Egg Processing Machinery Market Report

Published Date: 31 January 2026 | Report Code: egg-processing-machinery

Egg Processing Machinery Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Egg Processing Machinery market, including trends, forecasts, and insights into market dynamics from 2023 to 2033.

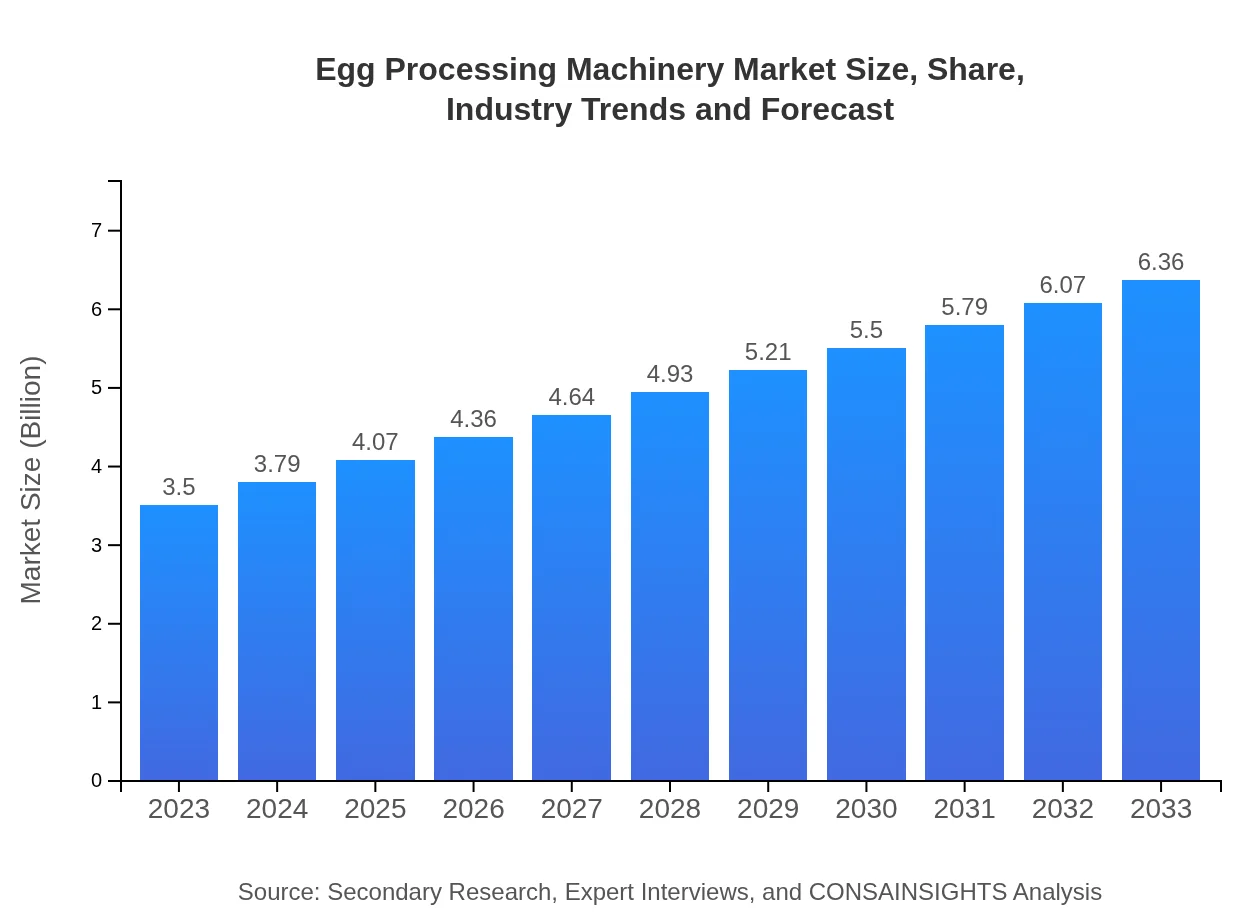

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $3.50 Billion |

| CAGR (2023-2033) | 6% |

| 2033 Market Size | $6.36 Billion |

| Top Companies | Moba Group, Sanovo Technology Group, STORCROQ, OMEGA |

| Last Modified Date | 31 January 2026 |

Egg Processing Machinery Market Overview

Customize Egg Processing Machinery Market Report market research report

- ✔ Get in-depth analysis of Egg Processing Machinery market size, growth, and forecasts.

- ✔ Understand Egg Processing Machinery's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Egg Processing Machinery

What is the Market Size & CAGR of Egg Processing Machinery market in 2023?

Egg Processing Machinery Industry Analysis

Egg Processing Machinery Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Egg Processing Machinery Market Analysis Report by Region

Europe Egg Processing Machinery Market Report:

Europe shows a promising market trajectory, expecting growth from $0.88 billion in 2023 to $1.59 billion by 2033. The market is supported by technological advancements in machinery, alongside strict regulations for food quality and safety which necessitate modern processing technologies.Asia Pacific Egg Processing Machinery Market Report:

In the Asia Pacific region, the market is expected to expand from $0.71 billion in 2023 to $1.29 billion by 2033. This growth is driven by increasing egg production in countries like China and India and rising consumer demand for processed egg products. The region's focus on modernization in agriculture and food processing is also anticipated to bolster market development.North America Egg Processing Machinery Market Report:

In North America, the Egg Processing Machinery market is forecasted to increase substantially from $1.36 billion in 2023 to $2.47 billion by 2033. This growth reflects trends such as increasing oven-ready meals and convenience foods, coupled with rising health awareness regarding protein consumption.South America Egg Processing Machinery Market Report:

The South American market for Egg Processing Machinery is projected to grow from $0.23 billion in 2023 to $0.42 billion by 2033. The growth is attributed to the rising food processing sector within Brazil and Argentina, alongside efforts to enhance food safety standards and processing efficiency.Middle East & Africa Egg Processing Machinery Market Report:

The Middle East and African Egg Processing Machinery market is set to grow from $0.32 billion in 2023 to $0.58 billion by 2033. Urbanization, evolving consumer preferences for convenience foods, and investments in agricultural infrastructure are key factors driving this growth.Tell us your focus area and get a customized research report.

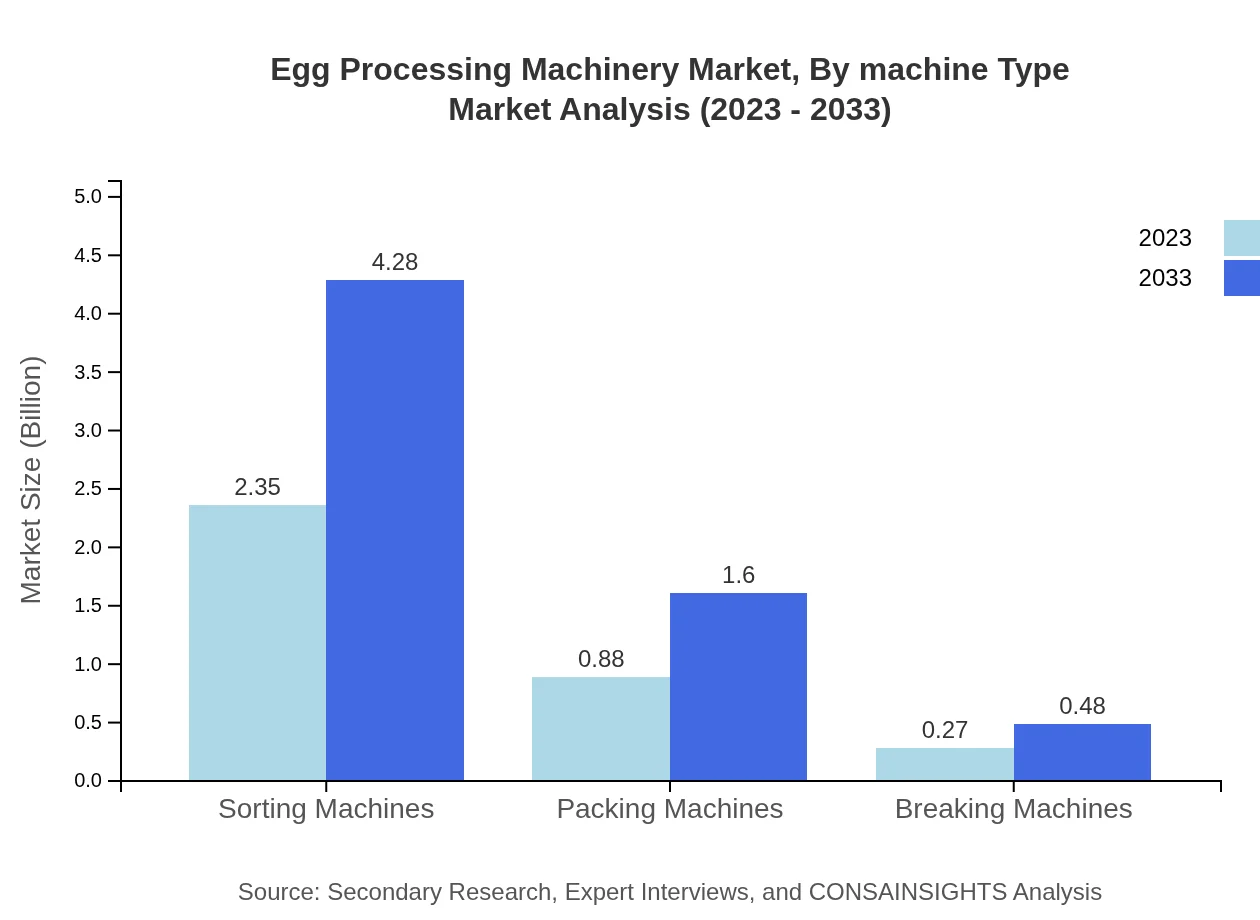

Egg Processing Machinery Market Analysis By Machine Type

The Egg Processing Machinery Market by Machine Type includes key segments like sorting machines, packing machines, and breaking machines. In 2023, sorting machines hold a market value of $2.35 billion, expected to grow to $4.28 billion in 2033, while packing machines and breaking machines also show similar growth trajectories reflecting efficiency improvements in egg processing operations.

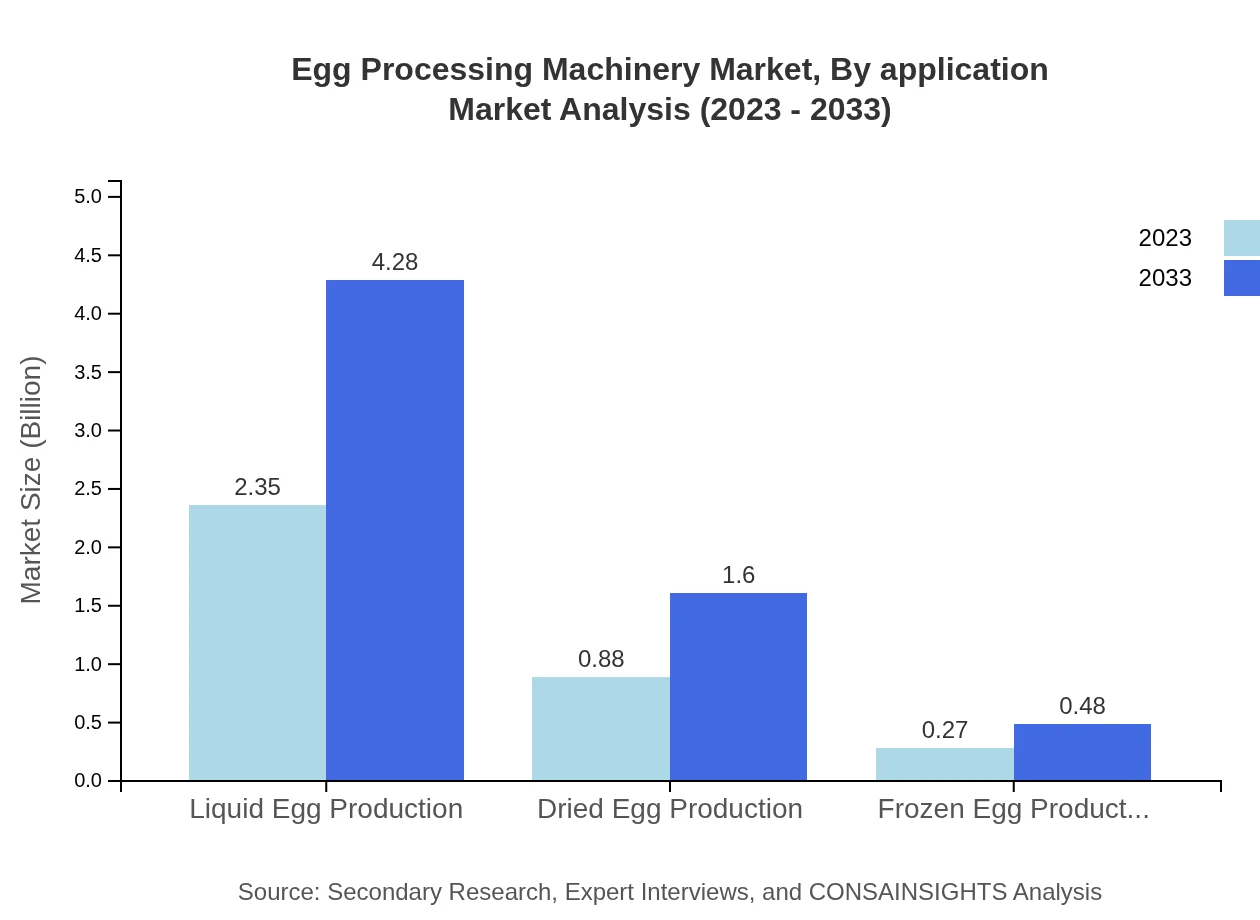

Egg Processing Machinery Market Analysis By Application

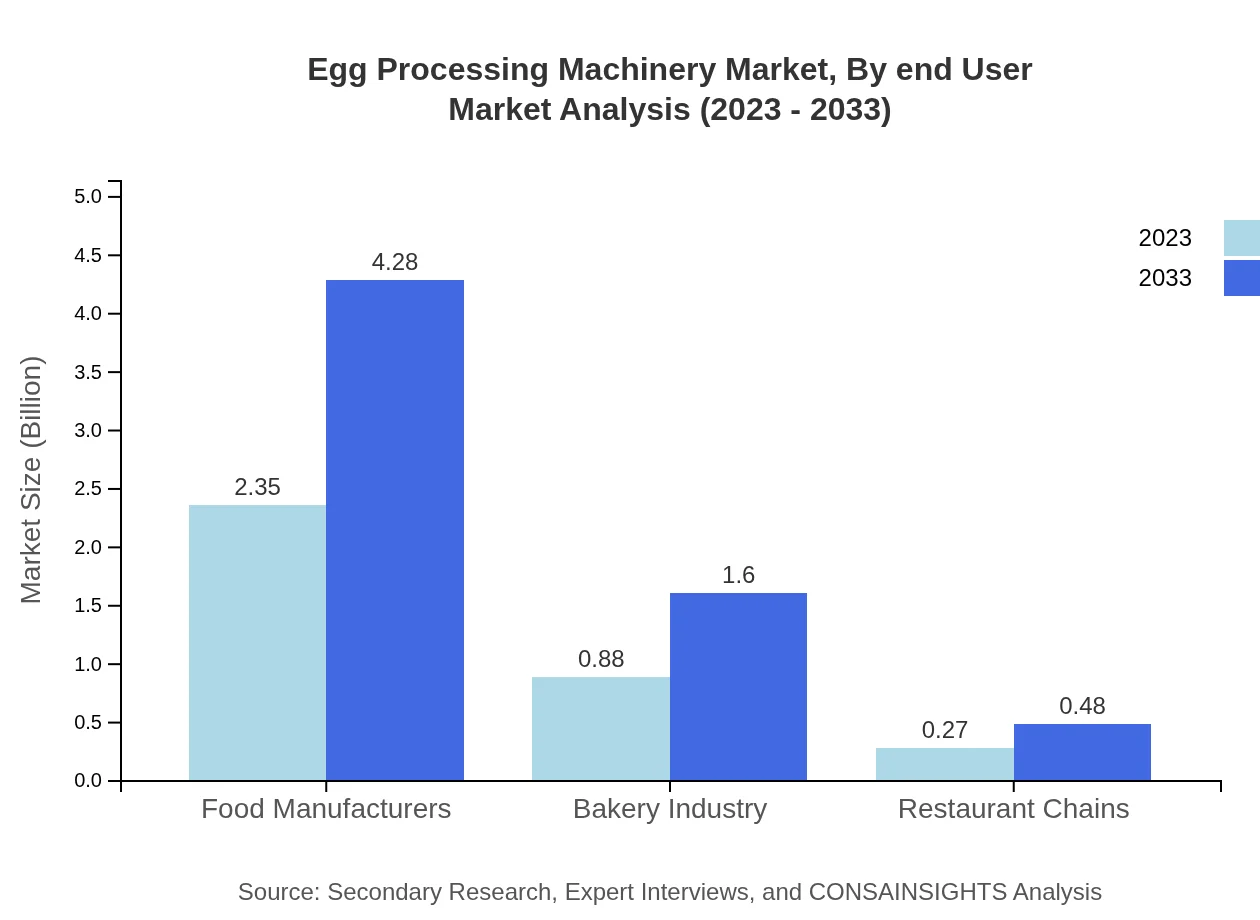

By application, the Egg Processing Machinery market is primarily driven by food manufacturers, which are projected to maintain a significant market share of 67.28% in 2023, growing to the same percentage in 2033. Other notable segments such as the bakery industry and restaurant chains indicate stable growth, from $0.88 billion to $1.60 billion and $0.27 billion to $0.48 billion, respectively.

Egg Processing Machinery Market Analysis By End User

The market served by various end-users indicates a strong preference from food manufacturers, fetching a size of $2.35 billion in 2023. Dried and liquid egg production remain primary focus areas, leading to a stable market landscape with proportional participations across applications focusing on efficiency and quality.

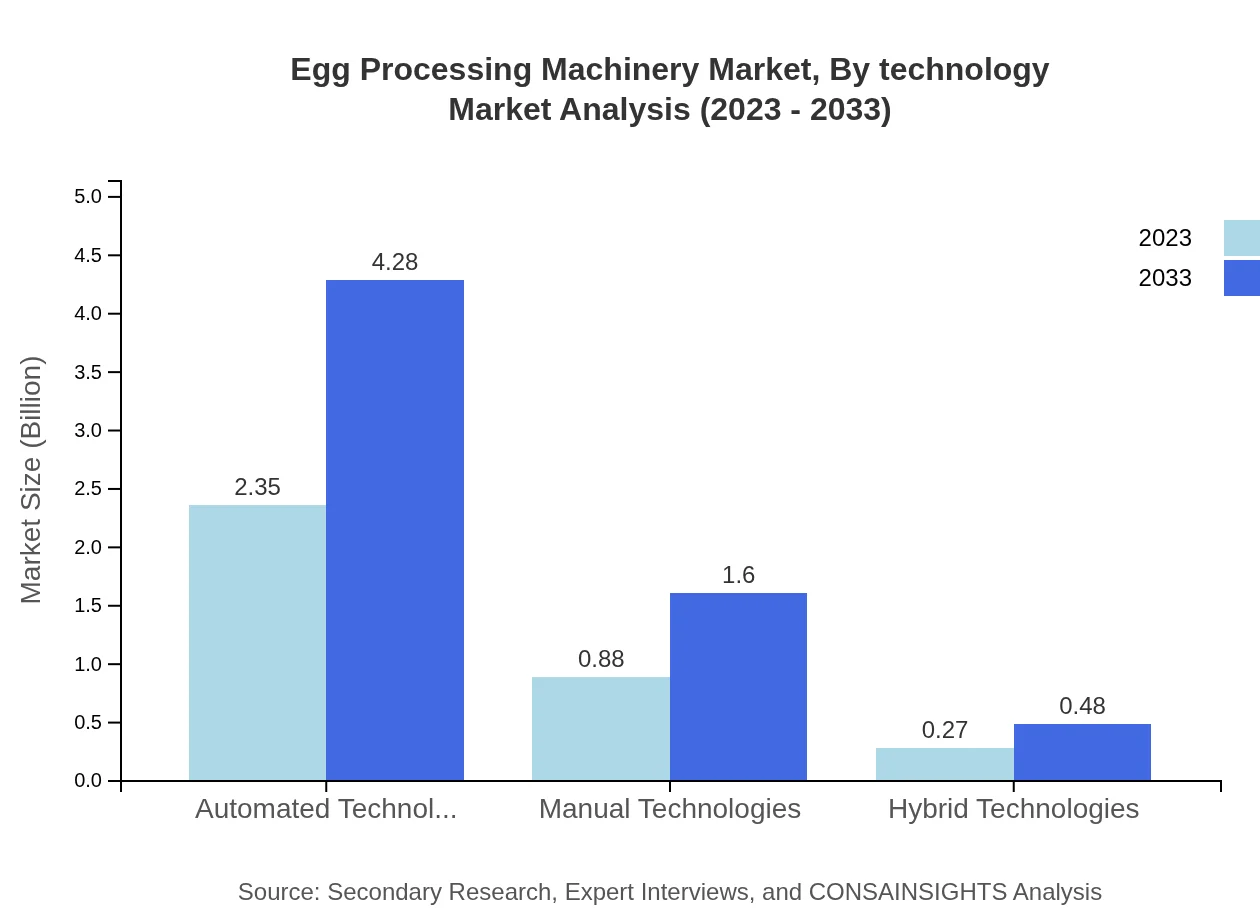

Egg Processing Machinery Market Analysis By Technology

The technological advancements in egg processing are categorized into automated, manual, and hybrid technologies. In 2023, automated technologies dominate the market with a size of $2.35 billion, forecasted to rise significantly to $4.28 billion by 2033. The industry's shift towards automation is expected to enhance productivity, accuracy, and reduce overhead costs.

Egg Processing Machinery Market Analysis By Region

Global Egg Processing Machinery Market, By Region Market Analysis (2023 - 2033)

Regional analyses indicate diversities across markets. North America leads in size and growth rate, with Europe and Asia Pacific following closely. Consequently, manufacturers must tailor strategies to meet regional demands effectively as market needs grow variably across these regions.

Egg Processing Machinery Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Egg Processing Machinery Industry

Moba Group:

Moba is a leading manufacturer of egg processing equipment, known for their innovative sorting, packing, and processing solutions aimed at enhancing egg production efficiency.Sanovo Technology Group:

Sanovo provides a wide range of egg processing machines and systems, contributing to advanced production practices and ensuring high-quality output in the egg processing industry.STORCROQ:

STORCROQ is renowned for their cutting-edge packing and sorting technology, focusing on innovative solutions that streamline processes for egg producers.OMEGA:

OMEGA specializes in egg handling and packing equipment, known for their high efficiency and commitment to improving food safety standards in the egg processing sector.We're grateful to work with incredible clients.

FAQs

What is the market size of egg Processing Machinery?

The global egg-processing machinery market is valued at approximately $3.5 billion in 2023, with a projected CAGR of 6% from 2023 to 2033, indicating robust growth and increasing demand for egg processing capabilities.

What are the key market players or companies in the egg Processing Machinery industry?

The egg-processing machinery market features several key players including Moba Group, Sanovo Technology Group, A&G Technology, and others, who collectively drive innovation and market growth through advanced processing technologies.

What are the primary factors driving the growth in the egg Processing machinery industry?

Significant growth drivers include rising egg consumption, technological advancements in processing machinery, increasing automation in food production, and growing demand for packaged egg products, all of which enhance operational efficiency.

Which region is the fastest Growing in the egg Processing machinery?

The North American region is the fastest-growing segment, projected to expand from $1.36 billion in 2023 to $2.47 billion by 2033, attributed to high demand for automated processing solutions and advanced technologies in food production.

Does ConsaInsights provide customized market report data for the egg Processing machinery industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs and requirements of stakeholders in the egg-processing machinery industry, ensuring comprehensive insights that align with strategic objectives.

What deliverables can I expect from this egg Processing machinery market research project?

Expect deliverables including detailed market analysis reports, growth forecasts, competitive landscape assessments, segment-wise insights, and actionable recommendations tailored to industry stakeholders and decision-makers.

What are the market trends of egg Processing machinery?

Key trends include increasing reliance on automated technologies for efficiency, a shift towards organic and free-range products, and innovations in machinery for better quality and sustainability, shaping the future landscape of the industry.