Explosion Proof Solenoid Valves Market Report

Published Date: 22 January 2026 | Report Code: explosion-proof-solenoid-valves

Explosion Proof Solenoid Valves Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Explosion Proof Solenoid Valves market, focusing on trends, sizes, and forecasts from 2023 to 2033. It encompasses insights about market dynamics, regional performance, and competitive landscapes to support stakeholders in informed decision-making.

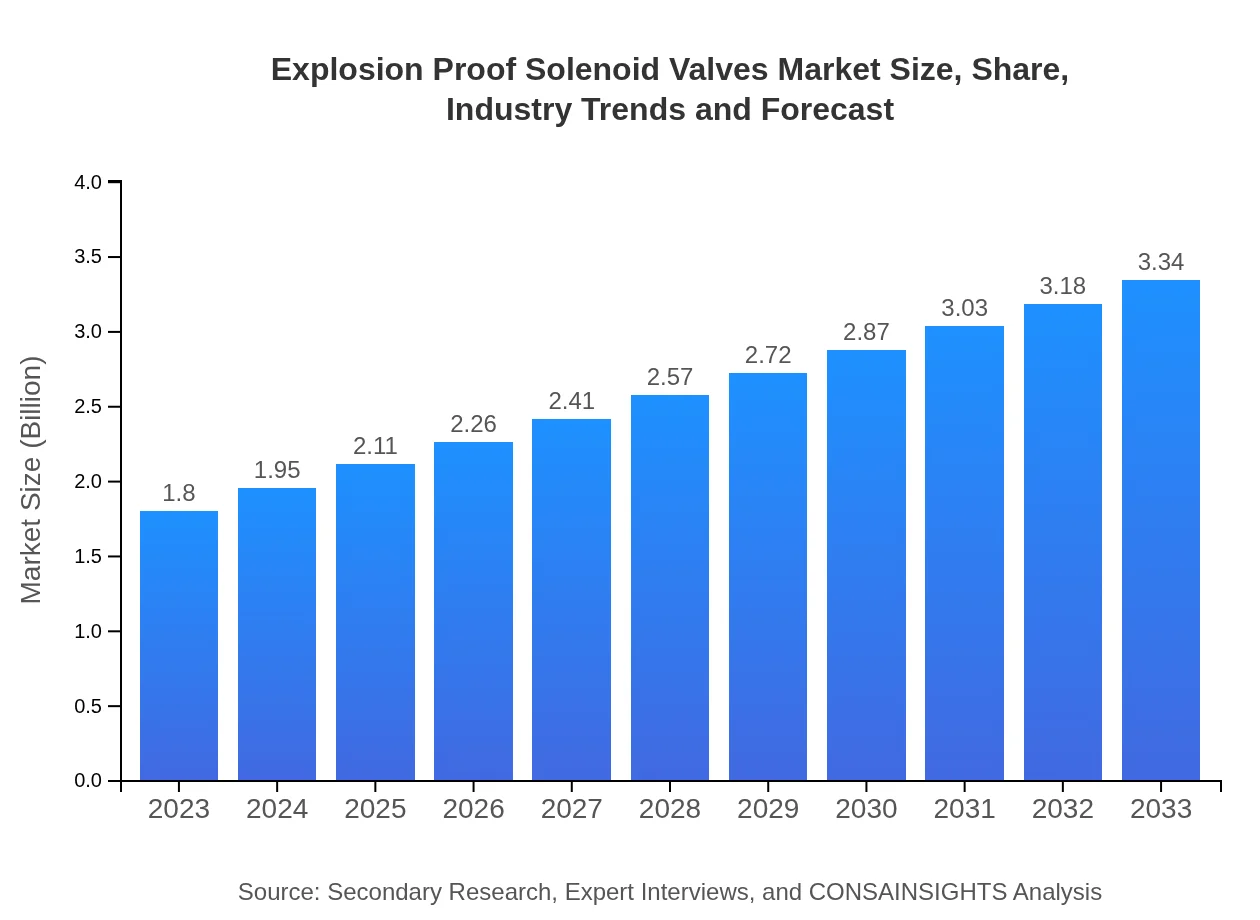

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $1.80 Billion |

| CAGR (2023-2033) | 6.2% |

| 2033 Market Size | $3.34 Billion |

| Top Companies | Parker Hannifin Corporation, Emerson Electric Co., Swagelok Company, SMC Corporation, Honeywell International Inc. |

| Last Modified Date | 22 January 2026 |

Explosion Proof Solenoid Valves Market Overview

Customize Explosion Proof Solenoid Valves Market Report market research report

- ✔ Get in-depth analysis of Explosion Proof Solenoid Valves market size, growth, and forecasts.

- ✔ Understand Explosion Proof Solenoid Valves's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Explosion Proof Solenoid Valves

What is the Market Size & CAGR of Explosion Proof Solenoid Valves market in 2023?

Explosion Proof Solenoid Valves Industry Analysis

Explosion Proof Solenoid Valves Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Explosion Proof Solenoid Valves Market Analysis Report by Region

Europe Explosion Proof Solenoid Valves Market Report:

The European market is forecasted to grow from $0.47 billion in 2023 to $0.87 billion by 2033. Regulations surrounding industrial safety and environmental protection are propelling demand. Germany and the UK are key contributors due to their advanced manufacturing sectors.Asia Pacific Explosion Proof Solenoid Valves Market Report:

In the Asia Pacific region, the market for Explosion Proof Solenoid Valves is projected to grow from $0.36 billion in 2023 to $0.67 billion by 2033. Increased industrialization and the rise of chemical and petrochemical sectors are primary growth drivers. Rapid urbanization and infrastructure development in countries like China and India further enhance demand for safety-compliant products.North America Explosion Proof Solenoid Valves Market Report:

North America leads the market with an anticipated rise from $0.63 billion in 2023 to $1.17 billion by 2033. The U.S. market is extensively driven by stringent safety regulations in industrial operations, particularly the oil & gas industry. Technological advancements and a focus on automated solutions also bolster market expansion.South America Explosion Proof Solenoid Valves Market Report:

The South American market is expected to increase from $0.17 billion in 2023 to $0.32 billion in 2033. Brazil's robust oil and gas sector, coupled with emerging investments in safety technologies, contributes to this growth. However, economic fluctuations pose challenges to sustained growth in this region.Middle East & Africa Explosion Proof Solenoid Valves Market Report:

The Middle East and Africa market is set to rise from $0.17 billion in 2023 to $0.32 billion by 2033, driven largely by growth in the oil and gas sector and initiatives aimed at enhancing industrial safety standards across the region.Tell us your focus area and get a customized research report.

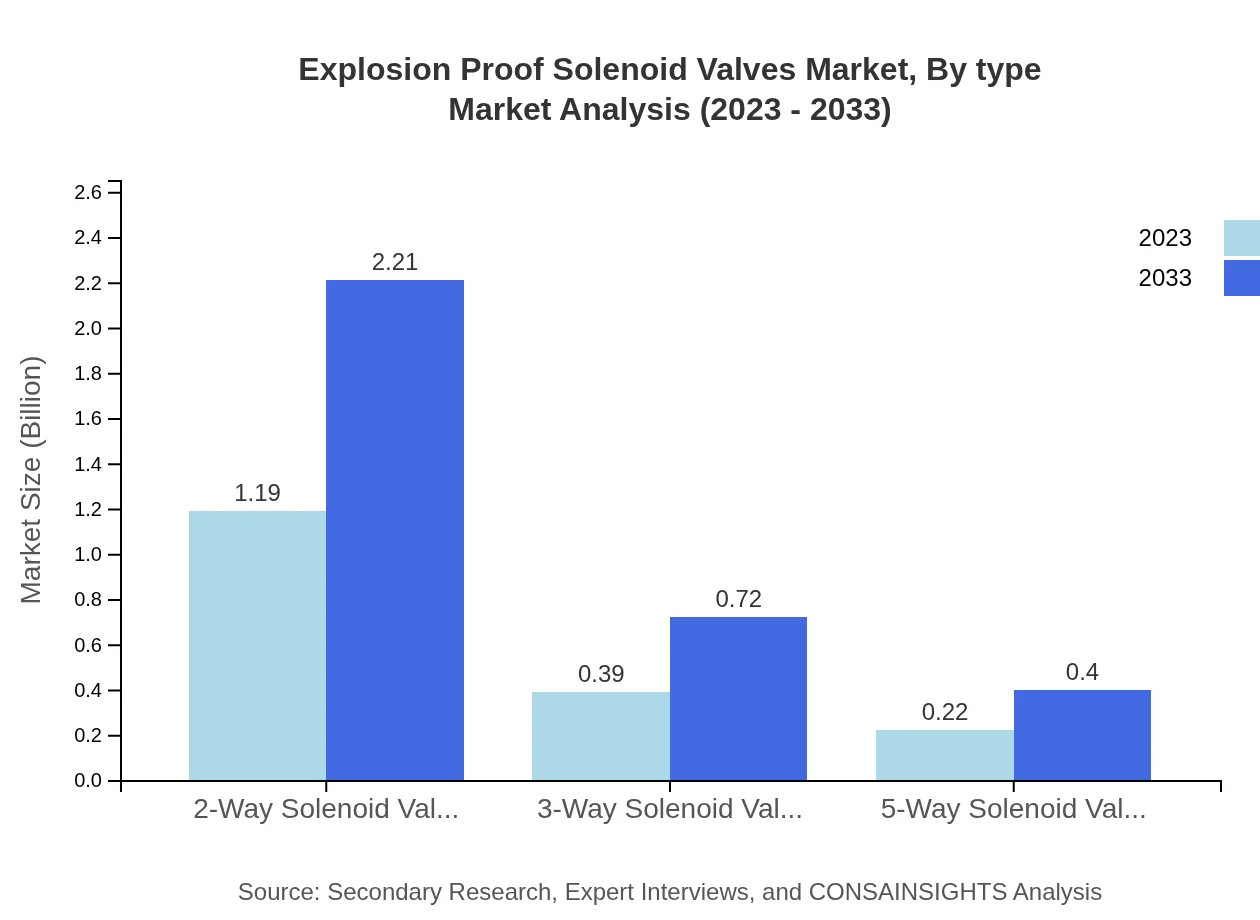

Explosion Proof Solenoid Valves Market Analysis By Type

The market is predominantly driven by 2-way solenoid valves, which dominate the market with a size of $1.19 billion in 2023, expected to grow to $2.21 billion by 2033. 3-way valves hold a wider application base with significant market presence, transitioning from $0.39 billion in 2023 to $0.72 billion by 2033. 5-way solenoid valves, while smaller, show growth potential, increasing from $0.22 billion to $0.40 billion in the same time frame.

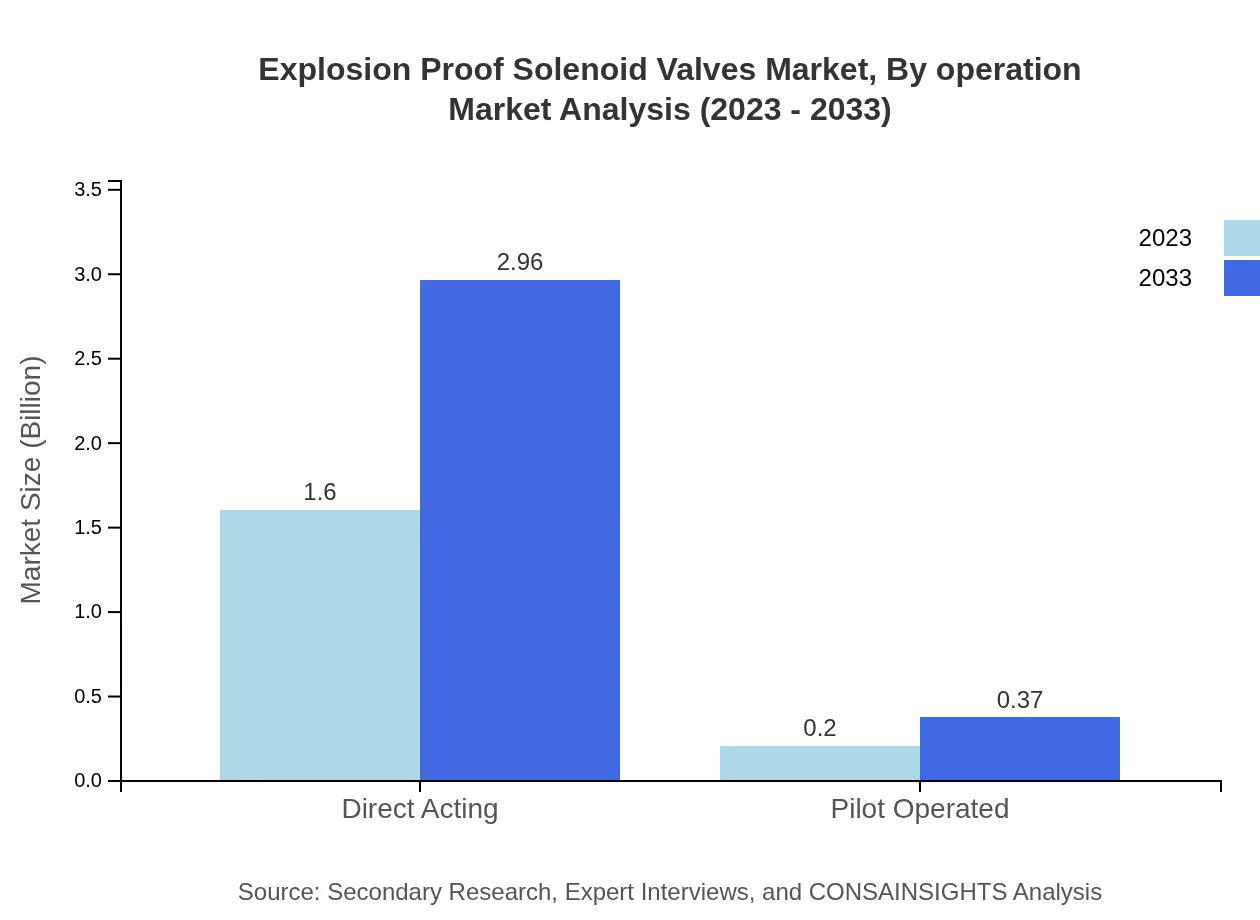

Explosion Proof Solenoid Valves Market Analysis By Operation

Direct acting solenoid valves account for the largest share, having reached $1.60 billion in 2023 and expected to nearly double by 2033, showcasing their critical role in industries requiring precise fluid control. Pilot operated valves, though smaller at $0.20 billion in 2023, are anticipated to grow owing to their efficiency and suitability in high-pressure applications, representing a growing segment.

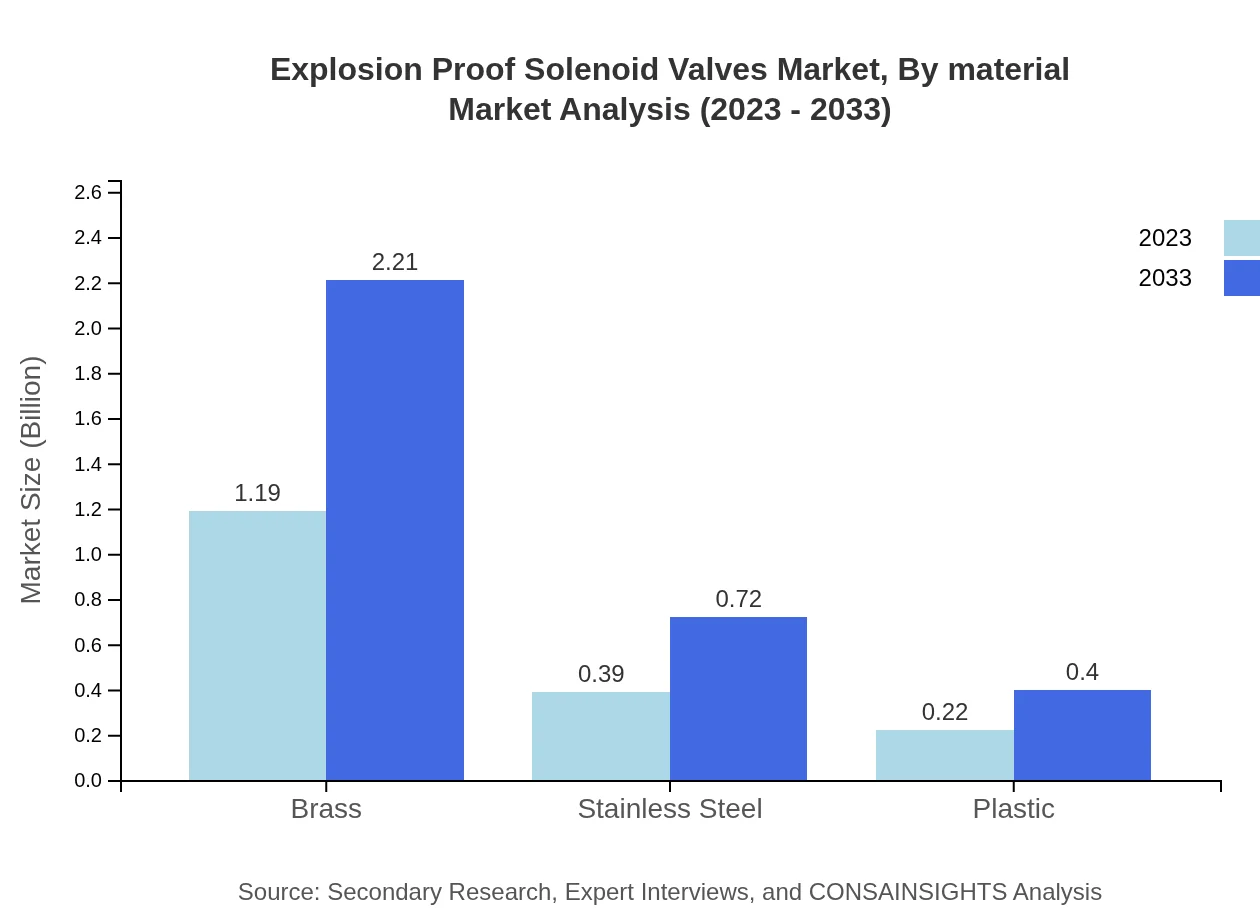

Explosion Proof Solenoid Valves Market Analysis By Material

Brass solenoid valves lead the segment with sales of $1.19 billion in 2023, expected to maintain their share due to their corrosion resistance and cost-effectiveness. Stainless steel solenoids will also see a proportional increase from $0.39 billion to $0.72 billion. Plastic valves represent a niche market but will grow with the demand for lightweight and chemically resistant options, projected to increase from $0.22 billion to $0.40 billion.

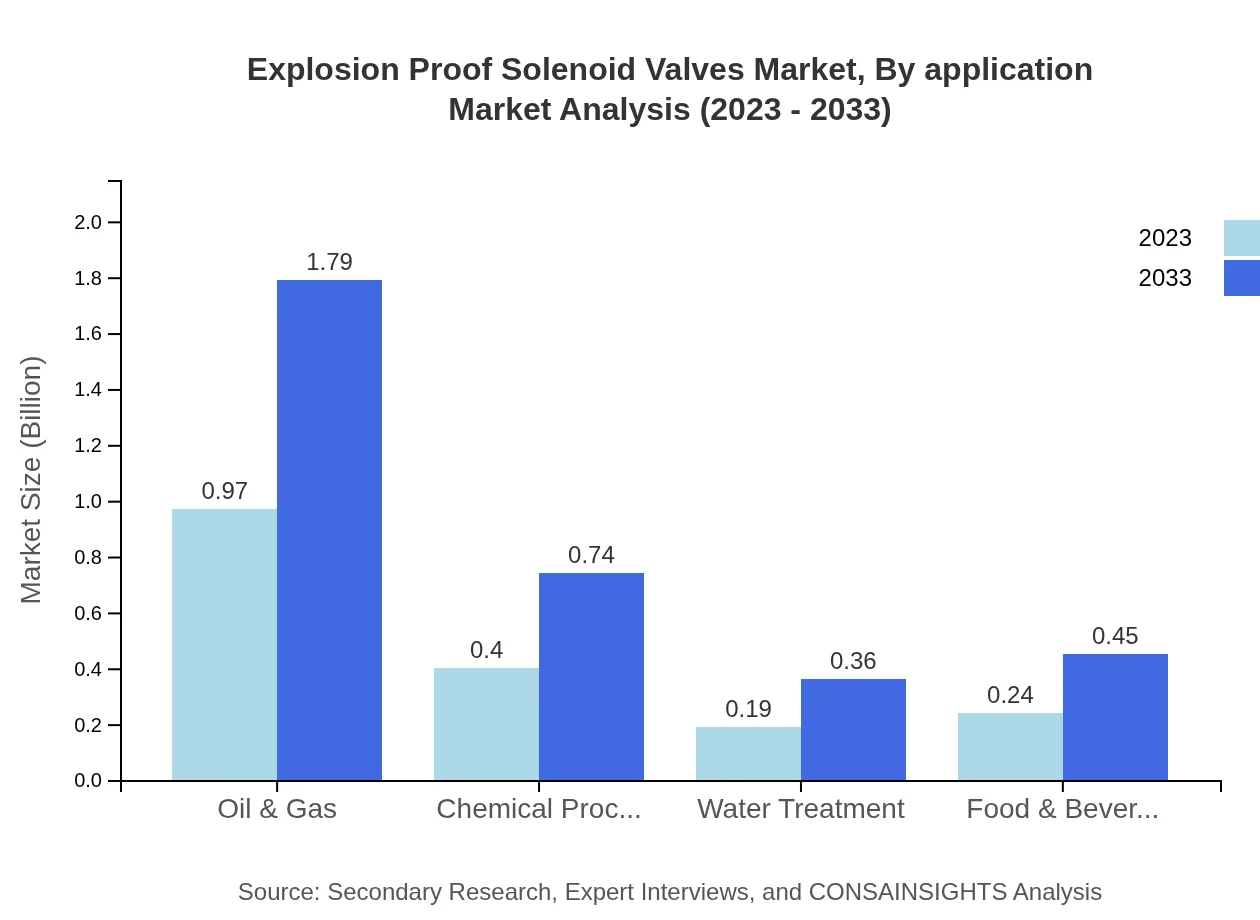

Explosion Proof Solenoid Valves Market Analysis By Application

Application-wise, the Oil & Gas sector dominates with a value of $0.97 billion in 2023, projected to grow to $1.79 billion by 2033. Chemical processing and water treatment industries also hold substantial shares, growing steadily due to investment in safety systems. The Food & Beverage sector sees slower growth but remains vital, increasing from $0.24 billion to $0.45 billion as interest in automation rises.

Explosion Proof Solenoid Valves Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Explosion Proof Solenoid Valves Industry

Parker Hannifin Corporation:

Parker Hannifin is a global leader in motion and control technologies, offering a wide range of explosion proof solenoid valves that cater to various industrial applications.Emerson Electric Co.:

Emerson Electric Co. specializes in automation and control systems; they manufacture advanced solenoid valves that meet stringent safety standards for hazardous environments.Swagelok Company:

Swagelok Company offers robust solenoid valves known for their reliability and versatility in fluid control for various industries, including oil and gas.SMC Corporation:

SMC is recognized for its innovation in pneumatic and fluid control systems, including explosion-proof variants, enhancing safety in critical functions.Honeywell International Inc.:

Honeywell specializes in safety and security solutions, providing high-performance solenoid valves designed for demanding and hazardous applications.We're grateful to work with incredible clients.

FAQs

What is the market size of explosion Proof solenoid valves?

The explosion-proof solenoid valves market is estimated to reach approximately $1.8 billion by 2033, growing at a CAGR of 6.2% from its current size.

What are the key market players or companies in the explosion Proof solenoid valves industry?

Key players in the explosion-proof solenoid valves market include major companies such as ASCO, Parker Hannifin, and SMC Corporation, which dominate the industry through technology and innovation.

What are the primary factors driving the growth in the explosion Proof solenoid valves industry?

The primary growth factors include increasing safety regulations across industries, rising demand in the oil and gas sector, and advancements in manufacturing technologies facilitating the production of more efficient solenoid valves.

Which region is the fastest Growing in the explosion Proof solenoid valves market?

The North American region is expected to be the fastest-growing market for explosion-proof solenoid valves, projected to grow from $0.63 billion in 2023 to $1.17 billion by 2033.

Does Co Insights provide customized market report data for the explosion Proof solenoid valves industry?

Yes, ConsaInsights offers customized market report data, tailored to client specifications, ensuring detailed information specific to the explosion-proof solenoid valves industry.

What deliverables can I expect from this explosion Proof solenoid valves market research project?

Expected deliverables include comprehensive market analysis reports, competitive landscape details, data on market trends and forecasts, along with insights about regulatory frameworks impacting the industry.

What are the market trends of explosion Proof solenoid valves?

Trends include an increasing focus on energy efficiency, growing applications in hazardous environments, and the shift towards automation and smart technologies in various industrial sectors.