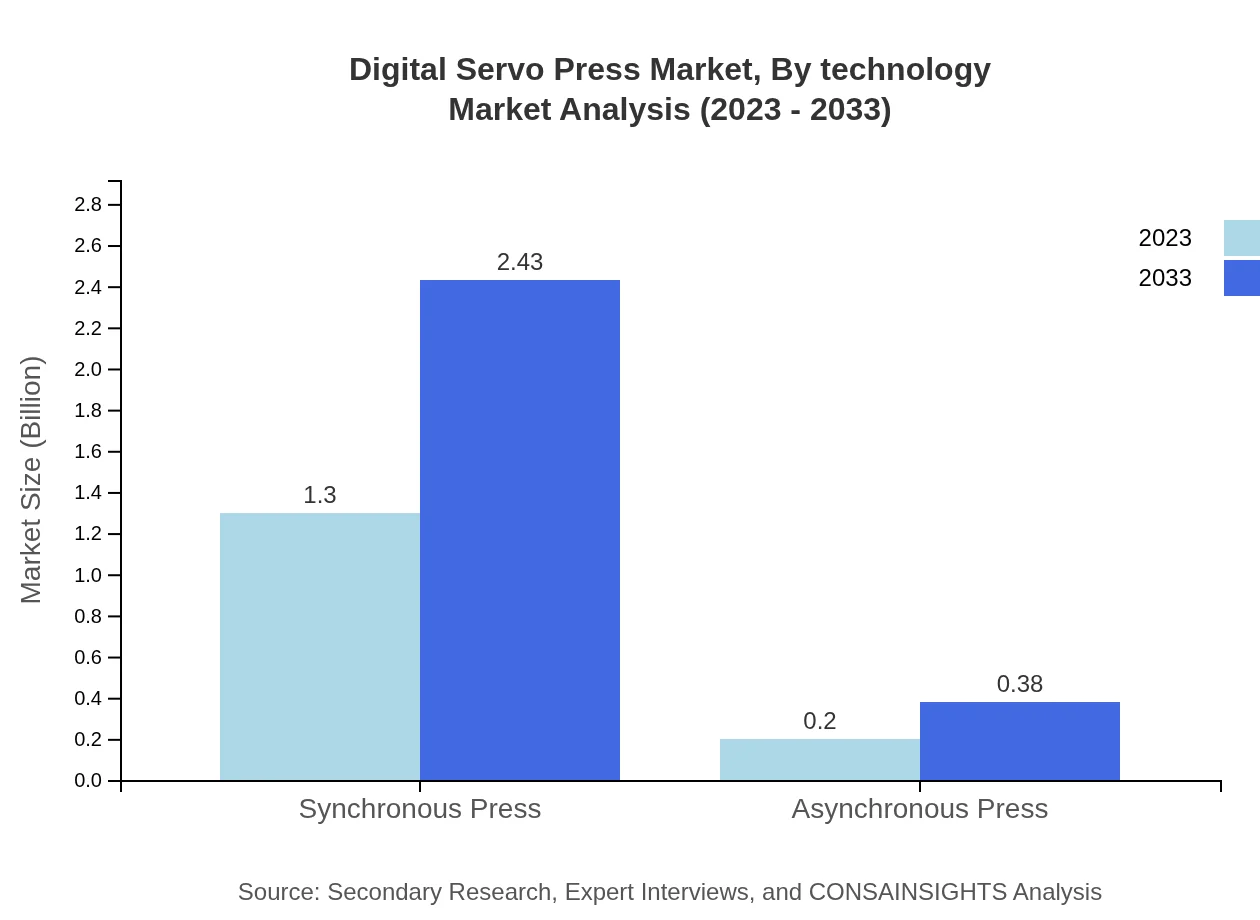

Digital Servo Press Market Analysis By Technology

The Digital Servo Press market is categorized into two primary technologies: Synchronous and Asynchronous Presses. The Synchronous Press segment, dominating with a market size of $1.30 billion in 2023, is projected to reach $2.43 billion by 2033, representing an 86.63% market share. The Asynchronous Press segment accounts for a smaller share, with a market size of $0.20 billion in 2023, expected to grow to $0.38 billion by 2033. This delineation highlights the preference for synchronous presses due to their enhanced efficiency and speed in operations.

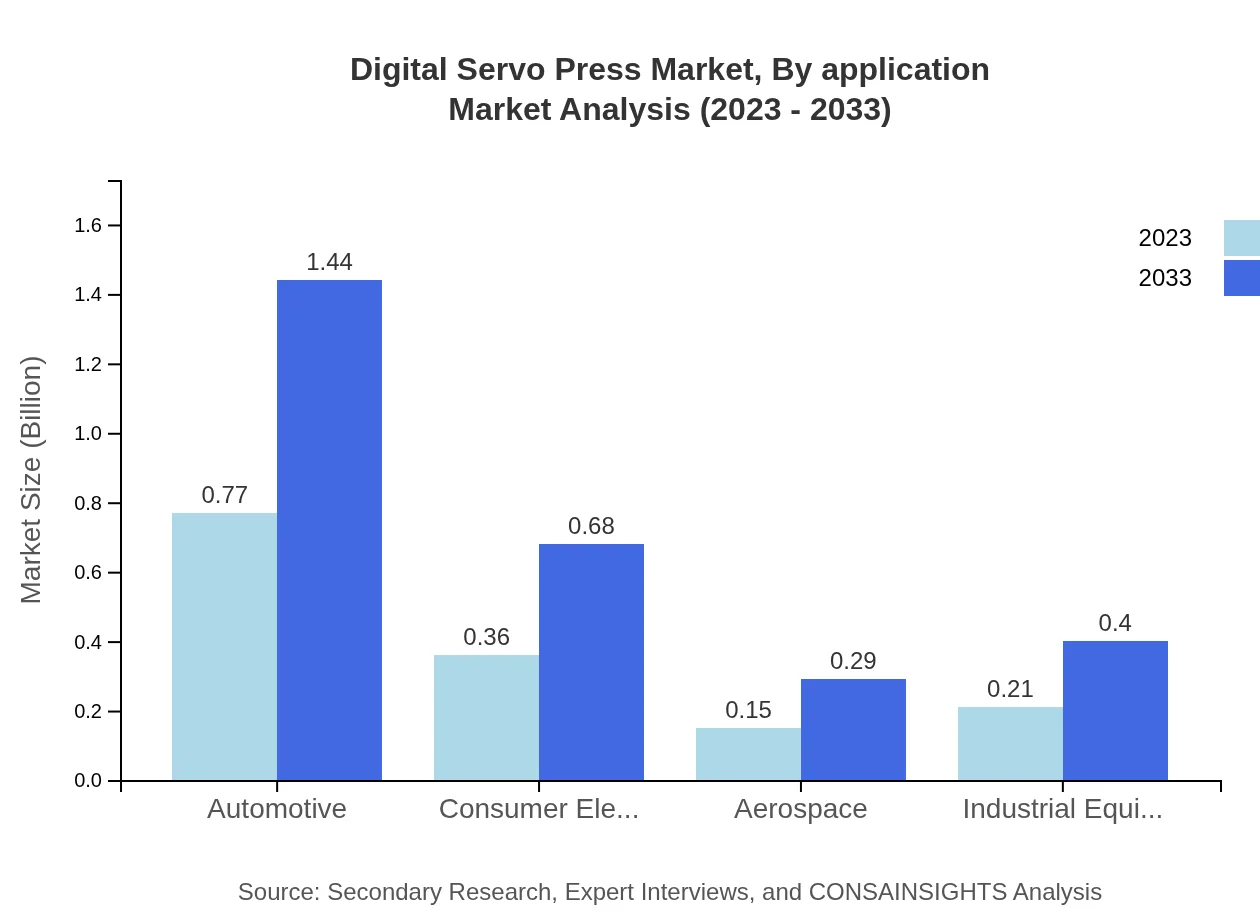

Digital Servo Press Market Analysis By Application

Applications of Digital Servo Press technology span several sectors, with Automotive leading at a market size of $0.77 billion in 2023, projected to grow to $1.44 billion by 2033, representing a 51.25% market share. Consumer Electronics follows with a market size of $0.36 billion in 2023, expected to reach $0.68 billion by 2033. Other notable applications include Aerospace with a market size of $0.15 billion and Industrial Equipment capturing 14.27% market share.

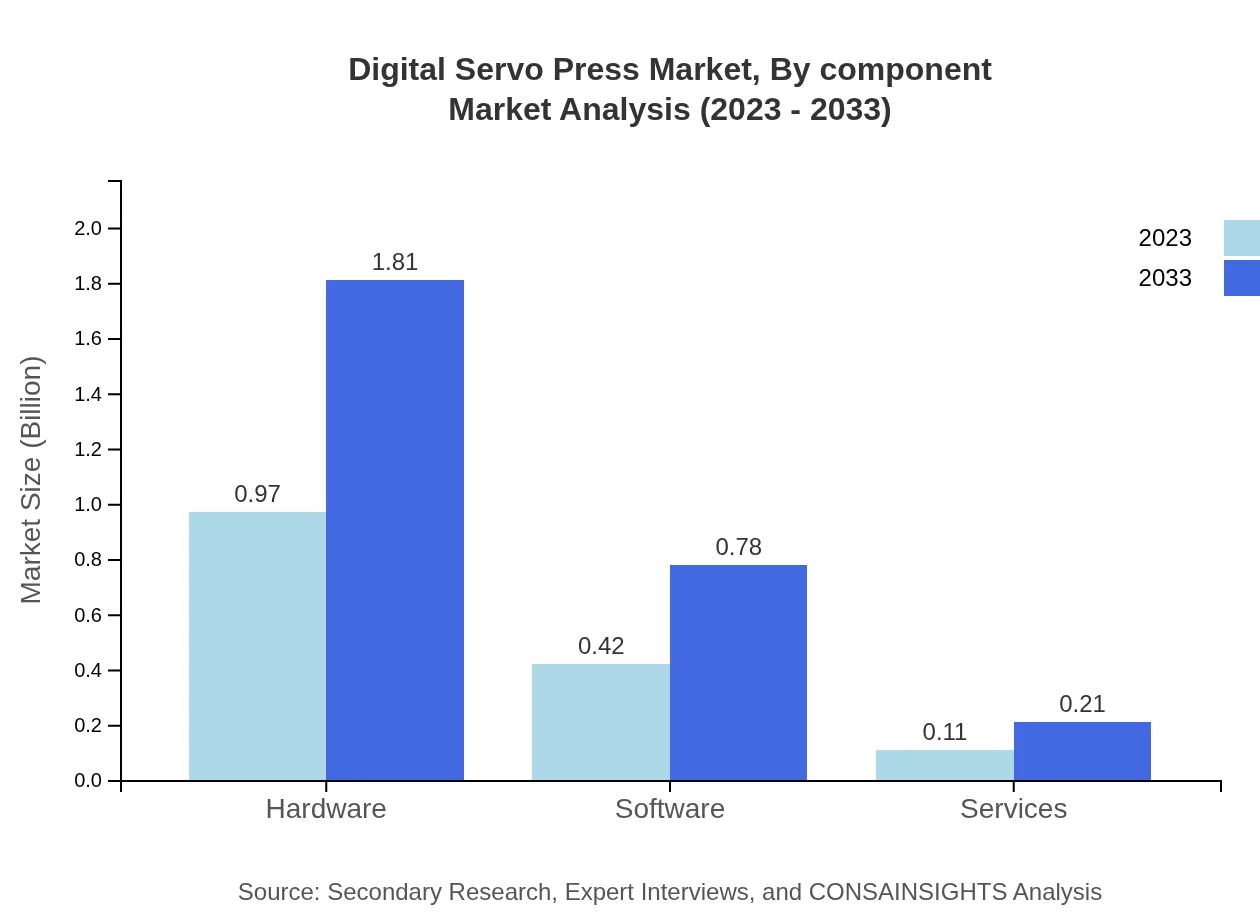

Digital Servo Press Market Analysis By Component

The market is segmented into Hardware, Software, and Services. The Hardware segment dominates the market with a size of $0.97 billion in 2023, anticipated to grow to $1.81 billion by 2033, maintaining a 64.49% market share. The Software segment is expected to rise from $0.42 billion to $0.78 billion, while Services will see growth from $0.11 billion to $0.21 billion, indicating a strong trend towards integrated solutions to enhance operational capabilities.

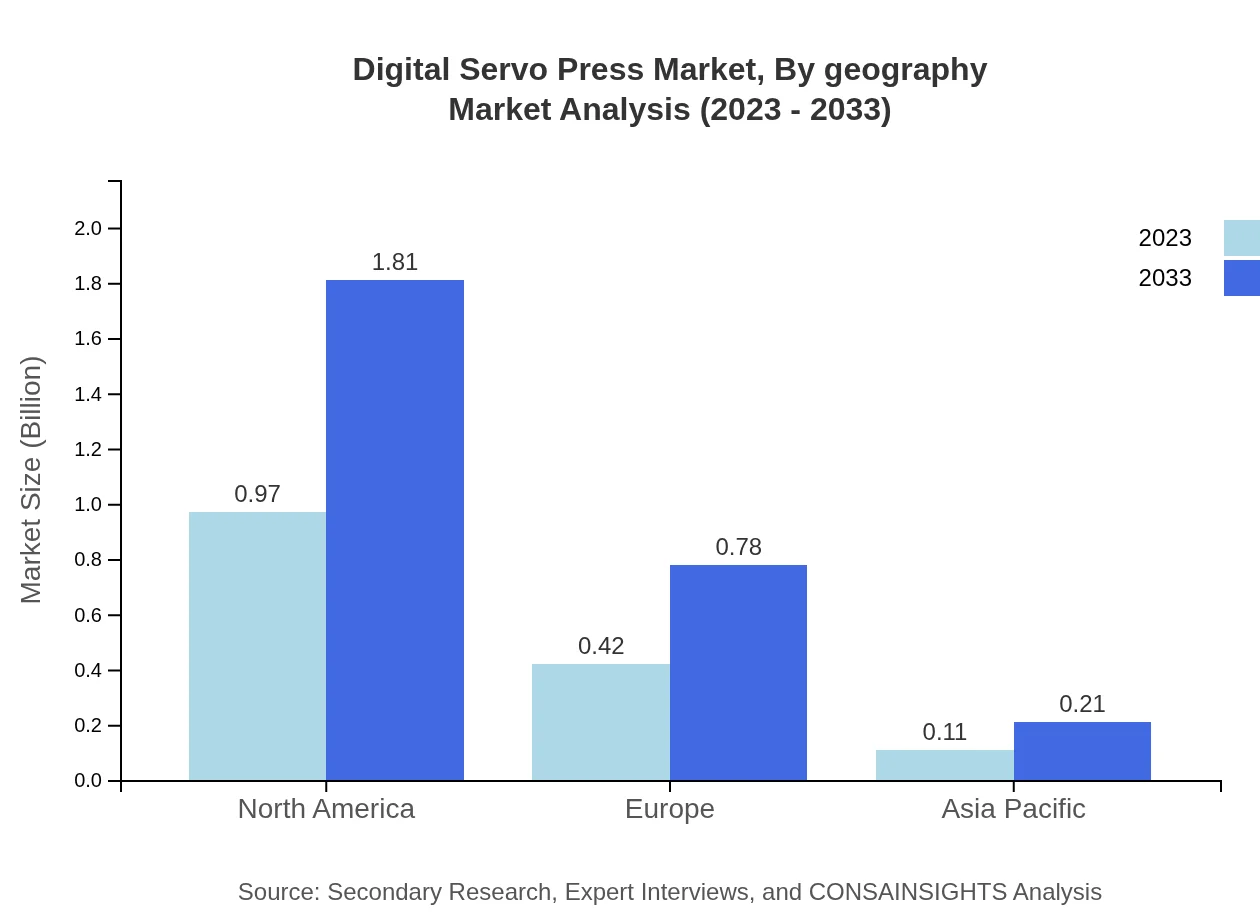

Digital Servo Press Market Analysis By Geography

Geographically, the North American market leads with a size of $0.97 billion expected to remain stable by 2033 at $1.81 billion. Europe follows with growth from $0.42 billion to $0.78 billion, while Asia Pacific's market size is forecasted to increase from $0.11 billion to $0.21 billion, demonstrating varying growth dynamics influenced by regional manufacturing demands.

Digital Servo Press Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Digital Servo Press Industry

Schuler Group:

A leading provider of innovative press technology and automation solutions, Schuler offers a wide range of digital servo presses designed for precision and optimization in high-volume production.AIDA Engineering:

Renowned for its advanced press and automation technologies, AIDA Engineering develops high-performance digital servo presses that excel in the automotive and electronics manufacturing sectors.Setco:

Setco specializes in producing high-quality servo presses known for their durability and precision, serving industries such as aerospace and automotive.GKN Powder Metallurgy:

GKN is a global leader in manufacturing powdered metal components and is significant in using digital servo pressing technologies to enhance product quality and efficiency.We're grateful to work with incredible clients.

FAQs

What is the market size of digital Servo Press?

The digital servo press market is projected to reach $1.5 billion by 2033, with a compound annual growth rate (CAGR) of 6.3%. This growth reflects increasing industry adoption and technological advancements in automation.

What are the key market players or companies in this digital Servo Press industry?

Key players in the digital servo press industry include leading machinery and automation firms. They play a significant role in driving innovation, enhancing production efficiency, and expanding market reach through strategic partnerships and acquisitions.

What are the primary factors driving the growth in the digital Servo Press industry?

The growth in the digital servo press industry is primarily driven by rising demand for automation in manufacturing, the need for precision in production processes, advancements in technology, and increasing investments in smart infrastructure and Industry 4.0 initiatives.

Which region is the fastest Growing in the digital Servo Press?

Among the regions, Europe is expected to witness the fastest growth in the digital servo press market, increasing from $0.56 billion in 2023 to $1.04 billion in 2033. Strong industrial growth and automation trends contribute to this expansion.

Does ConsaInsights provide customized market report data for the digital Servo Press industry?

Yes, ConsaInsights offers customized market report data tailored to specific client needs in the digital servo press industry. Clients can request detailed insights, specific segments, and region-focused analyses for strategic decision-making.

What deliverables can I expect from this digital Servo Press market research project?

Upon completion of the digital servo press market research project, clients can expect comprehensive reports, market size evaluations, trend analyses, segment breakdowns, and insights into competitive dynamics to aid in strategic planning.

What are the market trends of digital Servo Press?

Current market trends in the digital servo press industry include an increase in demand for high-precision applications, the integration of AI and IoT in manufacturing processes, and a growing focus on sustainable practices and energy efficiency across production lines.