Elastomeric Foam Market Report

Published Date: 22 January 2026 | Report Code: elastomeric-foam

Elastomeric Foam Market Size, Share, Industry Trends and Forecast to 2033

This report covers a comprehensive analysis of the elastomeric foam market from 2023 to 2033, detailing market size, growth trends, key players, regional insights, and future forecasts, providing valuable insights for stakeholders.

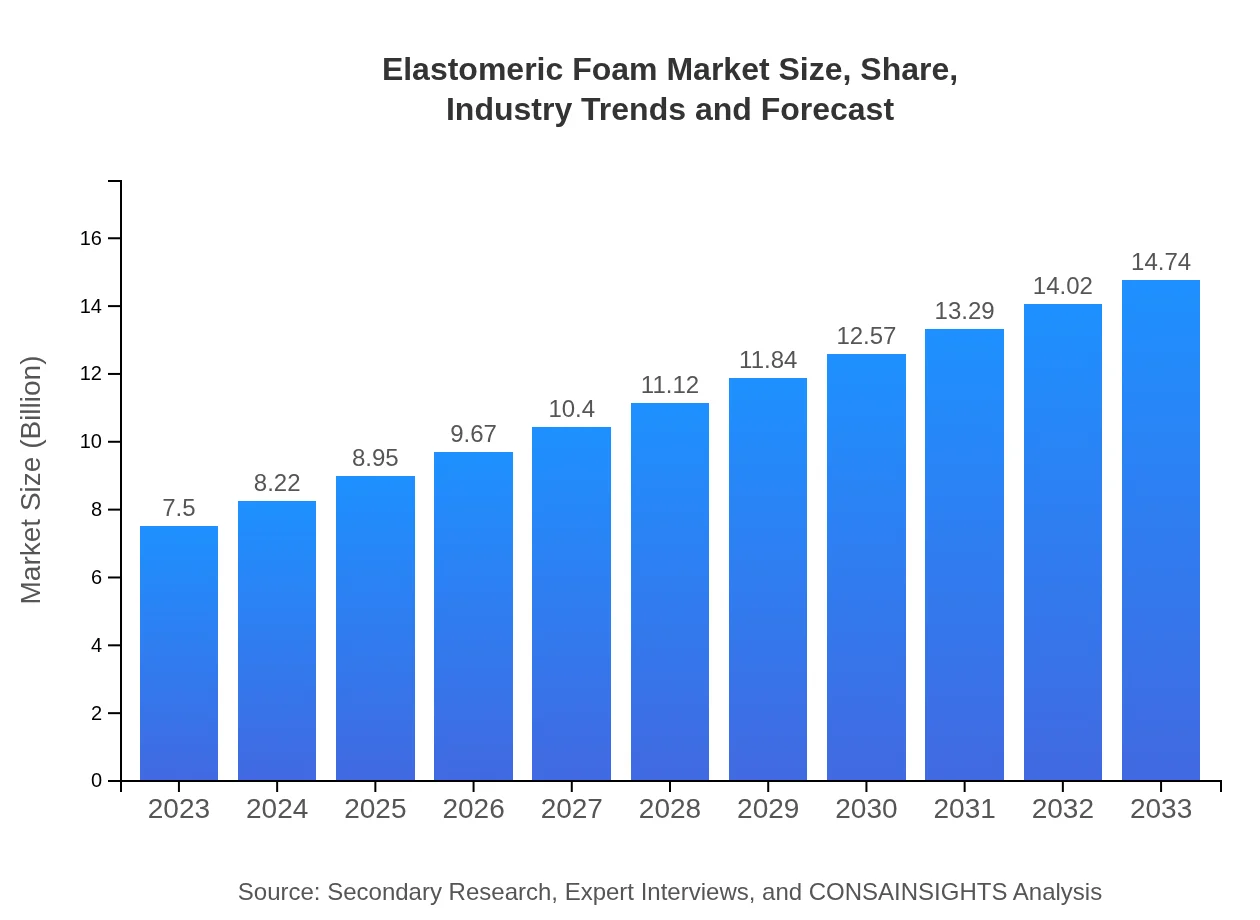

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $7.50 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $14.74 Billion |

| Top Companies | BASF SE, Dow Inc., Huntsman International LLC |

| Last Modified Date | 22 January 2026 |

Elastomeric Foam Market Overview

Customize Elastomeric Foam Market Report market research report

- ✔ Get in-depth analysis of Elastomeric Foam market size, growth, and forecasts.

- ✔ Understand Elastomeric Foam's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Elastomeric Foam

What is the Market Size & CAGR of Elastomeric Foam market in 2023?

Elastomeric Foam Industry Analysis

Elastomeric Foam Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Elastomeric Foam Market Analysis Report by Region

Europe Elastomeric Foam Market Report:

Europe is projected to experience a market increase from $2.12 billion in 2023 to $4.16 billion by 2033, propelled by stringent energy efficiency regulations and rising demand for sound-absorbing materials.Asia Pacific Elastomeric Foam Market Report:

In the Asia-Pacific region, the elastomeric foam market is projected to grow from $1.51 billion in 2023 to $2.97 billion by 2033, driven by booming construction activities and automotive manufacturing in countries like China and India.North America Elastomeric Foam Market Report:

North America stands as a prominent region for the elastomeric foam market, anticipating growth from $2.70 billion in 2023 to $5.30 billion by 2033. The focus on residential insulation and advancements in automotive technologies significantly contributes to this growth.South America Elastomeric Foam Market Report:

The South American market is expected to grow from $0.53 billion in 2023 to $1.04 billion by 2033, with increasing investments in infrastructure projects enhancing the demand for elastomeric foam.Middle East & Africa Elastomeric Foam Market Report:

The Middle East and Africa market is expected to see growth from $0.65 billion in 2023 to $1.28 billion by 2033, with a rise in construction projects and the demand for insulated products boosting elastomeric foam utilization.Tell us your focus area and get a customized research report.

Elastomeric Foam Market Analysis By Product Type

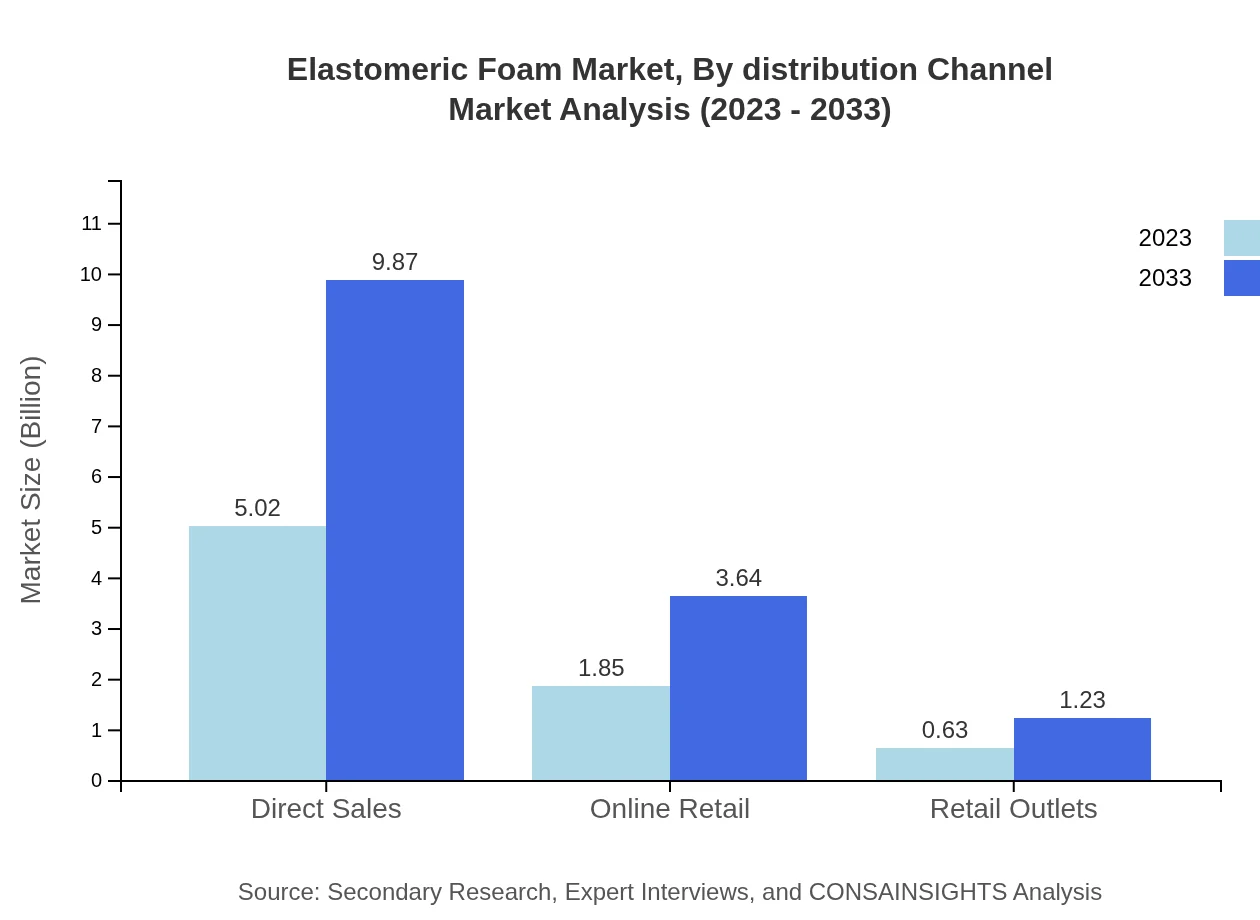

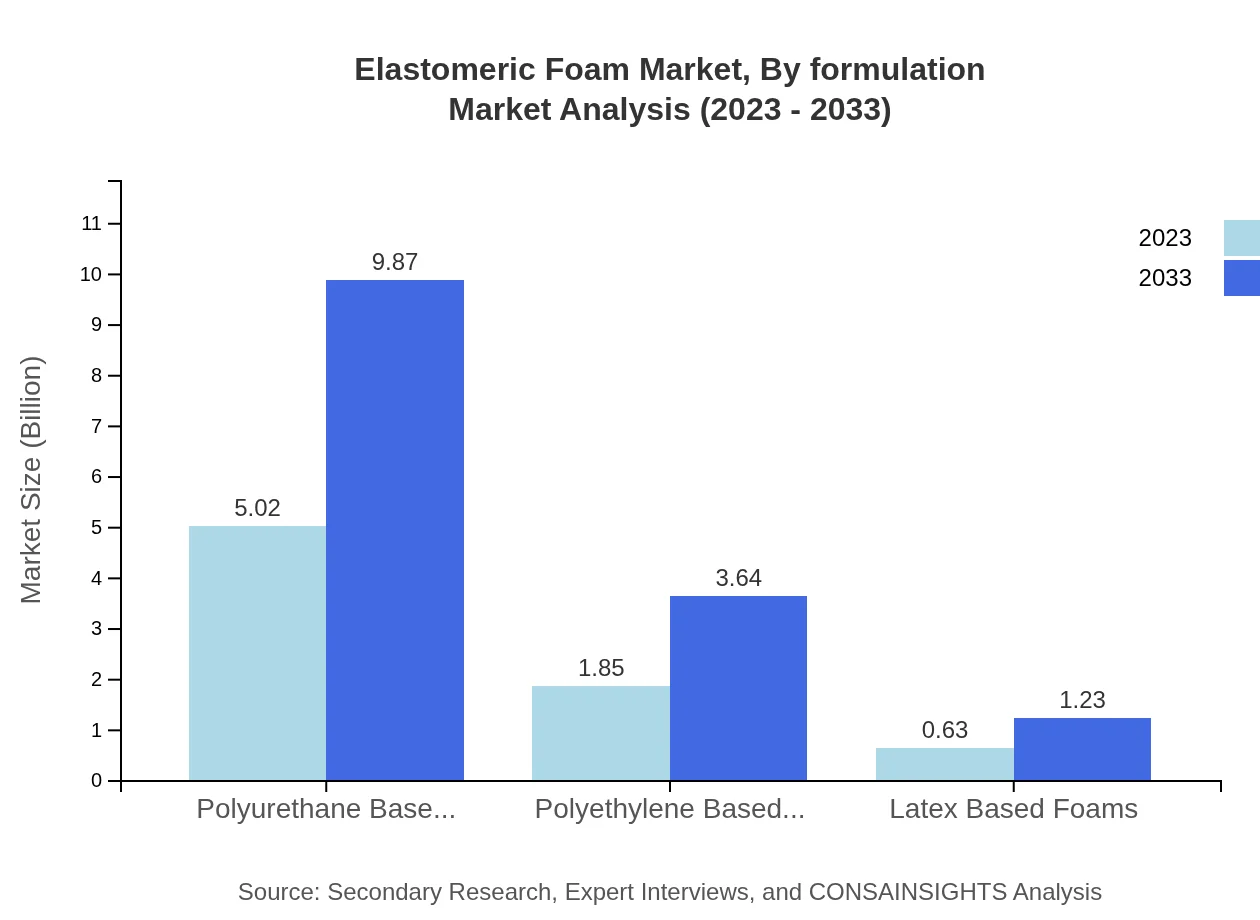

The elastomeric foam market by product type includes a variety of foams, such as polyurethane, polyethylene, and latex-based foams. Polyurethane-based foams dominate the market due to their versatility and superior insulation properties, expected to grow from $5.02 billion in 2023 to $9.87 billion by 2033. Polyethylene foams follow with a considerable share, supported by their lightweight nature and cushioning applications.

Elastomeric Foam Market Analysis By Application

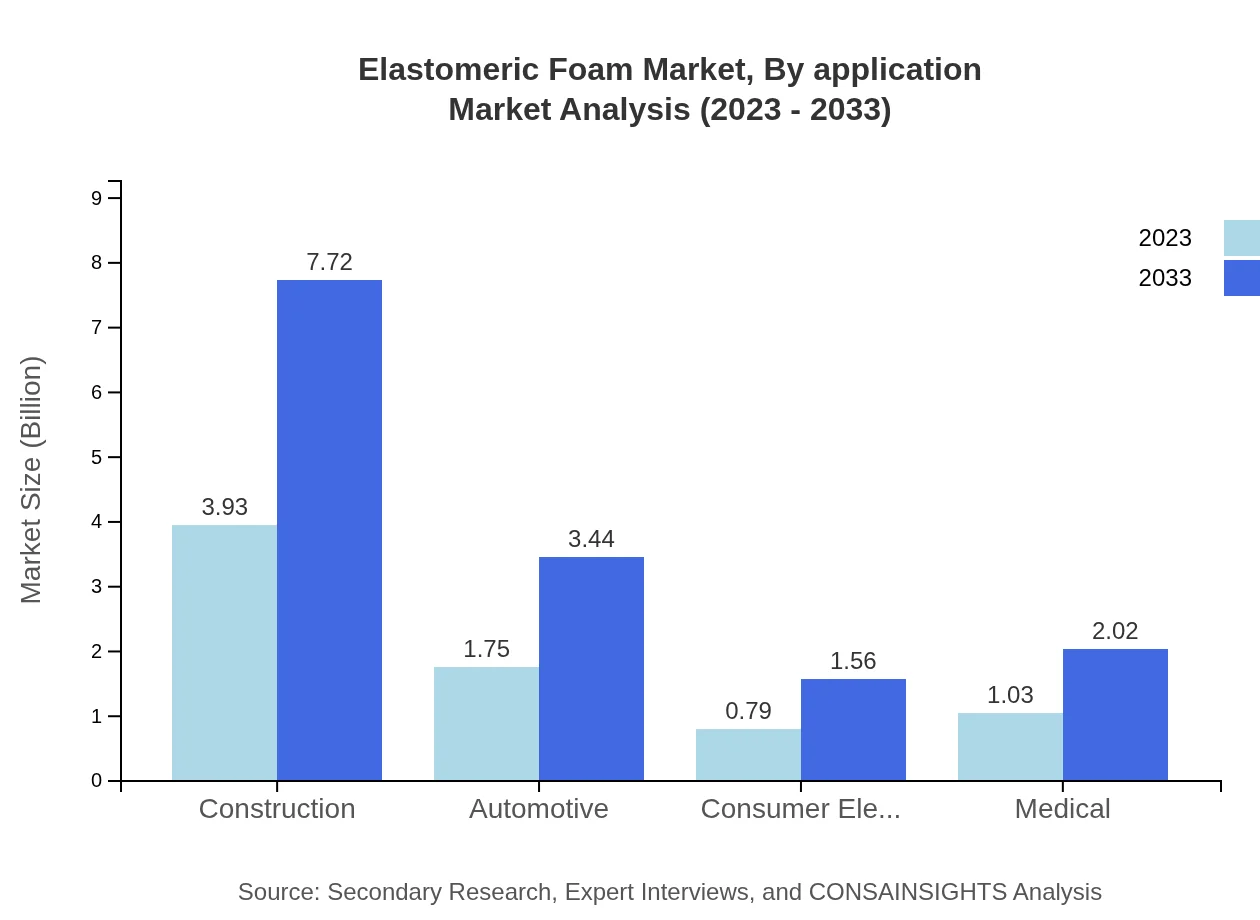

Elastomeric foam is widely used in applications such as construction, automotive, aerospace, and consumer goods. The construction segment stands out, with a market size expected to grow from $3.93 billion in 2023 to $7.72 billion by 2033, highlighting its importance in insulation and soundproofing. The automotive sector also plays a significant role, projected to rise from $1.75 billion to $3.44 billion within the same timeframe.

Elastomeric Foam Market Analysis By Distribution Channel

The distribution channels for elastomeric foam include direct sales, online retail, and retail outlets. Direct sales dominate with a share of 66.95% in 2023, expected to grow as manufacturers streamline their distribution strategies. Online retail is also on the rise, reflecting changing consumer behavior, with projections indicating growth from $1.85 billion to $3.64 billion by 2033.

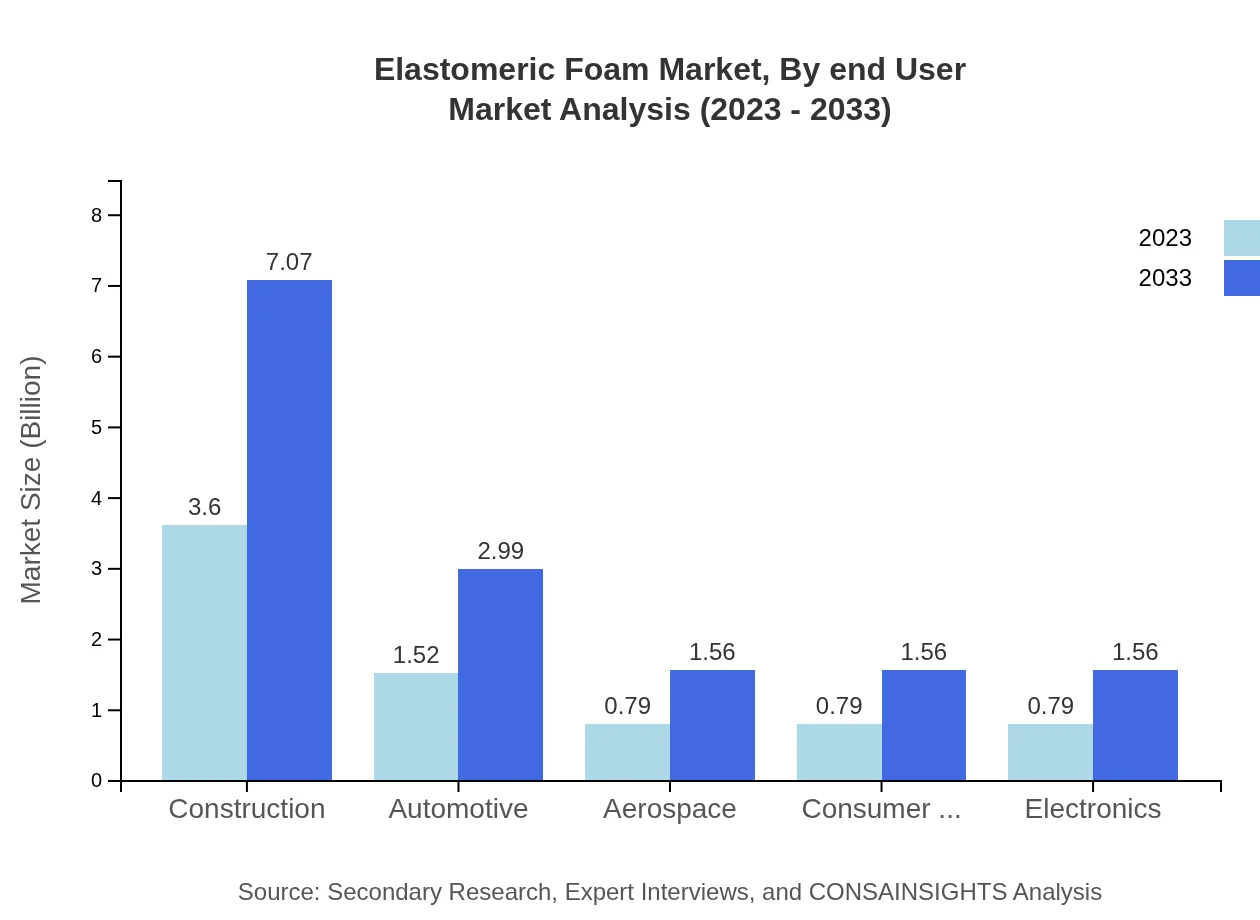

Elastomeric Foam Market Analysis By End User

Different end-user industries utilize elastomeric foam, including construction, automotive, medical, and consumer goods. The construction sector remains the largest end-user, present in various applications, while the medical industry also shows promising growth due to increasing demand for insulated medical devices.

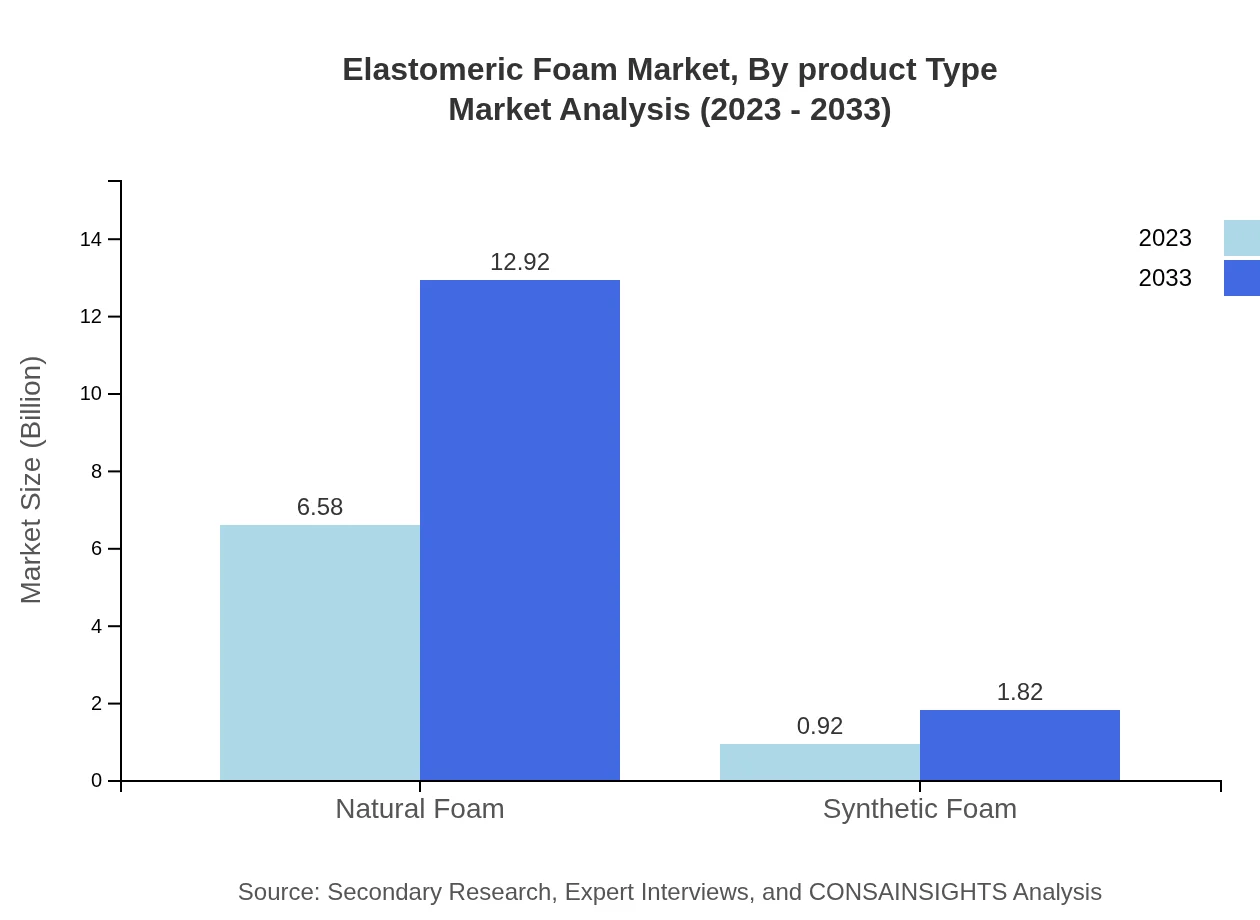

Elastomeric Foam Market Analysis By Formulation

The market can also be segmented by formulation, encompassing natural and synthetic foams. Notably, natural foams lead the market, comprising about 87.67% of the total share due to their eco-friendly characteristics, reinforcing their growing preference in green building initiatives.

Elastomeric Foam Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Elastomeric Foam Industry

BASF SE:

A global leader in production and innovation of chemical products, including elastomeric foams used in construction and automotive applications.Dow Inc.:

Known for its versatile product range, Dow is a key player in the elastomeric foam market, providing solutions to industries worldwide.Huntsman International LLC:

Engaged in the manufacture of flexible and durable elastomeric foams for diverse applications, making significant contributions to product innovation.We're grateful to work with incredible clients.

FAQs

What is the market size of elastomeric foam?

The global elastomeric foam market is currently valued at approximately $7.5 billion and is projected to grow at a CAGR of 6.8% over the next decade, indicating robust demand in various applications and sectors.

What are the key market players or companies in the elastomeric foam industry?

Key players in the elastomeric foam industry include notable manufacturers such as BASF SE, Huntsman Corporation, and The Dow Chemical Company, who lead the market through innovation, strategic alliances, and extensive distribution networks.

What are the primary factors driving the growth in the elastomeric foam industry?

Growth in the elastomeric foam industry is largely driven by increasing demand in construction, automotive, and consumer goods, alongside advancements in manufacturing technology and a growing emphasis on energy efficiency in insulation.

Which region is the fastest Growing in the elastomeric foam market?

The North American region is the fastest-growing market for elastomeric foam, projected to expand from $2.70 billion in 2023 to $5.30 billion by 2033, driven by construction and automotive sectors.

Does ConsaInsights provide customized market report data for the elastomeric foam industry?

Yes, ConsaInsights offers tailored market report data for the elastomeric foam industry, allowing businesses to obtain specific insights and analysis that cater to their unique requirements and strategic goals.

What deliverables can I expect from this elastomeric foam market research project?

From this market research project on elastomeric foam, you can expect comprehensive analysis reports, market forecasts, and insights into emerging trends and competitive landscapes tailored to inform strategic decision-making.

What are the market trends of elastomeric foam?

Current trends in the elastomeric foam market include increased utilization in sustainable construction materials, a shift towards advanced polymer technologies, and growing adoption in emerging markets across Asia-Pacific and Latin America.