Epitaxy Equipment Market Report

Published Date: 31 January 2026 | Report Code: epitaxy-equipment

Epitaxy Equipment Market Size, Share, Industry Trends and Forecast to 2033

This report analyzes the Epitaxy Equipment market, offering insights into market size, growth trends, and forecasts from 2023 to 2033. Key drivers, challenges, and opportunities are examined to provide stakeholders with valuable data for making informed decisions.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

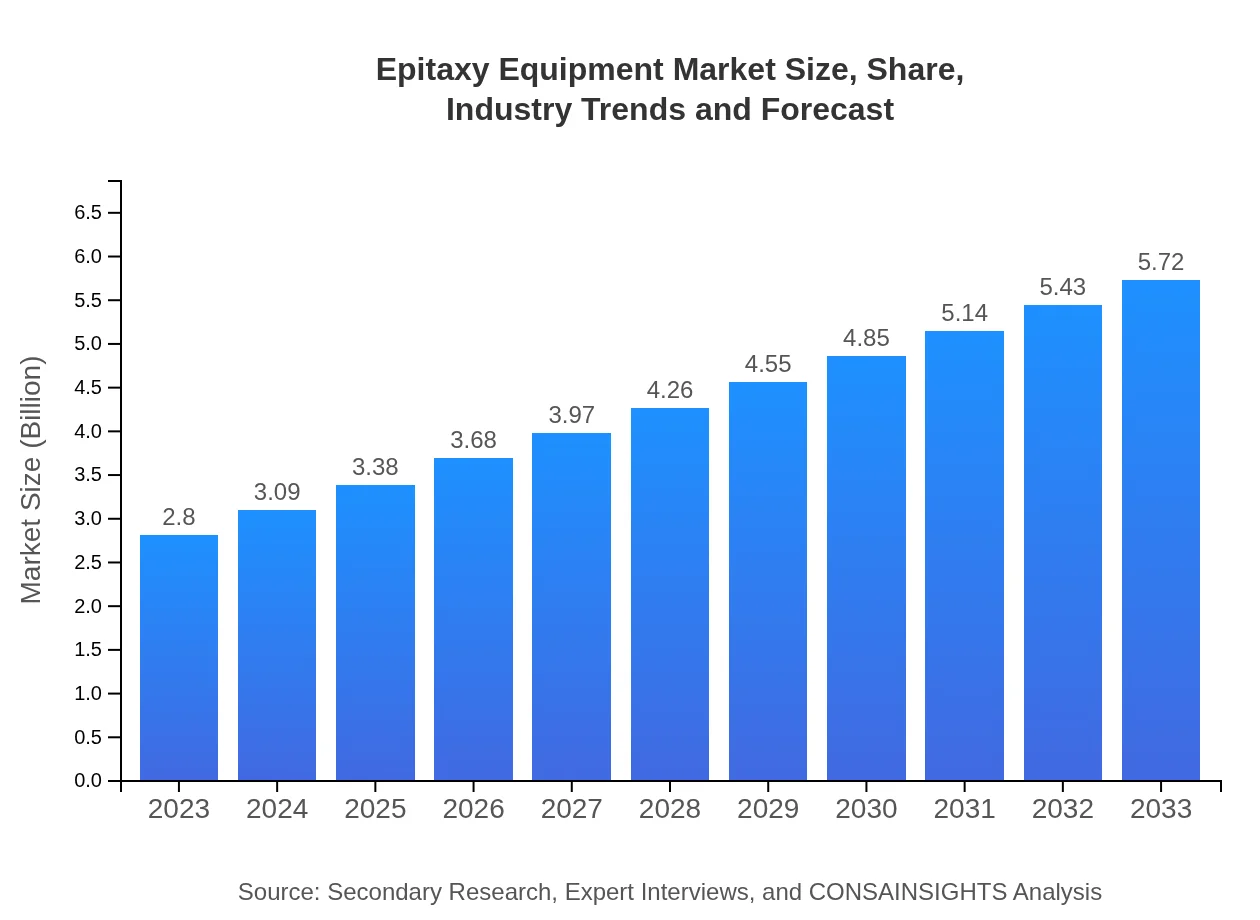

| 2023 Market Size | $2.80 Billion |

| CAGR (2023-2033) | 7.2% |

| 2033 Market Size | $5.72 Billion |

| Top Companies | Veeco Instruments Inc., AXT Inc., KLA Corporation, HITACHI High-Tech Science Corporation, Applied Materials |

| Last Modified Date | 31 January 2026 |

Epitaxy Equipment Market Overview

Customize Epitaxy Equipment Market Report market research report

- ✔ Get in-depth analysis of Epitaxy Equipment market size, growth, and forecasts.

- ✔ Understand Epitaxy Equipment's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Epitaxy Equipment

What is the Market Size & CAGR of Epitaxy Equipment market in 2023?

Epitaxy Equipment Industry Analysis

Epitaxy Equipment Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Epitaxy Equipment Market Analysis Report by Region

Europe Epitaxy Equipment Market Report:

The European Epitaxy Equipment market is anticipated to increase from $0.82 billion in 2023 to $1.68 billion by 2033. The region is focusing on enhancing its semiconductor capabilities to reduce dependence on external sources and promote stability within the market.Asia Pacific Epitaxy Equipment Market Report:

In 2023, the Asia Pacific Epitaxy Equipment market is valued at approximately $0.57 billion and is expected to reach $1.16 billion by 2033, reflecting a robust growth driven by semiconductor manufacturing hubs in China, Japan, and South Korea. The growing demand for electronic devices and renewable energy solutions is fueling this growth, with significant investments in technological improvements and infrastructure.North America Epitaxy Equipment Market Report:

In North America, the market size for Epitaxy Equipment is expected to grow from $0.93 billion in 2023 to $1.90 billion by 2033. The U.S. is a primary driver due to its advanced semiconductor manufacturing and R&D initiatives, particularly in Silicon Valley and other tech-centric regions.South America Epitaxy Equipment Market Report:

The South America Epitaxy Equipment market is projected to grow from $0.18 billion in 2023 to $0.36 billion by 2033. This growth is gradual but steady, supported by increasing interest in electronics and renewable energy industries as well as foreign investment in technology sectors.Middle East & Africa Epitaxy Equipment Market Report:

The Middle East and Africa market for Epitaxy Equipment is expected to grow from $0.30 billion in 2023 to $0.62 billion by 2033, supported by increasing government initiatives to promote technology development and innovation in the electronics sector.Tell us your focus area and get a customized research report.

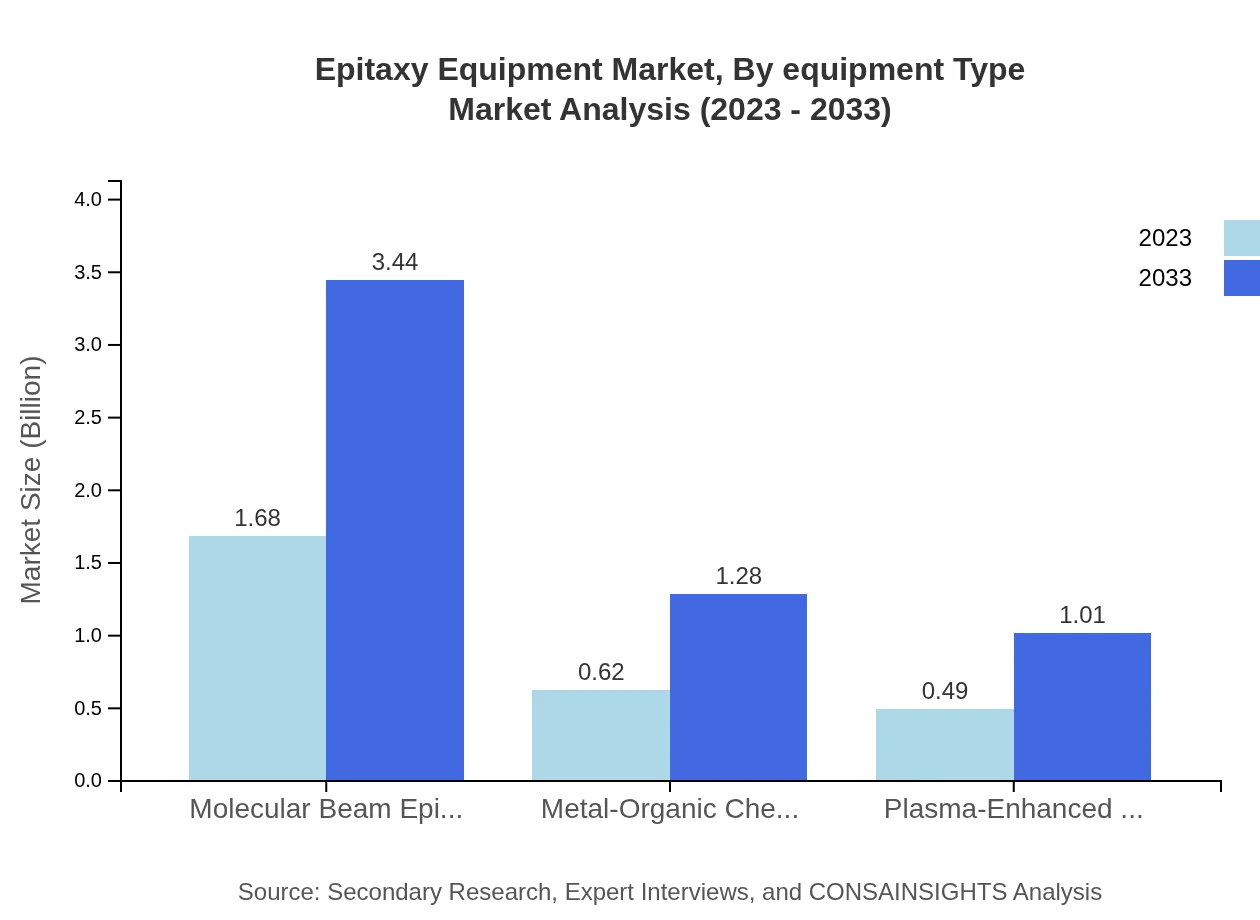

Epitaxy Equipment Market Analysis By Equipment Type

The equipment type segment is dominated by Molecular Beam Epitaxy (MBE), accounting for a significantly large market share due to its precision in atomic layer growth. MOCVD is also vital, catering primarily to LED and solar cell applications. PECVD is gaining traction in the silicon market for its affordability and efficiency in producing thin-film materials, making it crucial for array configurations.

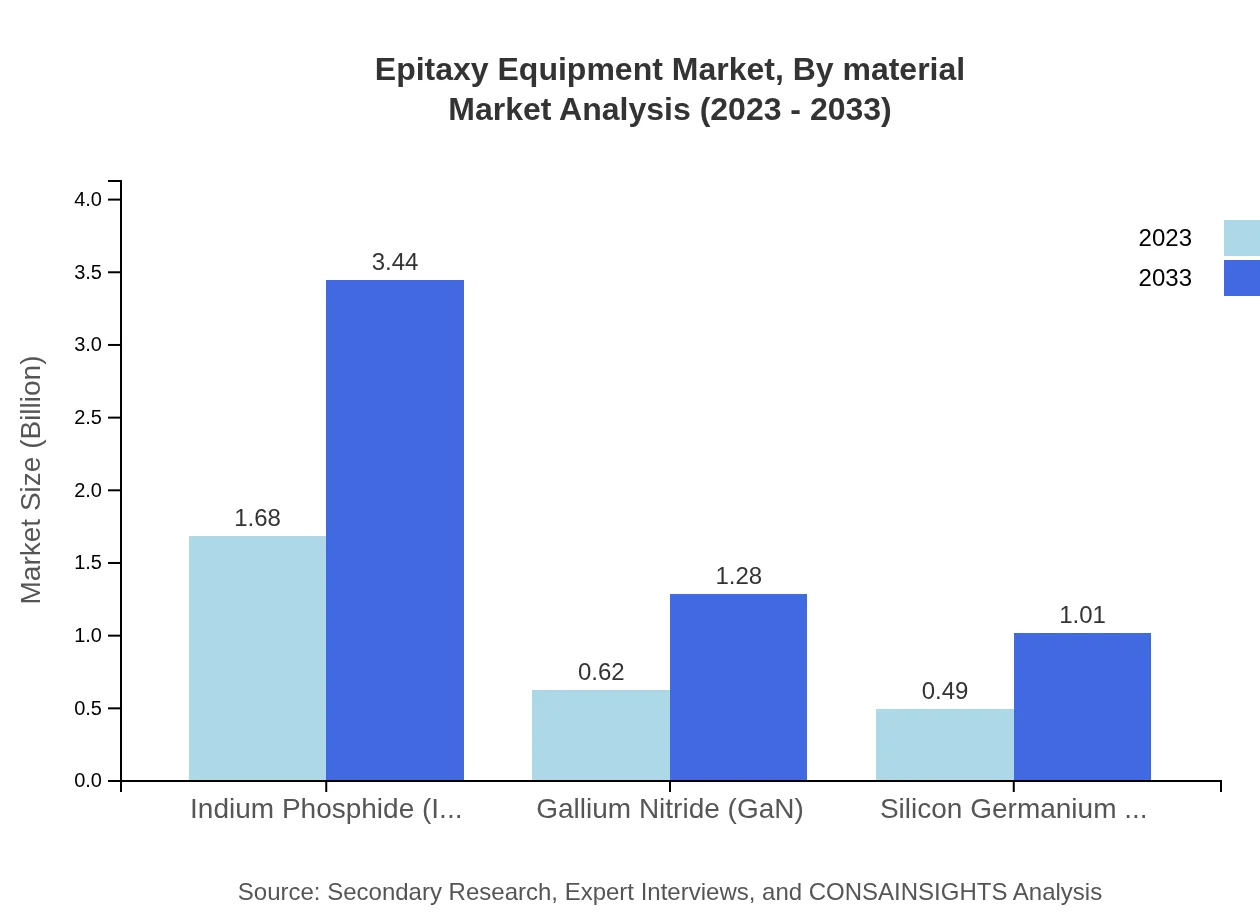

Epitaxy Equipment Market Analysis By Material

Epitaxy equipment utilizes a range of materials, with Indium Phosphide (InP) and Gallium Nitride (GaN) accounting for the majority of the market share due to their critical roles in high-frequency applications and power electronics. Silicon Germanium (SiGe) continues to see growth within telecommunications as demand for high-performance devices increases.

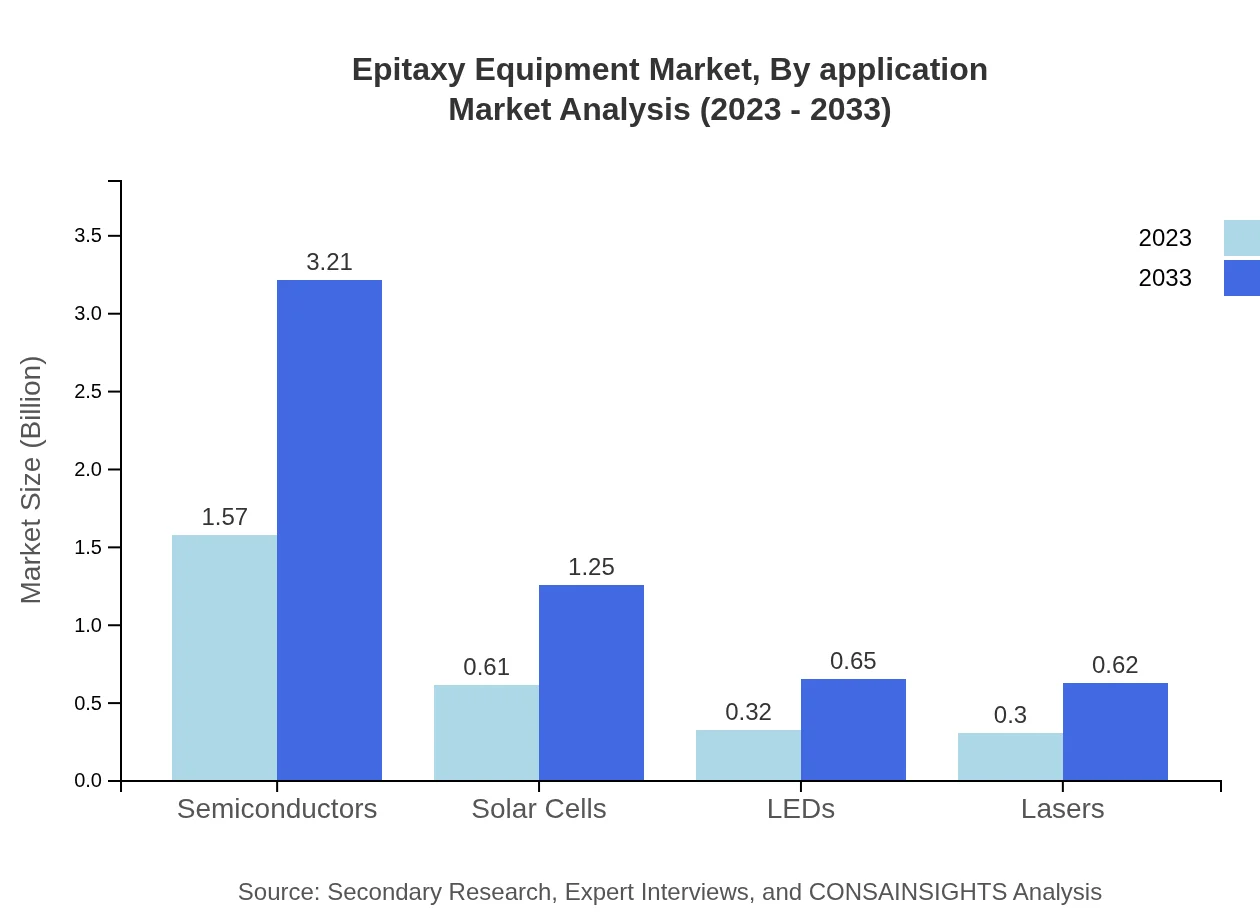

Epitaxy Equipment Market Analysis By Application

The semiconductor application segment is the largest. As the demand for smart devices escalates, the need for epitaxial layers has risen sharply. Telecommunications and renewable energy applications are also significant, driven by advancements in 5G networks and solar technology.

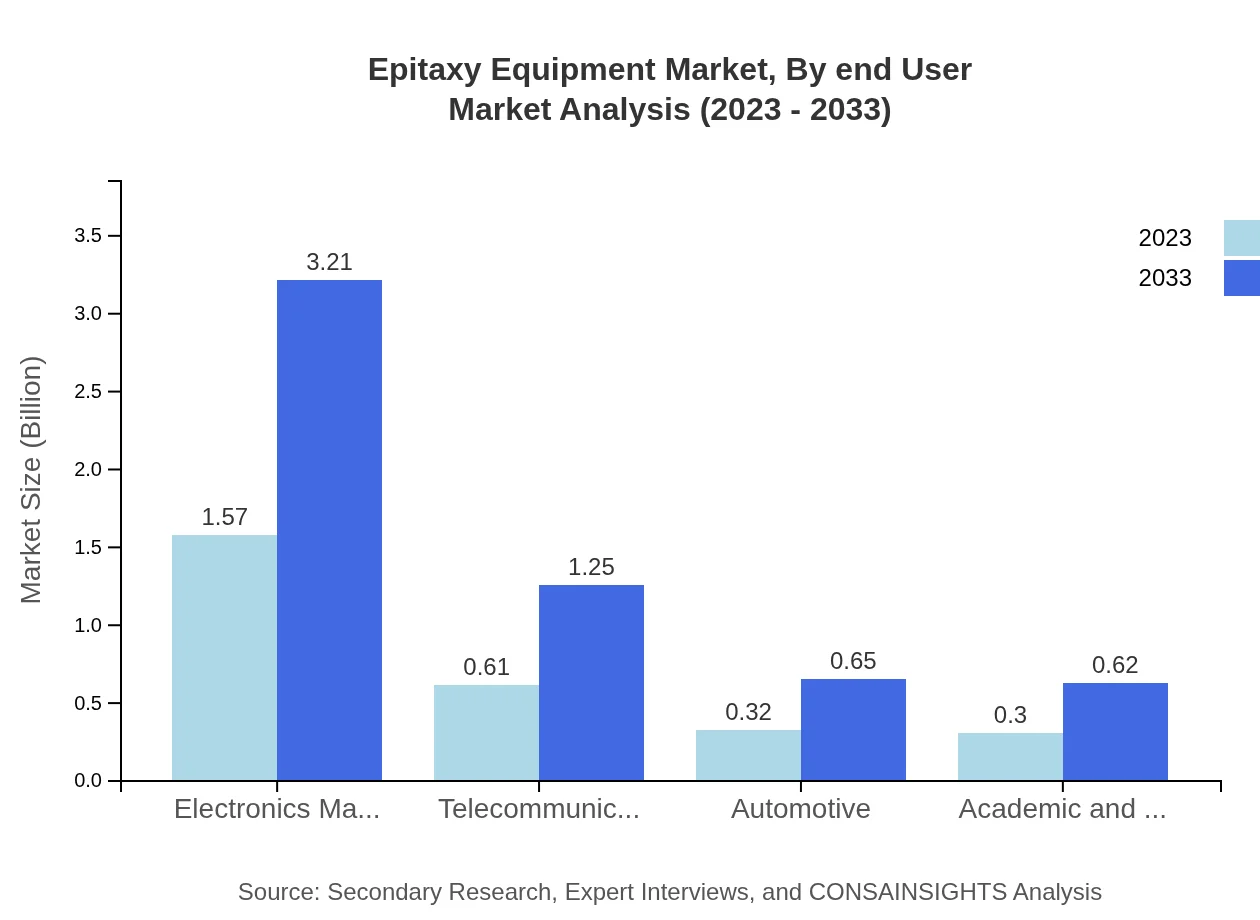

Epitaxy Equipment Market Analysis By End User

Major end-user industries include electronics manufacturers, telecommunications, automotive sectors, and academic institutions. Electronics manufacturers hold the highest market share, driven by their continuous demand for high-performance chips, while telecommunications and automotive sectors increasingly rely on advanced epitaxial technologies for next-gen applications.

Epitaxy Equipment Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Epitaxy Equipment Industry

Veeco Instruments Inc.:

A leader in MBE technology, specializing in developing advanced equipment for manufacturing compound semiconductors and optoelectronic devices.AXT Inc.:

Focuses on production and supply of raw materials used in epitaxial growth, particularly for compound semiconductor applications.KLA Corporation:

Engaged in the production of process control and yield management solutions, providing critical equipment for semiconductor manufacturing.HITACHI High-Tech Science Corporation:

Produces high-end tools for epitaxy and other semiconductor processes, focusing on innovation and quality.Applied Materials:

Offering a wide range of semiconductor fabrications tools and services, with a significant presence in the MOCVD market.We're grateful to work with incredible clients.

FAQs

What is the market size of epitaxy Equipment?

The epitaxy equipment market is projected to reach a size of $2.8 billion by 2033, exhibiting a CAGR of 7.2% from 2023. This growth reflects increasing demand in various electronic and semiconductor applications.

What are the key market players or companies in this epitaxy Equipment industry?

Key players in the epitaxy equipment market include leading firms specialized in semiconductor manufacturing and materials, ensuring advancements in technology and innovation tailored to meet rising market demands.

What are the primary factors driving the growth in the epitaxy equipment industry?

The growth in the epitaxy equipment industry is primarily driven by advancements in semiconductor technology, increased demand for high-performance electronic devices, and the rising proliferation of telecommunication technologies.

Which region is the fastest Growing in the epitaxy equipment?

The fastest-growing region in the epitaxy equipment market is Asia Pacific, expected to grow from $0.57 billion in 2023 to $1.16 billion by 2033, owing to robust semiconductor manufacturing growth.

Does ConsaInsights provide customized market report data for the epitaxy equipment industry?

Yes, ConsaInsights offers customized market report data for the epitaxy equipment industry, providing tailored insights based on specific client needs, preferences, and market dynamics.

What deliverables can I expect from this epitaxy equipment market research project?

Deliverables include comprehensive market analysis reports, trends, forecasts, and in-depth segment data focused on key regions and applications relevant to the epitaxy equipment market.

What are the market trends of epitaxy equipment?

Current trends indicate a shift towards advanced fabrication techniques, increased investment in research and development, and a focus on sustainability and efficiency within the epitaxy equipment market.