Drilling Machines Market Report

Published Date: 22 January 2026 | Report Code: drilling-machines

Drilling Machines Market Size, Share, Industry Trends and Forecast to 2033

This market report delves into the Drilling Machines sector, providing insights into market trends, sizes, and growth forecasts from 2023 to 2033. It highlights regional performance, industry analysis, market segmentation, and key players influencing the sector.

| Metric | Value |

|---|---|

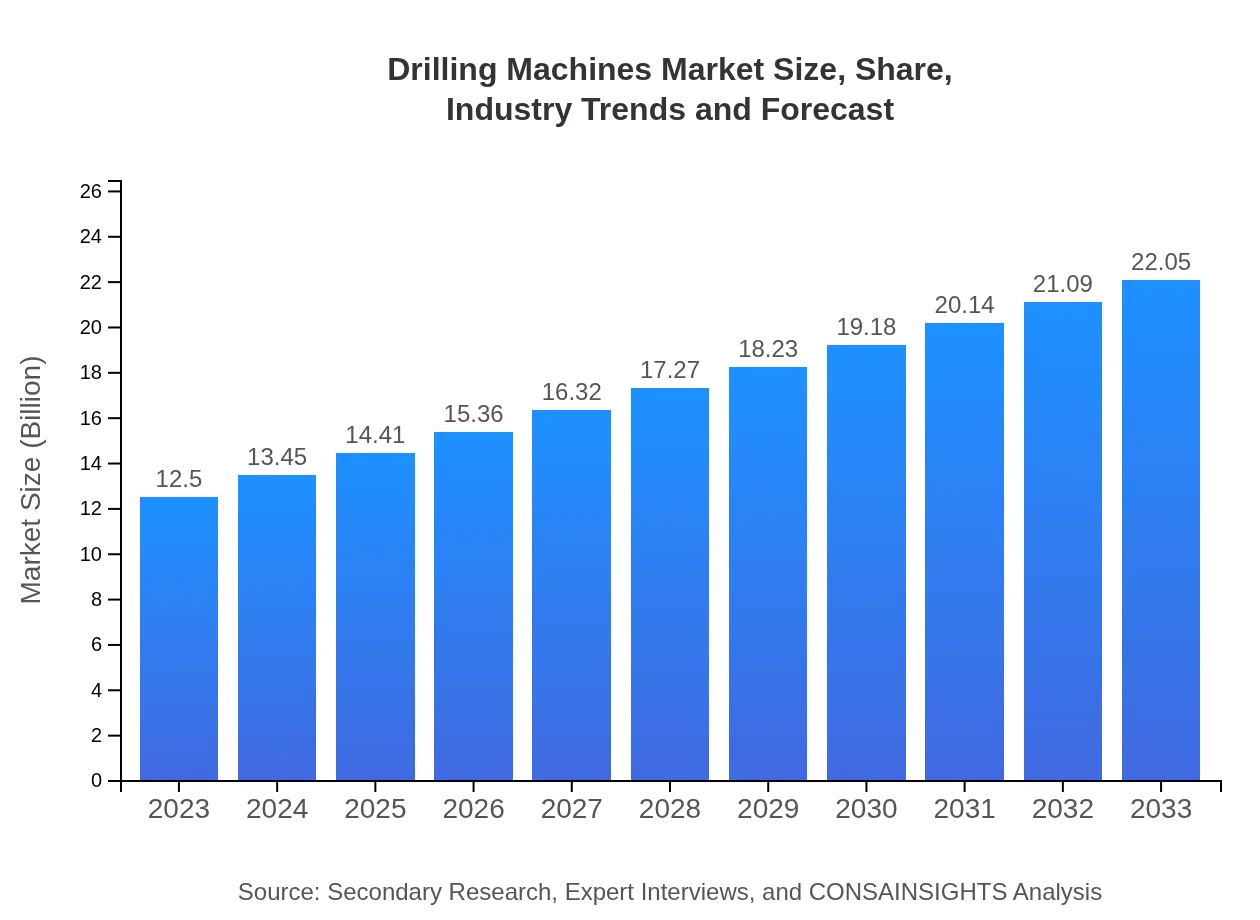

| Study Period | 2023 - 2033 |

| 2023 Market Size | $12.50 Billion |

| CAGR (2023-2033) | 5.7% |

| 2033 Market Size | $22.05 Billion |

| Top Companies | Caterpillar Inc., Atlas Copco, Schlumberger Limited, Sandvik AB |

| Last Modified Date | 22 January 2026 |

Drilling Machines Market Overview

Customize Drilling Machines Market Report market research report

- ✔ Get in-depth analysis of Drilling Machines market size, growth, and forecasts.

- ✔ Understand Drilling Machines's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Drilling Machines

What is the Market Size & CAGR of Drilling Machines market in 2023?

Drilling Machines Industry Analysis

Drilling Machines Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Drilling Machines Market Analysis Report by Region

Europe Drilling Machines Market Report:

Europe's market stands at $3.85 billion in 2023, growing to $6.79 billion by 2033. The focus on renewable energy projects and environmental regulations is leading to innovations in drilling techniques, fostering growth.Asia Pacific Drilling Machines Market Report:

In the Asia Pacific region, the Drilling Machines market size was approximately $2.48 billion in 2023, projected to grow to $4.37 billion by 2033 due to increasing investments in infrastructure and mining. Countries like China and India are leading the charge, driven by urban migration and industrialization.North America Drilling Machines Market Report:

North America showcases a robust market, with a valuation of $4.05 billion in 2023, anticipated to rise to $7.14 billion by 2033. Key contributors are the oil and gas sectors, alongside substantial infrastructural projects, particularly in the U.S. and Canada.South America Drilling Machines Market Report:

South America’s market is currently valued at about $0.78 billion and is expected to reach approximately $1.38 billion by 2033. The energy sector, specifically oil drilling, continues to drive demand, supported by strategic government policies aimed at enhancing resource extraction.Middle East & Africa Drilling Machines Market Report:

The Middle East and Africa report a market size of $1.34 billion in 2023, expected to reach $2.36 billion by 2033. Driven by oil exploration activities and infrastructure initiatives, the region remains crucial for drilling machine manufacturers.Tell us your focus area and get a customized research report.

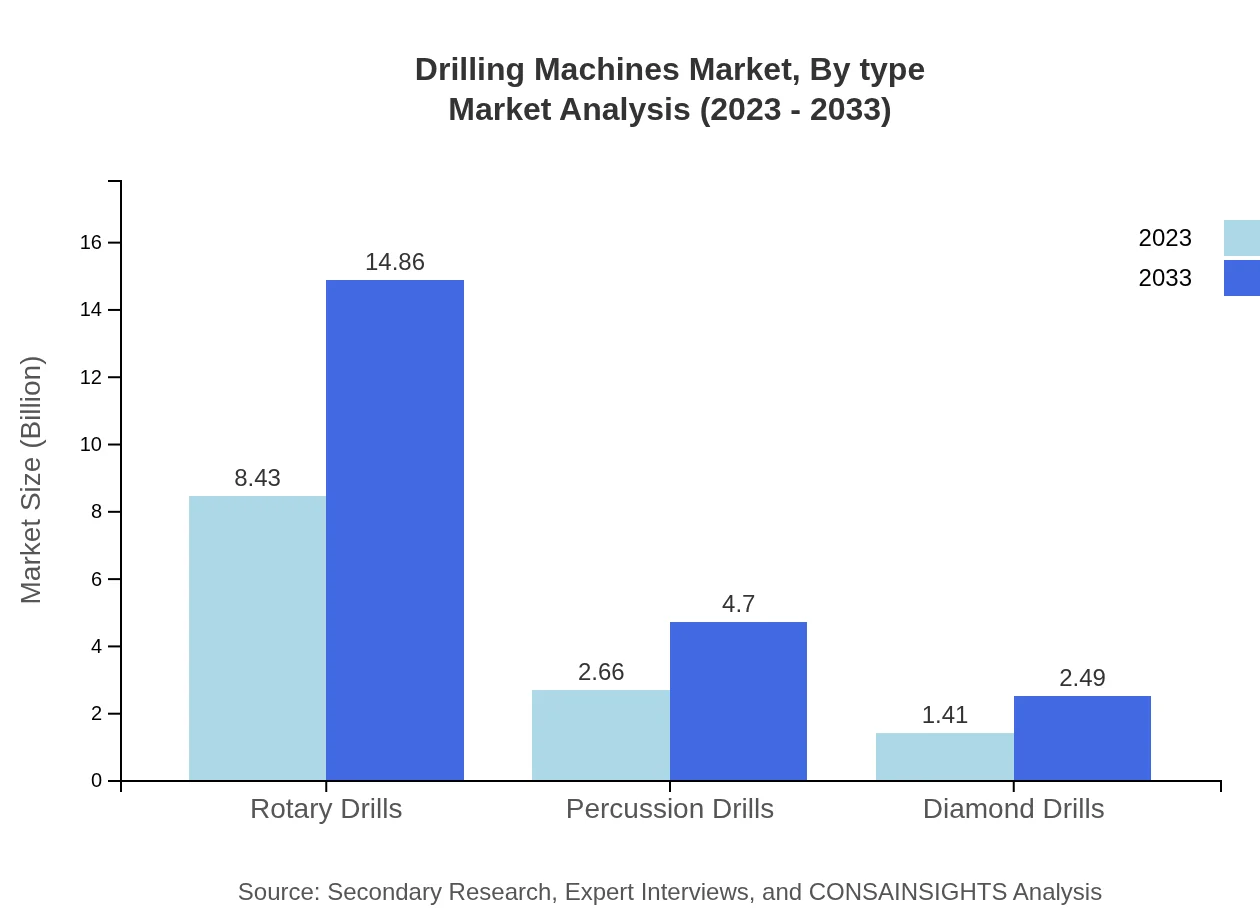

Drilling Machines Market Analysis By Type

The market by type is dominated by Rotary Drills, accounting for a sizable $8.43 billion in 2023, with expectations to reach $14.86 billion by 2033, holding a market share of 67.41%. Percussion Drills and Diamond Drills follow with sizes of $2.66 billion and $1.41 billion, respectively, indicating strong contributions across diverse applications including construction and mining.

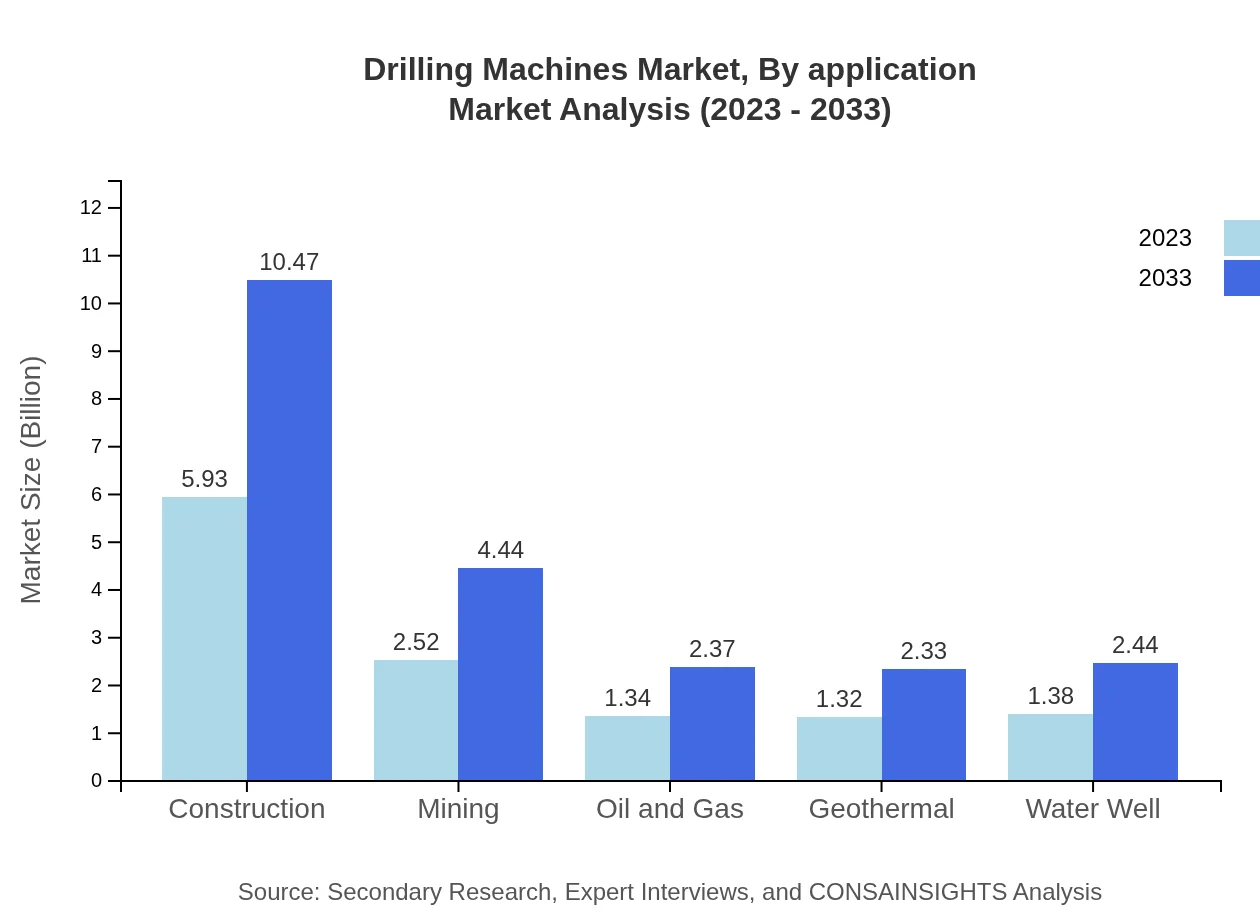

Drilling Machines Market Analysis By Application

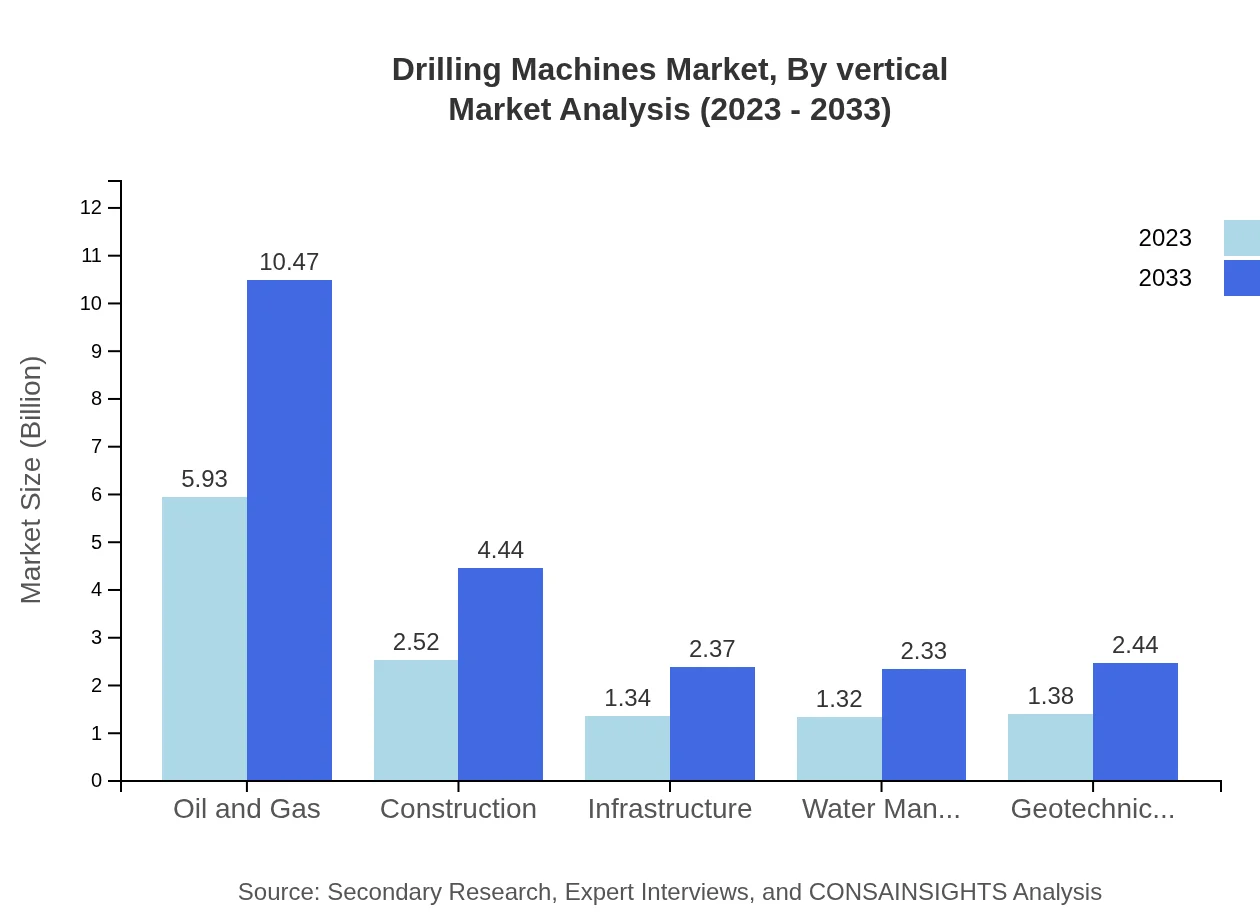

By application, the Oil and Gas sector leads with a size of $5.93 billion in 2023 and expected growth to $10.47 billion by 2033, capturing 47.48% market share. Other significant applications include Construction and Infrastructure, providing robust demand for drilling solutions across various projects.

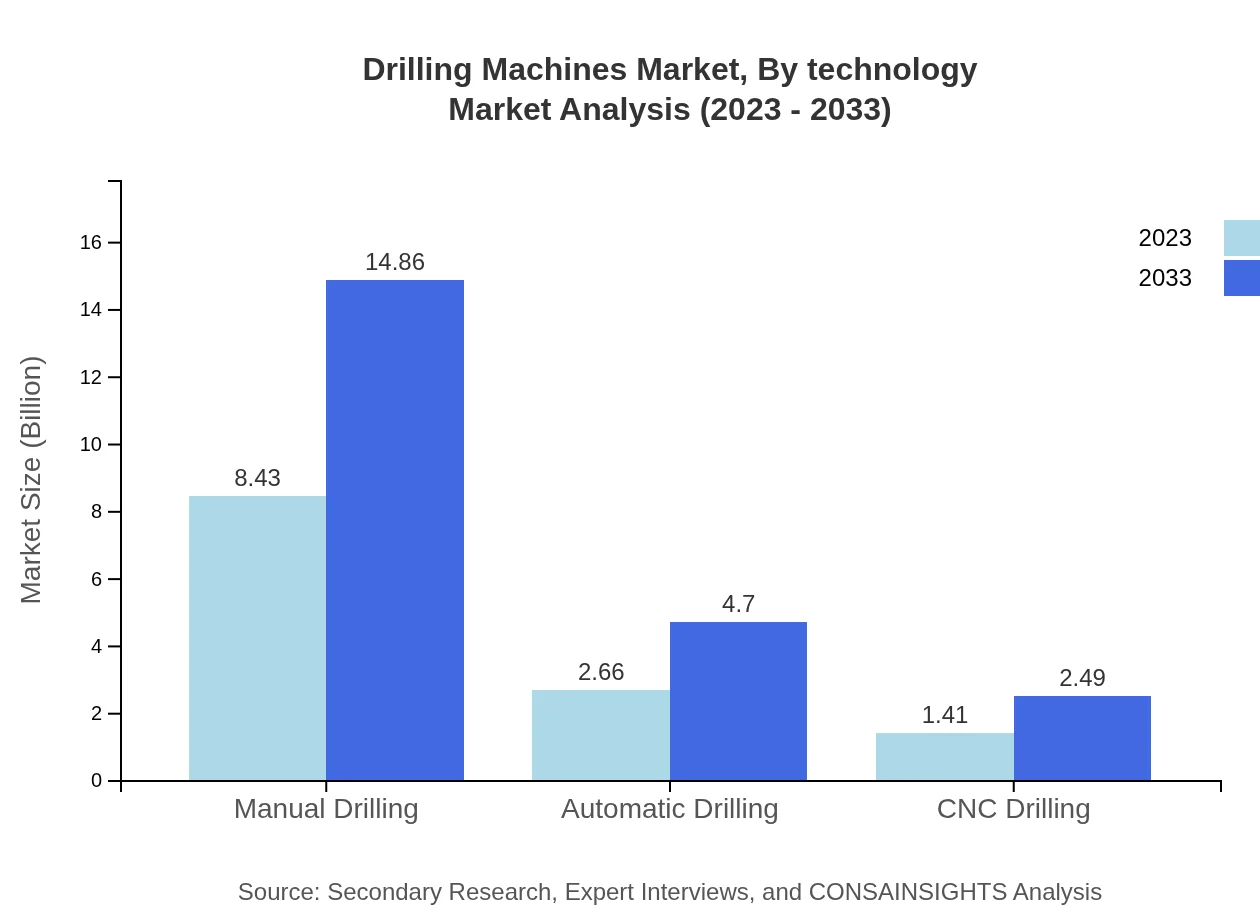

Drilling Machines Market Analysis By Technology

Drilling technologies are rapidly evolving, with Manual Drilling systems holding a substantial market size of $8.43 billion, projected to grow alongside Automatic and CNC Drilling technologies, both of which are garnering interest for their efficiency and precision in operations.

Drilling Machines Market Analysis By Vertical

The market by vertical highlights a strong presence in the Construction sector, with a size of $5.93 billion in 2023, reflecting robust investments in commercial and residential infrastructure, along with substantial input from Mining and Oil and Gas sectors.

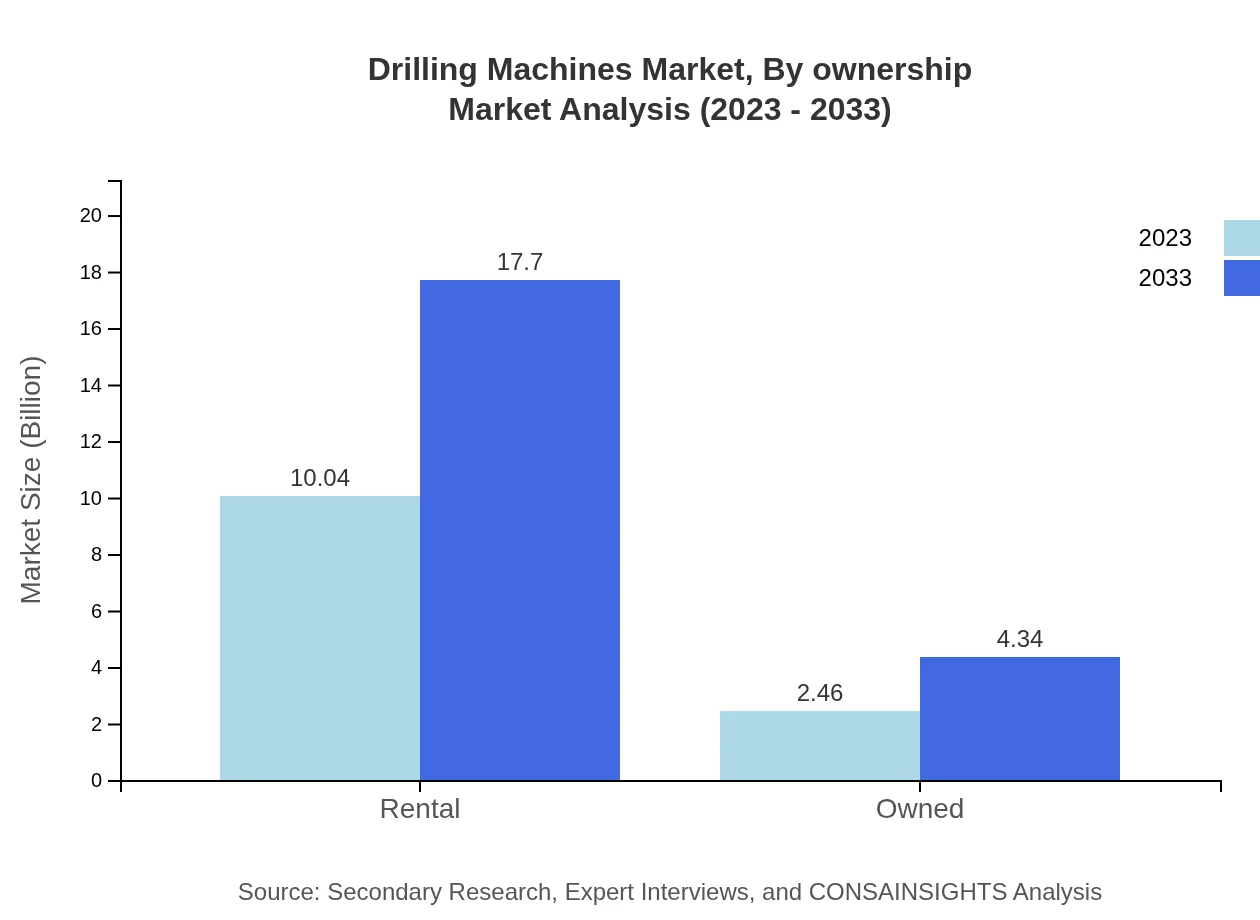

Drilling Machines Market Analysis By Ownership

The Drilling Machines market demonstrates a clear preference for rental models, with a market size of $10.04 billion in 2023, highlighting the trend of companies opting for flexible ownership to reduce capital expenses. This trend is anticipated to continue, marking a shift in financial strategies for businesses.

Drilling Machines Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Drilling Machines Industry

Caterpillar Inc.:

A leading player in the heavy machinery sector, Caterpillar manufactures advanced drilling machines and solutions for various industries, emphasizing innovation and sustainability.Atlas Copco:

Atlas Copco specializes in industrial tools and equipment, providing high-quality drilling machines designed for mining, construction, and energy applications.Schlumberger Limited:

A significant player in the oil and gas sector, Schlumberger offers advanced drilling technologies and services, driving efficiency and performance enhancements in exploration.Sandvik AB:

Sandvik is renowned for its innovative drilling solutions in mining and construction sectors, focusing on safety and operational efficiency.We're grateful to work with incredible clients.

FAQs

What is the market size of drilling Machines?

The global drilling machines market is valued at approximately $12.5 billion in 2023. It is expected to grow at a CAGR of 5.7%, reaching an estimated size of $22.4 billion by 2033.

What are the key market players or companies in the drilling Machines industry?

Key players in the drilling machines market include renowned manufacturers like Caterpillar Inc., Atlas Copco, and Sandvik. These companies lead in innovation and technological advancement, continuously enhancing their product offerings in line with market demands.

What are the primary factors driving the growth in the drilling machines industry?

Driving factors include increasing infrastructure projects, rising demand in oil and gas exploration, and advancements in drilling technologies. The shift towards automation and precision drilling further propels market growth.

Which region is the fastest Growing in the drilling machines market?

The Asia Pacific region is the fastest-growing in the drilling machines market, expected to expand from $2.48 billion in 2023 to $4.37 billion by 2033, reflecting significant investments in construction and infrastructure.

Does ConsaInsights provide customized market report data for the drilling machines industry?

Yes, ConsaInsights offers tailored market research solutions for the drilling machines industry. Custom reports provide in-depth analysis based on specific client needs and market segments.

What deliverables can I expect from this drilling Machines market research project?

Deliverables typically include comprehensive market reports, data analysis, competitor profiling, and insights into growth opportunities. Additionally, report summaries and presentations can be provided for stakeholder engagement.

What are the market trends of drilling machines?

Current trends include the growing adoption of automated drilling solutions, increased focus on energy efficiency, and the integration of advanced technologies like IoT. Rental services are also gaining traction as a flexible option for construction firms.