Electric Presses Market Report

Published Date: 22 January 2026 | Report Code: electric-presses

Electric Presses Market Size, Share, Industry Trends and Forecast to 2033

This report analyzes the Electric Presses market from 2023 to 2033, offering insights into market size, trends, regional analysis, and forecasts. It covers key players and technology impacts on the industry.

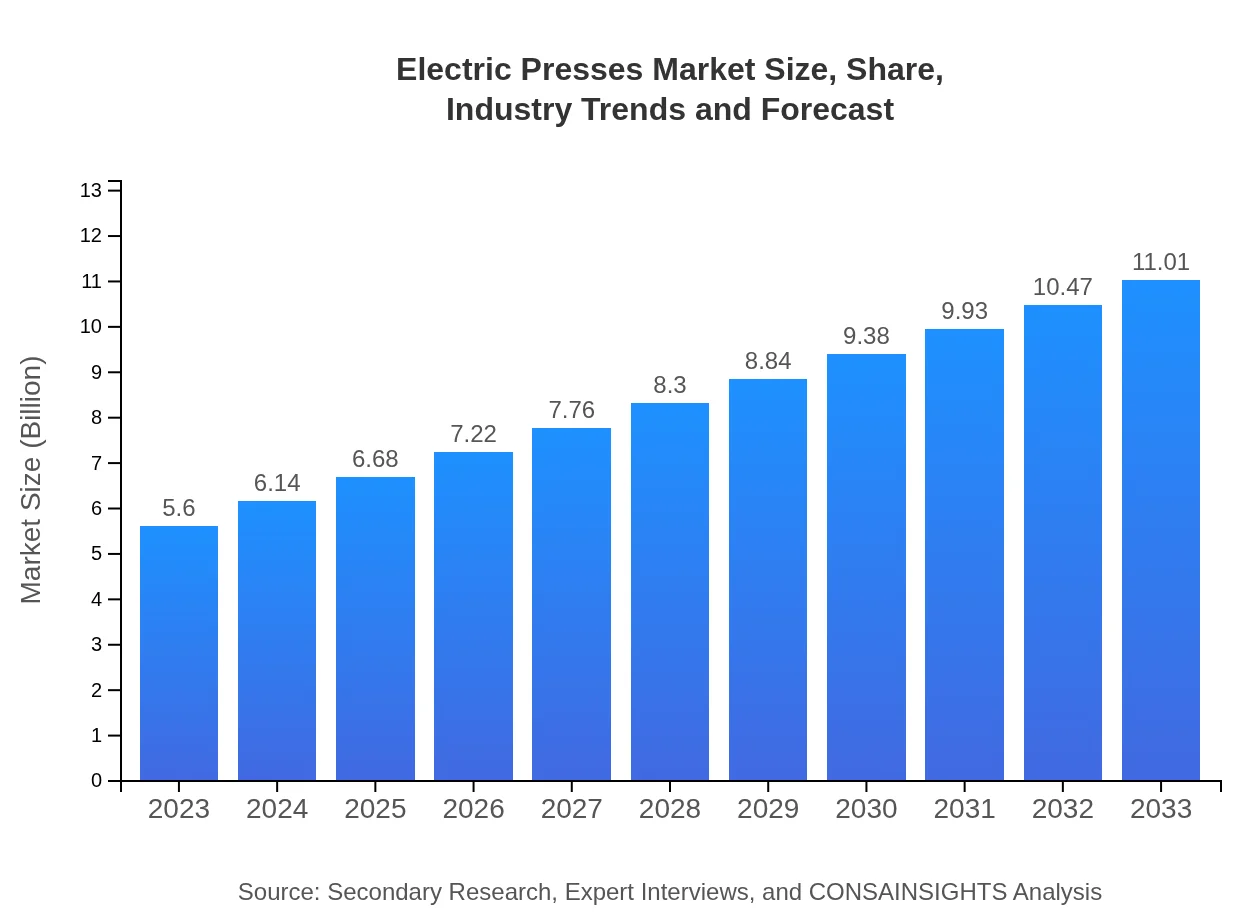

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.60 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $11.01 Billion |

| Top Companies | Schuler Group, Fagor Arrasate, AIDA Engineering, Ltd., Seyi Press |

| Last Modified Date | 22 January 2026 |

Electric Presses Market Overview

Customize Electric Presses Market Report market research report

- ✔ Get in-depth analysis of Electric Presses market size, growth, and forecasts.

- ✔ Understand Electric Presses's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Electric Presses

What is the Market Size & CAGR of Electric Presses market in 2023?

Electric Presses Industry Analysis

Electric Presses Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Electric Presses Market Analysis Report by Region

Europe Electric Presses Market Report:

The European market is anticipated to grow from USD 1.51 billion in 2023 to USD 2.97 billion by 2033, supported by stringent regulations aimed at enhancing energy efficiency and an inclination towards automation in manufacturing.Asia Pacific Electric Presses Market Report:

The Asia Pacific market is witnessing robust growth, projected to rise from USD 1.22 billion in 2023 to USD 2.40 billion by 2033. This growth is driven by rapid industrialization, investments in the automotive sector, and increasing production capacities in countries like China and India.North America Electric Presses Market Report:

North America holds a substantial share of the Electric Presses market, expanding from USD 1.85 billion in 2023 to USD 3.63 billion in 2033. This increase is fueled by technological innovations and a strong automotive manufacturing sector that sustains demand for electric presses.South America Electric Presses Market Report:

In South America, the Electric Presses market size is expected to double from USD 0.33 billion in 2023 to USD 0.66 billion by 2033. The growth can be attributed to expanding manufacturing industries and a growing emphasis on efficient production techniques.Middle East & Africa Electric Presses Market Report:

In the Middle East and Africa region, the market is expected to grow from USD 0.69 billion in 2023 to USD 1.35 billion by 2033. As manufacturing capabilities expand and economies diversify, the need for electric presses to enhance production efficiency is on the rise.Tell us your focus area and get a customized research report.

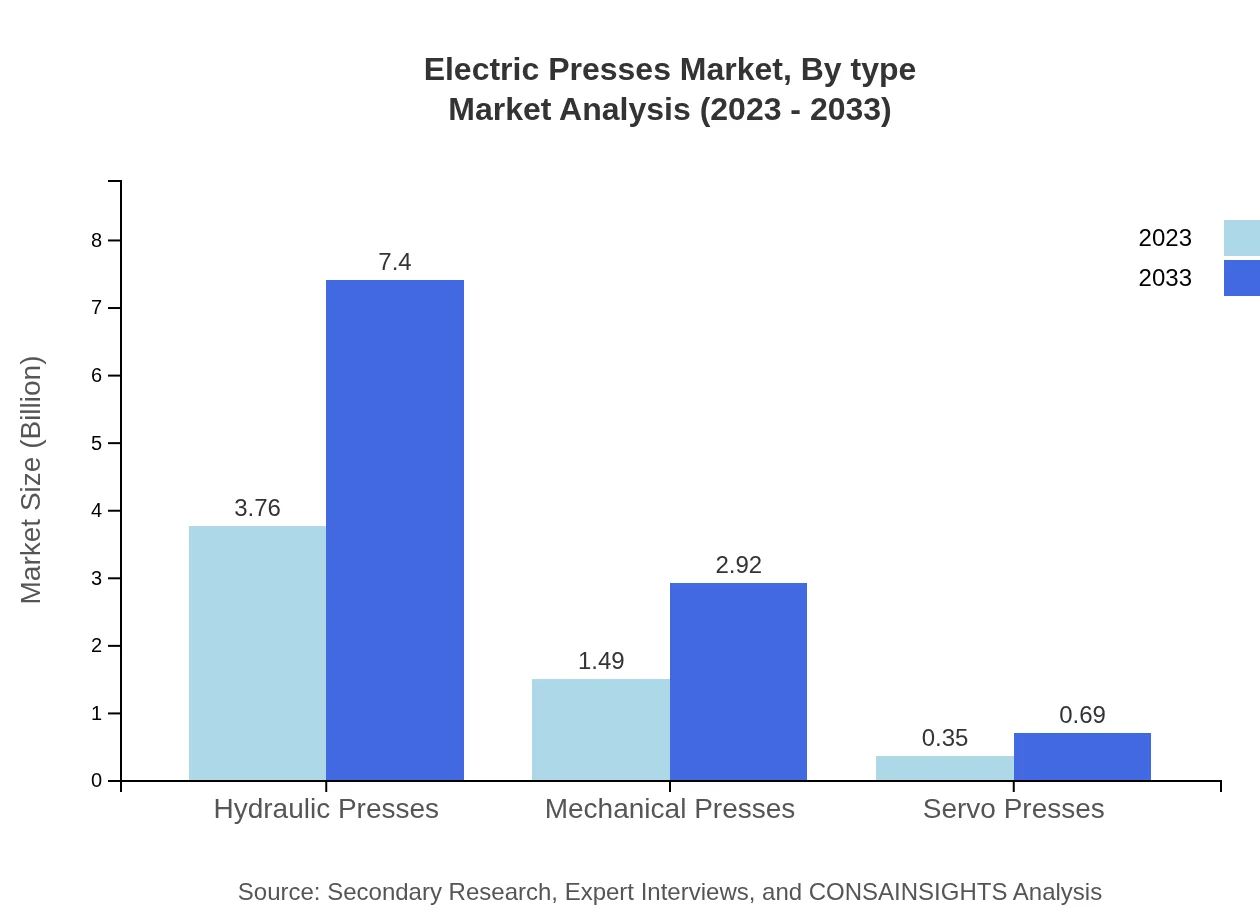

Electric Presses Market Analysis By Type

The market is segmented into hydraulic presses, mechanical presses, and servo presses, with hydraulic presses dominating the market in size and share. In 2023, hydraulic presses account for USD 3.76 billion and 67.21% market share, which is expected to increase to USD 7.40 billion in size by 2033, maintaining the same market share.

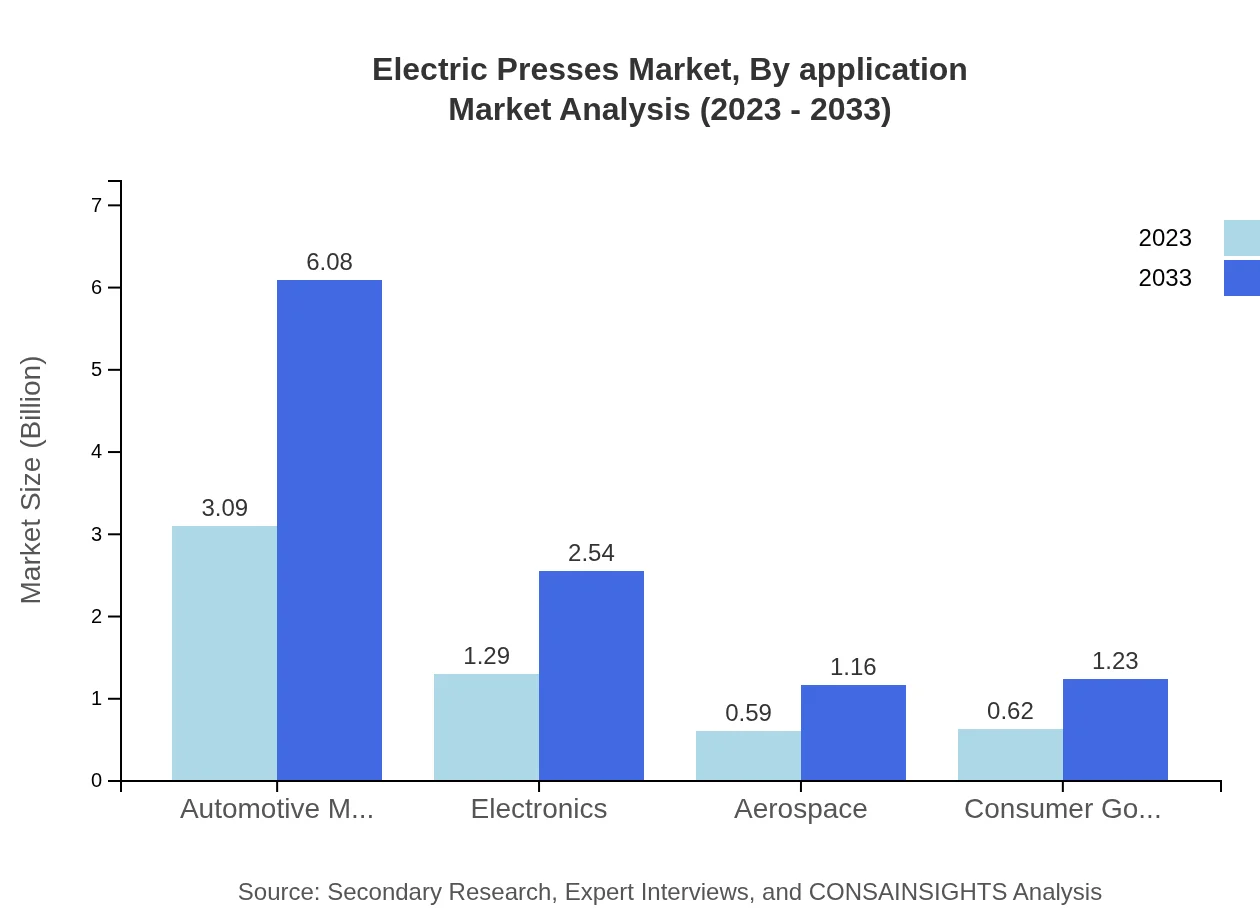

Electric Presses Market Analysis By Application

Applications of electric presses span across automotive and electronics, with automotive accounting for USD 3.09 billion in size in 2023. This segment is expected to grow to USD 6.08 billion by 2033, holding a market share of 55.26%. Electronics follows with a size of USD 1.29 billion in 2023, projected to reach USD 2.54 billion by 2033.

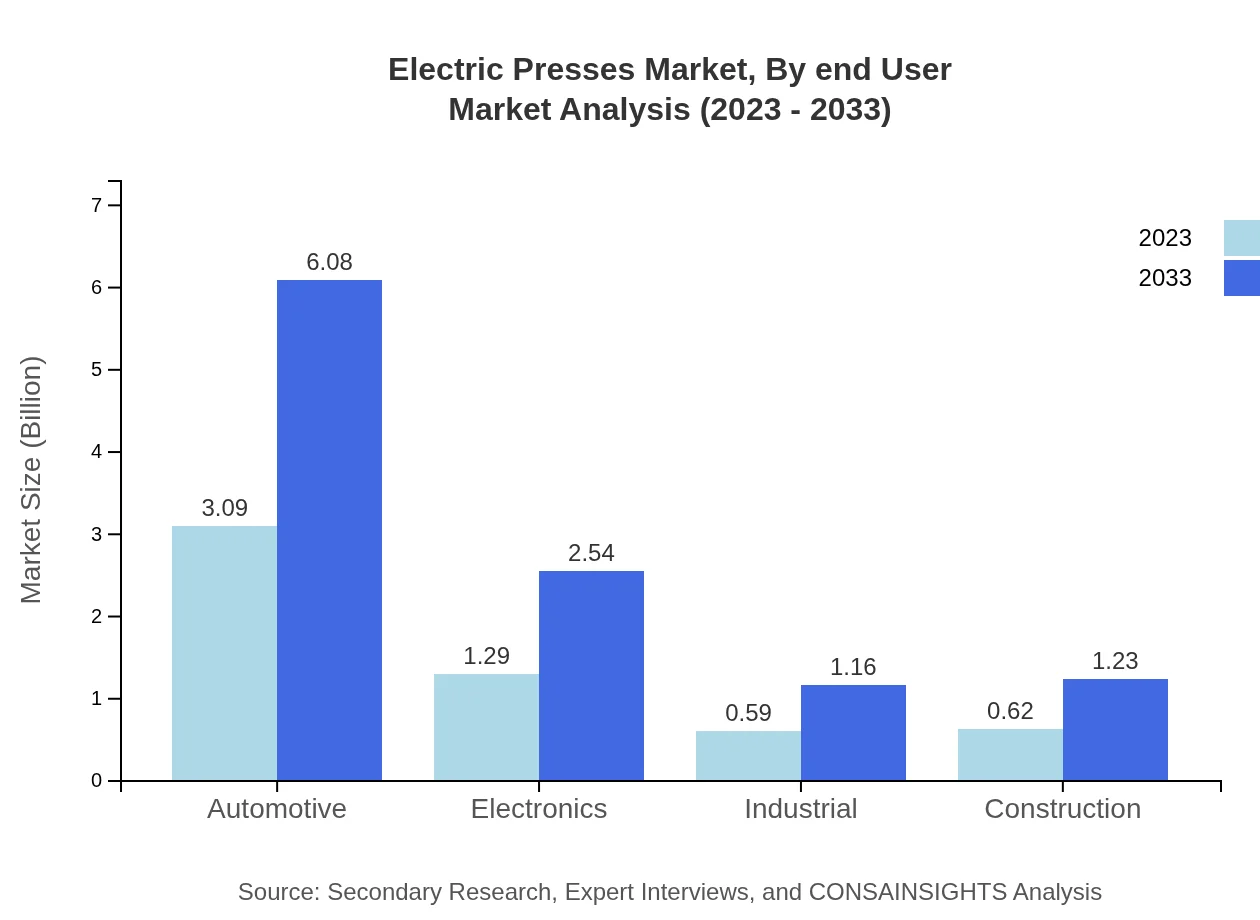

Electric Presses Market Analysis By End User

End-user industries such as automotive, electronics, aerospace, consumer goods, and industrial components significantly influence market dynamics. The automotive industry, for instance, commands a robust share of usage, which demonstrates continuous growth as the sector further embraces automation and efficiency.

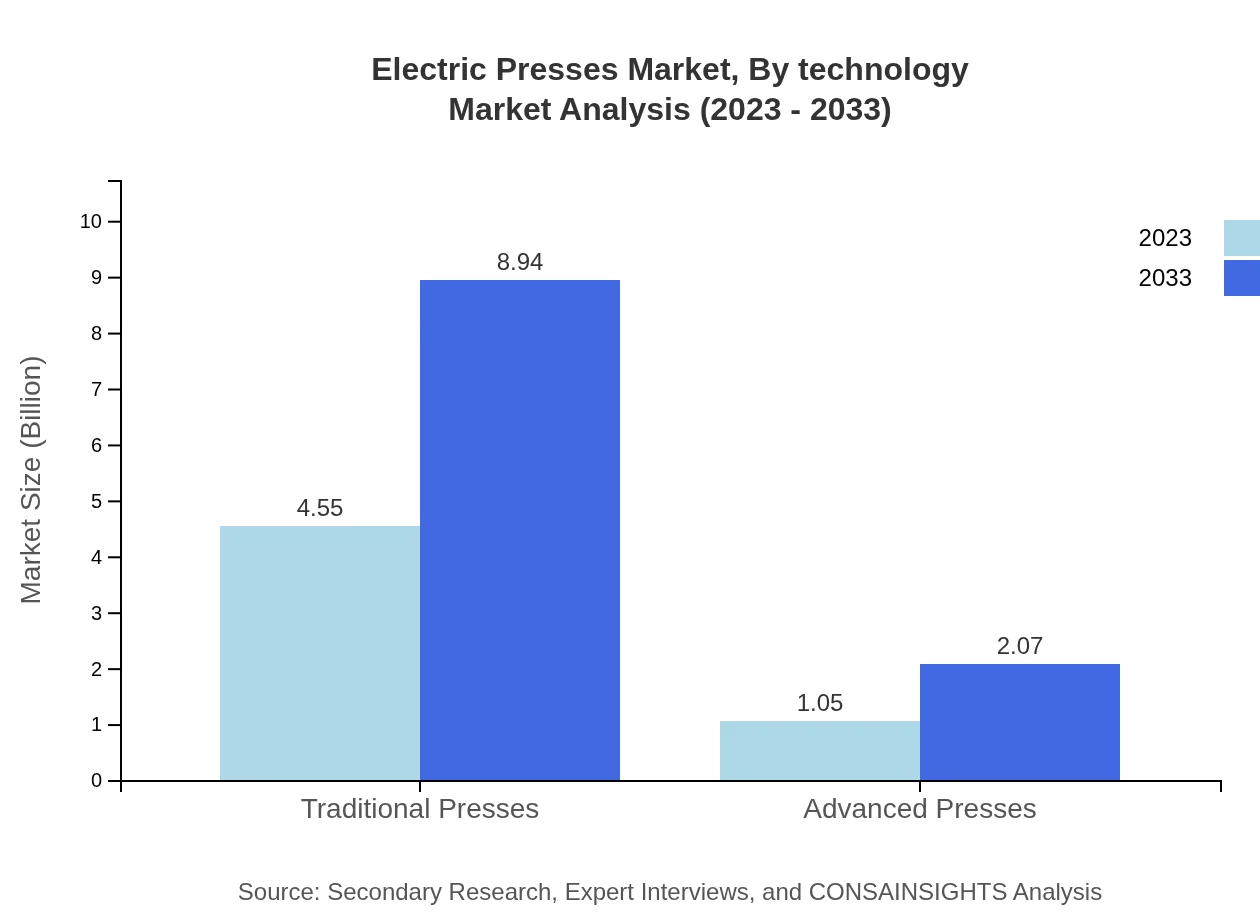

Electric Presses Market Analysis By Technology

The adoption of advanced technologies in electric presses, including automation and IoT integration, is transforming manufacturing processes. These technological advancements are anticipated to strengthen market growth while enhancing operational efficiency and precision in the manufacturing landscape.

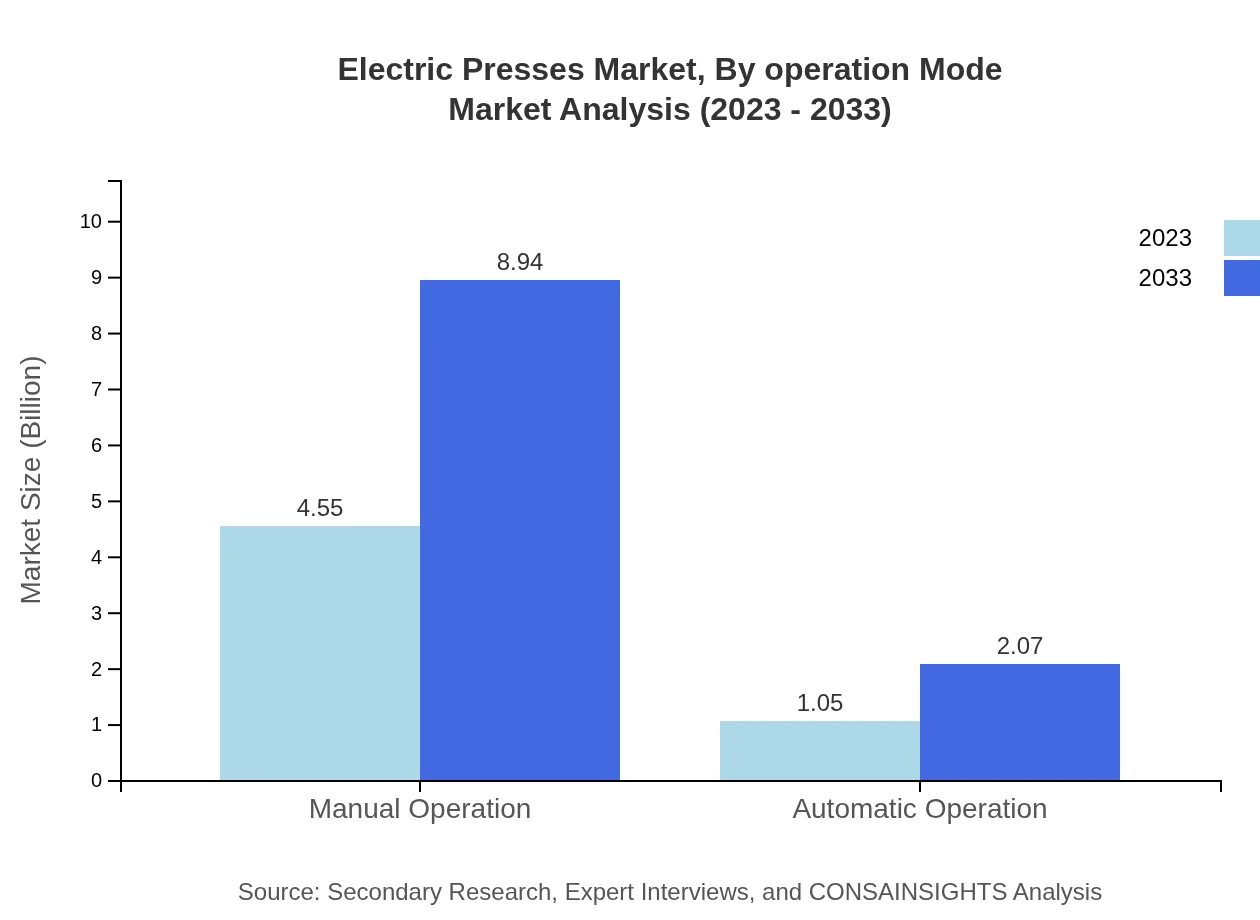

Electric Presses Market Analysis By Operation Mode

The market is also analyzed on the basis of operation modes, distinguishing between manual and automatic operations. Manual operations currently dominate the market share, but automatic operations are increasingly being adopted due to their efficiency and ease of use, indicating a shift in manufacturing paradigms.

Electric Presses Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Electric Presses Industry

Schuler Group:

A renowned player in machinery manufacturing, known for its advanced electric presses and comprehensive solutions across various industrial sectors.Fagor Arrasate:

An established name in the European market, providing innovative electric pressing systems tailored for automotive and industrial applications.AIDA Engineering, Ltd.:

A global leader with decades of experience, famous for its reliability in electric presses, catering mainly to the automotive and electronics markets.Seyi Press:

A prominent manufacturer recognized for its efficient electric pressing solutions, focusing on precision engineering.We're grateful to work with incredible clients.

FAQs

What is the market size of electric Presses?

The global electric presses market is projected to grow from $5.6 billion in 2023 to an estimated size reflecting a CAGR of 6.8% by 2033. This growth points to increasing demand across various sectors such as automotive and electronics.

What are the key market players or companies in the electric Presses industry?

Key players in the electric-presses market include industry giants recognized for their innovative technologies and high-quality equipment. They dominate through extensive research and development, catering primarily to sectors such as automotive, electronics, and manufacturing.

What are the primary factors driving the growth in the electric presses industry?

Growth in the electric presses industry is driven by the increasing demand for automation in manufacturing, advancements in technology, and the need for energy-efficient solutions. These factors combine to enhance productivity and reduce operational costs across industries.

Which region is the fastest Growing in the electric presses market?

Asia Pacific is expected to be the fastest-growing region in the electric presses market, with projected growth from $1.22 billion in 2023 to $2.40 billion by 2033. This growth is fueled by expanding manufacturing sectors and technological adoption.

Does ConsaInsights provide customized market report data for the electric presses industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs within the electric presses industry. This ensures clients receive targeted insights and analyses relevant to their unique market conditions.

What deliverables can I expect from this electric presses market research project?

Deliverables from the electric presses market research project include comprehensive reports, market analysis, segmented data insights, and actionable strategies. These resources are designed to support informed decision-making and strategic planning.

What are the market trends of electric presses?

Current trends in the electric presses market include a shift towards automation, increasing integration of smart technologies, and a focus on sustainability. Additionally, there is a rising trend in the adoption of hydraulic and servo presses in various industries.