Double Block Bleed Valves Market Report

Published Date: 22 January 2026 | Report Code: double-block-bleed-valves

Double Block Bleed Valves Market Size, Share, Industry Trends and Forecast to 2033

This report analyzes the Double Block Bleed Valves market, providing insights on market sizes, growth rates, and trends from 2023 to 2033. It covers industry analysis, segmentation, regional insights, and key players for comprehensive market understanding.

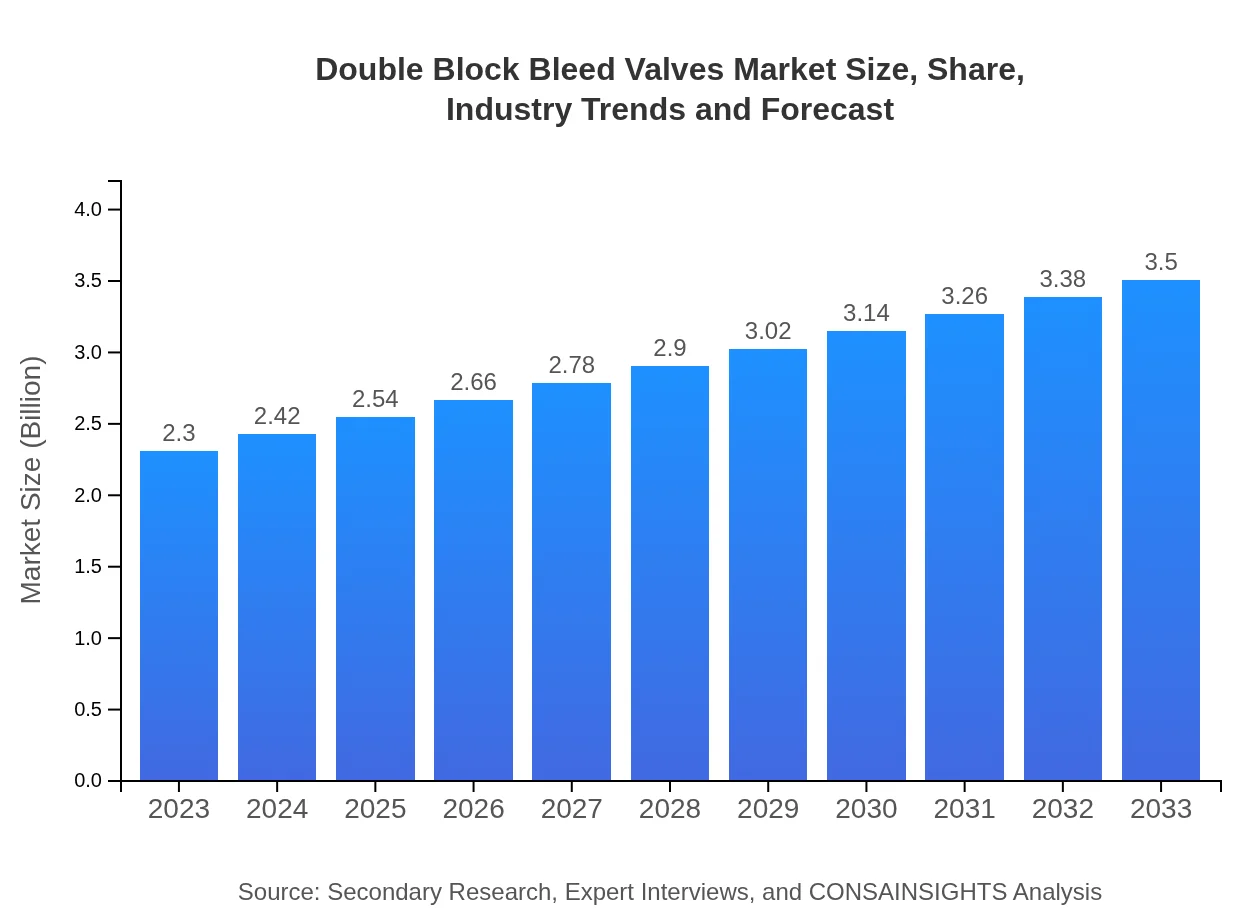

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $2.30 Billion |

| CAGR (2023-2033) | 4.2% |

| 2033 Market Size | $3.50 Billion |

| Top Companies | Emerson Electric Co., Valmet Corporation, Kitz Corporation, Spirax Sarco Ltd. |

| Last Modified Date | 22 January 2026 |

Double Block Bleed Valves Market Overview

Customize Double Block Bleed Valves Market Report market research report

- ✔ Get in-depth analysis of Double Block Bleed Valves market size, growth, and forecasts.

- ✔ Understand Double Block Bleed Valves's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Double Block Bleed Valves

What is the Market Size & CAGR of the Double Block Bleed Valves market in 2023?

Double Block Bleed Valves Industry Analysis

Double Block Bleed Valves Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Double Block Bleed Valves Market Analysis Report by Region

Europe Double Block Bleed Valves Market Report:

Europe shows a steady growth trajectory with a market value of 0.64 billion USD in 2023, projected to reach 0.97 billion USD by 2033. The focus on regulatory compliance regarding safety features significantly boosts demand.Asia Pacific Double Block Bleed Valves Market Report:

The Asia Pacific region is seeing a growing demand for Double Block Bleed Valves, with a market size of 0.43 billion USD in 2023, projected to reach 0.66 billion USD by 2033. This growth is primarily driven by the rapid industrialization and expanding oil and gas sector in countries like China and India.North America Double Block Bleed Valves Market Report:

North America continues to lead with a market size of 0.88 billion USD in 2023, anticipated to increase to 1.34 billion USD by 2033. The presence of major oil and gas companies and stringent safety regulations drive the market in this region.South America Double Block Bleed Valves Market Report:

In South America, the market is valued at 0.19 billion USD in 2023, expected to grow to 0.29 billion USD by 2033. This growth is attributed to the increasing activities in oil and gas exploration and production.Middle East & Africa Double Block Bleed Valves Market Report:

The Middle East and Africa's market is valued at 0.16 billion USD in 2023, expected to grow to 0.24 billion USD by 2033, driven largely by ongoing oil and gas projects and infrastructure development.Tell us your focus area and get a customized research report.

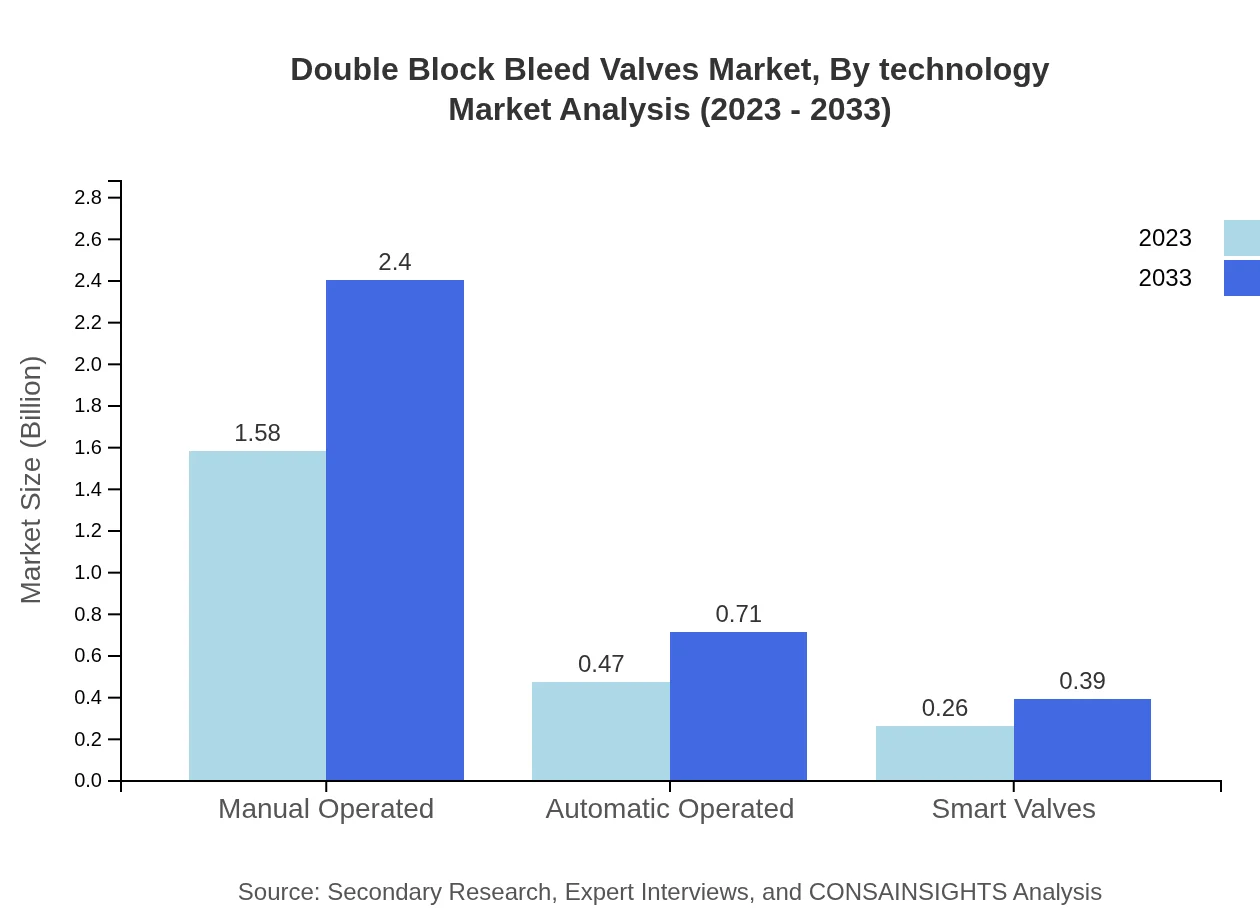

Double Block Bleed Valves Market Analysis By Technology

The Double Block Bleed Valves market is segmented by technology into manual operated, automatic operated, and smart valves. Manual operated valves dominate the market due to their reliability and ease of maintenance, holding 68.61% market share in 2023. Automatic and smart valves are gaining traction, set to expand their share as industries trend towards automation.

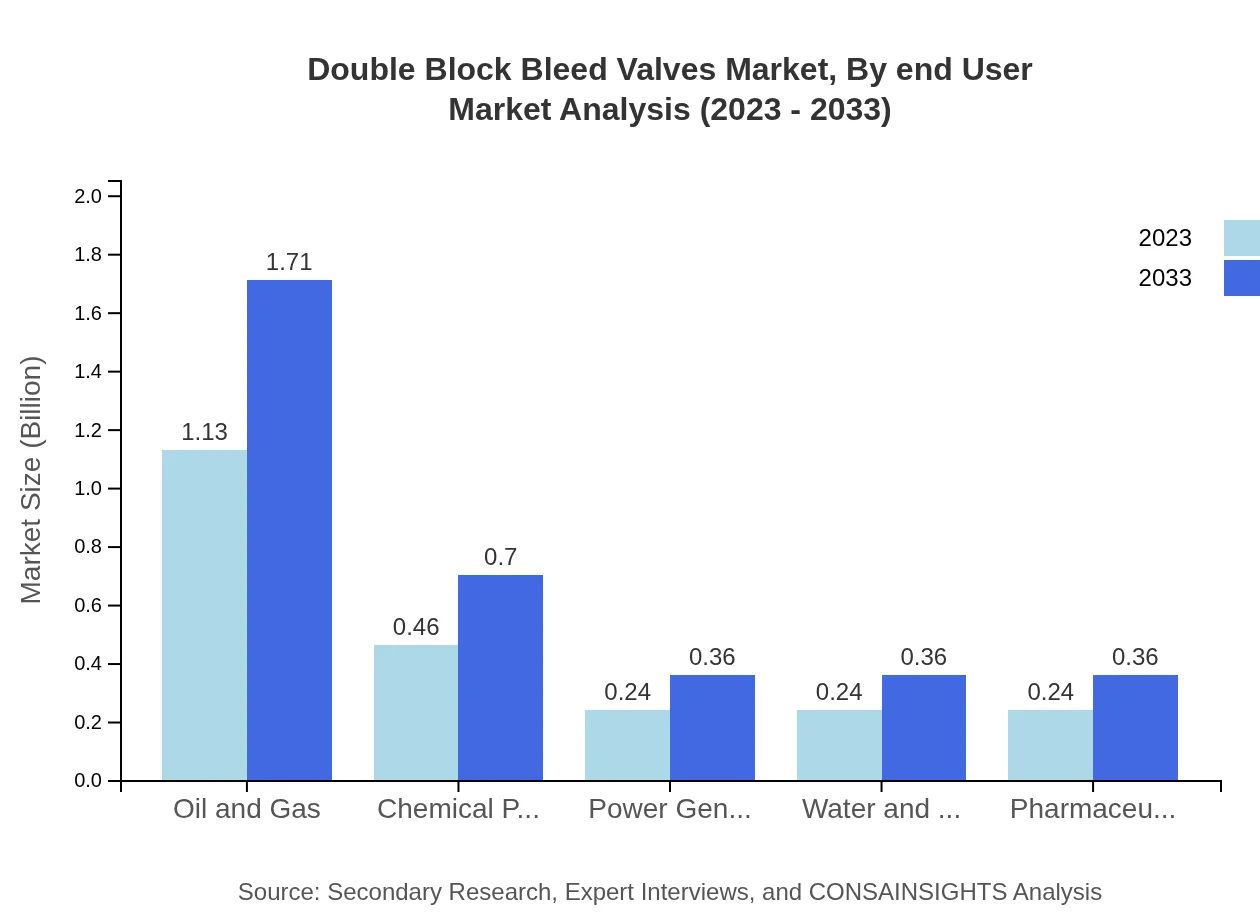

Double Block Bleed Valves Market Analysis By End User

Key end-user industries include oil and gas, chemical processing, power generation, water and wastewater treatment, and pharmaceuticals. The oil and gas sector holds the largest market share at 48.98% in 2023, while other sectors are also experiencing growth, reflecting the versatility and critical application of these valves across industries.

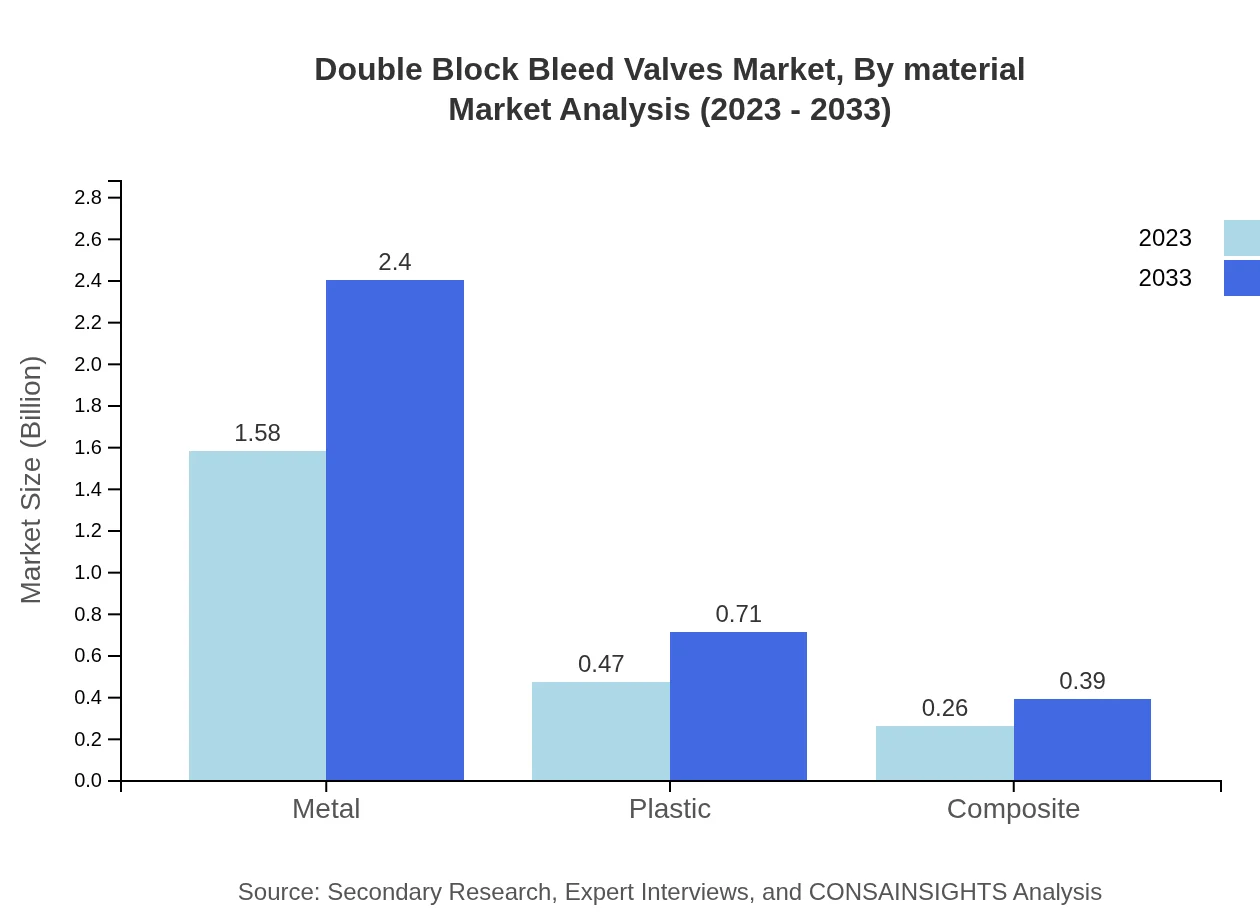

Double Block Bleed Valves Market Analysis By Material

The market is segmented by material into metal, plastic, and composite. Metal valves, primarily made from robust materials like stainless steel, account for a significant portion of the market at 68.61% in 2023. Plastics and composites are preferred for specific applications where weight and corrosion resistance are key.

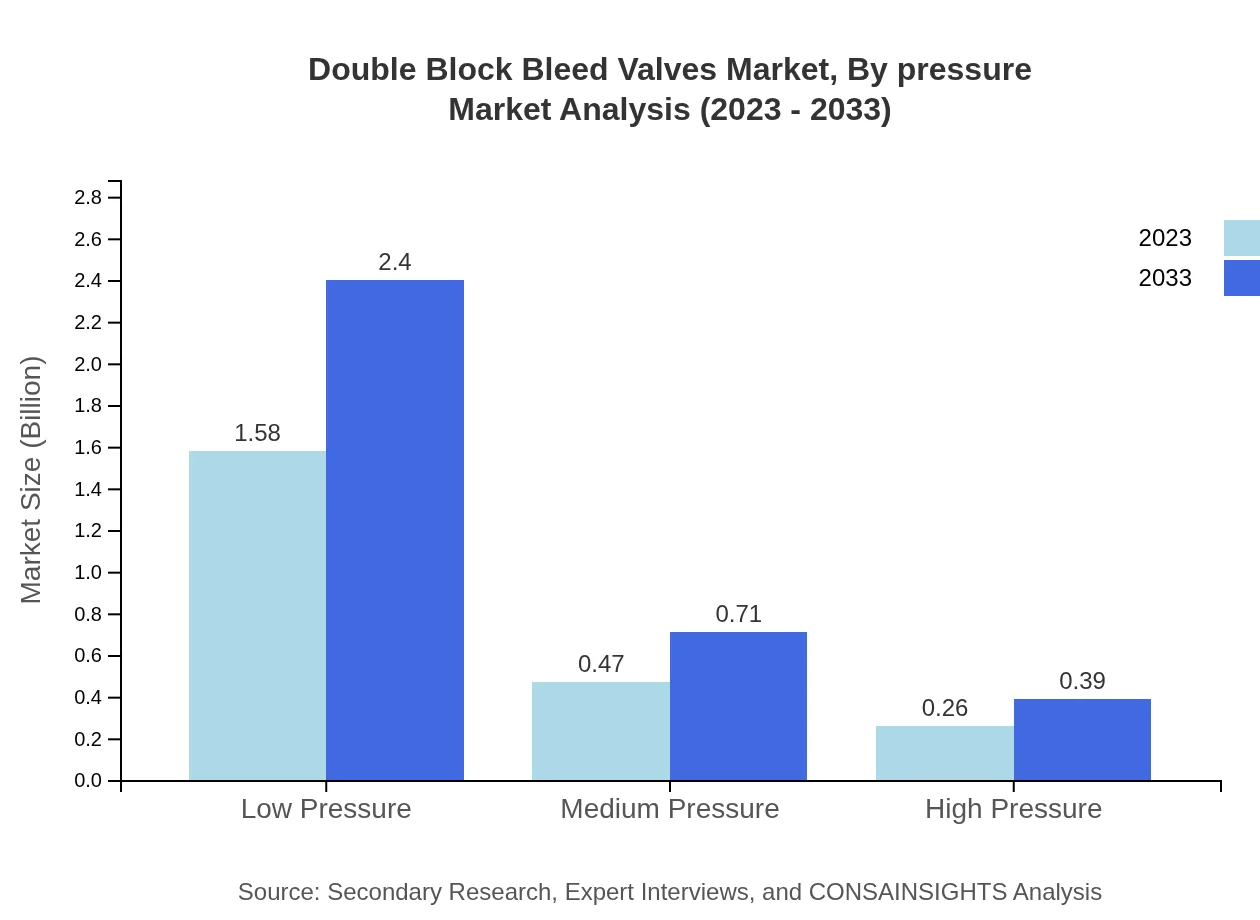

Double Block Bleed Valves Market Analysis By Pressure

Segmented by pressure, low pressure valves dominate the market at 68.61% share in 2023, suited for various industrial applications. Medium and high-pressure valves are critical for more demanding environments, poised for growth as industries expand.

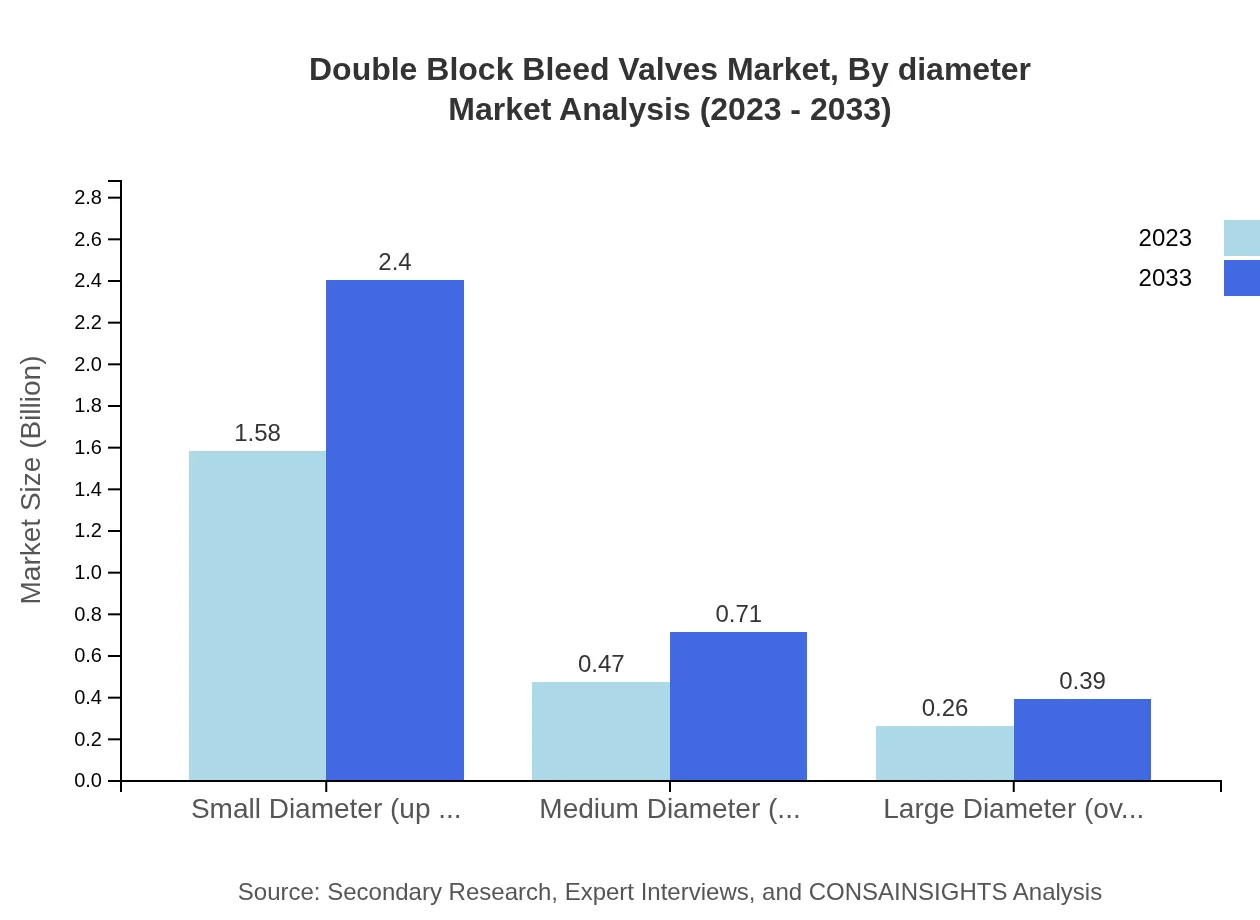

Double Block Bleed Valves Market Analysis By Diameter

Market segmentation by diameter shows small diameter valves (up to 2 inches) leading the market with 68.61% share in 2023, ideal for tight spaces and precise control. Medium and large diameter valves are essential for high-capacity systems, expanding as industrial needs evolve.

Double Block Bleed Valves Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in the Double Block Bleed Valves Industry

Emerson Electric Co.:

A global leader in automation solutions, providing a range of Double Block Bleed Valves known for reliability and innovative technology.Valmet Corporation:

Specializes in valves and automation services, offering advanced Double Block Bleed Valves that guarantee safety and efficiency in various applications.Kitz Corporation:

A Japanese manufacturer known for high-quality valves and fittings, including a comprehensive range of Double Block Bleed Valves for industrial applications.Spirax Sarco Ltd.:

Offers a variety of valve solutions including Double Block Bleed Valves, focusing on engineered solutions for steam and fluid control systems.We're grateful to work with incredible clients.

FAQs

What is the market size of Double Block Bleed Valves?

The global market size for Double Block Bleed Valves is projected at $2.3 billion in 2023, with a sustained growth rate of 4.2% CAGR expected through 2033.

What are the key market players or companies in the Double Block Bleed Valves industry?

Key players in the Double Block Bleed Valves market include major valve manufacturers and suppliers such as Emerson Electric Co., Flowserve Corporation, and Kitz Corporation, each playing an essential role in this specialized sector.

What are the primary factors driving the growth in the Double Block Bleed Valves industry?

Growth drivers include increasing demand for safety in critical applications, expansion in the oil and gas sector, and technological advancements in valve manufacturing and automation.

Which region is the fastest Growing in the Double Block Bleed Valves?

North America is the fastest-growing region, with a market increase from $0.88 billion in 2023 to $1.34 billion by 2033, reflecting strong infrastructure investments and industry advancements.

Does ConsaInsights provide customized market report data for the Double Block Bleed Valves industry?

Yes, ConsaInsights offers customized market report data tailored to specific requirements within the Double Block Bleed Valves industry, catering to unique needs of businesses and stakeholders.

What deliverables can I expect from this Double Block Bleed Valves market research project?

Deliverables typically include comprehensive market analysis reports, trend analyses, regional insights, segmentation details, and actionable recommendations to guide strategic decisions.

What are the market trends of Double Block Bleed Valves?

Market trends include a shift towards smart valve technologies, increased automation in manufacturing processes, and a growing focus on environmental regulations, emphasizing sustainable designs.