Distillation Systems Market Report

Published Date: 31 January 2026 | Report Code: distillation-systems

Distillation Systems Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the distillation systems market, encompassing trends, forecasts, and insights from 2023 to 2033. It covers market segmentation, regional analysis, industry leaders, and significant growth opportunities in the distillation sector.

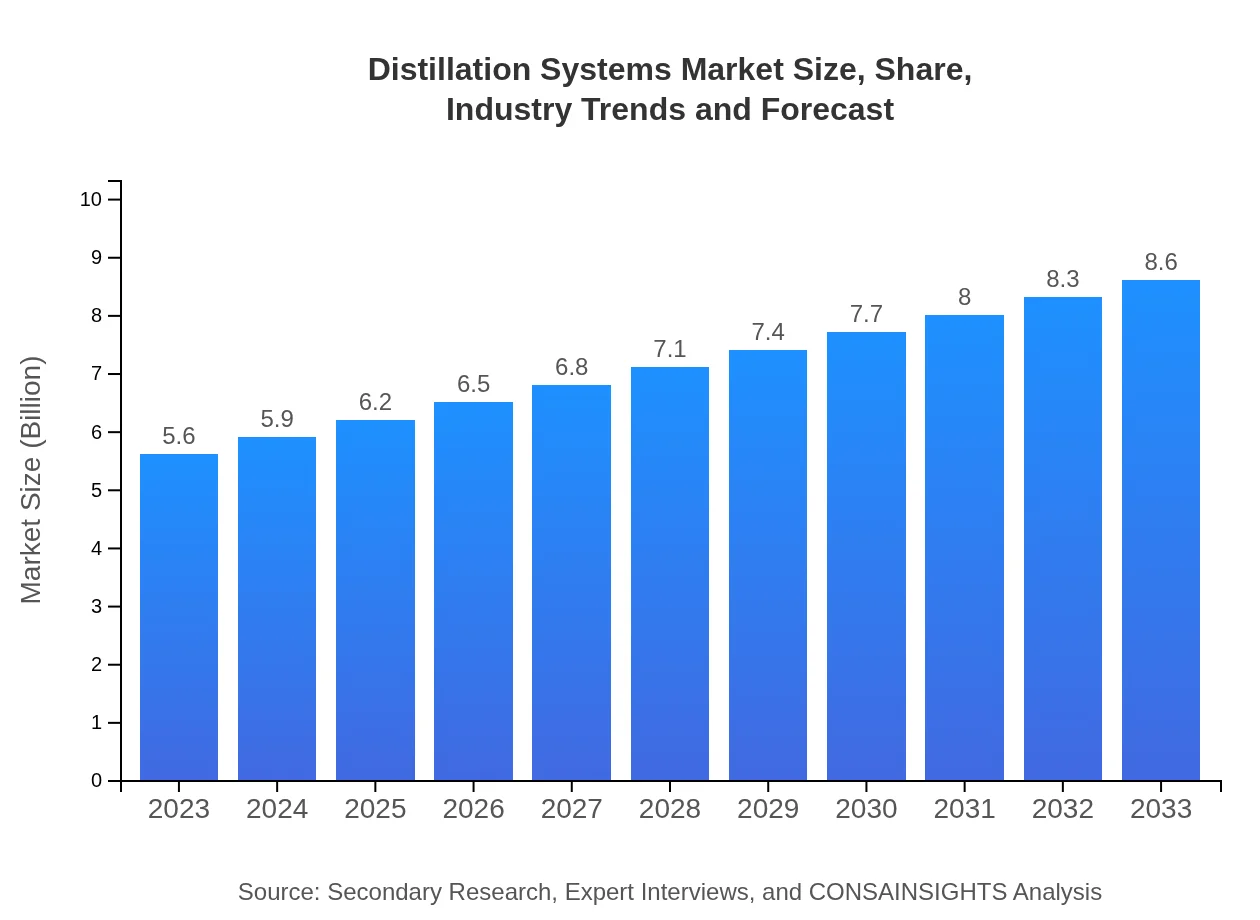

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.60 Billion |

| CAGR (2023-2033) | 4.3% |

| 2033 Market Size | $8.60 Billion |

| Top Companies | Honeywell Process Solutions, GEA Group, Yamato Scientific, Koch Modular Process Systems |

| Last Modified Date | 31 January 2026 |

Distillation Systems Market Overview

Customize Distillation Systems Market Report market research report

- ✔ Get in-depth analysis of Distillation Systems market size, growth, and forecasts.

- ✔ Understand Distillation Systems's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Distillation Systems

What is the Market Size & CAGR of Distillation Systems market in 2023?

Distillation Systems Industry Analysis

Distillation Systems Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Distillation Systems Market Analysis Report by Region

Europe Distillation Systems Market Report:

Europe's distillation systems market, estimated at $1.60 billion in 2023 and forecasted to reach $2.45 billion by 2033, is led by stringent regulations promoting the use of energy-efficient systems. Germany, France, and the UK are notable markets, with a solid focus on sustainability driving demand.Asia Pacific Distillation Systems Market Report:

The Asia Pacific region, valued at $1.22 billion in 2023, is projected to reach $1.88 billion by 2033, showcasing substantial growth. Major industrial activities combined with rapid urbanization and a booming manufacturing sector are driving this trend. Countries like China and India are key contributors to this growth, leveraging investments in chemical processing and food industries.North America Distillation Systems Market Report:

North America's market, projected to grow from $1.84 billion in 2023 to $2.82 billion in 2033, is fueled by advancements in technology innovation and strict adherence to regulations concerning environmental sustainability. The presence of major pharmaceutical and chemical companies in this region enhances the market's growth prospects.South America Distillation Systems Market Report:

In South America, the distillation systems market is valued at $0.46 billion in 2023 and is anticipated to grow to $0.70 billion by 2033. The demand for distillation systems in oil refining and chemical production, alongside increasing investments in infrastructure, are driving the market's expansion in this region.Middle East & Africa Distillation Systems Market Report:

Valued at $0.48 billion in 2023, the Middle East and Africa distillation systems market is anticipated to grow to $0.74 billion by 2033. The oil and gas sector heavily influences this market, with investments in refining technologies expected to spur growth significantly.Tell us your focus area and get a customized research report.

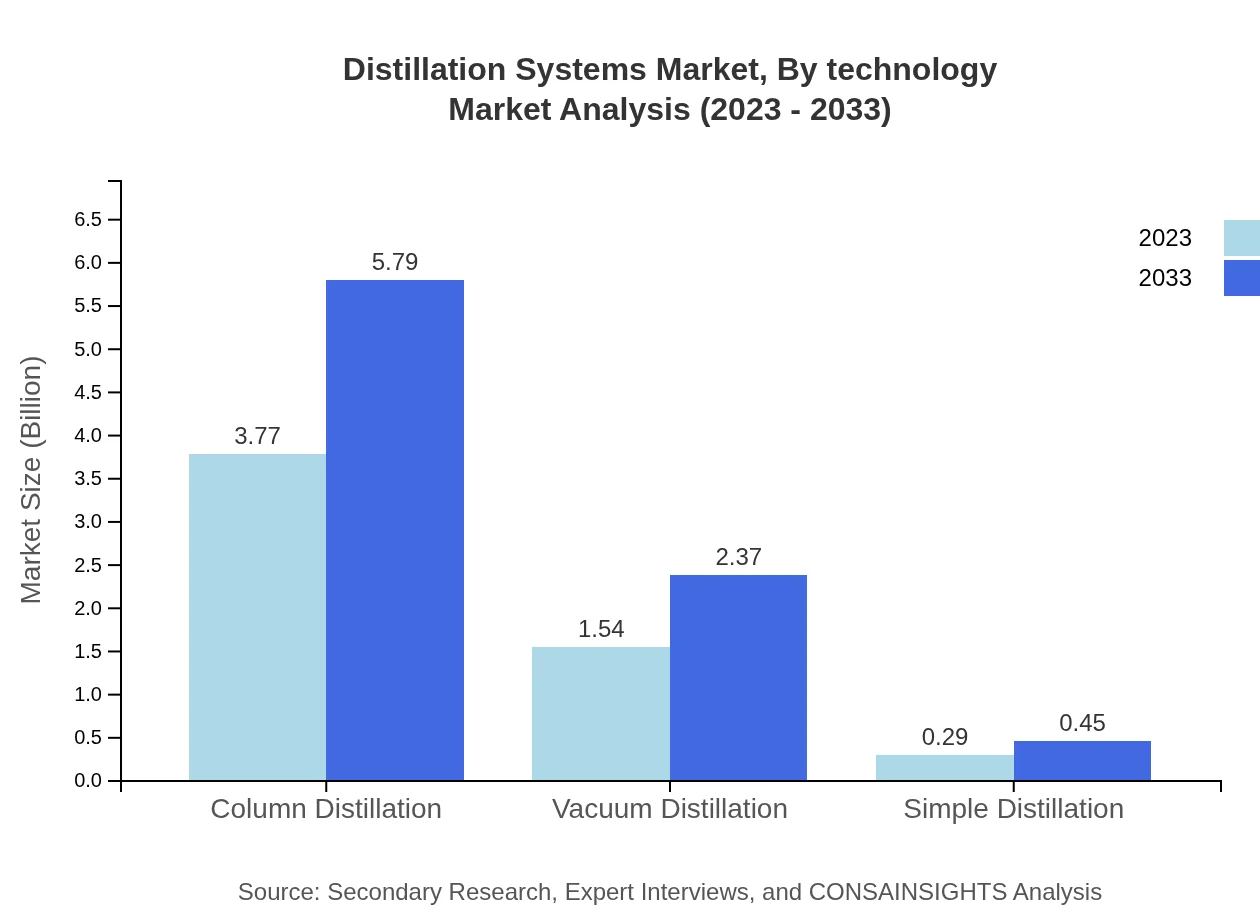

Distillation Systems Market Analysis By Technology

The segment of distillation technologies is vital, with Column Distillation holding a significant share of $3.77 billion in 2023, projected to grow to $5.79 billion by 2033. Vacuum Distillation represents an essential process for handling heat-sensitive materials, maintaining a market size of $1.54 billion and expected to reach $2.37 billion within the forecast period. Satellite technologies, like simple distillation, are also crucial despite their smaller market share.

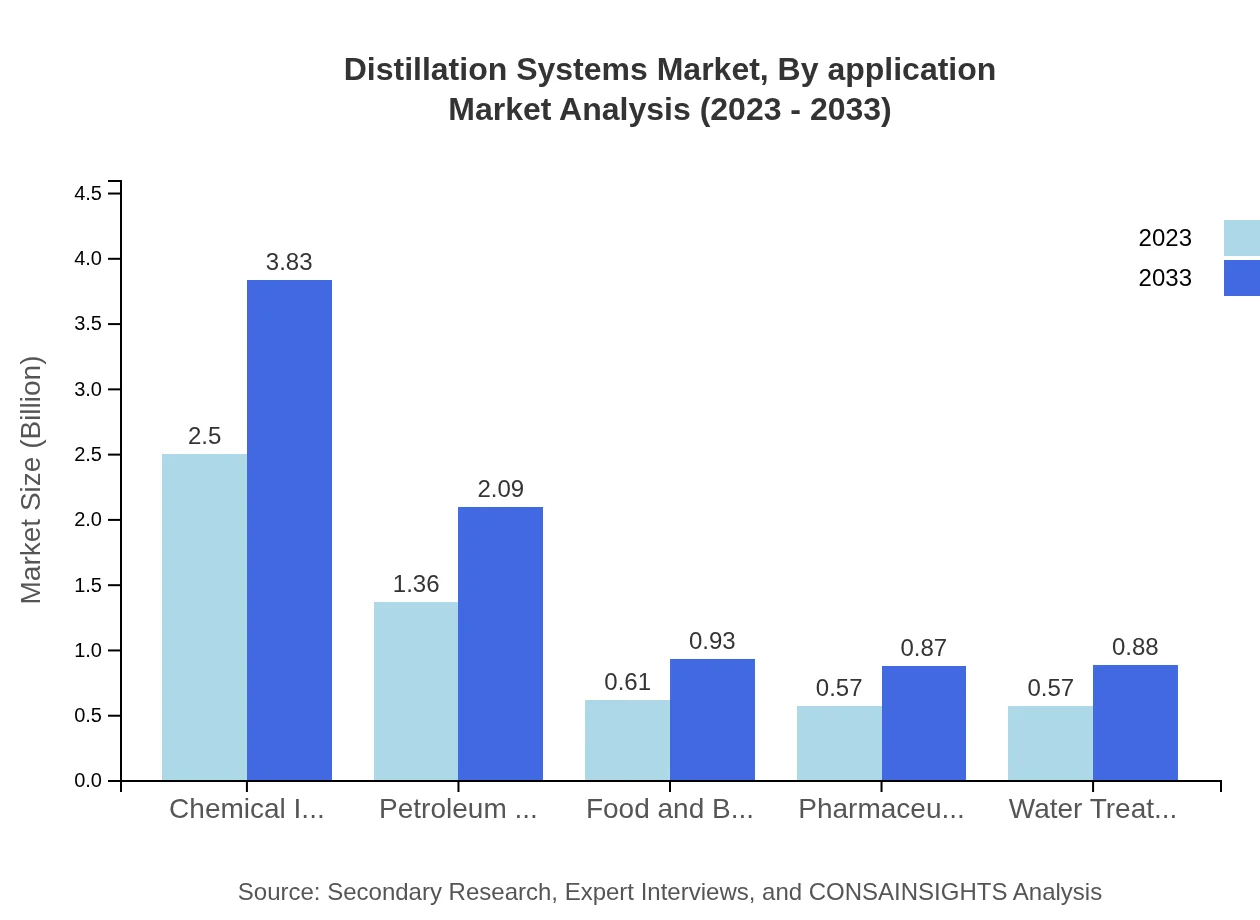

Distillation Systems Market Analysis By Application

The industrial applications segment dominates the market, valued at $2.93 billion in 2023, with significant growth prospects reaching $4.51 billion by 2033. Applications in the chemical industry alone reached $2.50 billion in 2023, driven by the need for separation processes. The food and beverage sector is expected to account for steady growth, emphasizing the need for high-quality distillation processes.

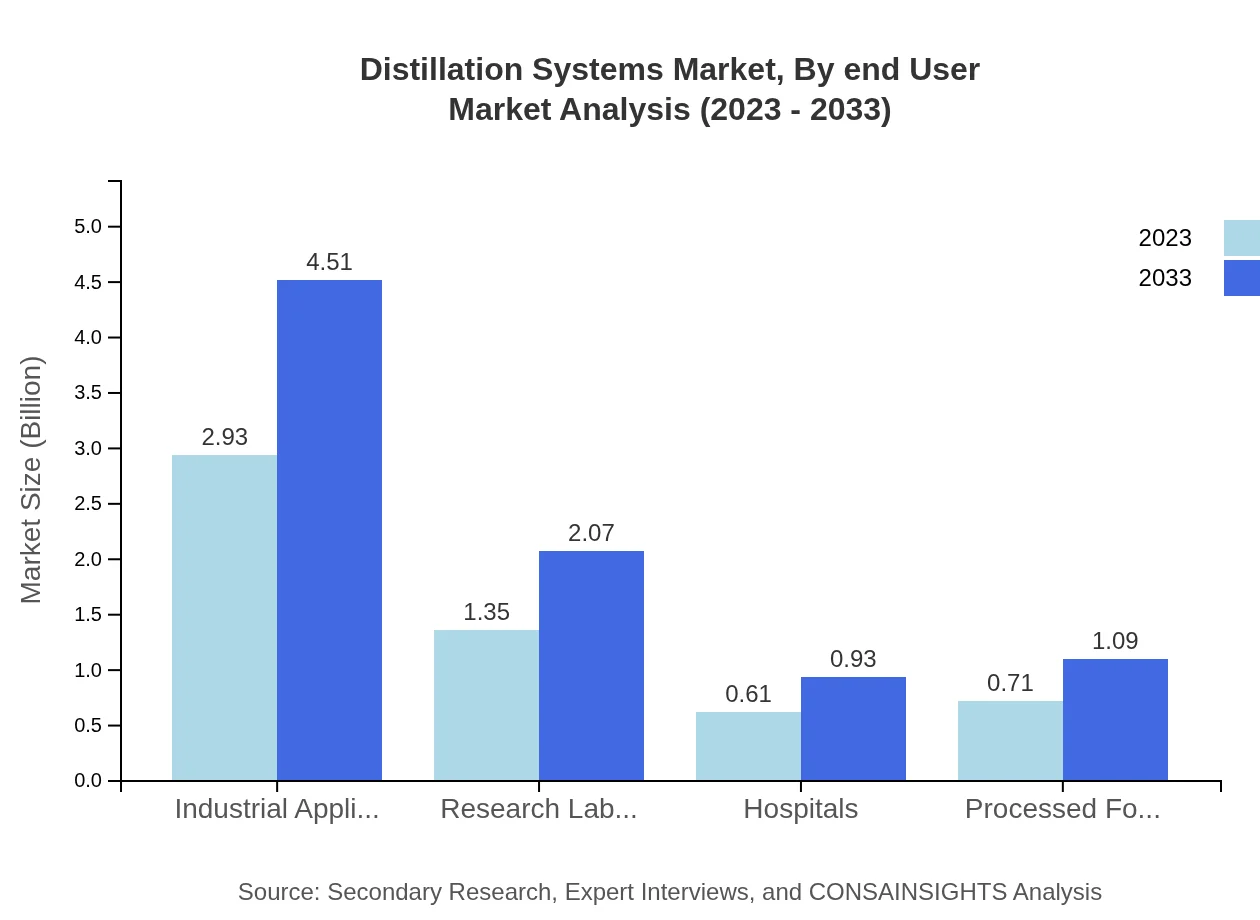

Distillation Systems Market Analysis By End User

In terms of end-user segmentation, industrial applications contribute the largest share, resulting in a size of $2.93 billion in 2023 and a projected $4.51 billion by 2033. Industries such as pharmaceuticals, with $0.57 billion in 2023, are growing steadily; however, the chemical sector leads with significant earnings and growth potential.

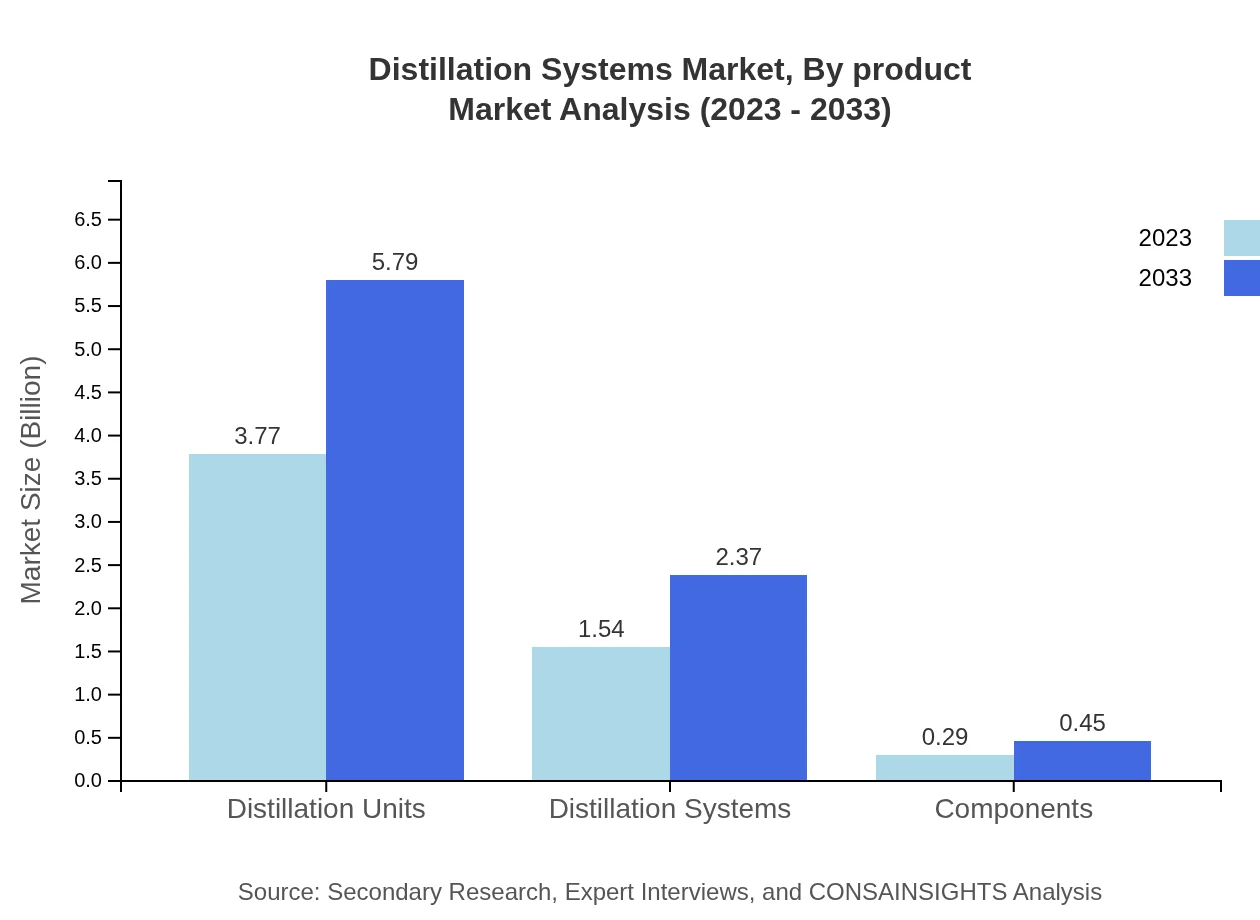

Distillation Systems Market Analysis By Product

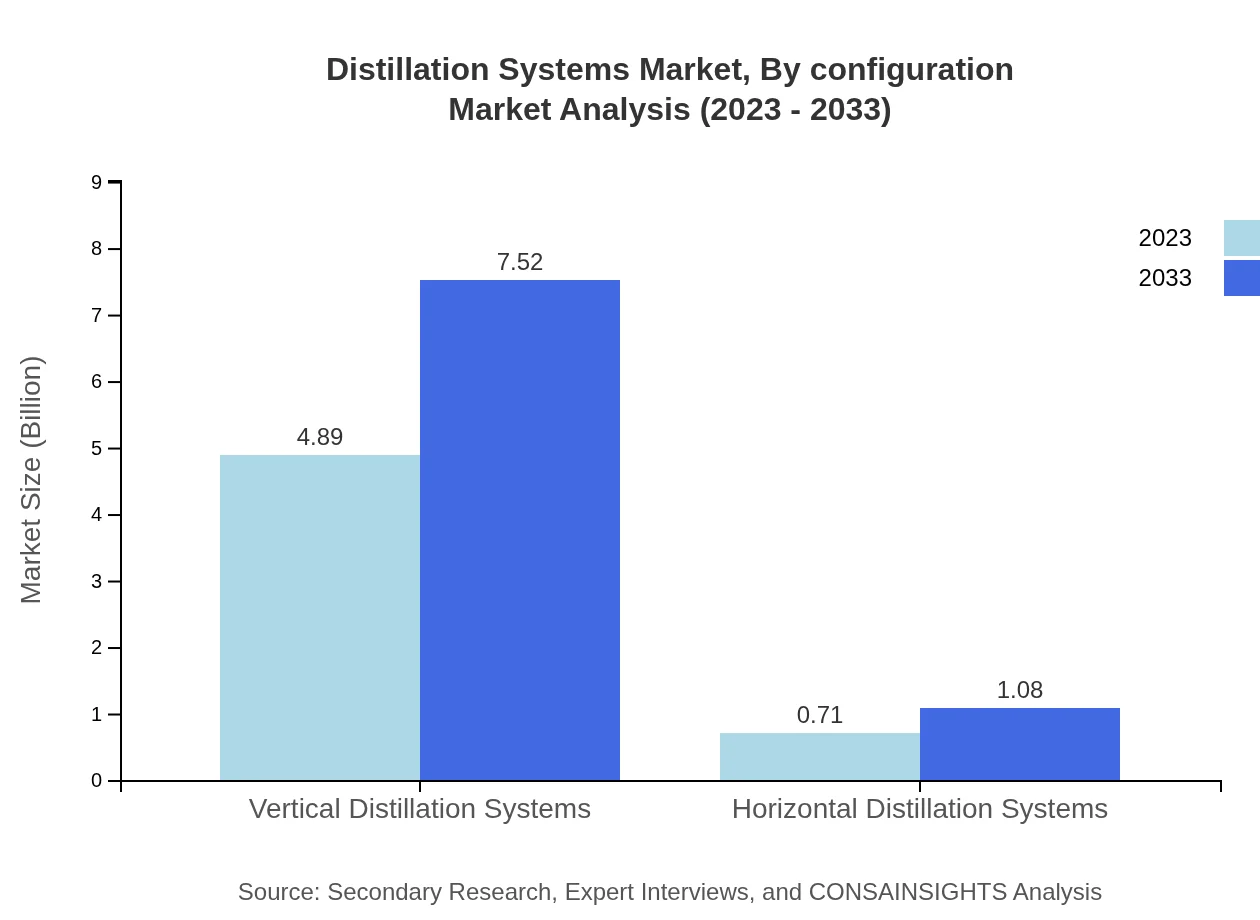

The distillation systems market's product segmentation primarily includes vertical and horizontal distillation systems, with vertical systems maintaining a substantial share at $4.89 billion projected to $7.52 billion by 2033. The horizontal systems, while smaller at $0.71 billion, represent an emerging market segment as manufacturers explore diverse system configurations.

Distillation Systems Market Analysis By Configuration

The market for distillation systems by configuration reveals diverse setups suited for various applications. The focus is on enhancing system compatibility and efficiency to boost performance. Innovations in modular designs are also gaining traction as industries seek systems that offer flexibility and scalability, catering to changing production needs.

Distillation Systems Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Distillation Systems Industry

Honeywell Process Solutions:

A leader in industrial automation, offering innovative solutions that enhance distillation processes through advanced technology and consultancy services.GEA Group:

Specializes in food processing technologies, as well as distillation systems for various applications, with a strong emphasis on sustainable solutions.Yamato Scientific:

Known for their high-quality laboratory equipment, including advanced distillation systems widely used in academic and industrial research.Koch Modular Process Systems:

Specializes in modular process technologies including innovative distillation solutions aimed at increasing efficiency in processing plants.We're grateful to work with incredible clients.

FAQs

What is the market size of distillation systems?

The global distillation systems market is valued at approximately $5.6 billion in 2023, with a projected CAGR of 4.3% from 2023 to 2033, leading to significant growth potential in the upcoming decade.

What are the key market players or companies in the distillation systems industry?

Key players in the distillation systems market include prominent companies such as Siemens, Alfa Laval, and Thermo Fisher Scientific, which offer advanced technologies and innovative solutions specializing in various distillation processes.

What are the primary factors driving the growth in the distillation systems industry?

Factors driving growth include increasing industrial applications, advancements in technology, heightened demand for pure solvents, and regulatory requirements for quality standards across sectors such as pharmaceuticals and chemicals.

Which region is the fastest Growing in the distillation systems?

The Asia Pacific region is projected to experience rapid growth, from $1.22 billion in 2023 to $1.88 billion by 2033, driven by industrial expansion and the rising number of manufacturing units.

Does ConsaInsights provide customized market report data for the distillation systems industry?

Yes, ConsaInsights offers customized market reports tailored to client needs, enabling specific insights into market dynamics, trends, and competitive landscapes within the distillation systems sector.

What deliverables can I expect from this distillation systems market research project?

Deliverables typically include comprehensive market analysis reports, detailed segment breakdowns, competitive landscape assessments, and forecasts, offering actionable insights for strategic planning in the distillation systems market.

What are the market trends of distillation systems?

Current trends include the increasing adoption of energy-efficient technologies, the evolution towards automation in manufacturing processes, and a shift towards sustainable practices in distillation methods across various industries.