Factory Automation Platform As A Service Market Report

Published Date: 22 January 2026 | Report Code: factory-automation-platform-as-a-service

Factory Automation Platform As A Service Market Size, Share, Industry Trends and Forecast to 2033

This report explores the Factory Automation Platform as a Service market, providing insights into its dynamics, growth drivers, and the competitive landscape for the forecast period from 2023 to 2033. It discusses market size, segmentation, and trends shaping the industry's future.

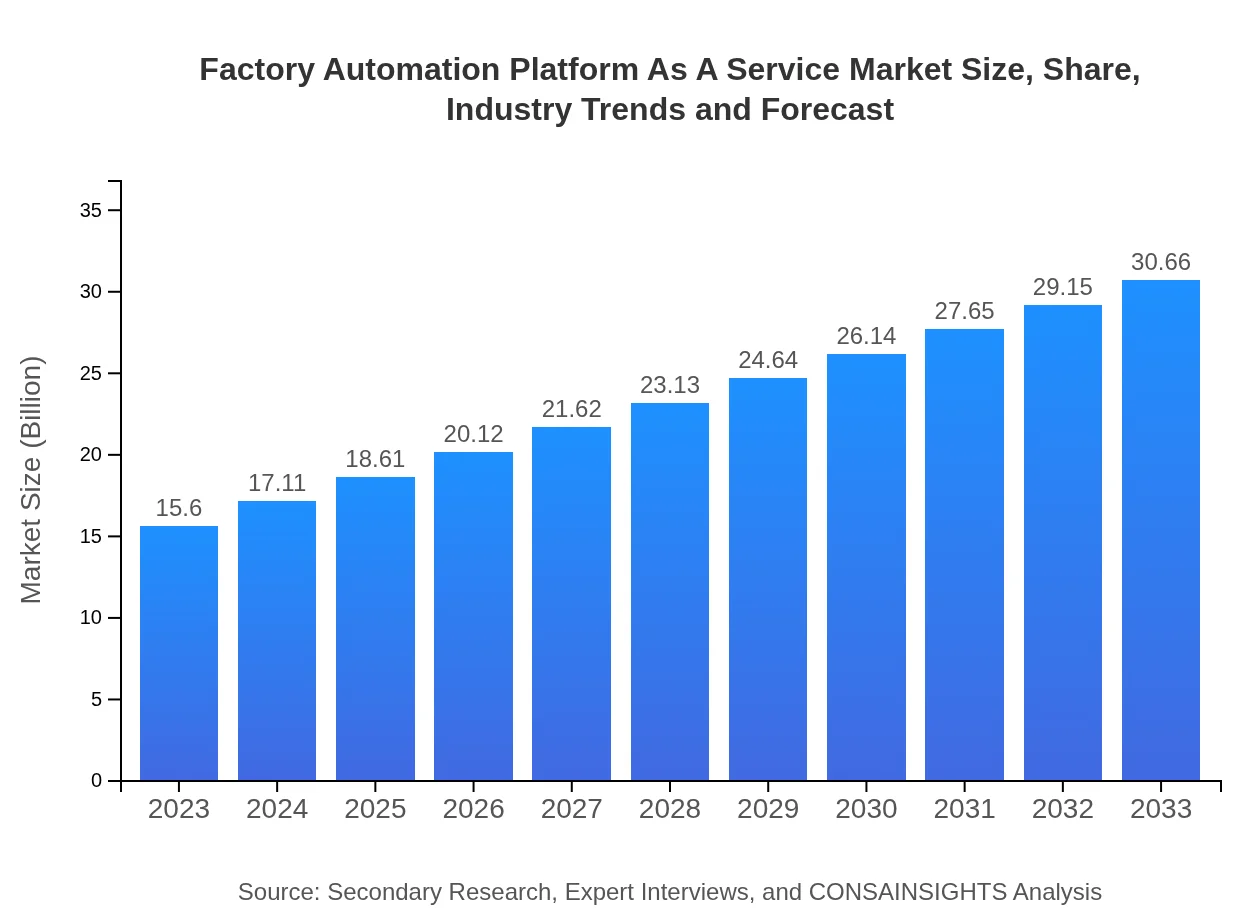

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $15.60 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $30.66 Billion |

| Top Companies | Siemens AG, Rockwell Automation, Inc., ABB Ltd., Schneider Electric SE, Emerson Electric Co. |

| Last Modified Date | 22 January 2026 |

Factory Automation Platform As A Service Market Overview

Customize Factory Automation Platform As A Service Market Report market research report

- ✔ Get in-depth analysis of Factory Automation Platform As A Service market size, growth, and forecasts.

- ✔ Understand Factory Automation Platform As A Service's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Factory Automation Platform As A Service

What is the Market Size & CAGR of Factory Automation Platform As A Service market in 2023?

Factory Automation Platform As A Service Industry Analysis

Factory Automation Platform As A Service Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Factory Automation Platform As A Service Market Analysis Report by Region

Europe Factory Automation Platform As A Service Market Report:

Europe’s market is anticipated to develop from $3.76 billion in 2023 to $7.39 billion in 2033, primarily driven by stringent regulations on operational efficiency and a strong trend towards sustainability in manufacturing processes.Asia Pacific Factory Automation Platform As A Service Market Report:

In Asia Pacific, the Factory Automation PaaS market is projected to grow from $3.26 billion in 2023 to $6.41 billion by 2033. The region’s growth is fueled by rapid industrialization, increased investment in smart manufacturing, and a strong push for digital transformation across various sectors.North America Factory Automation Platform As A Service Market Report:

North America is expected to lead the market, with its size projected to grow from $5.21 billion in 2023 to $10.24 billion by 2033. The presence of advanced industrial ecosystems and high adoption rates for innovative technologies are driving robust growth in this region.South America Factory Automation Platform As A Service Market Report:

The South America region demonstrates a rise in demand for automation solutions, projected to increase from $1.31 billion in 2023 to $2.57 billion by 2033. Factors contributing to this growth include investments in infrastructure and a growing emphasis on operational efficiency.Middle East & Africa Factory Automation Platform As A Service Market Report:

The Middle East and Africa region is set to expand from $2.06 billion in 2023 to $4.05 billion by 2033, benefiting from increasing investments in smart infrastructure and initiatives to enhance productivity across various industries.Tell us your focus area and get a customized research report.

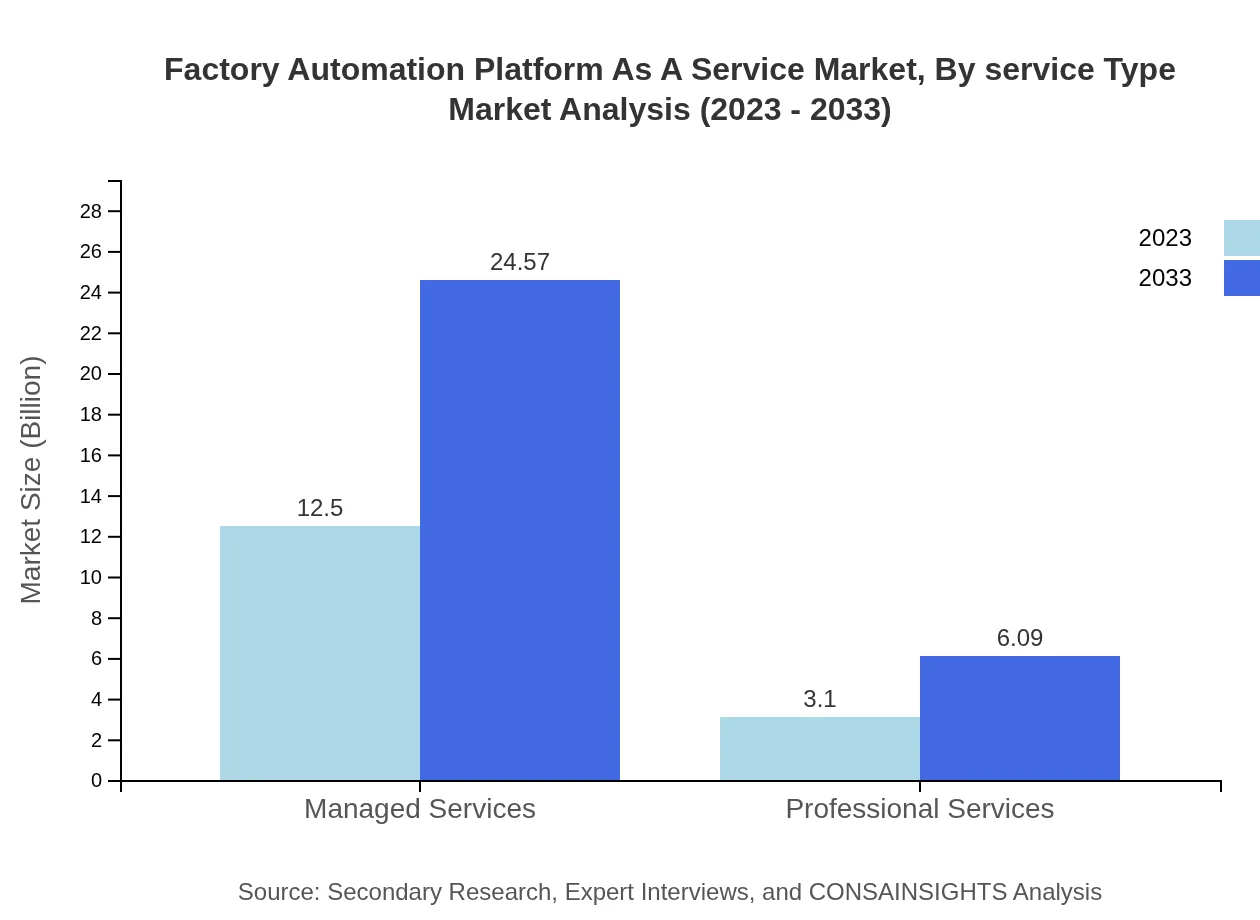

Factory Automation Platform As A Service Market Analysis By Service Type

The service type segmentation shows that cloud-based solutions dominate the market with a size of $12.50 billion in 2023, expected to rise to $24.57 billion by 2033, holding a share of 80.14%. On-premise solutions account for $3.10 billion in 2023 and are expected to grow to $6.09 billion, maintaining a 19.86% market share.

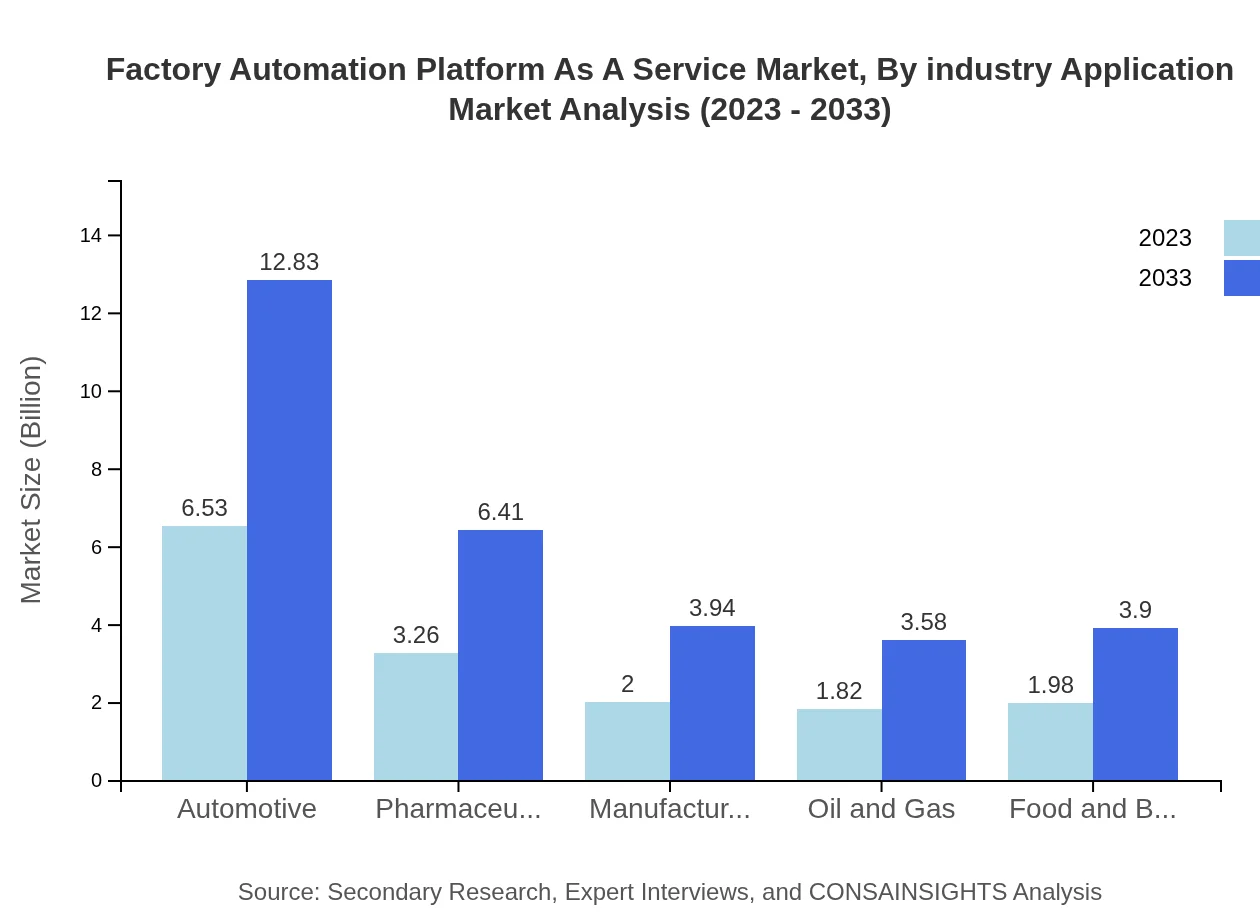

Factory Automation Platform As A Service Market Analysis By Industry Application

In the industry application segment, the automotive sector emerges as a key player, with a market size of $6.53 billion in 2023, expected to grow to $12.83 billion by 2033, maintaining a share of 41.86%. The pharmaceutical sector follows with a size of $3.26 billion accelerating to $6.41 billion (20.89% share). Manufacturing and food & beverage sectors also display significant contributions to the market.

Factory Automation Platform As A Service Market Analysis By Platform Type

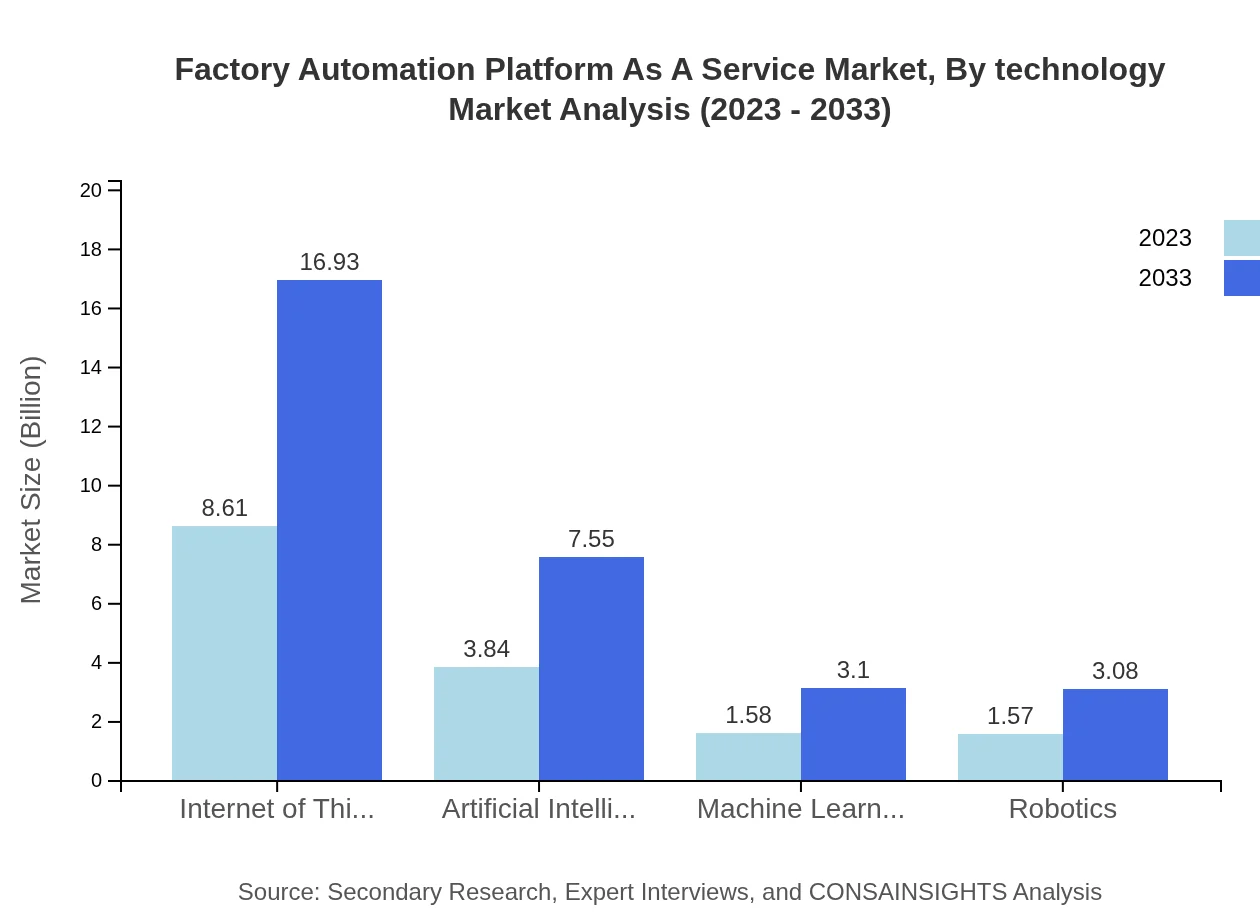

This segment highlights IoT as a central theme, with a market size of $8.61 billion in 2023, projected to reach $16.93 billion by 2033, representing a substantial 55.22% share throughout the forecast period. Other platforms such as AI and Robotics contribute to the evolution of factory automation, with notable growth trajectories expected in their respective markets.

Factory Automation Platform As A Service Market Analysis By Technology

Technological advancements in automation are pivotal, with IoT playing a crucial role, commanding a size of $8.61 billion in 2023 and expected to double by 2033. AI and machine learning are also gaining traction, with projected market sizes of $3.84 billion and $1.58 billion in 2023, growing to $7.55 billion and $3.10 billion, respectively, reflecting technology’s transformative impact.

Factory Automation Platform As A Service Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Factory Automation Platform As A Service Industry

Siemens AG:

A global leader in automation technology, Siemens AG provides innovative factory automation solutions and platforms that enhance operational efficiency and production control.Rockwell Automation, Inc.:

Rockwell Automation specializes in industrial automation and information technology, delivering services that empower businesses to optimize their manufacturing processes.ABB Ltd.:

ABB is recognized for its pioneering efforts in automation and robotics, providing comprehensive solutions that drive productivity and reliability in industrial operations.Schneider Electric SE:

Schneider Electric focuses on energy management and automation, offering integrated solutions that promote sustainability and efficiency in manufacturing.Emerson Electric Co.:

Emerson delivers technology and engineering services that enhance manufacturing performance, particularly in process automation.We're grateful to work with incredible clients.

FAQs

What is the market size of factory Automation Platform As A Service?

The global market size for Factory Automation Platform as a Service is estimated at $15.6 billion in 2023, with a projected CAGR of 6.8% from 2023 to 2033, indicating strong growth in this sector.

What are the key market players or companies in this industry?

Key players in the Factory Automation Platform as a Service industry include leading tech companies specializing in automation solutions, IoT technology providers, and cloud service providers who drive innovation and market expansion.

What are the primary factors driving the growth in the factory Automation Platform As A Service industry?

Growth drivers include rising demand for automation in manufacturing, improved efficiency, cost reduction through cloud solutions, and the integration of IoT and AI technologies into industrial processes.

Which region is the fastest Growing in the factory Automation Platform As A Service?

The fastest-growing region in the Factory Automation Platform as a Service sector is North America, with a market size projected to grow from $5.21 billion in 2023 to $10.24 billion by 2033.

Does ConsaInsights provide customized market report data for the factory Automation Platform As A Service industry?

Yes, ConsaInsights offers customized market reports tailored to specific needs in the factory automation sector, enabling clients to access relevant data and insights as per their unique requirements.

What deliverables can I expect from this factory Automation Platform As A Service market research project?

Deliverables include detailed market analysis, segmentation data, regional insights, competitive landscape reports, trend analysis, and forecasts, providing a comprehensive overview of the market.

What are the market trends of factory Automation Platform As A Service?

Market trends encompass increased adoption of IoT solutions, growing preference for cloud-based services, AI-driven automation enhancements, and a shift towards digitalization in manufacturing sectors.