Explosion Proof Equipment Market Report

Published Date: 22 January 2026 | Report Code: explosion-proof-equipment

Explosion Proof Equipment Market Size, Share, Industry Trends and Forecast to 2033

This report analyzes the Explosion Proof Equipment market from 2023 to 2033, providing insights into market size, growth trends, segmentation, regional analysis, and leading players affecting the industry landscape.

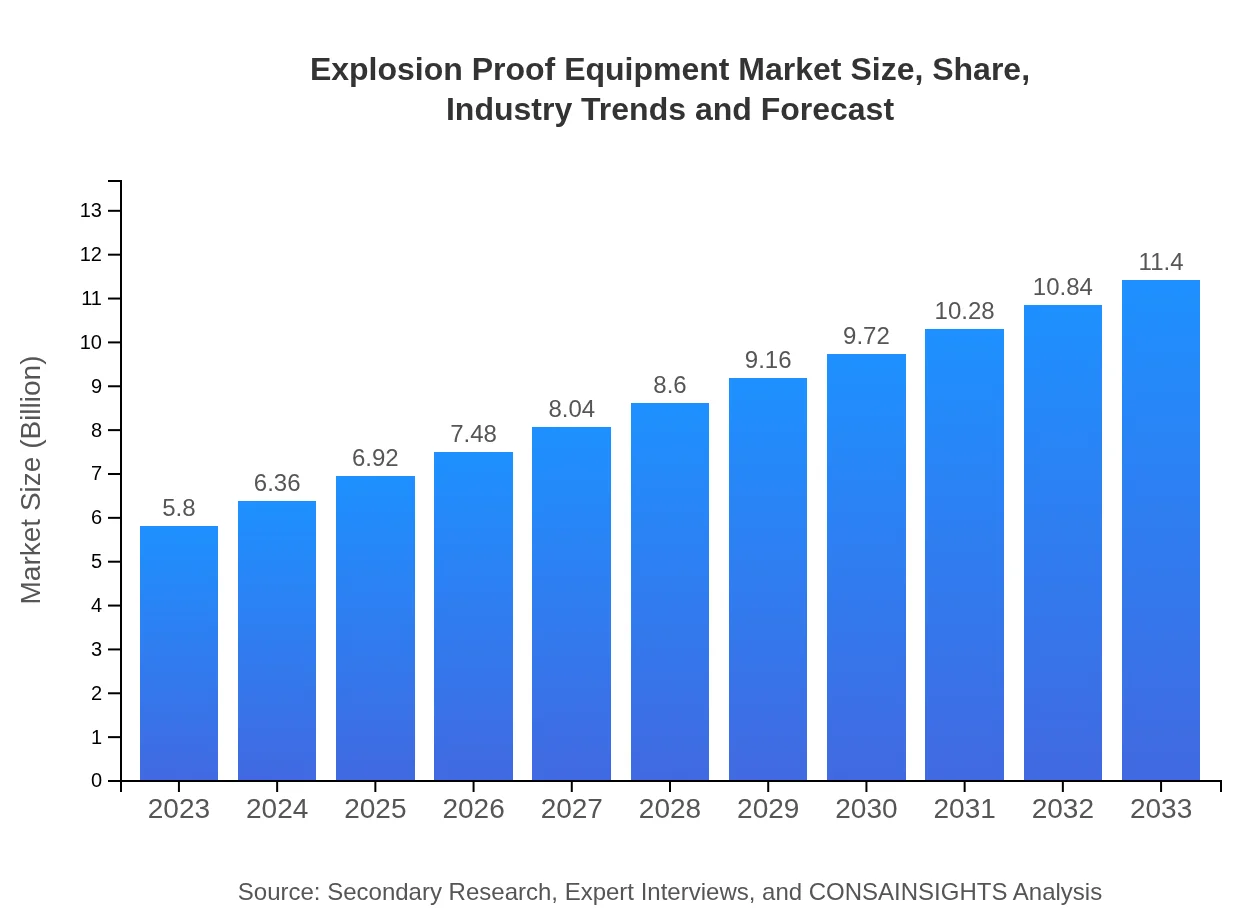

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.80 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $11.40 Billion |

| Top Companies | Eaton, Honeywell , Pepperl+Fuchs, Emerson Electric Co., Schneider Electric |

| Last Modified Date | 22 January 2026 |

Explosion Proof Equipment Market Overview

Customize Explosion Proof Equipment Market Report market research report

- ✔ Get in-depth analysis of Explosion Proof Equipment market size, growth, and forecasts.

- ✔ Understand Explosion Proof Equipment's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Explosion Proof Equipment

What is the Market Size & CAGR of Explosion Proof Equipment market in 2023?

Explosion Proof Equipment Industry Analysis

Explosion Proof Equipment Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Explosion Proof Equipment Market Analysis Report by Region

Europe Explosion Proof Equipment Market Report:

Europe's market is projected to expand from USD 1.71 billion in 2023 to USD 3.37 billion by 2033, led by stringent European Union regulations on safety and a substantial presence of key industry players.Asia Pacific Explosion Proof Equipment Market Report:

The Asia Pacific region is projected to experience significant growth from USD 1.05 billion in 2023 to USD 2.06 billion by 2033, driven by expanding industrial activities and stricter safety regulations across countries like China and India.North America Explosion Proof Equipment Market Report:

North America holds a significant share of the Explosion Proof Equipment market; it is expected to grow from USD 2.18 billion in 2023 to USD 4.28 billion by 2033, largely due to advanced regulatory frameworks and a strong focus on workplace safety.South America Explosion Proof Equipment Market Report:

South America shows moderate growth potential, with the market size expected to grow from USD 0.07 billion in 2023 to USD 0.13 billion by 2033, influenced by regional economic stability and increasing investments in safety equipment.Middle East & Africa Explosion Proof Equipment Market Report:

The Middle East and Africa market is set to increase from USD 0.79 billion in 2023 to USD 1.55 billion by 2033, as growing oil and gas exploration activities continue to drive demand for safety solutions.Tell us your focus area and get a customized research report.

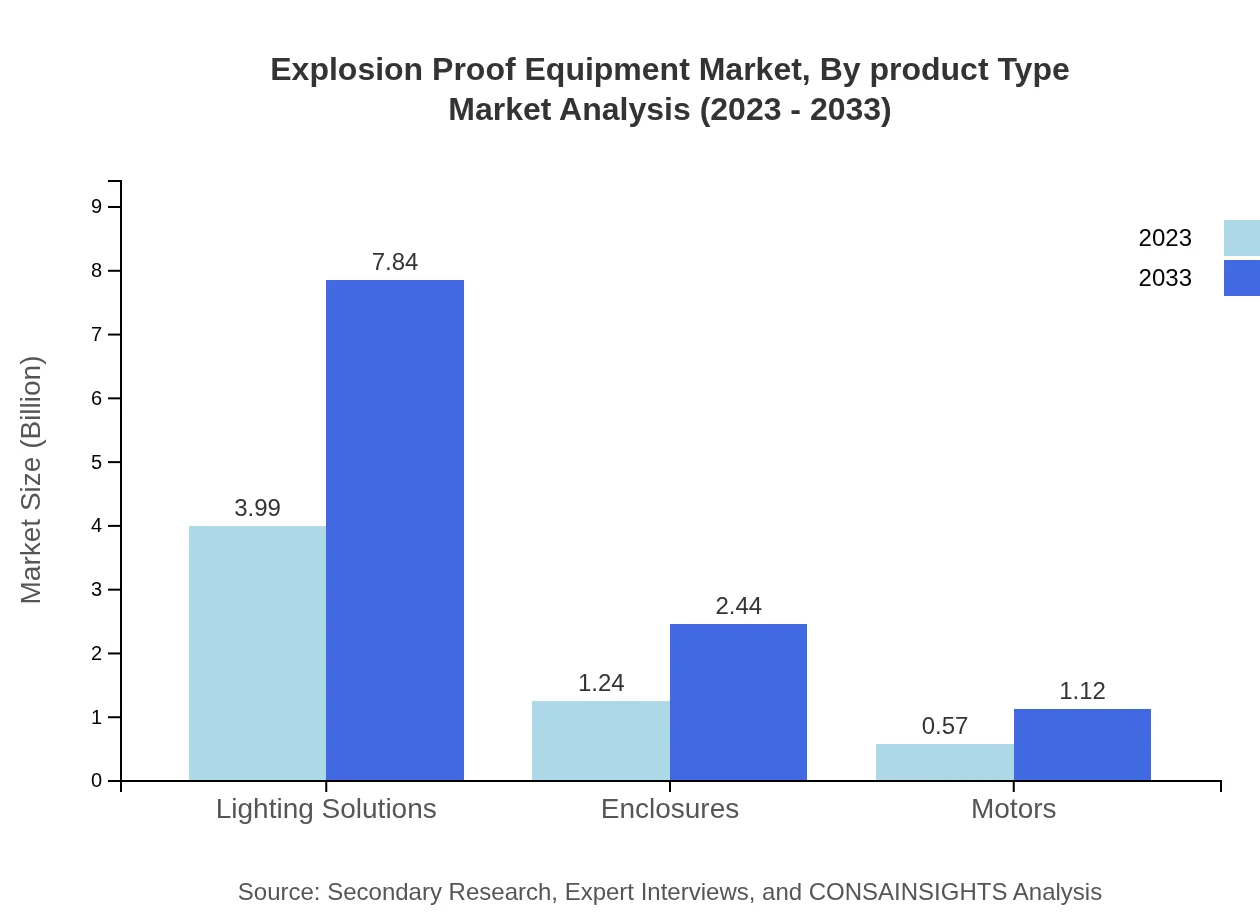

Explosion Proof Equipment Market Analysis By Product Type

The market is dominated by lighting solutions, accounting for a market size of USD 3.99 billion in 2023 and expected to reach USD 7.84 billion by 2033. Enclosures and motors are also significant segments, with the former projected to increase from USD 1.24 billion to USD 2.44 billion, while motors grow from USD 0.57 billion to USD 1.12 billion.

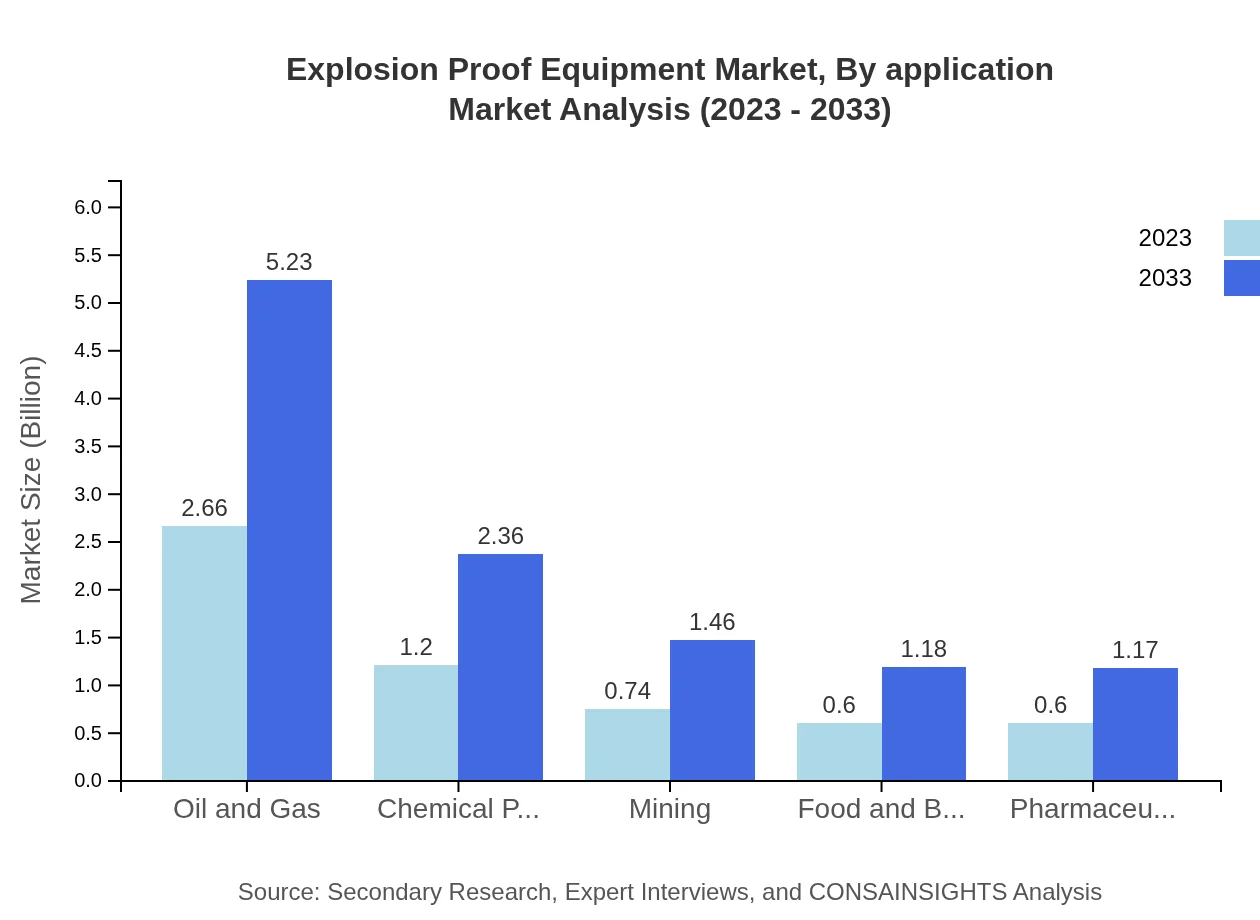

Explosion Proof Equipment Market Analysis By Application

The Oil & Gas industry remains the primary consumer of explosion-proof equipment, with a market size anticipated to climb from USD 3.27 billion in 2023 to USD 6.42 billion in 2033. Chemical processing and mining sectors also represent substantial applications, contributing significantly to market growth.

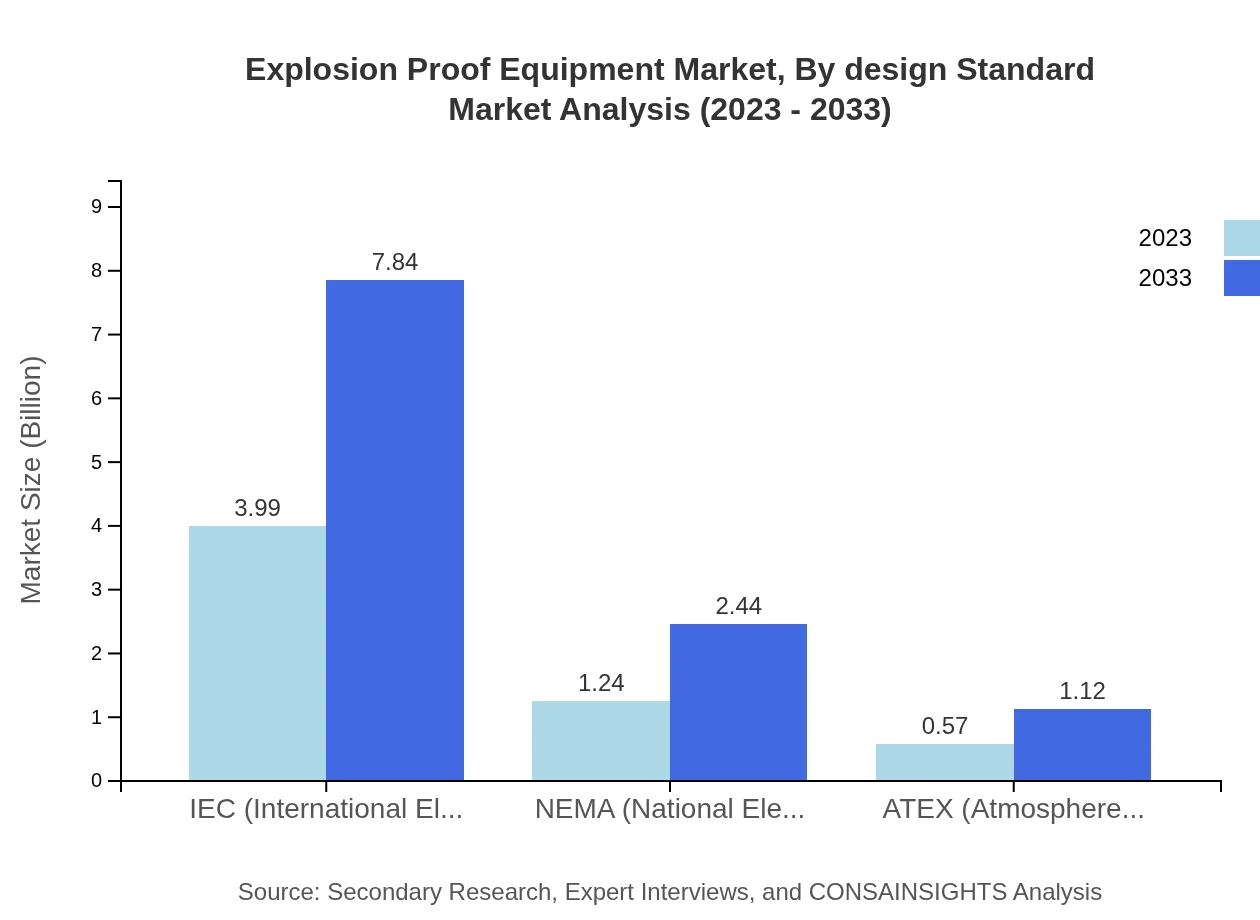

Explosion Proof Equipment Market Analysis By Design Standard

The IEC (International Electrotechnical Commission) and ATEX design standards dominate the market due to strict compliance requirements within the industry. The IEC segment is expected to remain robust, with expected growth consistent with the expanding regulatory environment.

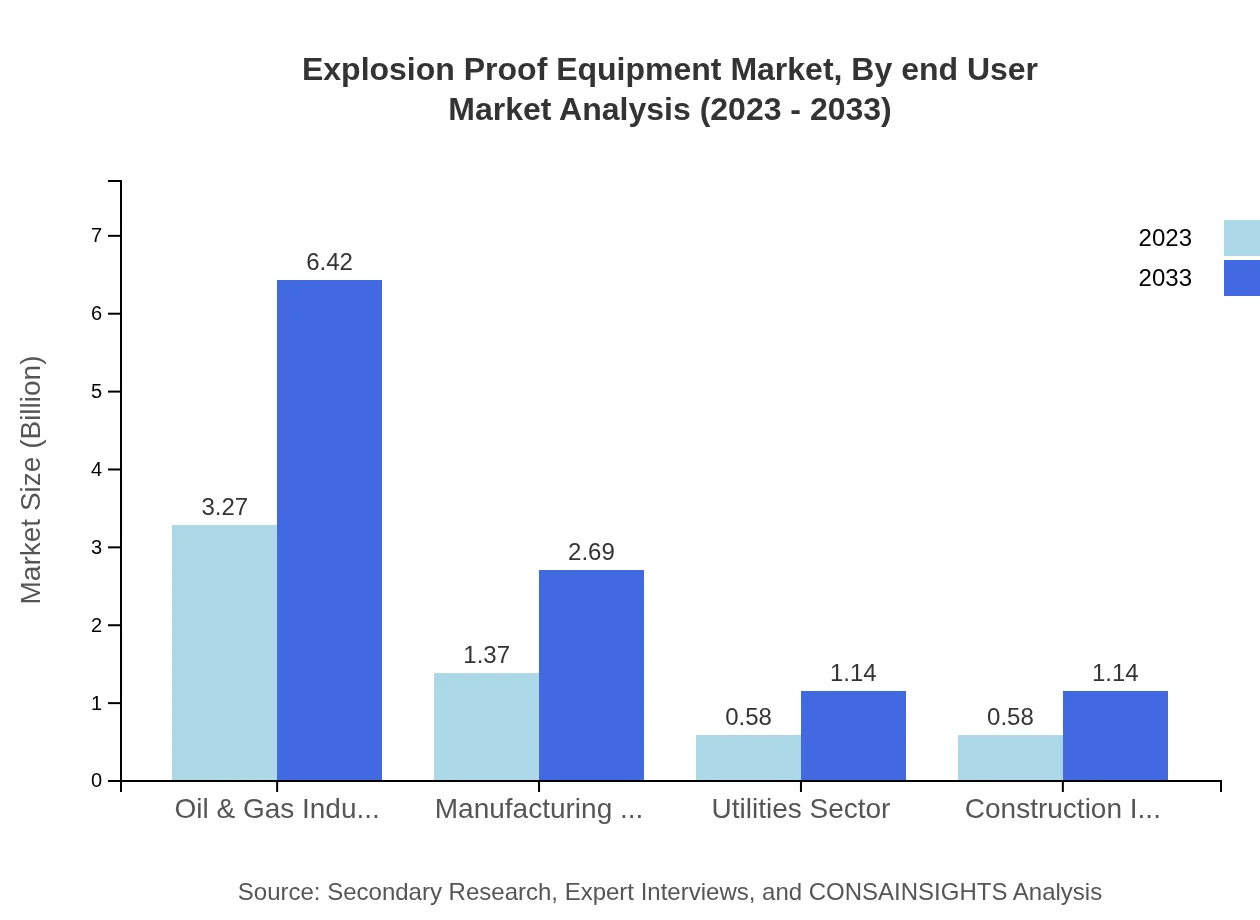

Explosion Proof Equipment Market Analysis By End User

Key end-user industries include Oil & Gas, Utilities, and Manufacturing. The Utility sector shows promising growth, with market size expected to increase to USD 1.14 billion by 2033, up from USD 0.58 billion in 2023.

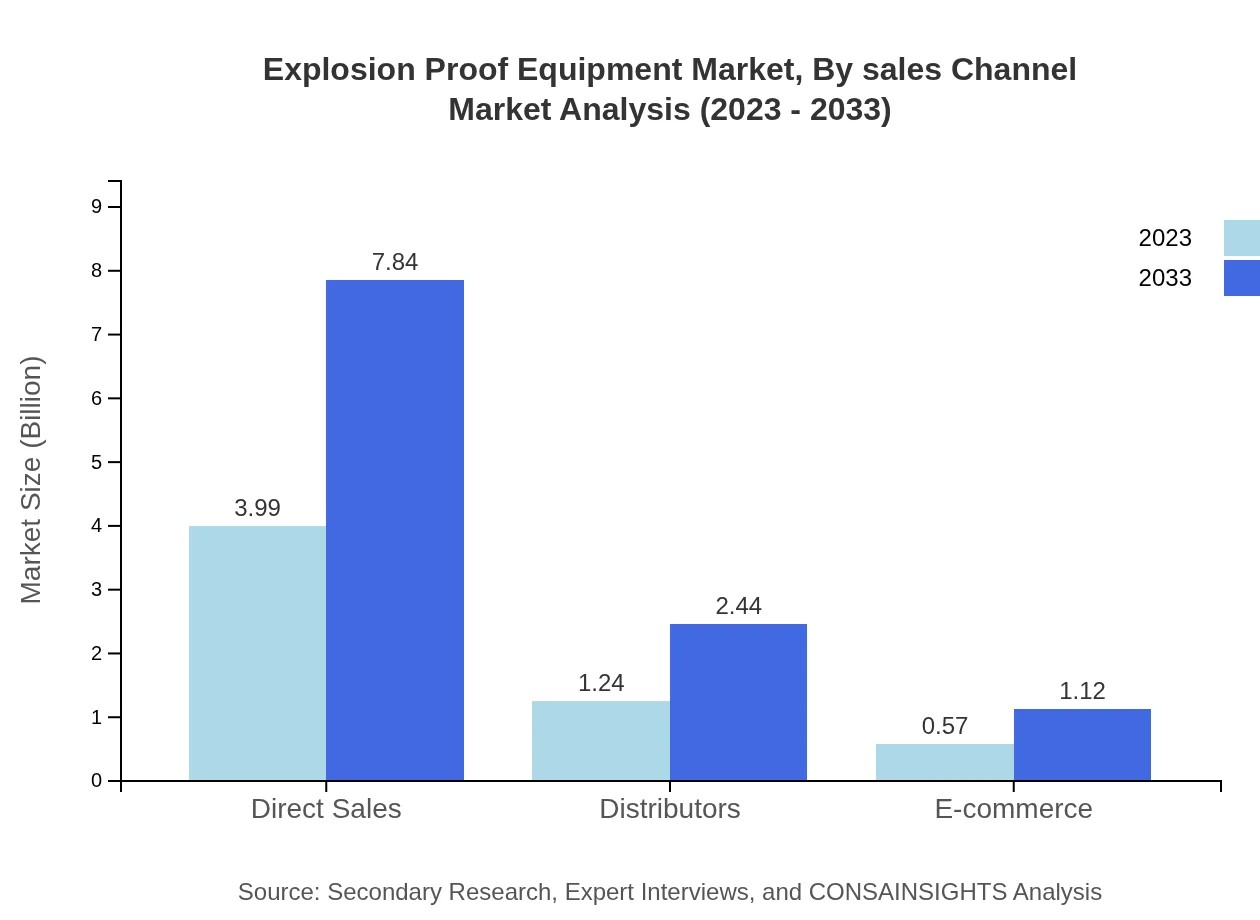

Explosion Proof Equipment Market Analysis By Sales Channel

Direct sales and distributors are the primary sales channels, with direct sales projected to stay dominant, expected to rise from USD 3.99 billion in 2023 to USD 7.84 billion by 2033, reflecting direct engagement with end-users.

Explosion Proof Equipment Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Explosion Proof Equipment Industry

Eaton:

Eaton is a global leader focused on electrical safety and management solutions, providing reliable explosion-proof equipment for critical industries.Honeywell :

Honeywell specializes in a wide range of safety equipment, renowned for its innovative explosion-proof products that enhance safety in hazardous environments.Pepperl+Fuchs:

Pepperl+Fuchs is recognized for its extensive range of explosion-proof sensors and devices, essential for critical safety applications.Emerson Electric Co.:

Emerson is a prominent player offering automation solutions, including a variety of explosion-proof equipment for process industries.Schneider Electric:

Schneider Electric provides integrated safety solutions, including a range of explosion-proof devices for diverse industries.We're grateful to work with incredible clients.

FAQs

What is the market size of explosion Proof equipment?

The global explosion-proof equipment market is projected to reach approximately $5.8 billion by 2033, growing at a CAGR of 6.8% from its current valuation.

What are the key market players or companies in the explosion Proof equipment industry?

Key players in the explosion-proof equipment market include major companies like Siemens AG, Eaton Corporation, and Emerson Electric Co. These companies lead with innovative technologies and extensive product portfolios.

What are the primary factors driving the growth in the explosion Proof equipment industry?

Factors driving the growth of the explosion-proof equipment market include increasing safety regulations in hazardous environments, rising demand from oil & gas sectors, and technological advancements in safety equipment.

Which region is the fastest Growing in the explosion Proof equipment market?

The North America region is identified as the fastest-growing market for explosion-proof equipment, projected to grow from $2.18 billion in 2023 to $4.28 billion by 2033.

Does ConsaInsights provide customized market report data for the explosion Proof equipment industry?

Yes, ConsaInsights offers customized market reports tailored to specific needs in the explosion-proof equipment industry. This ensures relevant insights and data for stakeholders.

What deliverables can I expect from this explosion Proof equipment market research project?

Deliverables include detailed market analysis, competitive landscape insights, segment forecasts, regional performance, and actionable recommendations for market entry and growth.

What are the market trends of explosion Proof equipment?

Current trends include innovation in design, increasing adoption of smart technologies, and a focus on sustainable development, particularly in sectors like oil & gas and manufacturing.