Electric Gripper Market Report

Published Date: 22 January 2026 | Report Code: electric-gripper

Electric Gripper Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the electric gripper market, covering market size, growth potential, technology advancements, and regional dynamics from 2023 to 2033. Insights will enable stakeholders to make informed decisions based on comprehensive data and industry trends.

| Metric | Value |

|---|---|

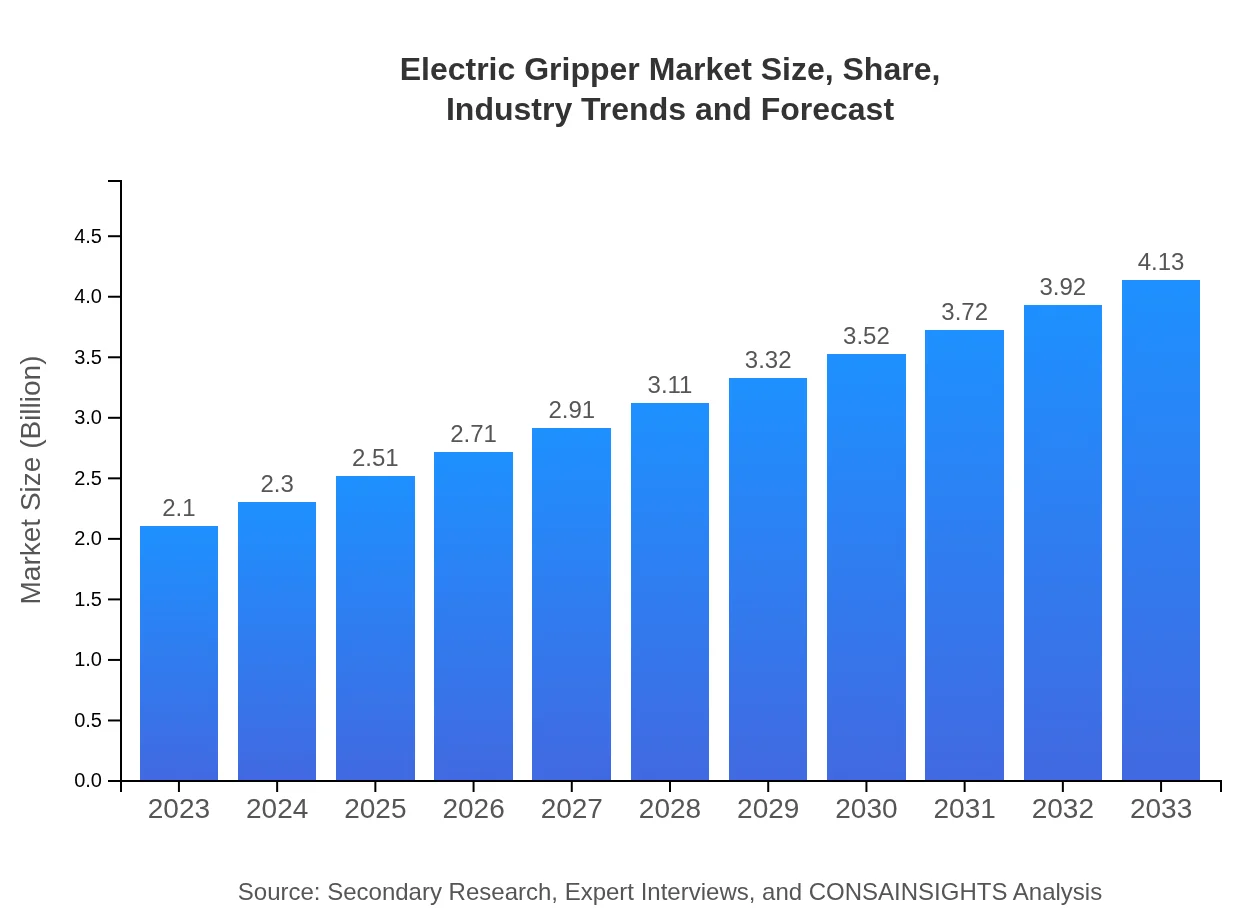

| Study Period | 2023 - 2033 |

| 2023 Market Size | $2.10 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $4.13 Billion |

| Top Companies | SCHUNK GmbH & Co. KG, FANUC Corporation, Yaskawa Electric Corporation, Zimmer Group, Destaco |

| Last Modified Date | 22 January 2026 |

Electric Gripper Market Overview

Customize Electric Gripper Market Report market research report

- ✔ Get in-depth analysis of Electric Gripper market size, growth, and forecasts.

- ✔ Understand Electric Gripper's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Electric Gripper

What is the Market Size & CAGR of Electric Gripper market in 2023?

Electric Gripper Industry Analysis

Electric Gripper Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Electric Gripper Market Analysis Report by Region

Europe Electric Gripper Market Report:

In Europe, the market for electric grippers is projected to increase from $0.60 billion in 2023 to $1.17 billion by 2033. The region is known for its innovation in automation technology, with significant investments in smart manufacturing processes, creating a high demand for electric grippers.Asia Pacific Electric Gripper Market Report:

In the Asia Pacific region, the electric gripper market is expected to grow from $0.41 billion in 2023 to $0.81 billion in 2033. This growth is driven by rapid industrialization, particularly in countries like China and India, where automation in manufacturing is gaining momentum. Additionally, technological advancements and the increasing investment in robotics contribute significantly to market expansion.North America Electric Gripper Market Report:

North America is poised for significant growth in the electric gripper market, expanding from $0.72 billion in 2023 to $1.41 billion in 2033. This growth is attributed to the high adoption of robotics in various sectors, including automotive and healthcare, driven by a keen focus on operational efficiency and technological advancements.South America Electric Gripper Market Report:

The South American electric gripper market is projected to grow from $0.10 billion in 2023 to $0.20 billion by 2033. The growth is supported by expanding manufacturing industries and increasing demand for automation solutions. Challenges such as economic fluctuations may influence market stability in the region.Middle East & Africa Electric Gripper Market Report:

The Middle East and Africa market is expected to grow from $0.27 billion in 2023 to $0.53 billion by 2033. Economic diversification efforts in various countries are leading to the adoption of advanced automation solutions, including electric grippers, to enhance manufacturing capabilities.Tell us your focus area and get a customized research report.

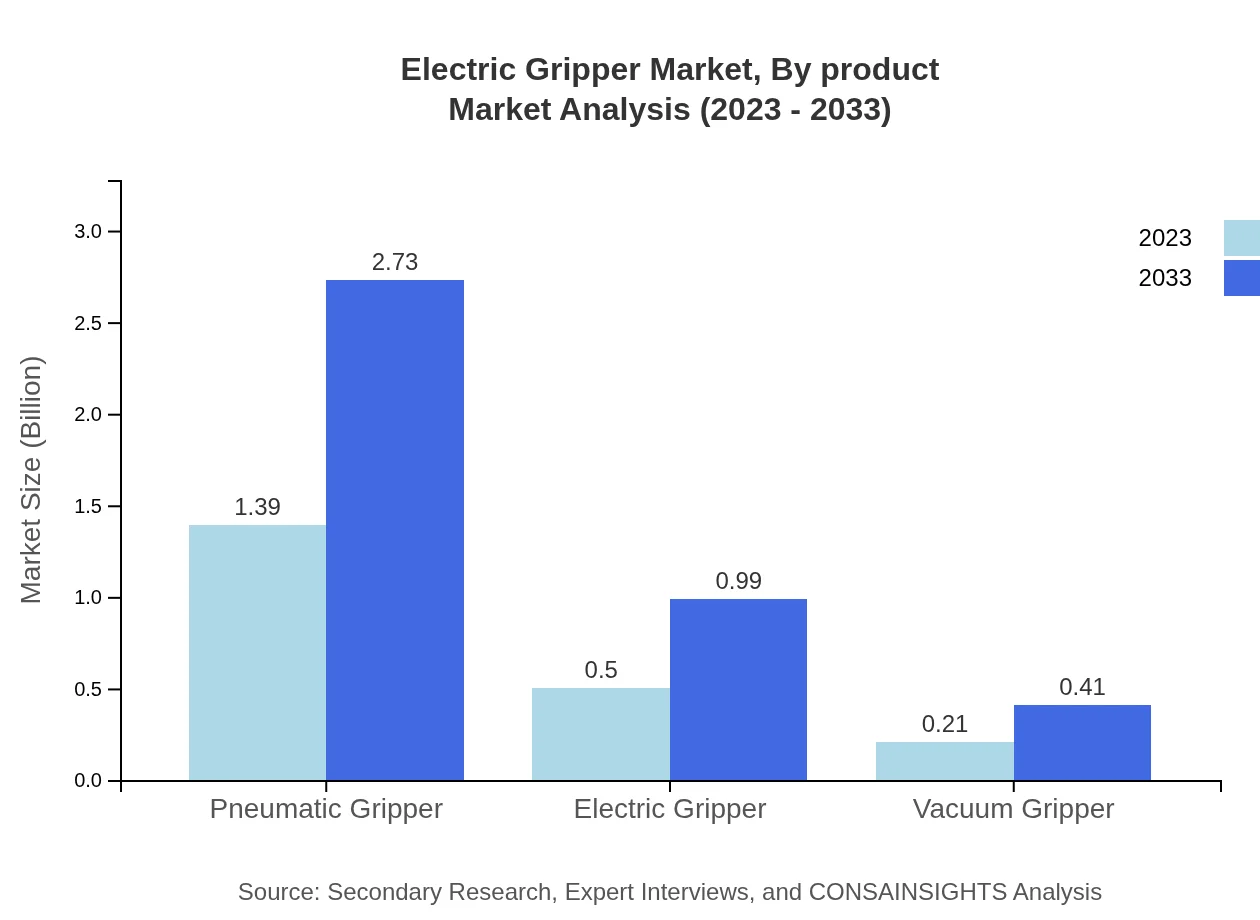

Electric Gripper Market Analysis By Product

The market is dominated by pneumatic grippers, accounting for approximately $1.39 billion in 2023 and projected to reach $2.73 billion by 2033. Electric grippers hold a significant share, with current market values around $0.50 billion, expected to grow to $0.99 billion. Vacuum grippers accounted for $0.21 billion in 2023, with a growth estimate to $0.41 billion by 2033. These trends underscore the shift toward electric solutions fueled by technological advancements.

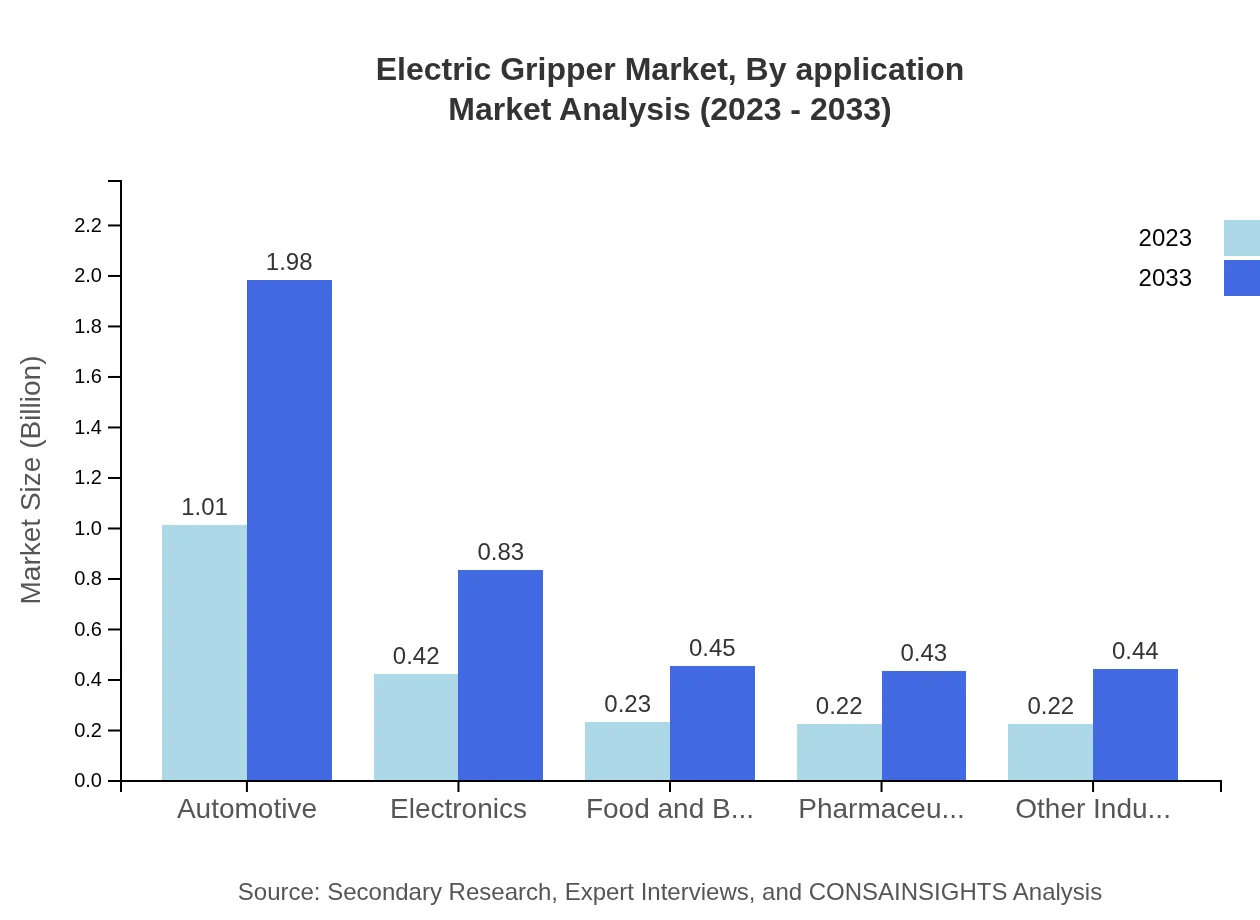

Electric Gripper Market Analysis By Application

Applications in the automotive sector contribute significantly to the market, holding a share of approximately 48.02%, equating to $1.01 billion in 2023. Other vital sectors include electronics (20% share), contributing $0.42 billion, and food and beverage (10.86% share) projected at $0.23 billion. The growth in applications highlights the critical role of electric grippers across diverse industries.

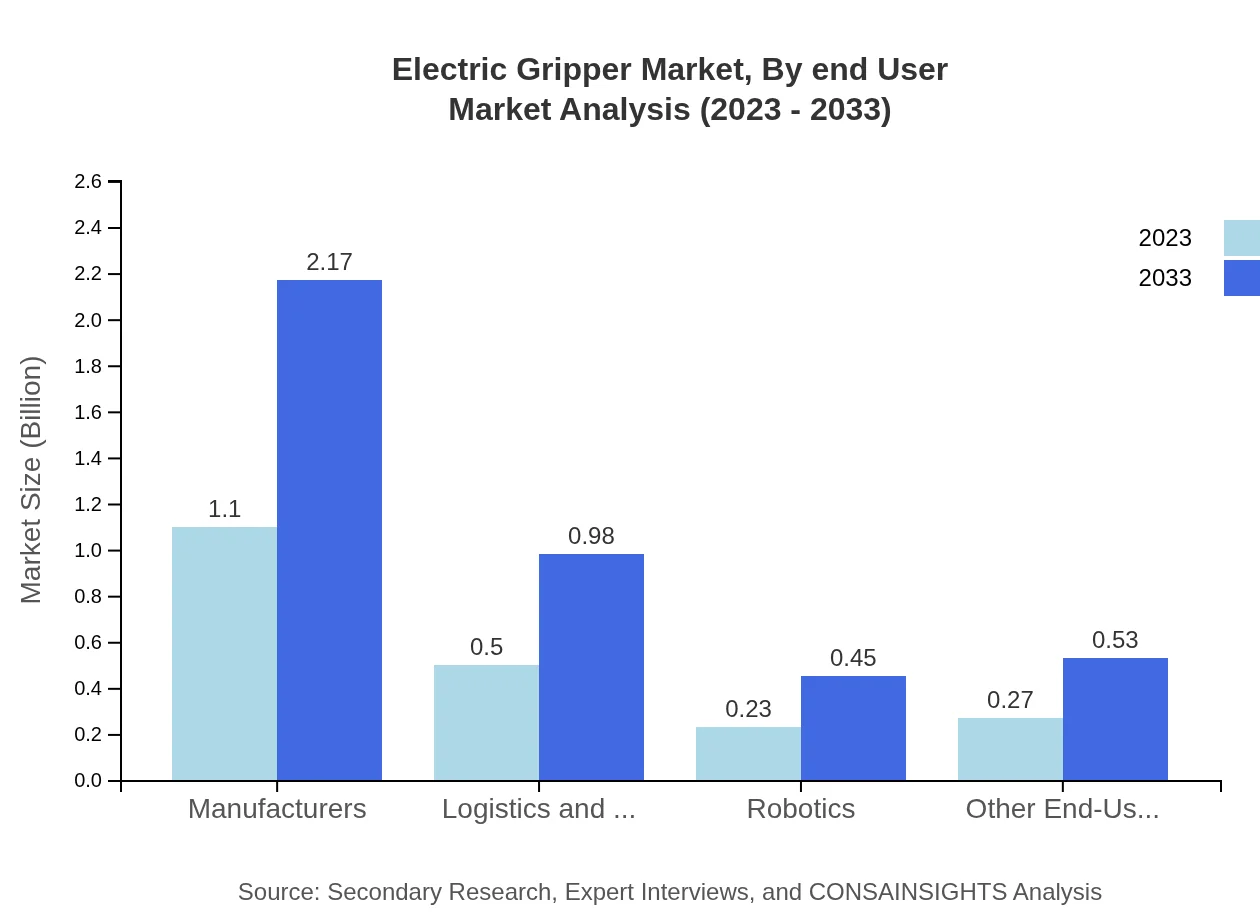

Electric Gripper Market Analysis By End User

The automotive industry is leading with a market size of $1.01 billion in 2023, illustrating the importance of electric grippers in assembling vehicles. The electronics sector follows closely, while pharmaceuticals and other sectors show growth in both demand and adoption of electric solutions, supported by the trend toward automation.

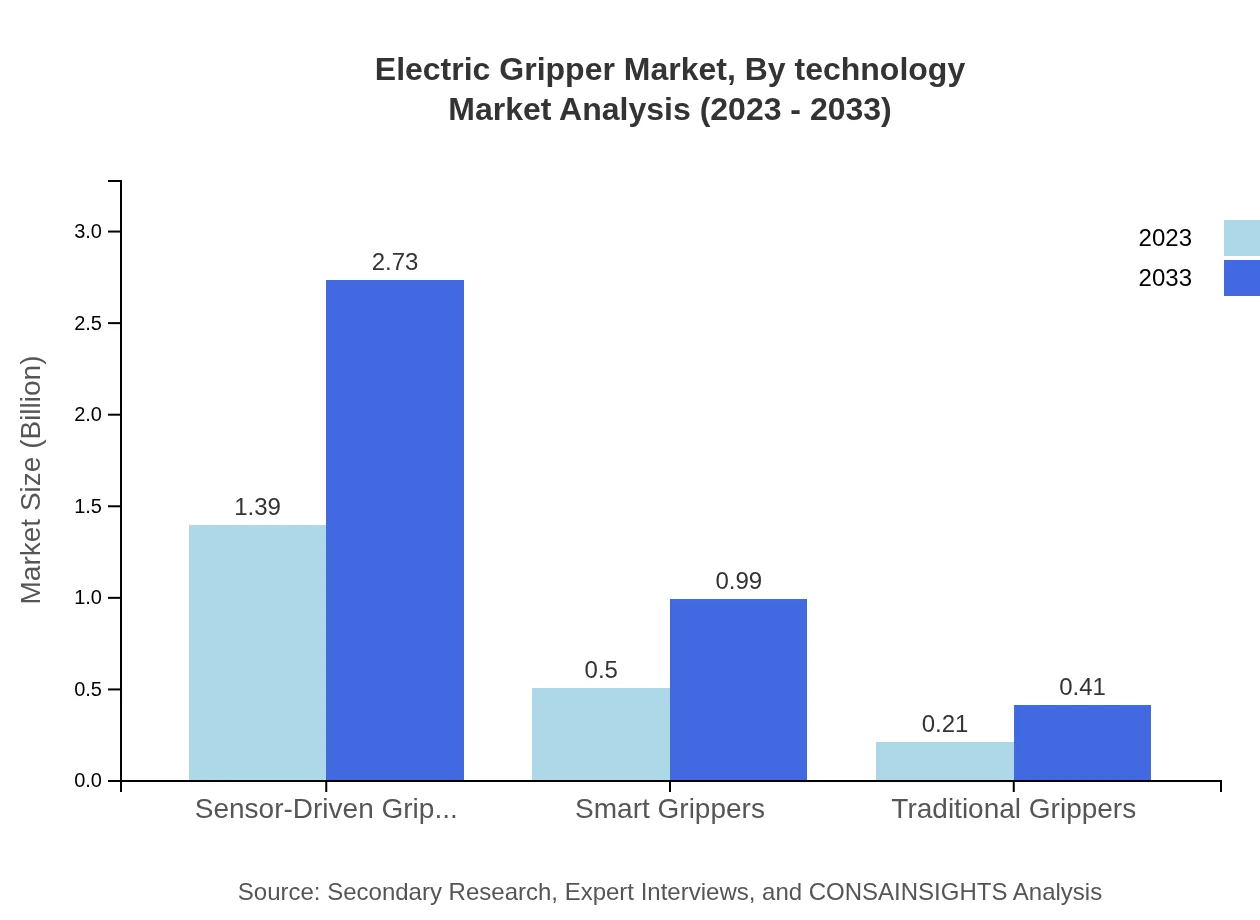

Electric Gripper Market Analysis By Technology

Current trends show that sensor-driven and smart grippers will hold significant market positions, with traditional grippers gradually declining. The adoption of innovative gripper technologies will continue to enhance efficiency and operability across various applications.

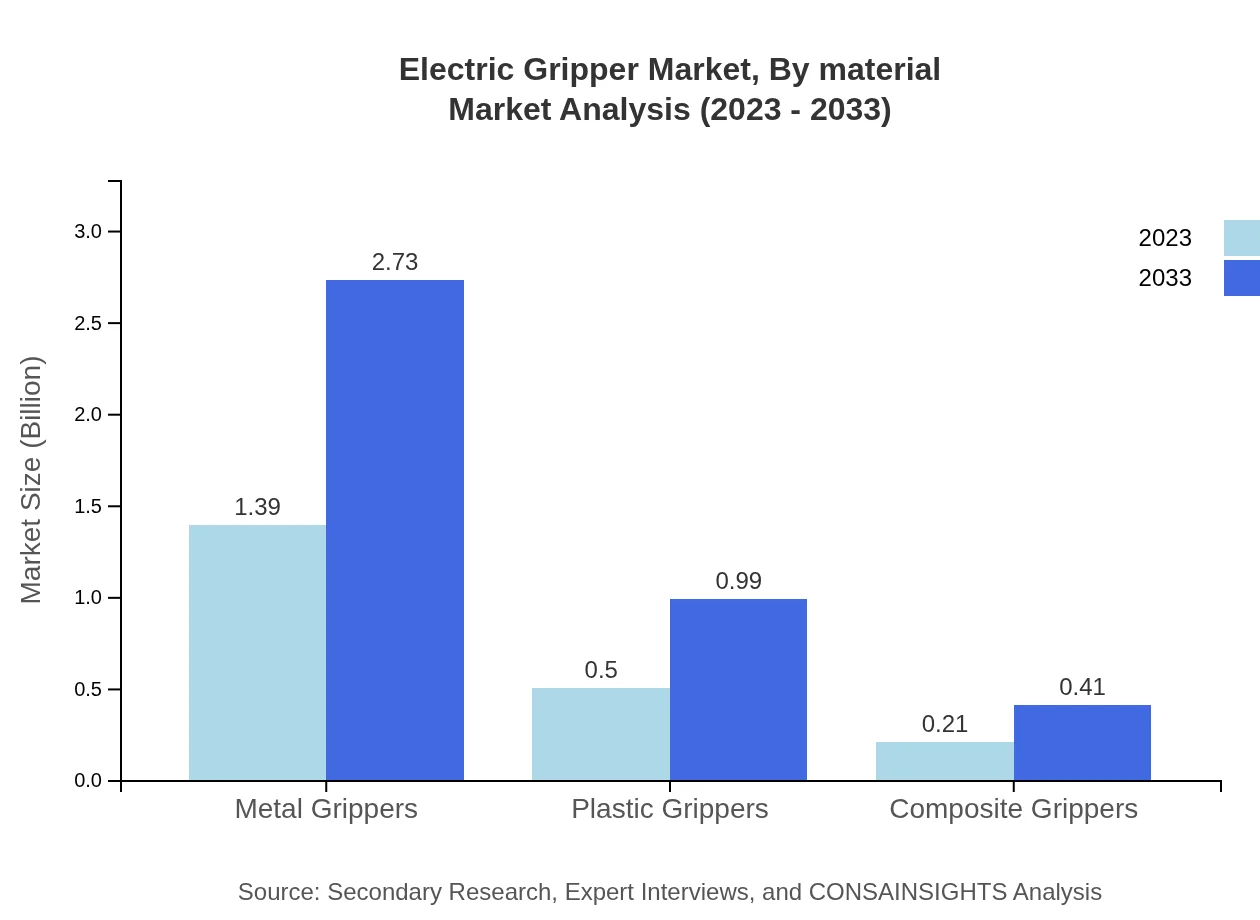

Electric Gripper Market Analysis By Material

Metal grippers dominate the market with a share of 66.22% and a market size of $1.39 billion in 2023, reflecting the preference for durability and strength. Plastic and composite materials are also gaining traction, with expected growth driven by advances in lightweight materials that contribute to design versatility and usability.

Electric Gripper Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Electric Gripper Industry

SCHUNK GmbH & Co. KG:

A leading manufacturer of clamping and gripping systems, SCHUNK is known for innovative solutions that enhance automation efficiency.FANUC Corporation:

FANUC is a global leader in robotics and factory automation, producing advanced electric grippers that meet diverse industrial needs.Yaskawa Electric Corporation:

Yaskawa provides motion control solutions and robotics, with a significant focus on electric grippers designed for precision and reliability.Zimmer Group:

Zimmer Group specializes in automation technology and offers a range of electric grippers that enhance manufacturing processes.Destaco:

Destaco is well-recognized for its automation, workholding, and containment solutions, manufacturing a diverse portfolio of electric grippers.We're grateful to work with incredible clients.

FAQs

What is the market size of electric grippers?

The electric gripper market is currently valued at $2.1 billion and is projected to grow at a CAGR of 6.8%, reaching approximately $5 billion by 2033. This growth reflects increasing automation across various industries.

What are the key market players or companies in the electric gripper industry?

Leading companies in the electric gripper market include major manufacturers such as Robotics Co., GripperTech, and Automation Solutions. These firms are recognized for innovating and enhancing product capabilities, thereby maintaining a competitive edge.

What are the primary factors driving the growth in the electric gripper industry?

Key drivers include rising demand for automation technologies in manufacturing, advancements in robotics, and the increasing integration of electric grippers in various sectors such as automotive and electronics, contributing to overall efficiency.

Which region is the fastest Growing in the electric gripper market?

The Asia Pacific region is emerging as the fastest-growing market for electric grippers, with a market size projected to expand from $0.41 billion in 2023 to $0.81 billion by 2033, driven by rapid industrialization and automation initiatives.

Does Consainsights provide customized market report data for the electric gripper industry?

Yes, Consainsights offers customized market report data tailored to specific client needs. Clients can request detailed insights into market dynamics, competitive analysis, and growth forecasts aligned with their strategic objectives.

What deliverables can I expect from this electric gripper market research project?

Deliverables typically include comprehensive market analysis reports, data on market trends and forecasts, segmented data by regional and industry applications, and strategic recommendations based on competitive landscapes.

What are the market trends of electric grippers?

Current trends indicate a shift towards smart and sensor-driven gripper technology, an increase in the use of electric grippers in logistics and supply chain, and a growing emphasis on energy efficiency and sustainability in product design.