Electron Beam Machining Market Report

Published Date: 22 January 2026 | Report Code: electron-beam-machining

Electron Beam Machining Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Electron Beam Machining market from 2023 to 2033, covering critical insights, market trends, segmentation, and regional performances, alongside key players shaping the industry.

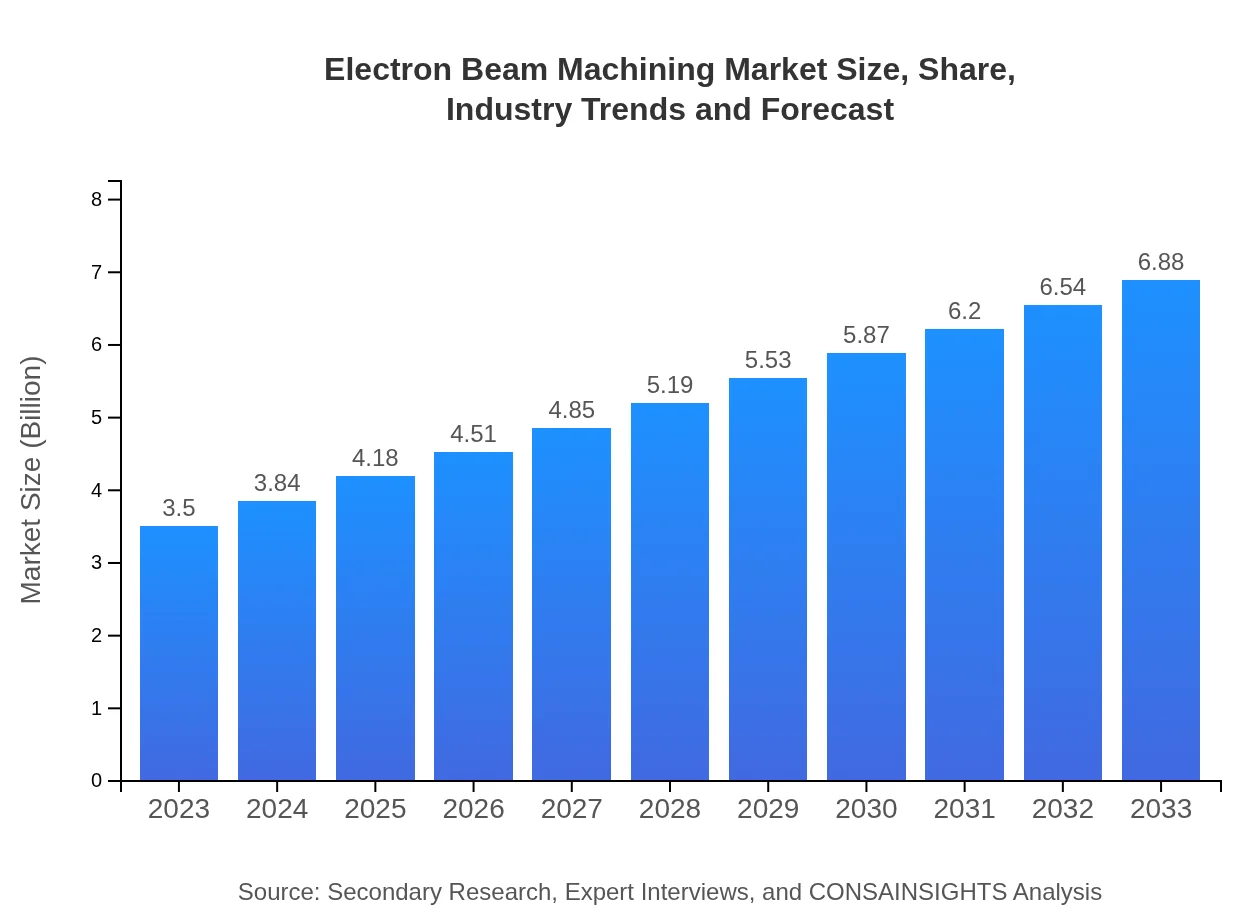

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $3.50 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $6.88 Billion |

| Top Companies | Fives Group, Nikon, Heraeus, FANUC |

| Last Modified Date | 22 January 2026 |

Electron Beam Machining Market Overview

Customize Electron Beam Machining Market Report market research report

- ✔ Get in-depth analysis of Electron Beam Machining market size, growth, and forecasts.

- ✔ Understand Electron Beam Machining's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Electron Beam Machining

What is the Market Size & CAGR of Electron Beam Machining market in 2023?

Electron Beam Machining Industry Analysis

Electron Beam Machining Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Electron Beam Machining Market Analysis Report by Region

Europe Electron Beam Machining Market Report:

The European market is set to transition from 1.10 billion USD in 2023 to 2.16 billion USD by 2033, driven by innovations across several industries, particularly in medical devices and automotive manufacturing, where precision is critical.Asia Pacific Electron Beam Machining Market Report:

In the Asia Pacific region, the market for Electron Beam Machining is on the rise, with a market value of approximately 0.66 billion USD expected to grow to 1.29 billion USD by 2033. The growth is spurred by an increase in aerospace and automotive manufacturing, coupled with technological advancements in the region.North America Electron Beam Machining Market Report:

North America, valued at 1.26 billion USD in 2023 and projected to double to 2.47 billion USD by 2033, remains a significant market due to a strong aerospace and defense sector investing heavily in advanced manufacturing technologies.South America Electron Beam Machining Market Report:

The South American market, starting at 0.14 billion USD in 2023 and anticipated to reach 0.28 billion USD by 2033, is gradually expanding due to the rising adoption of EBM technologies in local manufacturing sectors.Middle East & Africa Electron Beam Machining Market Report:

The Middle East and Africa expect a market increase from 0.34 billion USD in 2023 to approximately 0.67 billion USD by 2033, as EBM applications begin to penetrate into emerging markets and oil-derived sectors.Tell us your focus area and get a customized research report.

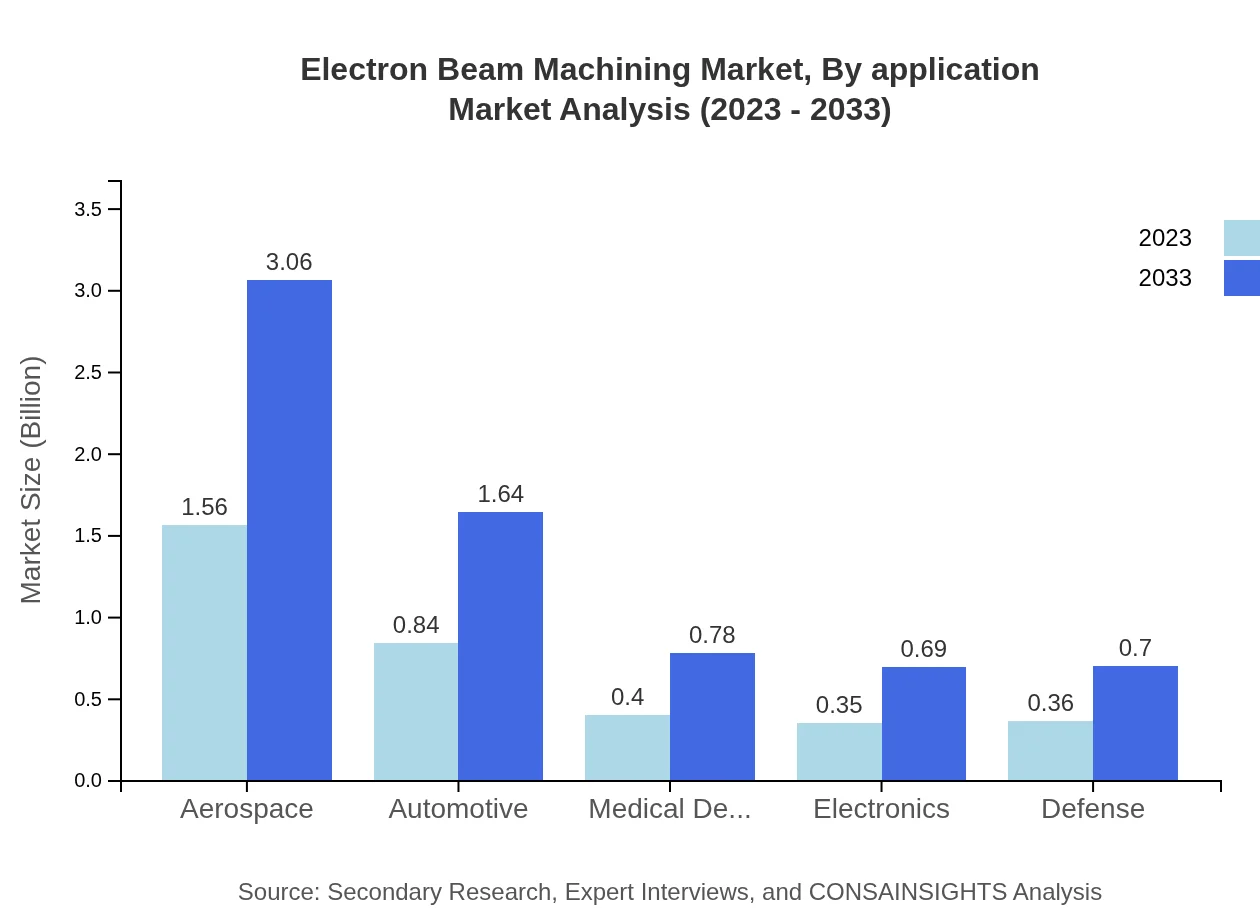

Electron Beam Machining Market Analysis By Application

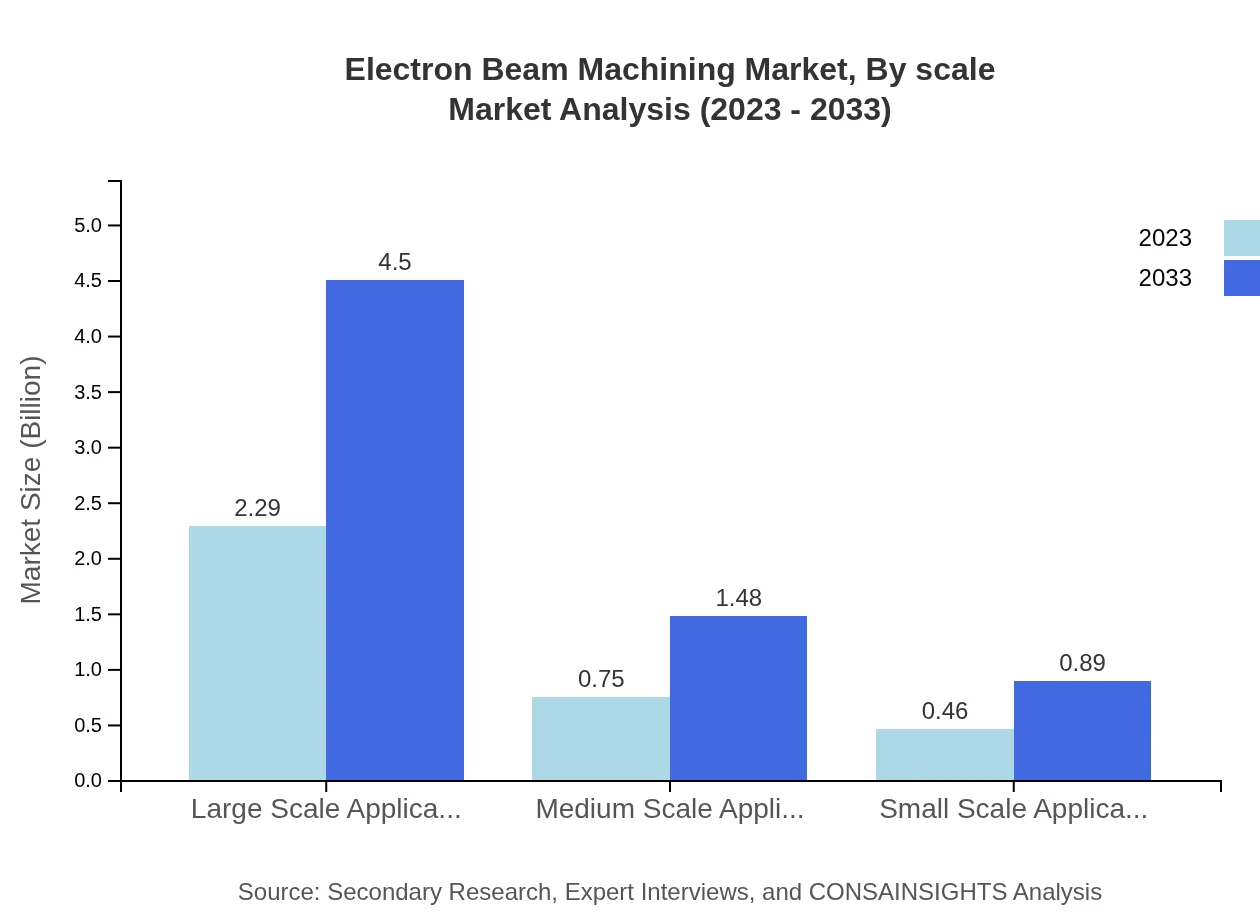

The Electron Beam Machining market by application shows a marked preference for large-scale applications, which alone accounts for 65.44% of the market share and is anticipated to reach 4.50 billion USD by 2033. Medium and small scale applications will show steady growth resulting in market sizes expected to attain 1.48 billion USD and 0.89 billion USD, respectively, by the same year.

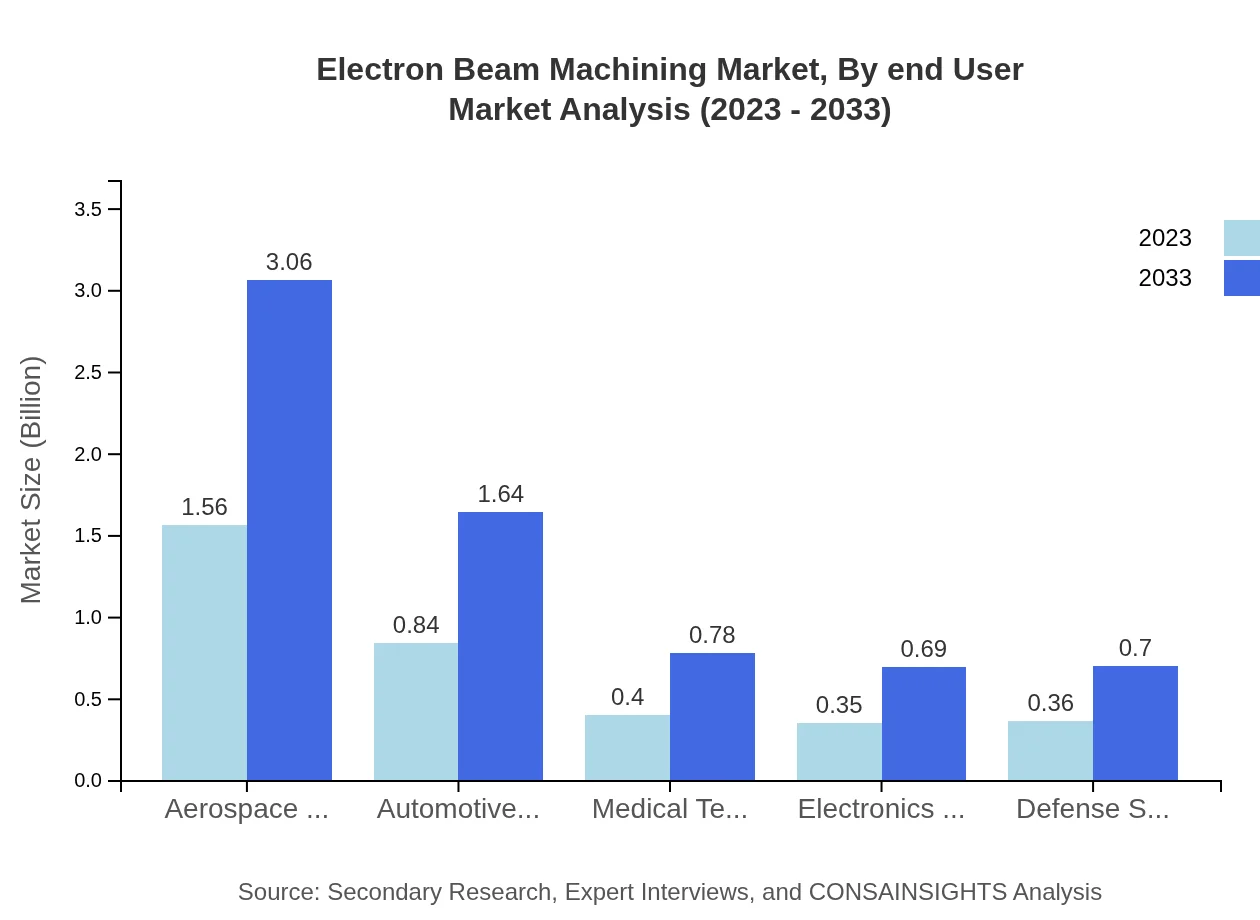

Electron Beam Machining Market Analysis By End User

Key end-user industries leveraging EBM include aerospace, automotive, medical technology, electronics, and defense. The aerospace sector captures a significant market share of 44.51% in 2023, with projections estimating growth to 3.06 billion USD by 2033, reflecting the importance of precision in the industry.

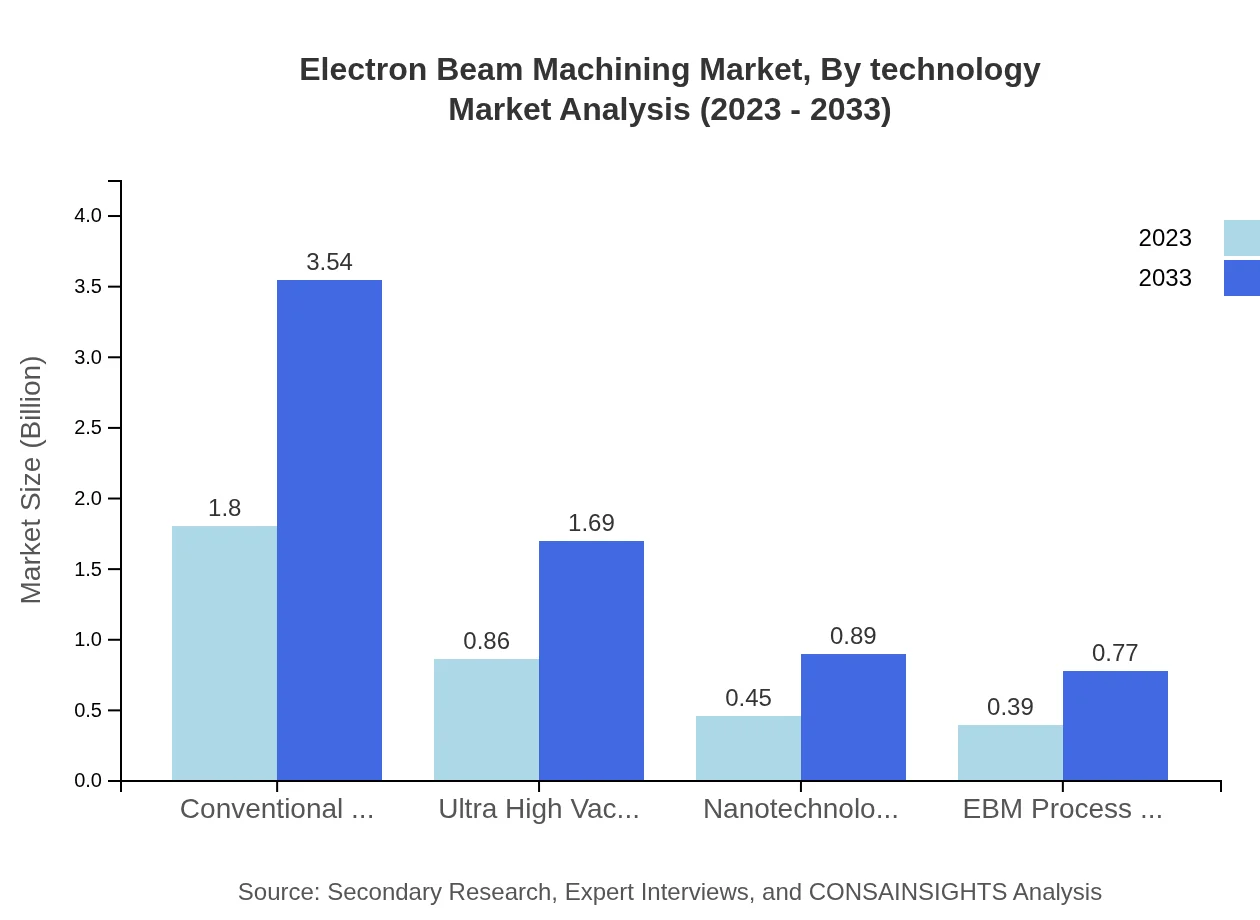

Electron Beam Machining Market Analysis By Technology

The technology segment showcases an inclination towards Conventional EBM, accounting for 51.4% of market share, expected to grow to 3.54 billion USD by 2033. Innovations in Ultra High Vacuum EBM and nanotechnology in EBM are also leading trends shaping market growth, indicating diversification in technology applications.

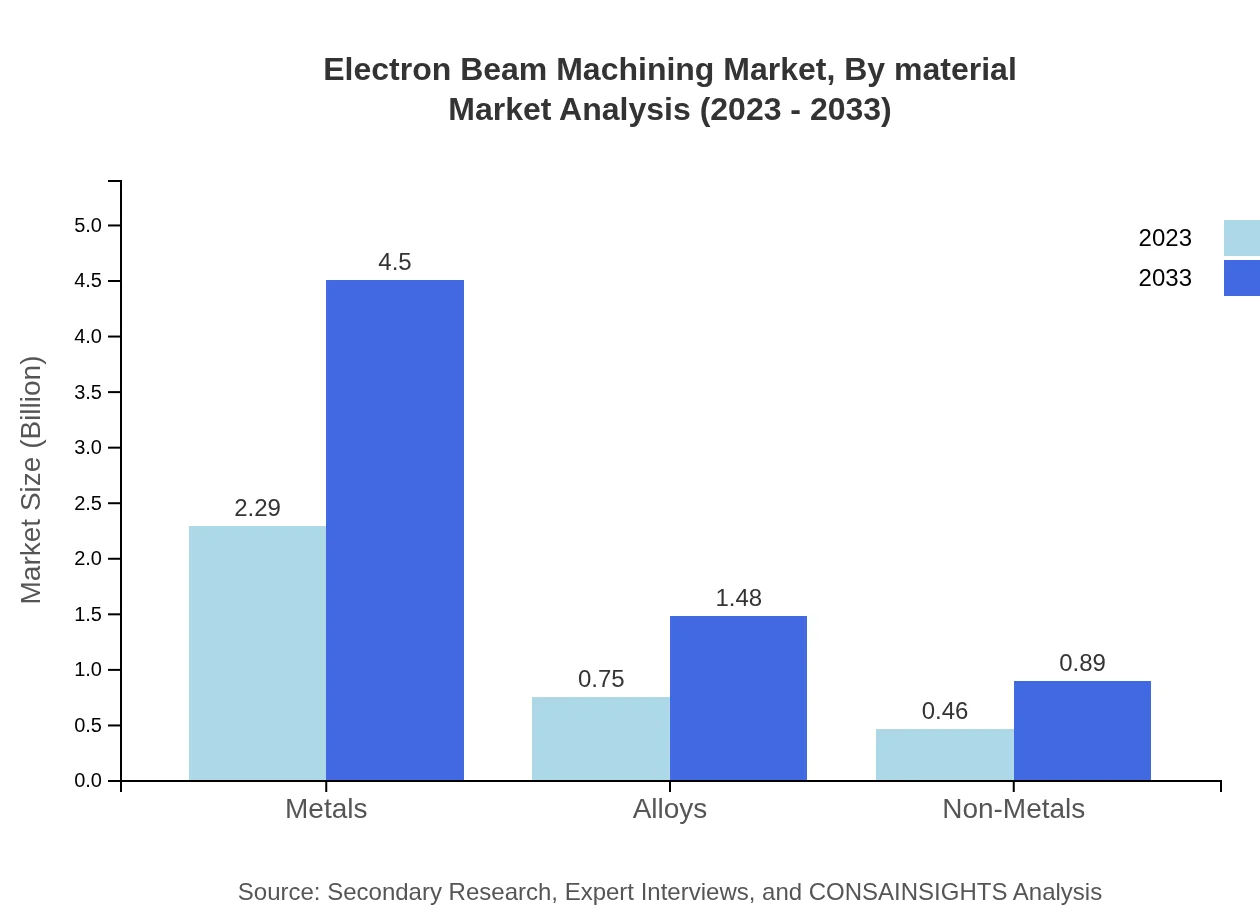

Electron Beam Machining Market Analysis By Material

Materials processed via EBM largely include metals, alloys, and non-metals. Metals dominate by value, reflecting robust performance at 2.29 billion USD in 2023 and a projection of 4.50 billion USD by 2033. Alloys and non-metals are also significant contributors, expected to achieve 1.48 billion USD and 0.89 billion USD, respectively.

Electron Beam Machining Market Analysis By Scale

Analysis of the market by scale indicates that large-scale applications significantly lead, with a market size of 2.29 billion USD in 2023, projected to reach 4.50 billion USD by 2033, signaling the need for extensive capacity in high-precision machining. Medium and small-scale applications are also anticipated to grow, attaining sizes of 1.48 billion USD and 0.89 billion USD, respectively.

Electron Beam Machining Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in the Electron Beam Machining Industry

Fives Group:

Fives Group is a global leader in providing advanced manufacturing technologies with a robust presence in the electron beam machining domain offering innovative solutions tailored for aerospace and automotive industries.Nikon:

Nikon specializes in precision machining technologies, including EBM solutions that support complex component manufacturing in the electronics and medical sectors.Heraeus:

Heraeus provides material solutions and advanced electron-beam welding techniques that enhance the manufacturing capabilities for high-precision sectors, encompassing aerospace and defense applications.FANUC:

FANUC is a prominent player known for robotics and CNC manufacturing solutions, including innovations in EBM that improve productivity and efficiency in various applications.We're grateful to work with incredible clients.

FAQs

What is the market size of electron Beam Machining?

The electron-beam machining market size is projected to reach $3.5 billion by 2033, with a compound annual growth rate (CAGR) of 6.8% during the forecast period. This growth highlights the increasing adoption of precise machining technologies across various industries.

What are the key market players or companies in this electron Beam Machining industry?

Key players in the electron-beam machining industry include companies specializing in advanced manufacturing technologies, precision engineering, and specialized machining services. Leading manufacturers focus on innovation and expanding their service offerings to remain competitive.

What are the primary factors driving the growth in the electron Beam Machining industry?

The growth of the electron-beam machining industry is driven by increasing demand for precision machining in sectors like aerospace, automotive, and medical technology. Advancements in technology and the push for lightweight, high-performance materials further fuel market expansion.

Which region is the fastest Growing in the electron Beam Machining?

The fastest-growing region in the electron-beam machining market is North America, projected to reach a market size of $2.47 billion by 2033, up from $1.26 billion in 2023. This growth is supported by strong aerospace and automotive industries.

Does ConsaInsights provide customized market report data for the electron Beam Machining industry?

Yes, ConsaInsights offers tailored market report data for the electron-beam machining industry. Clients can request specific insights based on their needs, including detailed analysis on segments, regions, and emerging trends.

What deliverables can I expect from this electron Beam Machining market research project?

Deliverables from the electron-beam machining market research project include comprehensive reports, market analysis, segmentation insights, competitive landscape, and forecasts for market growth across various regions and applications.

What are the market trends of electron Beam Machining?

Current market trends in electron-beam machining include growth in large-scale applications, advancing automation technologies, and increased focus on nanotechnology integration. There is also a shift towards more energy-efficient and eco-friendly machining processes.